Preparation technique and device for ultra-pure hydrogen phosphide

A technology of hydrogen peroxide and process, which is applied in the field of producing ultra-high-purity hydrogen peroxide, can solve the problems that the quality cannot meet the use requirements, the product index of high-purity hydrogen peroxide is low, and the impurity content is low, and it achieves a small footprint, The effect of reducing content and easy automatic operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A process for the continuous production of ultra-high-purity hydrogen peroxide, first mixing industrial-grade hydrogen peroxide raw materials with modified activated carbon with a weight of 0.5% to 2% of hydrogen peroxide raw materials, and then operating under the operating pressure of 0.1 to 0.2MPa The filtrate is pumped into the multi-tower series rectification tower, and the metal ion complexing agent is added to the first-stage tower, and the semi-finished product out of the tower runs at 1.0-1.4MPa Reverse osmosis is carried out under pressure. After the reverse osmosis is completed, the ultra-high-purity hydrogen peroxide product is obtained by nanofiltration membrane filtration at an operating pressure of 0.5-0.8 MPa. In this embodiment, the amount of modified activated carbon is peroxide The weight of hydrogen raw material is 0.5%, 1% or 2%; the pressure selection for microfiltration membrane filtration or ultrafiltration membrane filtration is: 0.1, 0.15 or 0.2...

Embodiment 2

[0030] 35% (weight) in raw material tank 1, the technical grade hydrogen peroxide that contains impurity more is passed in the gac premixer 2, and the gac of modification adds by 1% of hydrogen peroxide treatment capacity, removes organic carbon here . The hydrogen peroxide with reduced organic carbon content is passed through the pipeline through the microfiltration ultrafiltration filter 3 (the pore size of the microfiltration membrane is 0.2-0.8 μm, the operating pressure is 0.1-0.2 MPa, the temperature is controlled at 20-25 ° C, the ultrafiltration membrane The pore size is 0.01-0.05μm, the operating pressure is 0.1-0.2MPa, and the temperature is controlled at 20-25°C), where macromolecular organic matter and small particle impurities are removed. The treated hydrogen peroxide is then input into the multi-tower series rectification column 4 with polymer metal ion complexing agent through the pump 8 made of oxidation-resistant and corrosion-resistant materials, where most ...

Embodiment 3

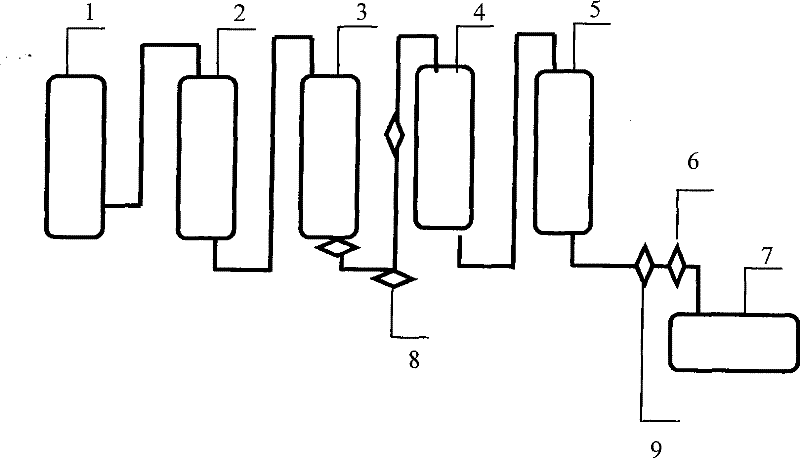

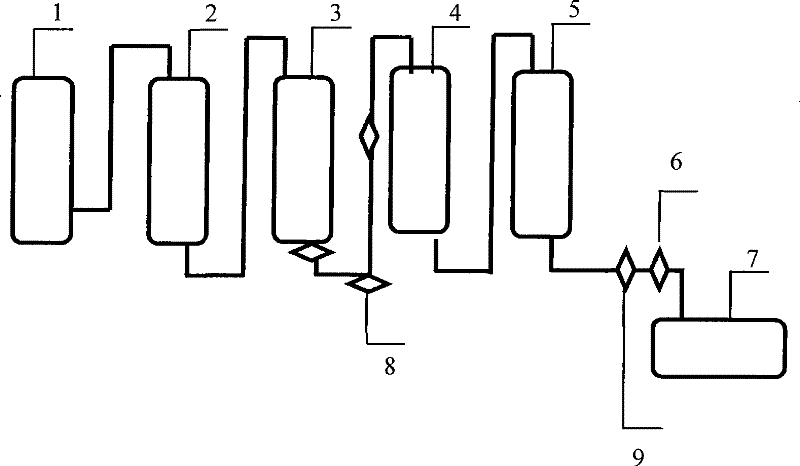

[0032] A device for implementing the above-mentioned continuous production of ultra-high-purity hydrogen peroxide, comprising a raw material tank 1, an activated carbon premixer 2, a microfiltration ultrafiltration filter 3, a multi-tower series rectification tower 4, and a reverse osmosis device 5 , nanofilter 6, finished product receiver 7, pump 8 and valve 9, the outlet of raw material tank 1 is connected with the inlet of activated carbon premixer 2, the outlet of activated carbon premixer 2 is connected with the inlet of microfiltration ultrafiltration filter 3, and the outlet of microfiltration ultrafiltration Filter 3 outlet and pump 8

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com