System and method for concentrating and purifying hydrogen peroxide

A hydrogen peroxide and concentration tower technology, applied in chemical instruments and methods, peroxide/peroxyhydrate/peroxyacid/superoxide/ozonide, sustainable manufacturing/processing, etc., can solve high energy consumption problems , to achieve the effect of low cost, saving investment and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

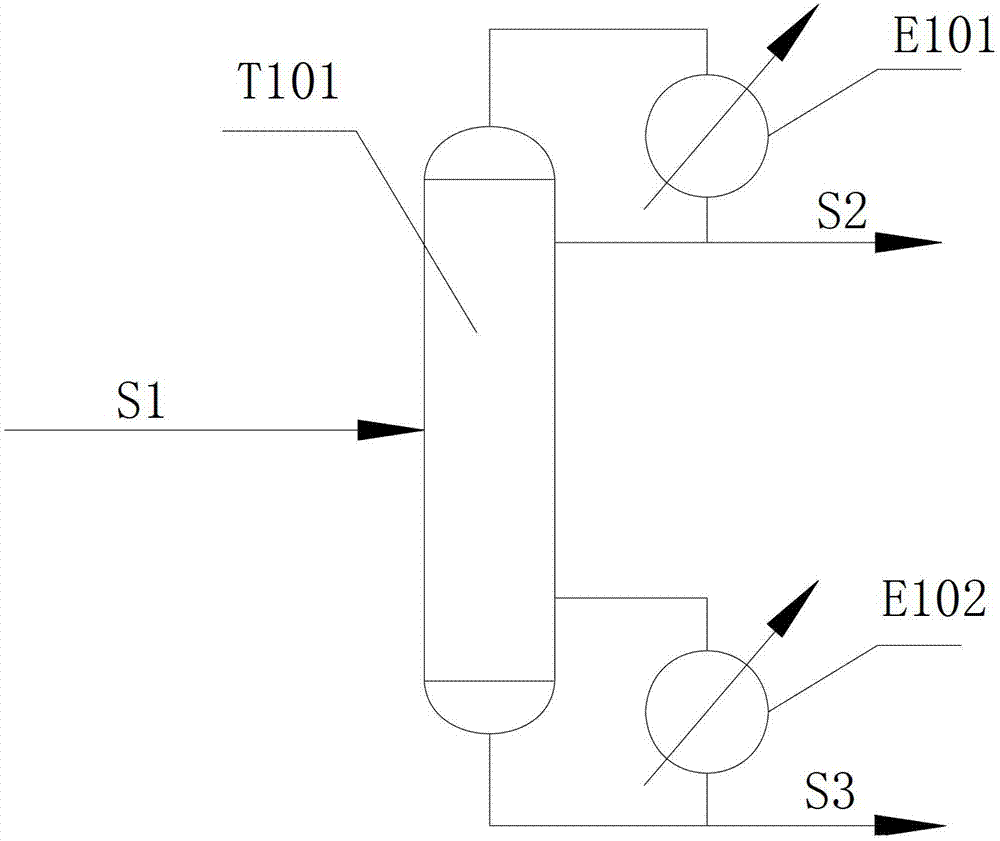

[0026] As attached to the manual figure 1 As shown, the hydrogen peroxide concentrated rectification tower T101 is provided with a feed inlet, and the top of the tower is connected to the inlet of the condenser E101, and a part of the outlet of the condenser E101 is extracted, and a part is refluxed to the T101 tower top reflux stream inlet; the hydrogen peroxide concentrated rectification tower T101 tower A part of the product is extracted from the bottom, and a part is connected to the inlet of the bottom reboiler E102 of the hydrogen peroxide concentration tower, and the outlet of the bottom reboiler E102 of the hydrogen peroxide concentration tower is connected to the bottom reflux flow inlet of the hydrogen peroxide concentration distillation tower T101.

[0027] 25~35%wt hydrogen peroxide is used as raw material, mixed with stabilizer, and then sent to the hydrogen peroxide concentration and rectification tower T101, the gas phase at the top of the tower enters the conden...

Embodiment 2

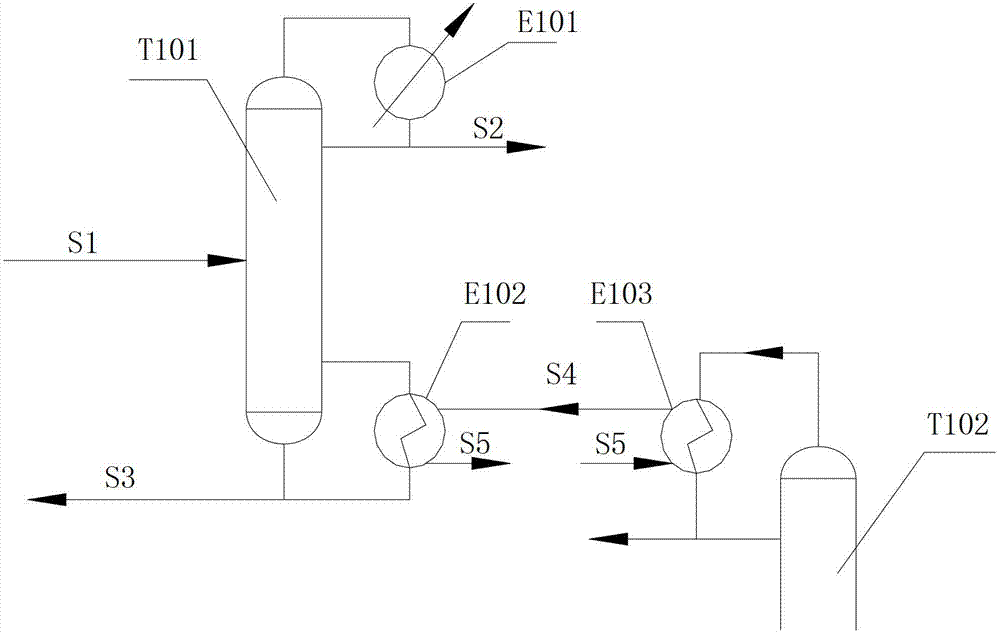

[0031] As attached to the manual figure 2 shown, with figure 1The difference is that a steam generator E103 is connected behind the reboiler E102 at the bottom of the tower; the top of the rectification column T102 whose steam heat is not utilized is connected to the tube side inlet of the steam generator E103; the shell side of the steam generator E103 The inlet is filled with the cold stream in the soft water system, and the cold stream in the soft water system exchanges heat with the top of the distillation tower T102, where the heat of the steam at the top of the factory is not utilized, and becomes the hot stream in the soft water system, and then exits from the shell side Entering the shell-side entrance of the reboiler E102 at the bottom of the hydrogen peroxide concentration tower, the hot stream in the softening water system heats the bottom material of the hydrogen peroxide concentration and rectification tower T101, and after the temperature drops, it becomes the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com