Method for extracting acetic acid in salt-containing acetic acid aqueous solution by one-sided line heat integration azeotropic rectification method

A technology of acetic acid aqueous solution and azeotropic distillation, which is applied in the technical field of chemical heat transfer and separation, can solve the problems of large energy consumption and consumption, and achieve the effects of reducing investment and occupying space, simplifying the process and simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

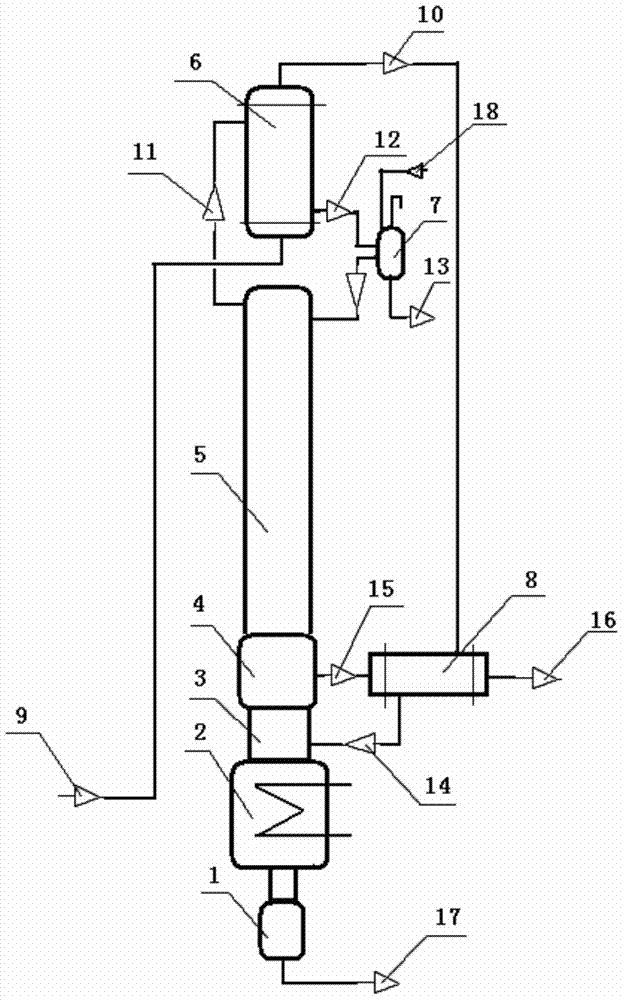

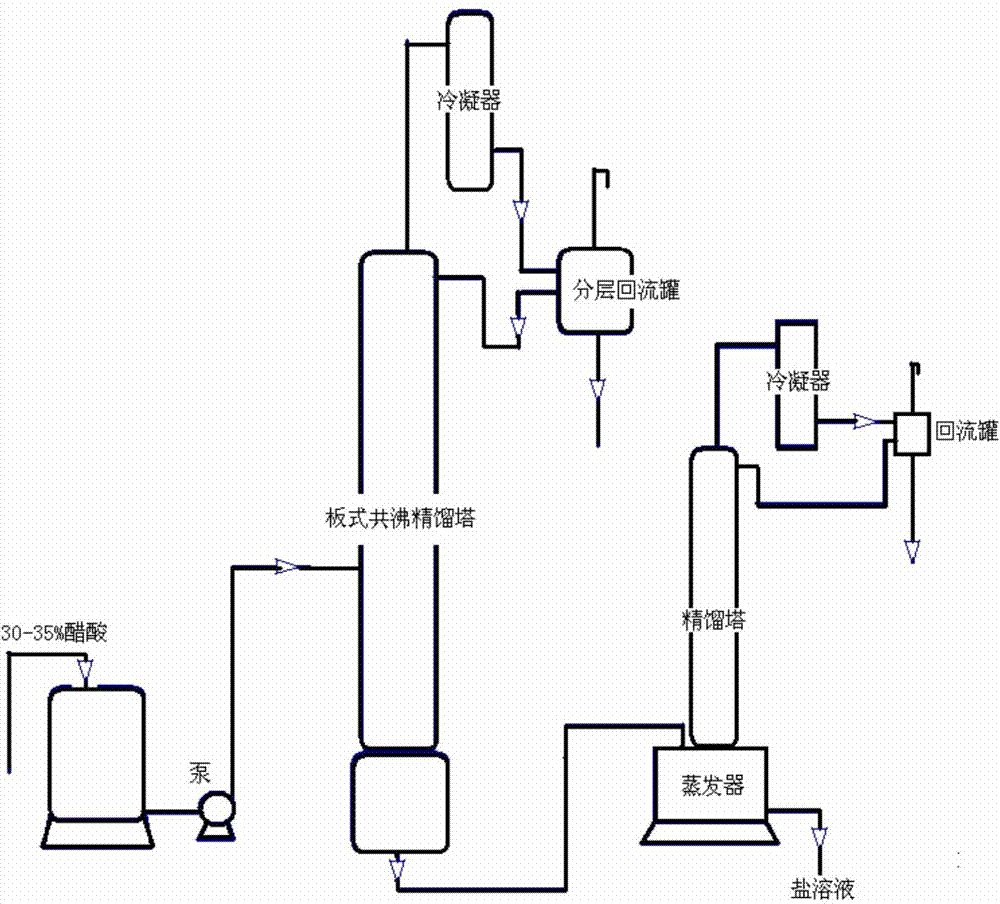

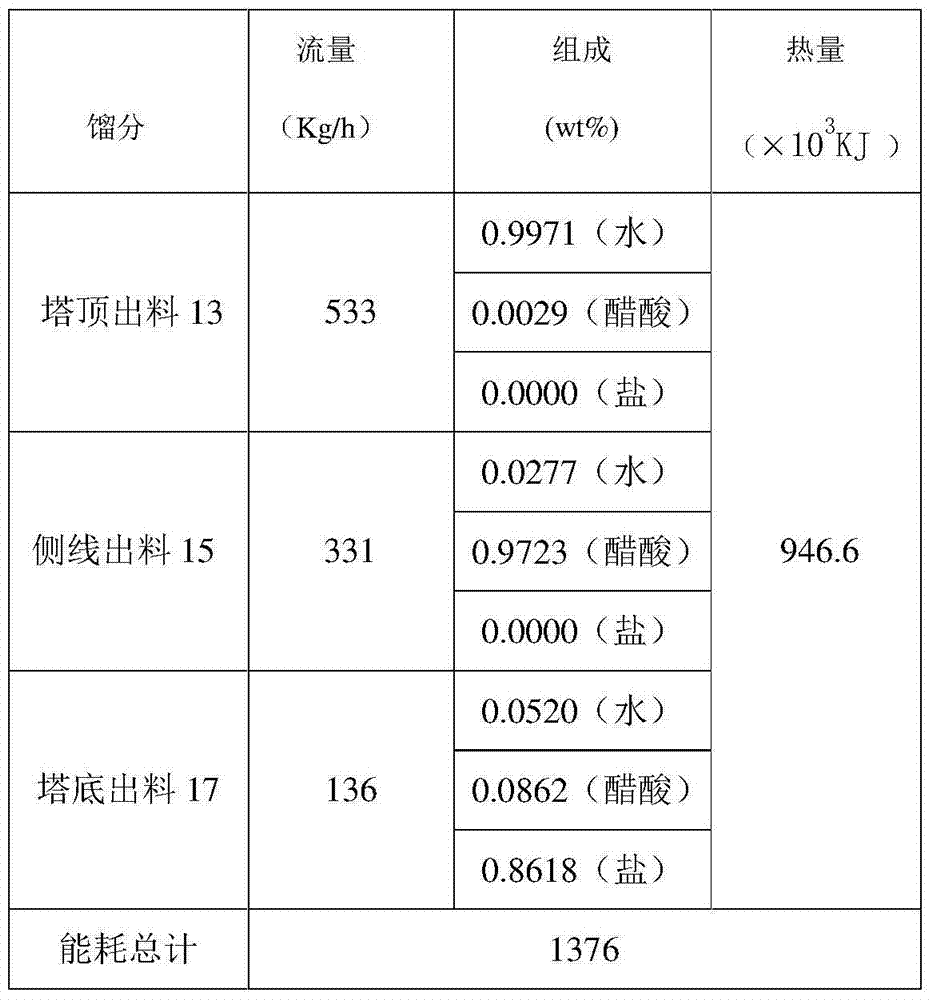

[0021] According to the single-side line azeotropic heat integrated rectification method of the present invention extracts the method for acetic acid in the saline acetic acid aqueous solution, technological process is as follows figure 1 As shown, the single-side line heat integrated azeotropic distillation device is mainly composed of a salt reduction chamber 1, a tower kettle 2, a feed section 3, a side line discharge section 4, an azeotropic distillation column 5, a top condenser 6, a liquid-liquid It is composed of stratified tank 7 and side line condenser 8. The main streams involved in the process flow include raw material saline acetic acid aqueous solution 9, raw material 10 after preheating at the top of single side line azeotropic rectification tower, and steam 11 at the top of single side line azeotropic rectification tower , single side line azeotropic distillation tower top condensate 12, single side line azeotropic distillation tower top discharge 13, raw materi...

Embodiment 2

[0035] According to the same method and process as in Example 1, extract acetic acid in the saline acetic acid aqueous solution, the weight percentage of raw materials is composed of 30-35% acetic acid, 52-58% water and 10-15% salt, select single side line azeotropic rectification The number of trays of the tower is N=65-75, and the reflux ratio is controlled at 2-3:1, so that the aqueous phase of the tower top discharge contains about 0.2-0.4% acetic acid, and the acetic acid content of the side stream discharge reaches more than 97%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com