Method for preparing ethanol by hydrogenating acetic acid

A technology for producing ethanol and acetic acid, which is applied in chemical instruments and methods, preparation of hydroxyl compounds, and preparation of organic compounds, etc., can solve the problems of high production cost and high price of ethanol, and achieve long stable operation time of the device and good activity stability , to avoid post-processing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

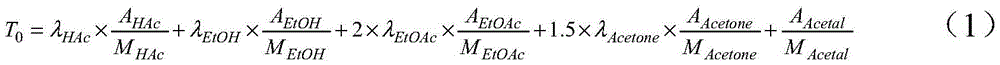

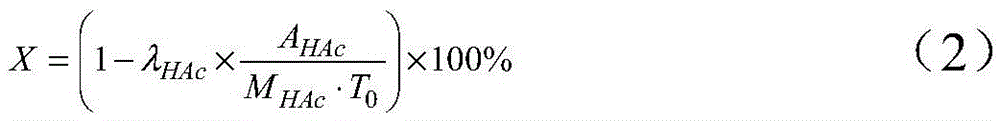

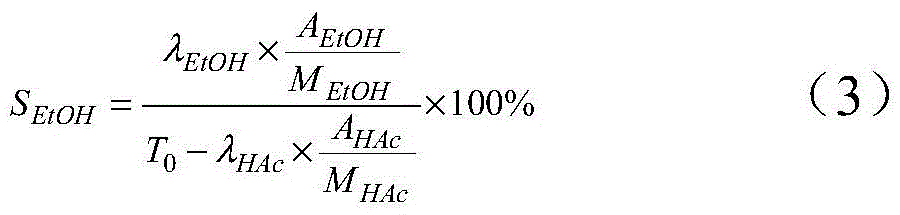

Method used

Image

Examples

Embodiment 1

[0044] Example 1: 1% WC / SiO 2 Catalyst preparation

[0045] Weigh 10g of porous silica gel carrier (its specific surface area is 480m 2 / g), from 0.13g (4.3974×10 -5 mol) of ammonium metatungstate and distilled water to prepare 12mL impregnation solution, the tungsten concentration is 4.3974×10 -5 mol / mL, the volume of the impregnation solution is equal to the volume of the maximum adsorption water of the catalyst support. Carry out impregnation at room temperature according to the equal volume impregnation method, add 12mL impregnation solution dropwise to 10g carrier, and keep stirring. After the dropwise addition, it was allowed to stand at room temperature for 3 hours, then dried at 90°C for 3 hours; the temperature was programmed to rise to 400°C at a rate of 1°C / min, and calcined for 10 hours. Then, the dried catalyst precursor is loaded into a tubular reactor, with n-pentane as the carbon source, and hydrogen gas is introduced into the reactor at a pressure of 0.1MP...

Embodiment 2

[0046] Example 2: 5% WC / SiO 2 Catalyst preparation

[0047] Weigh the porous silica gel carrier of 10g, by 0.65g (2.1987×10 -4 mol) of ammonium metatungstate and distilled water to prepare 12mL impregnation solution, its tungsten concentration is 2.1987×10 -4 mol / mL, the volume of the impregnation solution is equal to the volume of the maximum adsorption water of the catalyst support. Carry out impregnation at room temperature according to the equal volume impregnation method, add 12mL impregnation solution dropwise to 10g carrier, and keep stirring. After the dropwise addition, it was allowed to stand at room temperature for 24 hours, then dried at 60°C for 24 hours; the temperature was programmed to rise to 700°C at a rate of 2°C / min, and calcined for 1 hour. Then, the dried catalyst precursor is loaded into a tubular reactor, with n-pentane as the carbon source, and hydrogen gas is introduced into the reactor at a pressure of 0.5MPa and a mass space velocity of n-pentane...

Embodiment 3

[0048] Example 3: 10% WC / SiO 2 Catalyst preparation

[0049] Weigh the porous silica gel carrier of 10g, by 1.3g (4.3974 * 10 -4 mol) of ammonium metatungstate and distilled water to prepare 12mL impregnation solution, the tungsten concentration is 4.3974×10 -4 mol / mL, the volume of the impregnation solution is equal to the volume of the maximum adsorption water of the catalyst support. Carry out impregnation at room temperature according to the equal volume impregnation method, add 12mL impregnation solution dropwise to 10g carrier, and keep stirring. After the dropwise addition, it was allowed to stand at room temperature for 6 hours, then dried at 80°C for 12 hours; the temperature was programmed to rise to 650°C at a rate of 5°C / min, and calcined for 4 hours. Then, the dried catalyst precursor is packed into a tubular reactor, with n-pentane as the carbon source, and hydrogen gas is introduced into the reactor at a pressure of 5.0 MPa and a mass space velocity of n-pent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com