Patents

Literature

41results about How to "Avoid frequent switching operations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

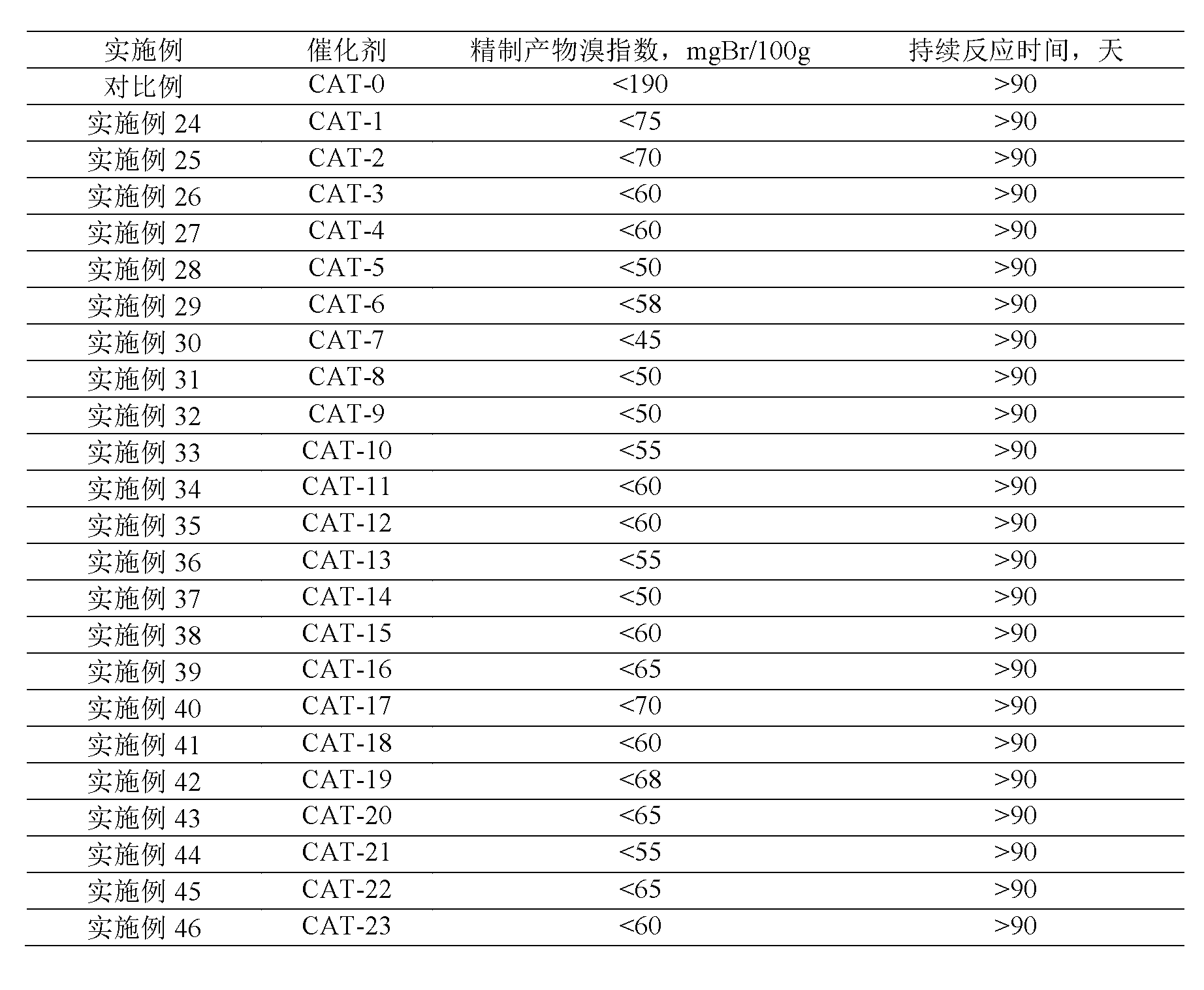

Method for removing micro-quantity alkene in aromatic hydrocarbon

ActiveCN103012034ASimple processDoes not consume hydrogenChemical recyclingChemical modification purification/separationAlkyl transferSolid acid

The invention discloses a method for removing micro-quantity alkene in aromatic hydrocarbon. The method comprises the following steps of: contacting and reacting the aromatic hydrocarbon with a solid acid catalyst under the condition of temperature of 30-350 DEG C, pressure of 0.1-12MPa and feeding quality airspeed of 0.1-15 h<-1>, so that micro-quantity alkene in the aromatic hydrocarbon undergoes adsorbing, overlapping and alkylation reaction so as to remove the micro-quantity alkene in the aromatic hydrocarbon. The method is simple in process procedure, free of oxygen consumption and low in device investment and operation expense; and the catalyst is good in activity stability, the device is long in stable operation time, the aromatic hydrocarbon loss is small, the frequent switching operation between reactor reaction and regeneration is avoided, and the catalyst can be regenerated, so that a great deal of waste catalyst is prevented from being buried, and the environment is less polluted.

Owner:ZHEJIANG UNIV OF TECH

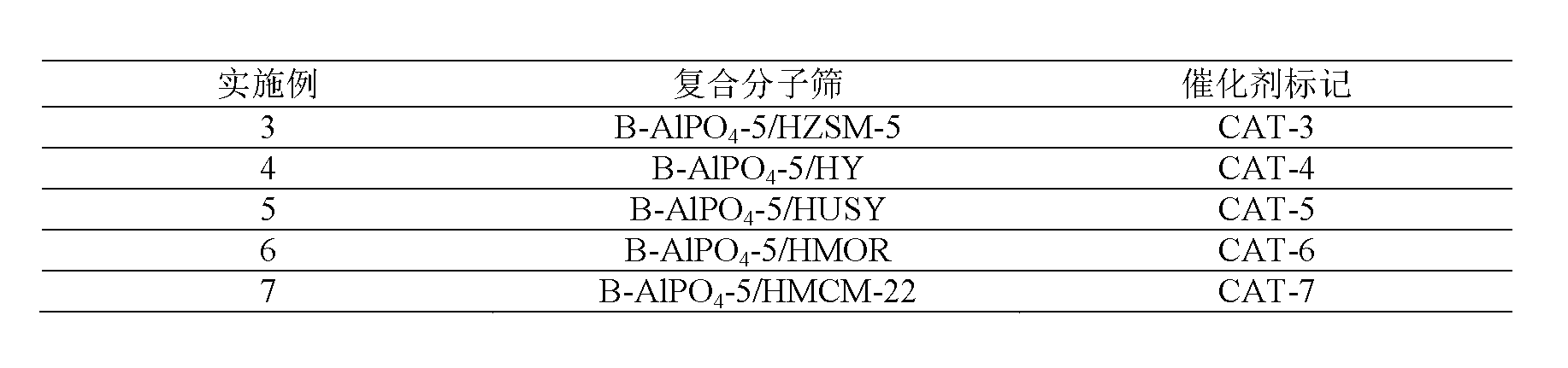

Method for removing trace hydrocarbon out of aromatic hydrocarbon by utilizing HMCM-41 type mesoporous molecular sieve

ActiveCN103012035ASimple processLow device investment and operating costsChemical modification purification/separationMolecular sieveAlkene

The invention discloses a method for removing hydrocarbon out of aromatic hydrocarbon by utilizing an HMCM-41 type mesoporous molecular sieve. The method comprises the following steps of allowing aromatic hydrocarbon to contact and react with solid acid catalyst under conditions that the temperature is between 30 and 350 DEG C, the pressure is between 0.1 and 12MPa and the feeding mass space velocity is between 0.1 and 15 hour<-1> to obtain hydrocarbon removed aromatic hydrocarbon, wherein the hydrocarbon is reformed oil, reformed hydrocarbon or aromatic hydrocarbon generated by a steam cracking device. The method is simple in process flow, does not consume hydrogen, and is low in device investment and operation cost; the catalyst is good in activity stability, the device is stable and long in operation time, less hydrocarbon is lost, and operation of frequent switching between reaction and regeneration of the reactor can be avoided; and the catalyst is reproducible to avoid massive waste catalyst accumulation and bury, and has small influence on the environment.

Owner:ZHEJIANG UNIV OF TECH

Production method of HRB500E high-strength and anti-seismic rebar

ActiveCN109554613AAvoid frequent switching operationsAvoid idle waits for operationsChemical compositionRebar

The invention provides a production method of an HRB500E high-strength and anti-seismic rebar. The production method comprises the step that a billet is manufactured. The billet is prepared from the components in percentage: 0.20%-0.25% of C, 0.40%-0.70% of Si, 1.30%-1.60% of Mn, less than or equal to 0.045% of P, less than or equal to 0.045% of S, 0.020%-0.050% of V, 0.0050%-0.0120% of N, and thebalance of Fe and inevitable impurities; the components are basically the same as component formulas used in the production of HRB400 and HRB400E, steel has multiple stages, namely, by adjusting rolling processes, the production of HRB500E and HRB400E can be realized with the same chemical composition formula. Therefore, according to the production method of the HRB500E high-strength and anti-seismic rebar, a unified production technique can be adopted in the preparation of raw materials and blank, the production efficiency is improved favourably, the frequencies of adjusting preparation parameters such as temperature and the proportion of the components are reduced, the stability of products is improved, and the production efficiency is improved favourably.

Owner:SHANDONG SHIHENG SPECIAL STEEL GROUP

Synthesis method of linear alkylbenzene

InactiveCN1868985AImprove conversion rateEasy to operateMolecular sieve catalystsHydrocarbonsAlkyl transferMolecular sieve

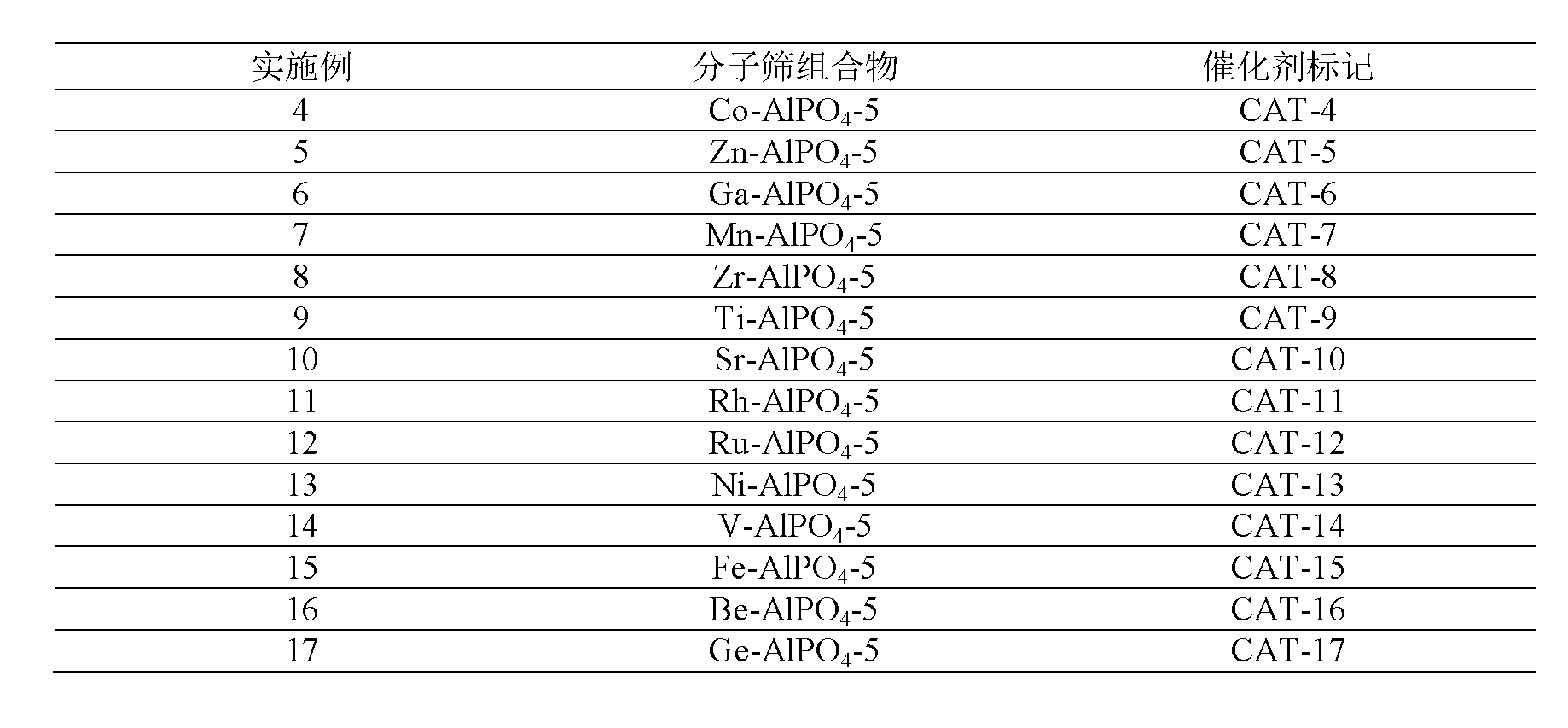

A process for preparing straight-chain alkylbenzene from C2-C20 straight-chain olefine and benzene features the alkylating reaction between benzene and olefine in the ratio of (2-100):1 in supercritical condition (290-450 deg.C and 5-15 MPa) under the action of solid acid catalyst. Said catalyst is the P-Al molecular sieve with AIPO4-5 crystal structure or the P-Al molecular sieve composition containing substitute element.

Owner:ZHEJIANG UNIV OF TECH

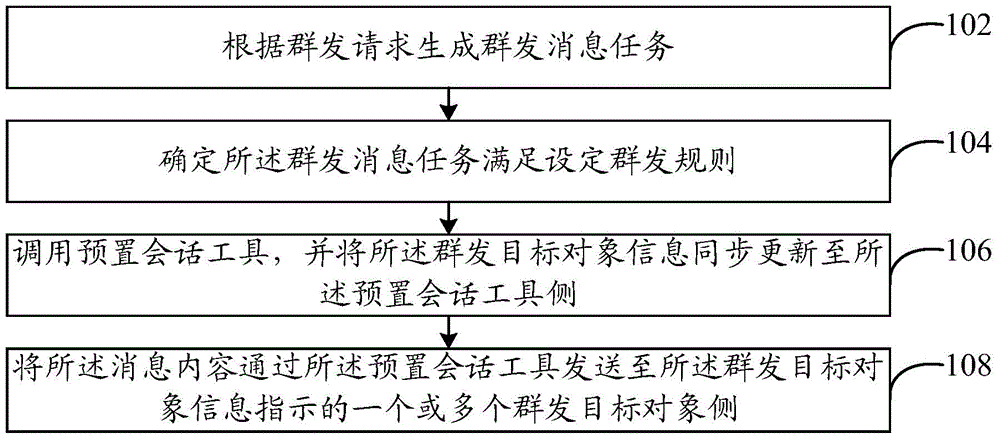

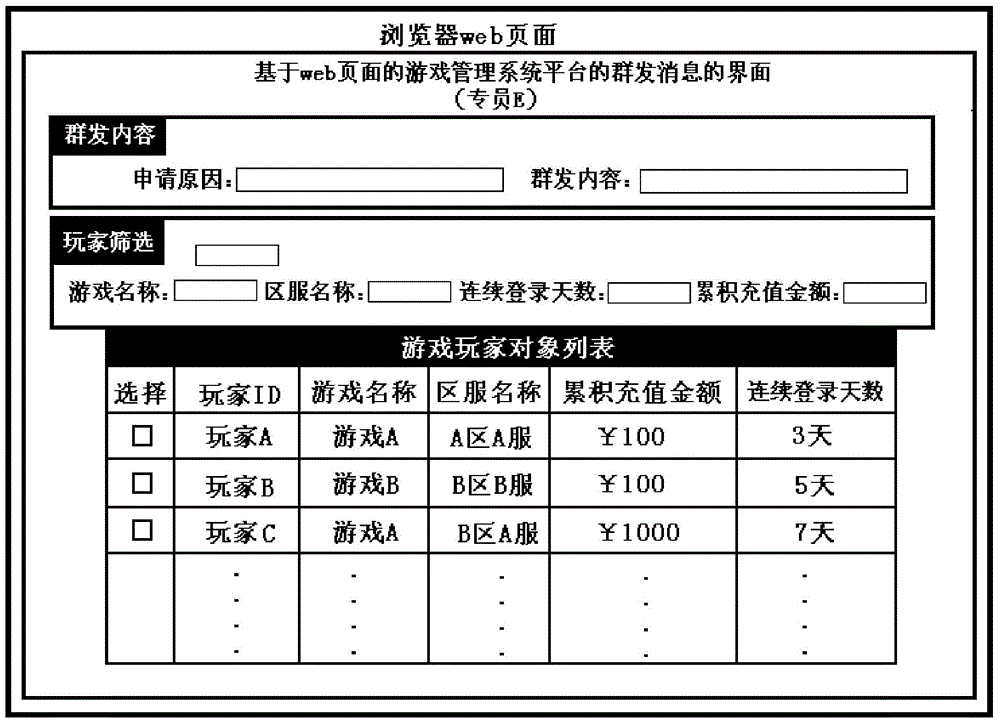

Group-sending message processing method and system as well as electronic device

ActiveCN105791080AImprove accuracyImprove sending efficiencyData switching networksMessage processingComputer science

The invention discloses a group-sending message processing method and system as well as an electronic device. The group-sending message processing method comprises the steps of generating a message group-sending task based on a group-sending request, wherein the group-sending request carries message content and group-sending target object information; determining a fact that the message group-sending task satisfies a set groups-sending rule; calling a preset session tool and synchronously updating the group-sending target object information to the side of the preset session tool; and sending the message content to the side of one or multiple group-sending target objects indicated by the group-sending target object information through the preset session tool, wherein the one or multiple group-sending target objects belong to a jurisdictional region of one message sender. Through the group-sending message processing method and system as well as the electronic device, the problem of low message content delivery efficiency is solved.

Owner:BEIJING QIHOO TECH CO LTD

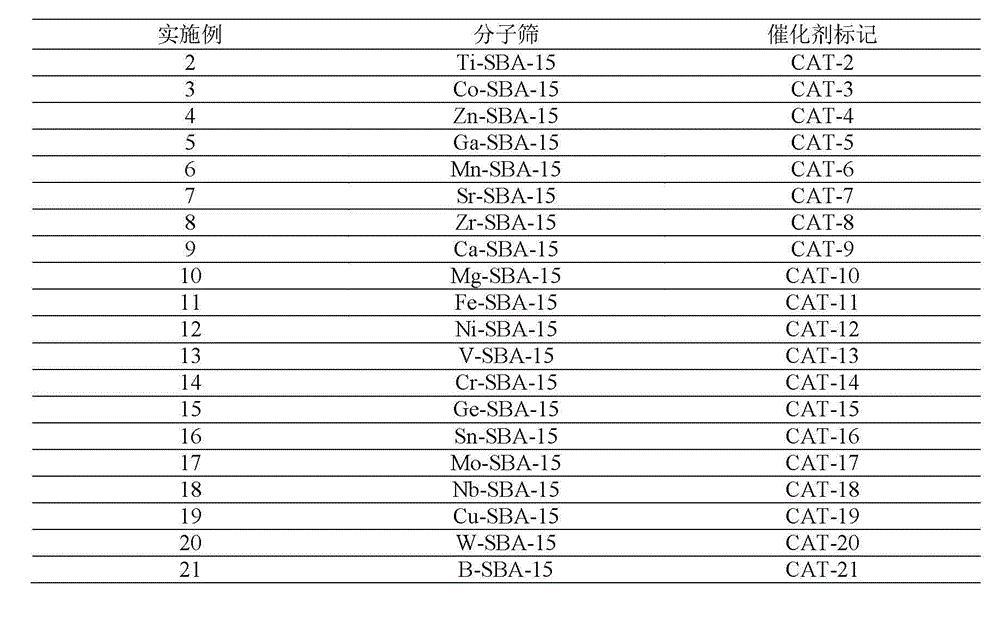

Method of preparing linear alkylbenzene

InactiveCN101058523AGood activity and stabilityImprove conversion rateMolecular sieve catalystsHydrocarbonsAlkyl transferMolecular sieve

The invention discloses a synthesizing method of straight-line alkyl benzene, which comprises the following steps: adopting straight-line olefin with carbon atom number between 2 and 20 and benzene as raw material; inputting in the reactor; reacting benzene and olefin with molar rate at 2-100:1 at 290-450 deg. c under 5-15Mpa hypercritical condition; setting the air speed at 0. 1-20h-1; making solid acid as catalyst; adopting one of loaded modified (1) SBA-15 typed molecular sieve, (2) HY typed molecular sieve, (3) USY typed molecular sieve, (4) H beta typed molecular sieve, (5) H-Moderite typed molecular sieve, (6) HZSM-20 typed molecular sieve as composite typed solid acid catalyst. The invention improves transmitting rate of olefin with stable operation, which possesses good using prospect.

Owner:ZHEJIANG UNIV OF TECH

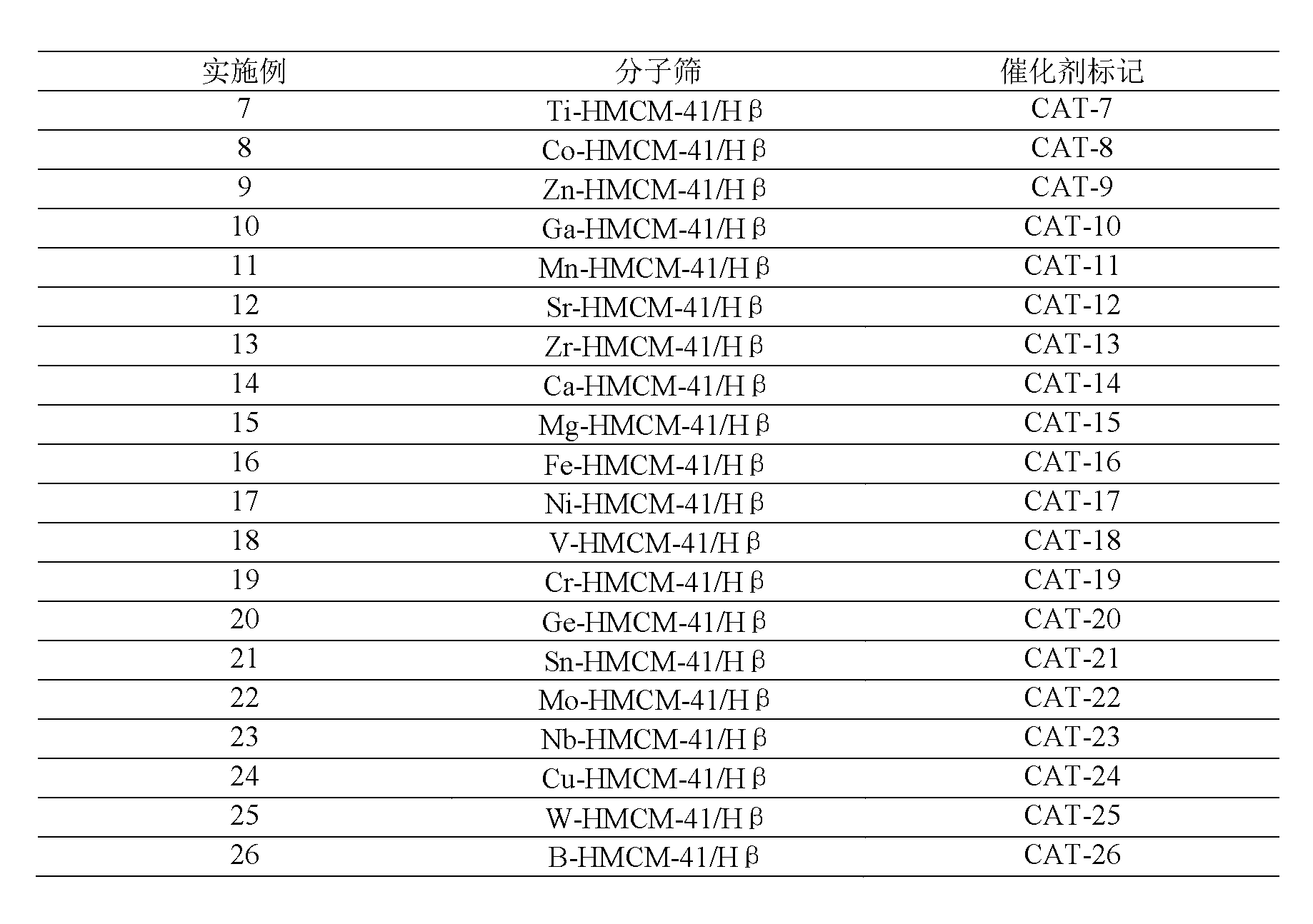

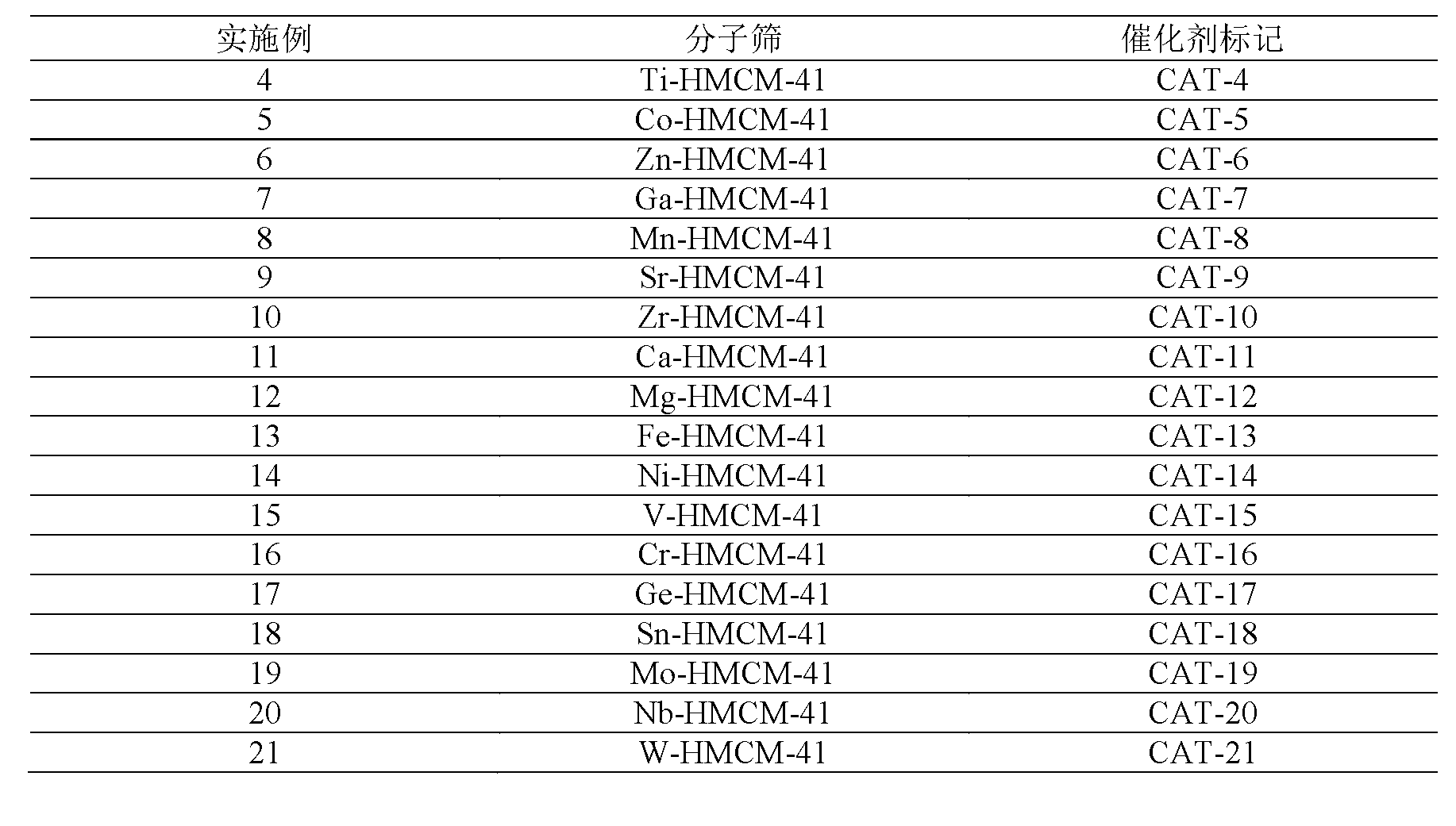

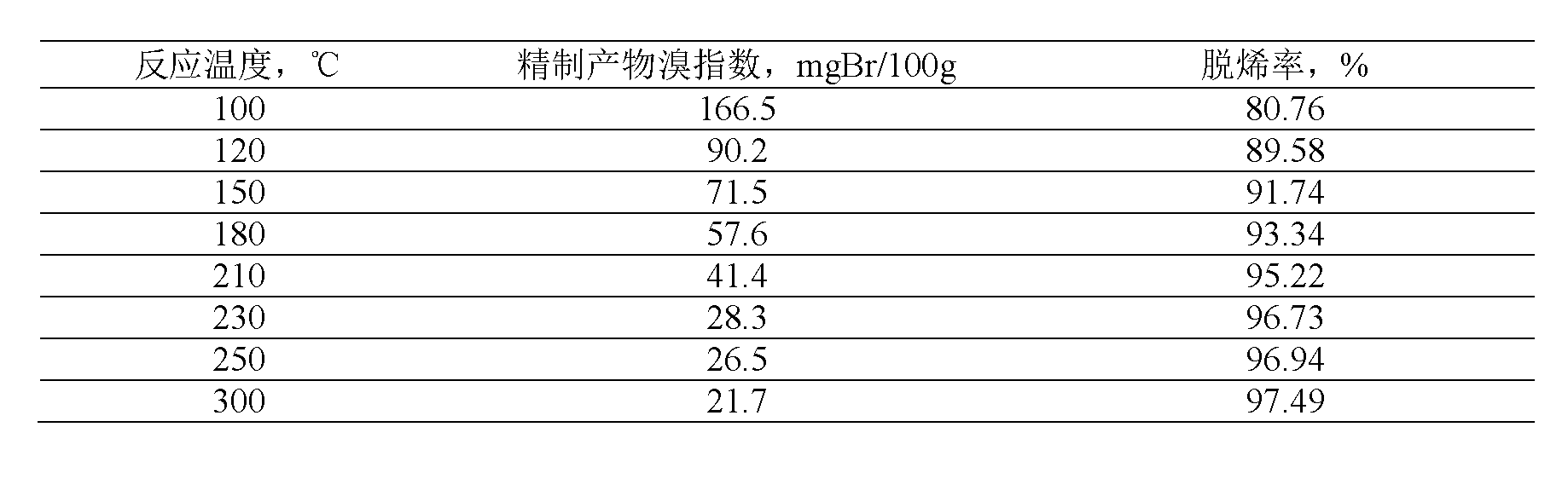

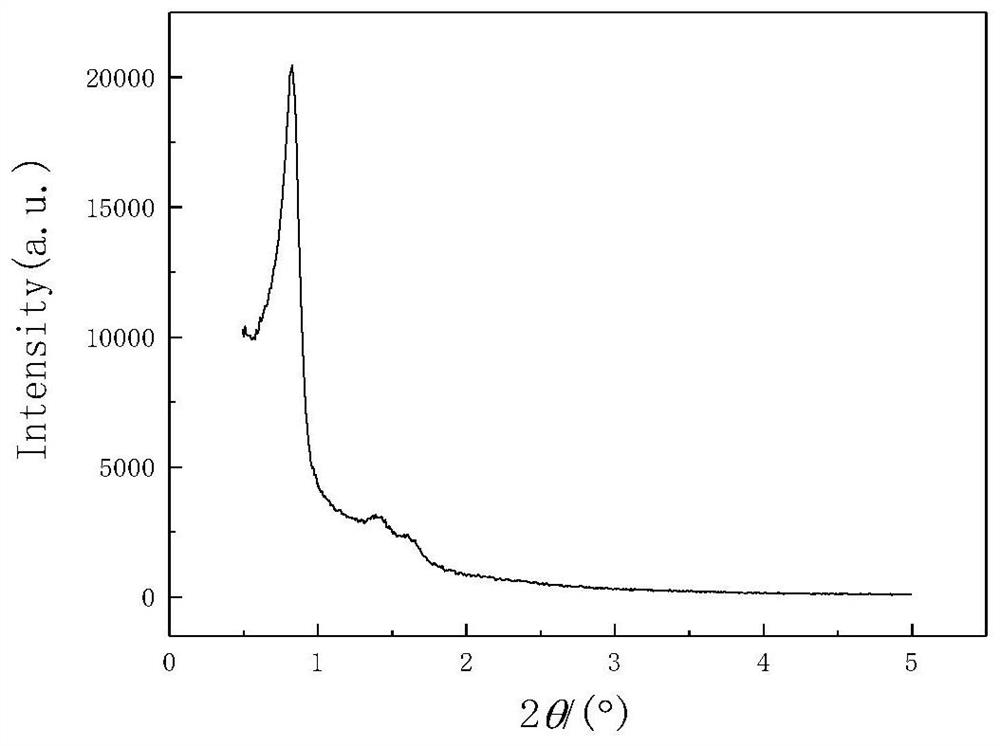

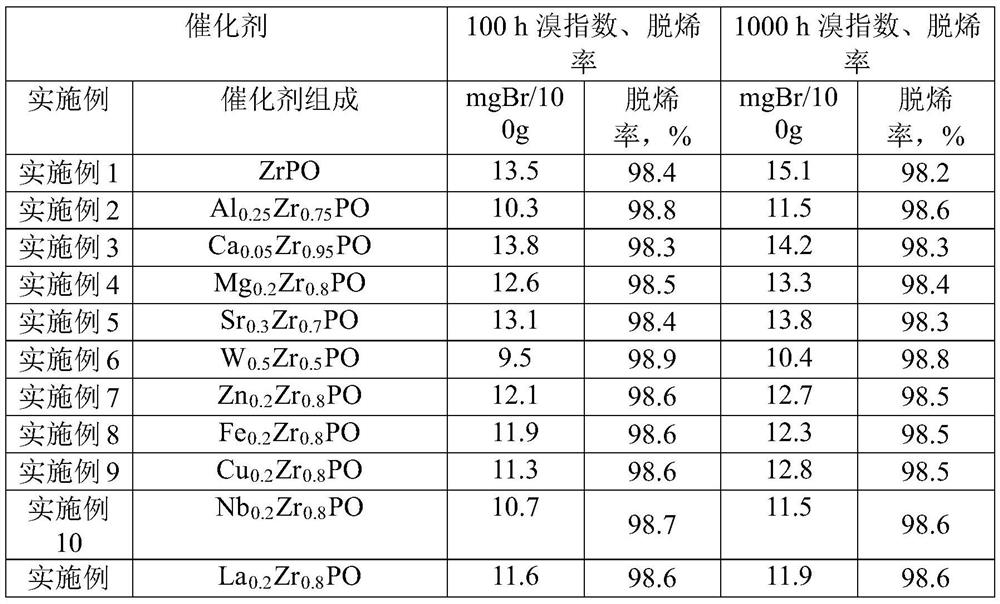

Method for removing tiny amount of olefins in aromatic hydrocarbons by using solid acid catalyst

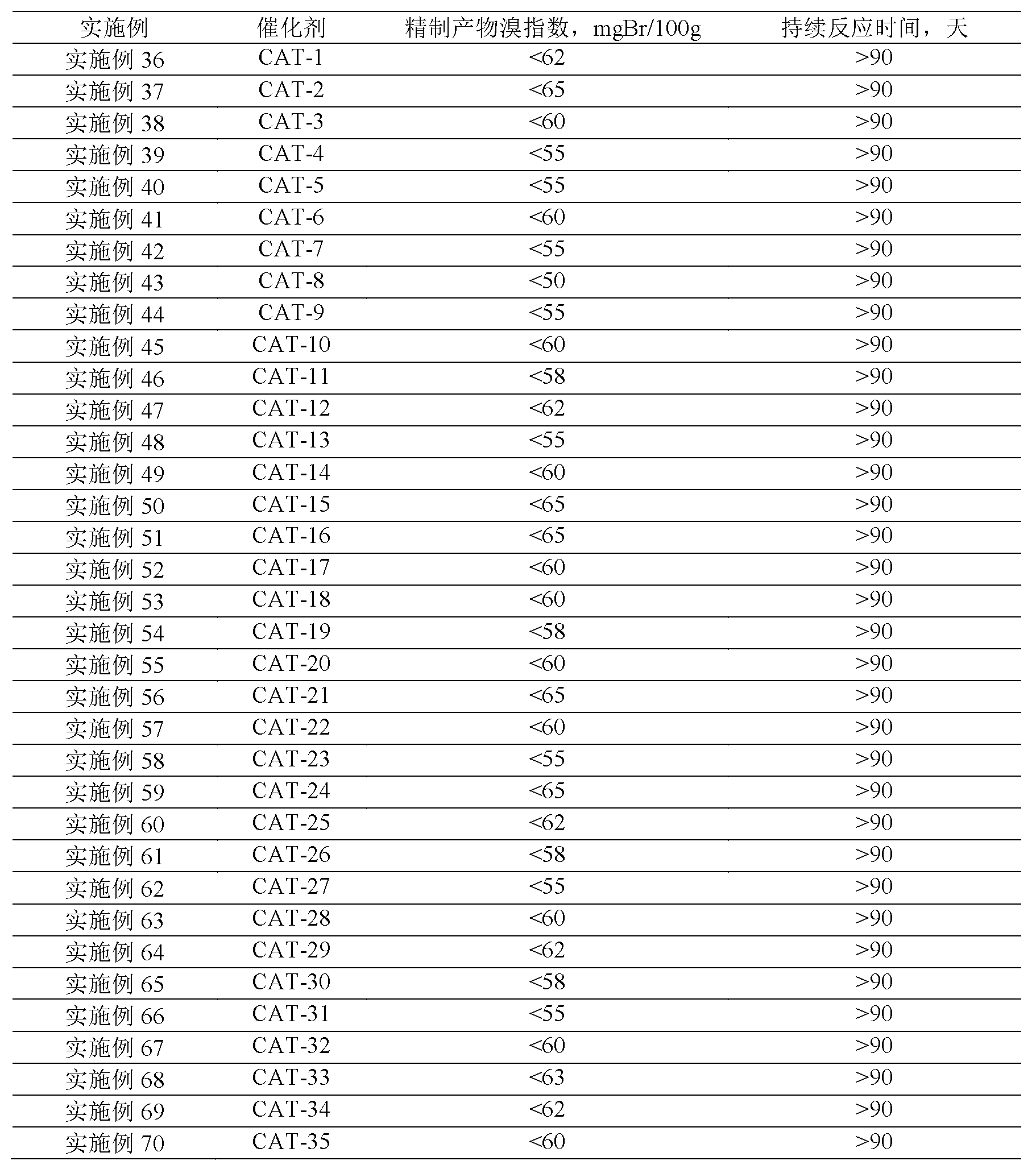

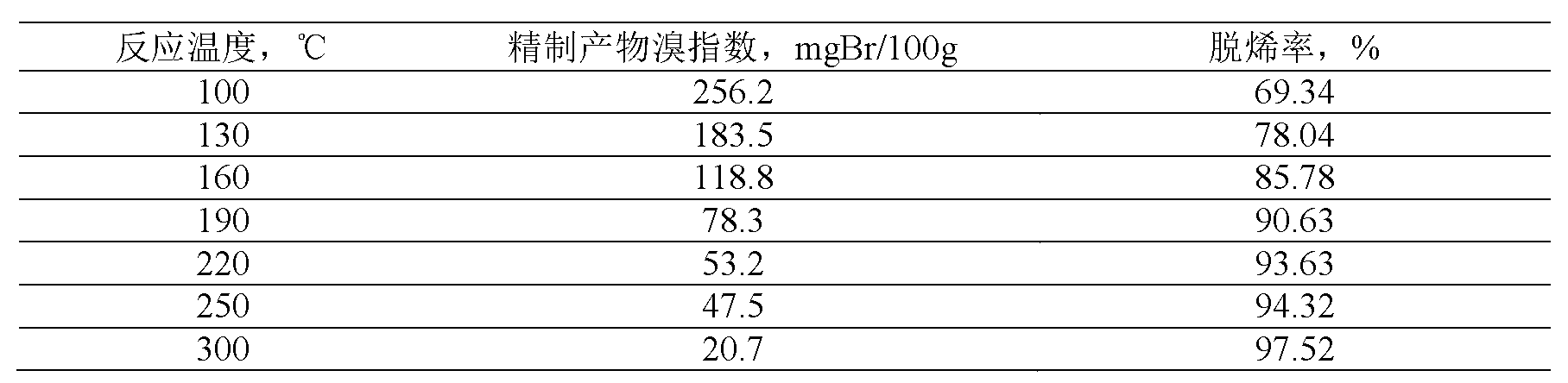

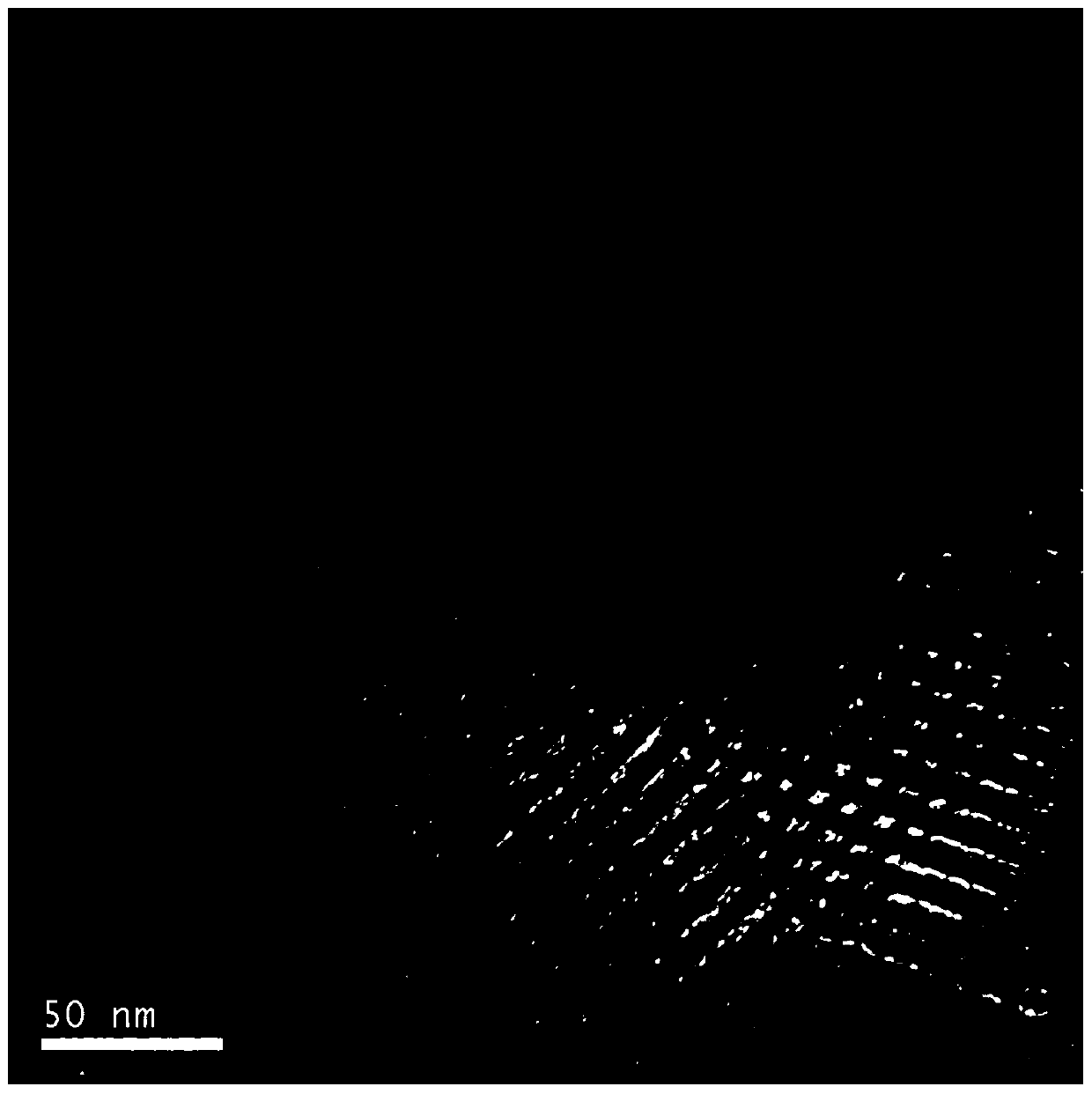

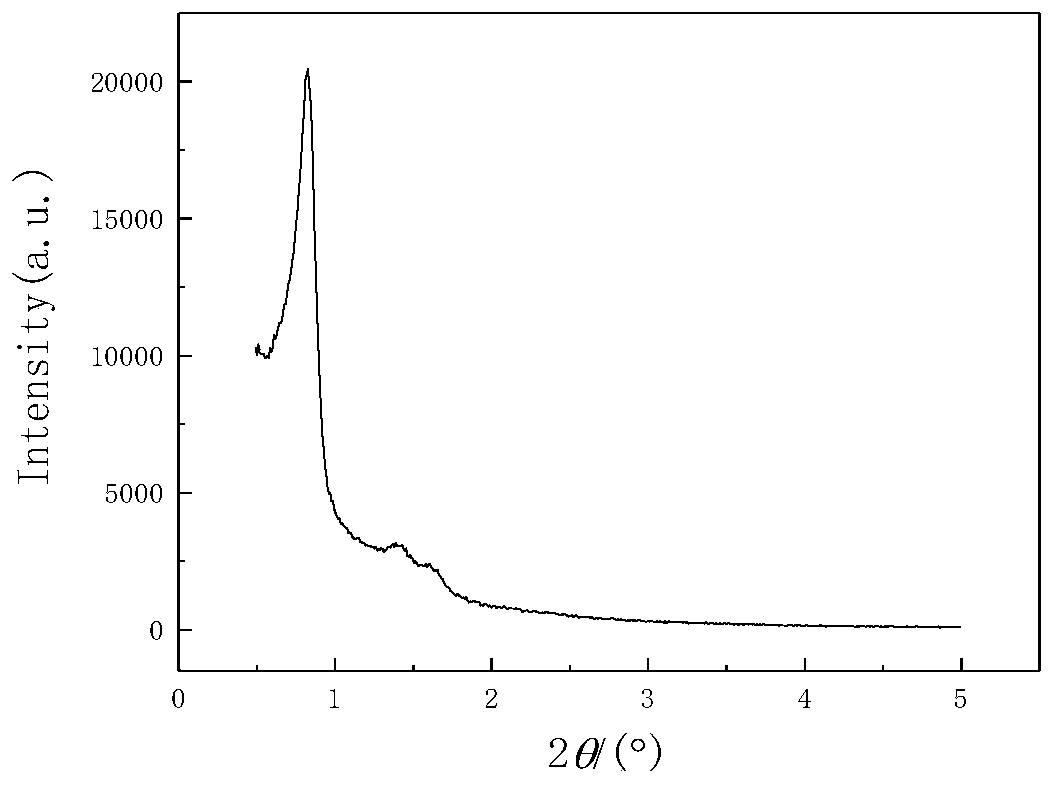

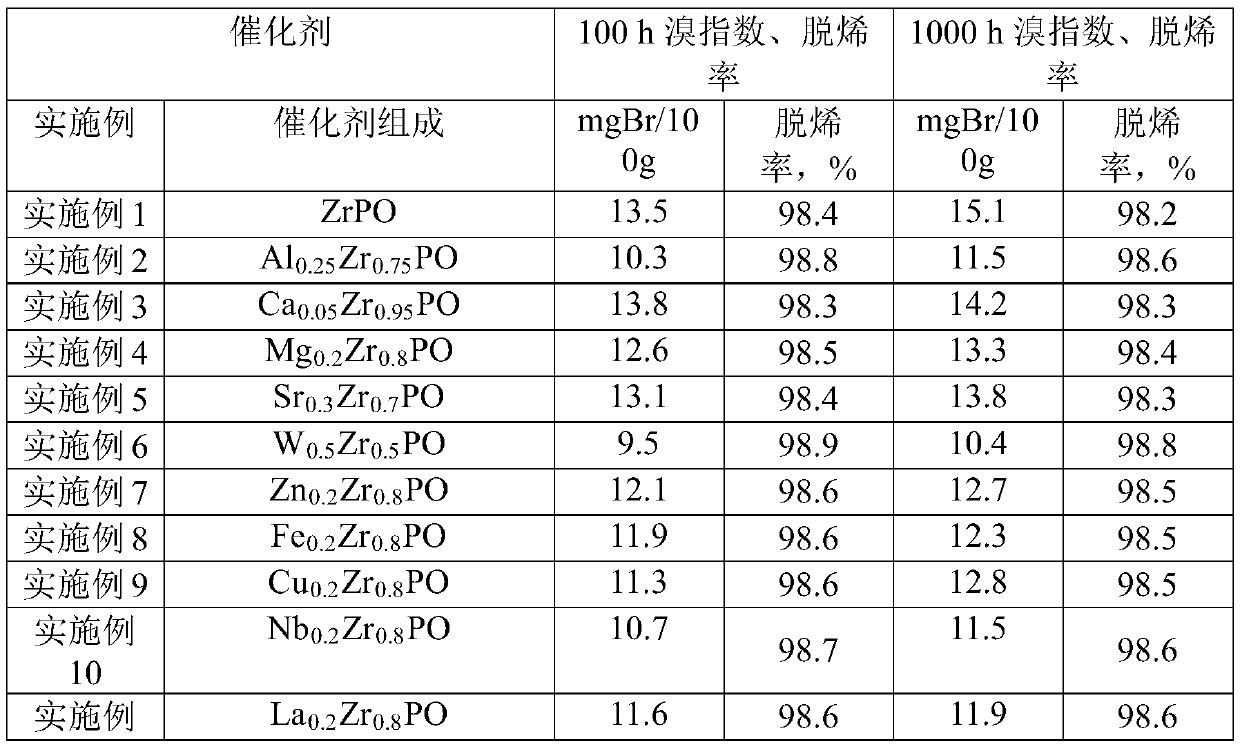

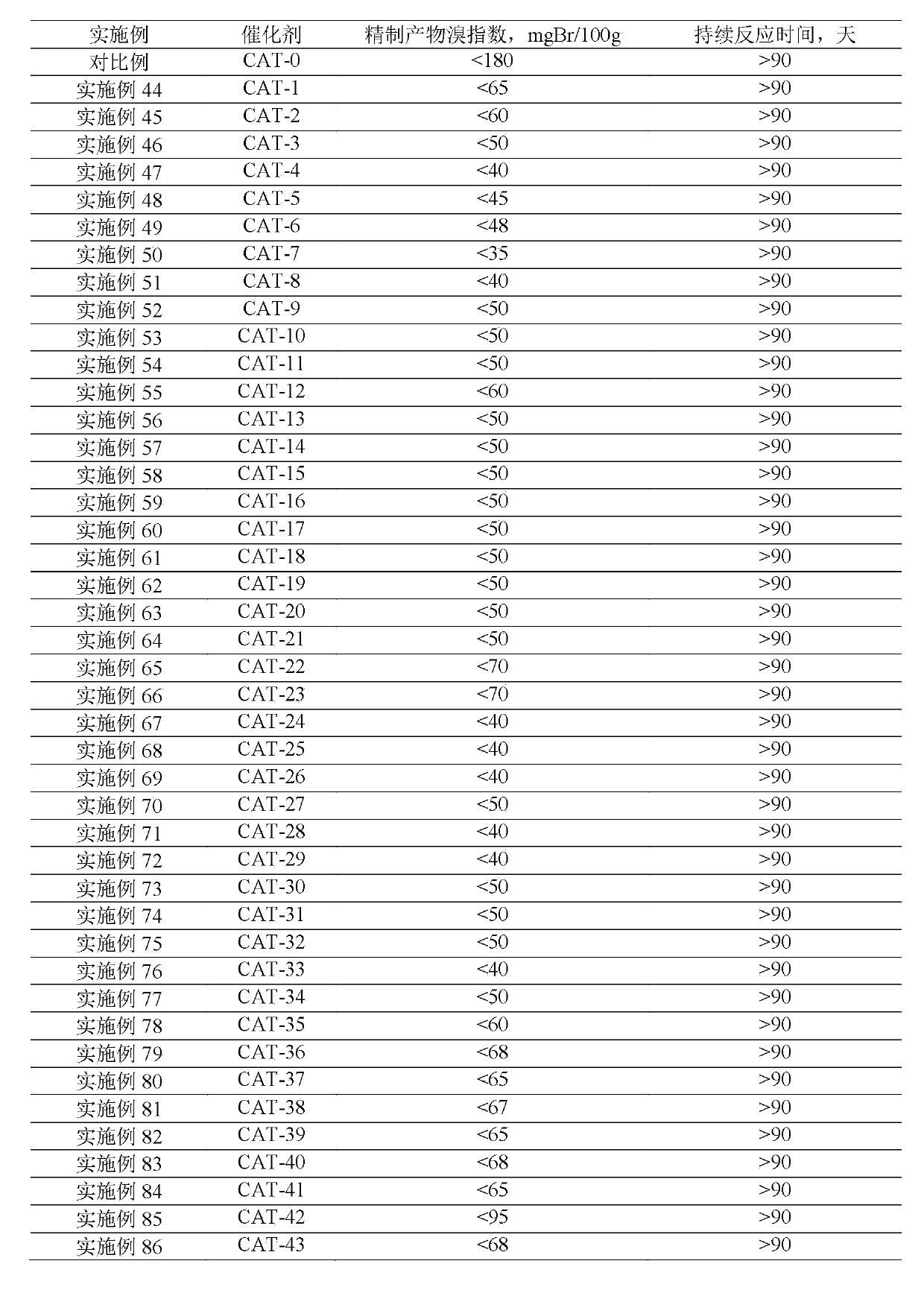

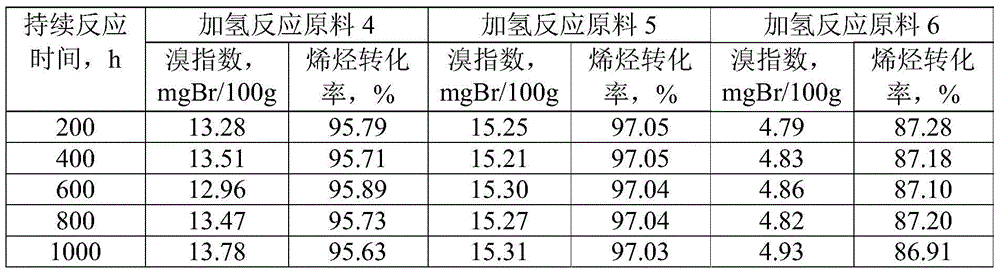

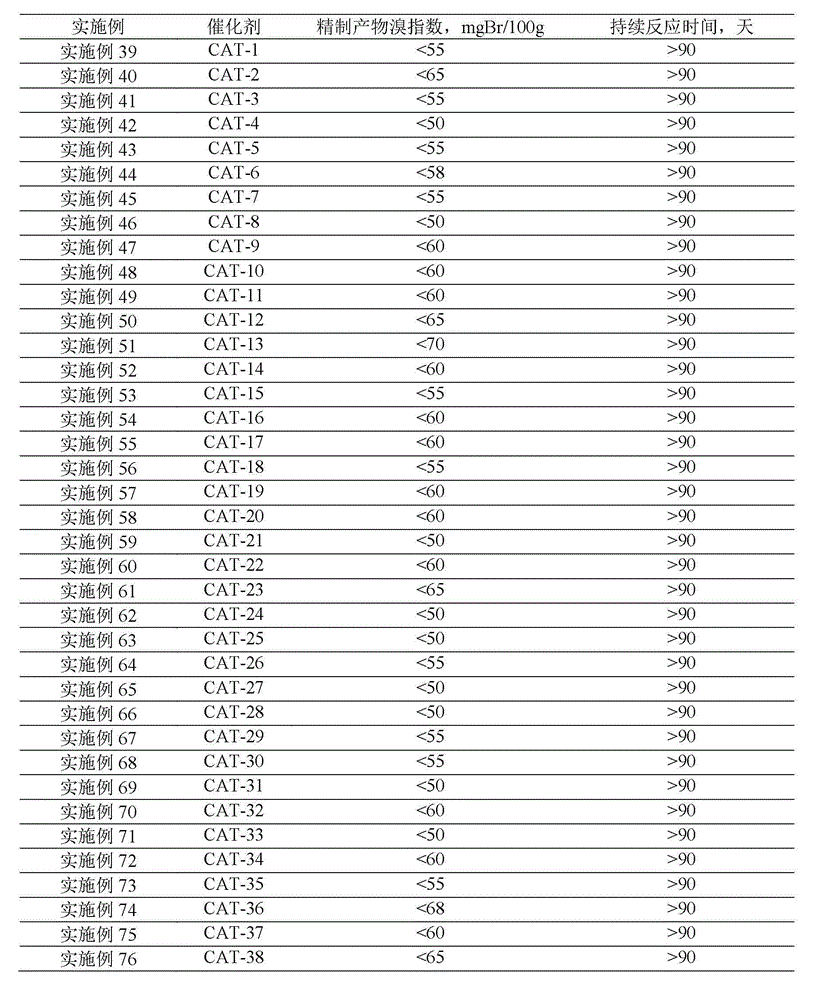

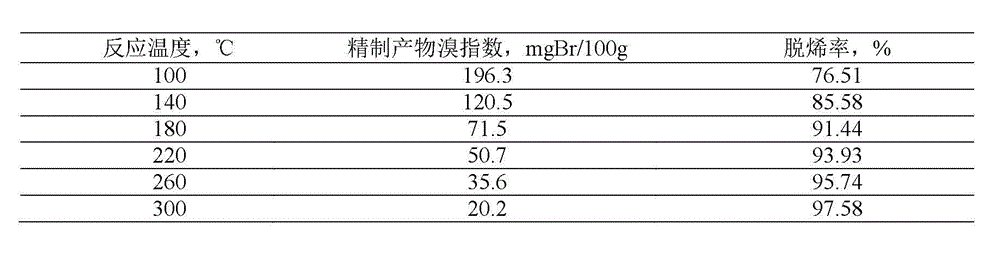

ActiveCN110813371AImprove the coordination effectEnhanced Surface AcidityMolecular sieve catalystsTreatment with plural serial stages onlyMolecular sievePtru catalyst

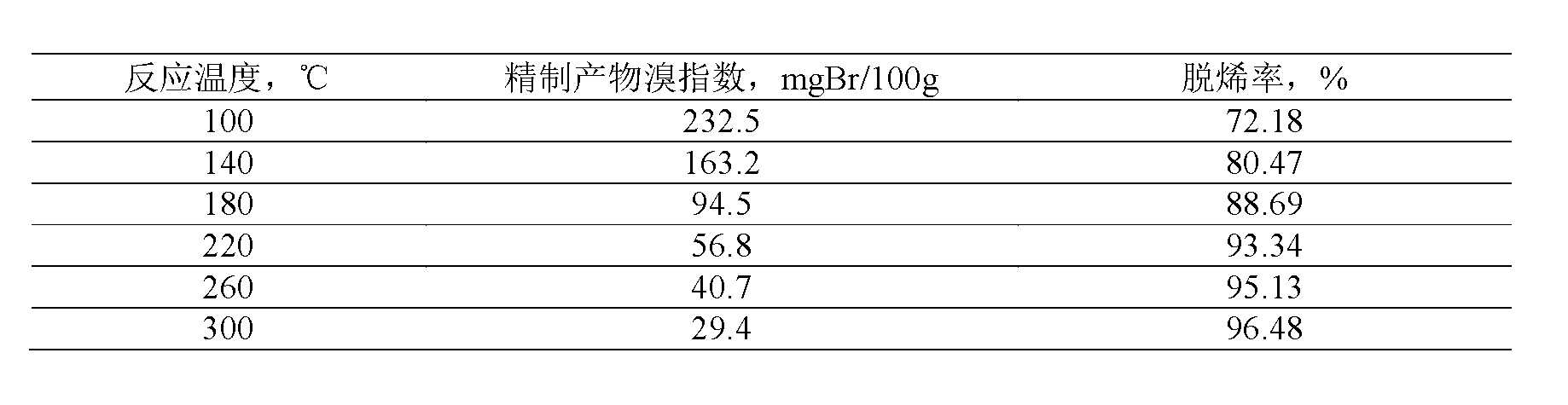

The invention discloses a method for removing a tiny amount of olefins in aromatic hydrocarbon by using a solid acid catalyst. Liquid-phase aromatic hydrocarbons contact and react with the solid acidcatalyst at a temperature of 100-300 DEG C under a pressure of 0.2-10 MPa and a feeding mass space velocity of 0.2-15 h<-1> to carry out alkylation and superposition reactions on the tiny amount of olefins in the aromatic hydrocarbons in order to remove the tiny amount of olefins in the aromatic hydrocarbons, refine the aromatic hydrocarbons and obtain olefin-removed aromatic hydrocarbons; the solid acid catalyst is a meso-porous zirconium phosphate molecular sieve catalyst or a modified mesoporous zirconium phosphate molecular sieve catalyst loaded with a modifying compound; the solid acid catalyst prepared by the method has a high activity, and the olefin removal rate is 98% or above; the catalyst has a good activity stability, and the activity stabilization time exceeds 3000 h; and theselectivity of the reaction for removing olefins from aromatic hydrocarbons is high, and the generation mass fraction of toluene refined by C8 aromatic hydrocarbons is less than 0.1%, and frequent switching operation of reactor reaction and regeneration can be avoided.

Owner:ZHEJIANG UNIV OF TECH

Method for removing trace hydrocarbon from aromatic hydrocarbon by utilizing AlPO4-5 type Al-P molecular sieve

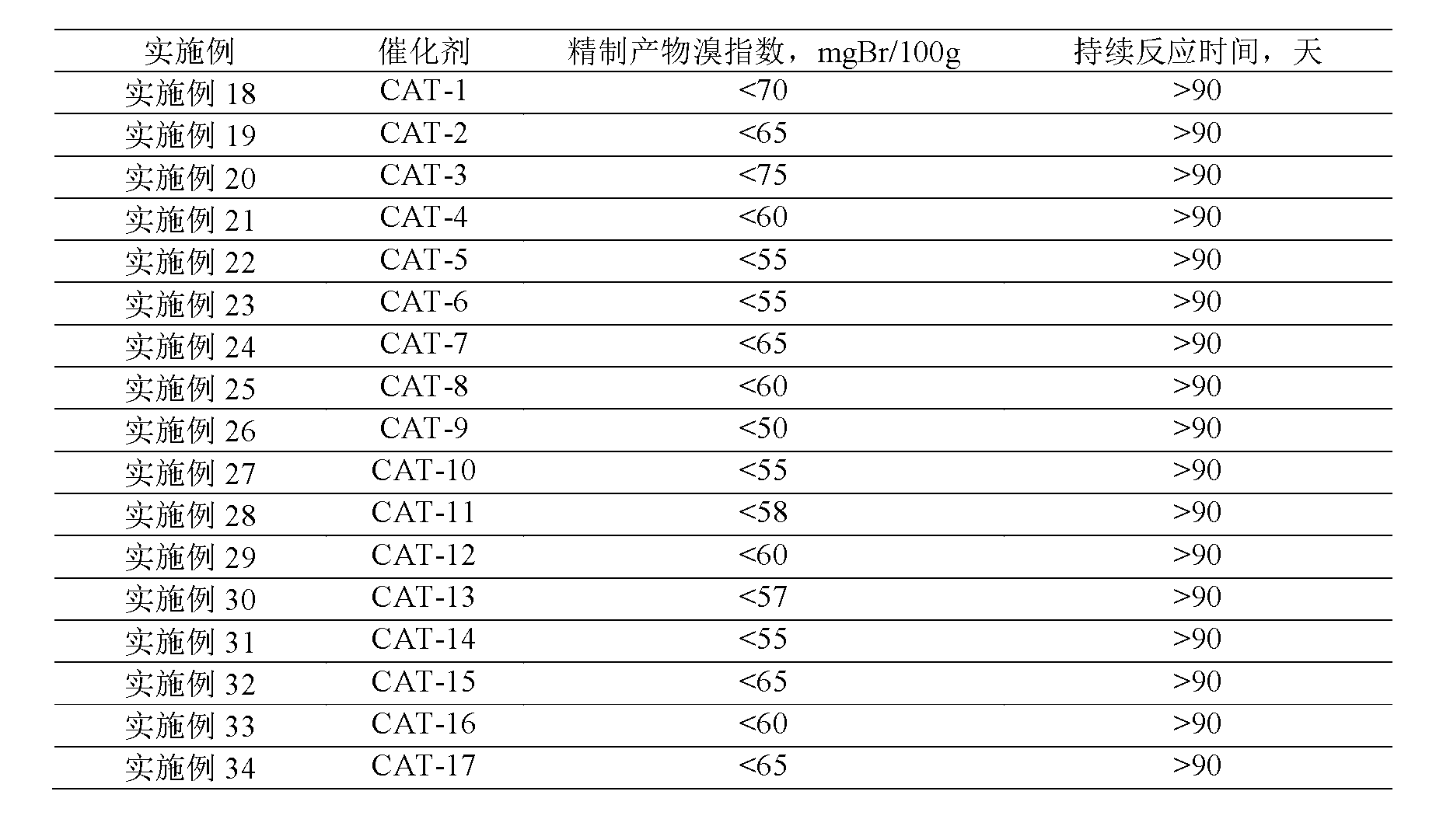

InactiveCN103013556ASimple processDoes not consume hydrogenCatalytic crackingMolecular sieve catalystsMolecular sieveHydrogen

The invention discloses a method for removing trace hydrocarbon from aromatic hydrocarbon by utilizing an AlPO4-5 type Al-P molecular sieve. The method comprises the following steps: allowing aromatic hydrocarbon to contact and react with solid acid catalyst under conditions that the temperature is between 30 and 350 DEG C, the pressure is between 0.1 and 12MPa and the mass space velocity is between 0.1 and 15 hour<-1> to obtain hydrocarbon removed aromatic hydrocarbon, wherein the hydrocarbon is reformed oil, reformed hydrocarbon or aromatic hydrocarbon generated by steam cracking. The method is simple in process flow, does not consume hydrogen, and is low in device investment and operation cost; the catalyst is good in activity stability, the device is stable and long in operation time, less hydrocarbon is lost, and operation of frequent switching between reaction and regeneration of the reactor can be avoided; and the catalyst is reproducible to avoid massive waste catalyst accumulation and bury, and has small influence on the environment.

Owner:ZHEJIANG UNIV OF TECH

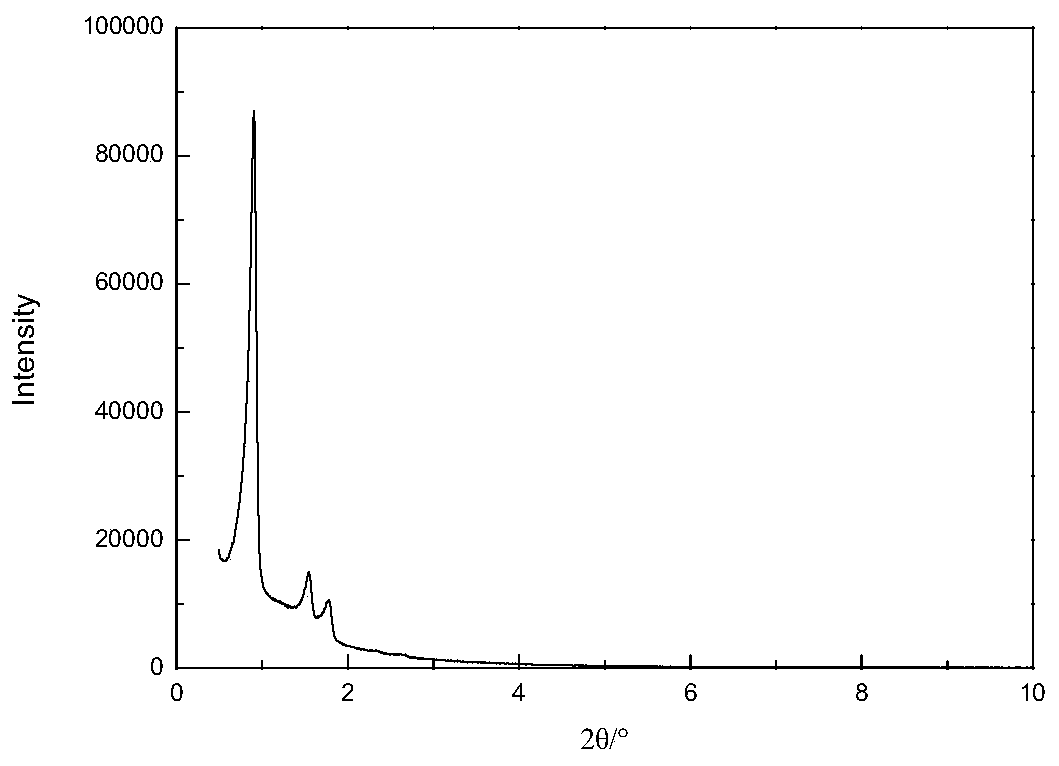

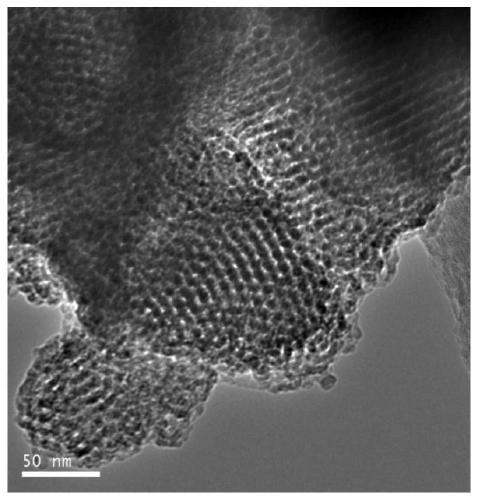

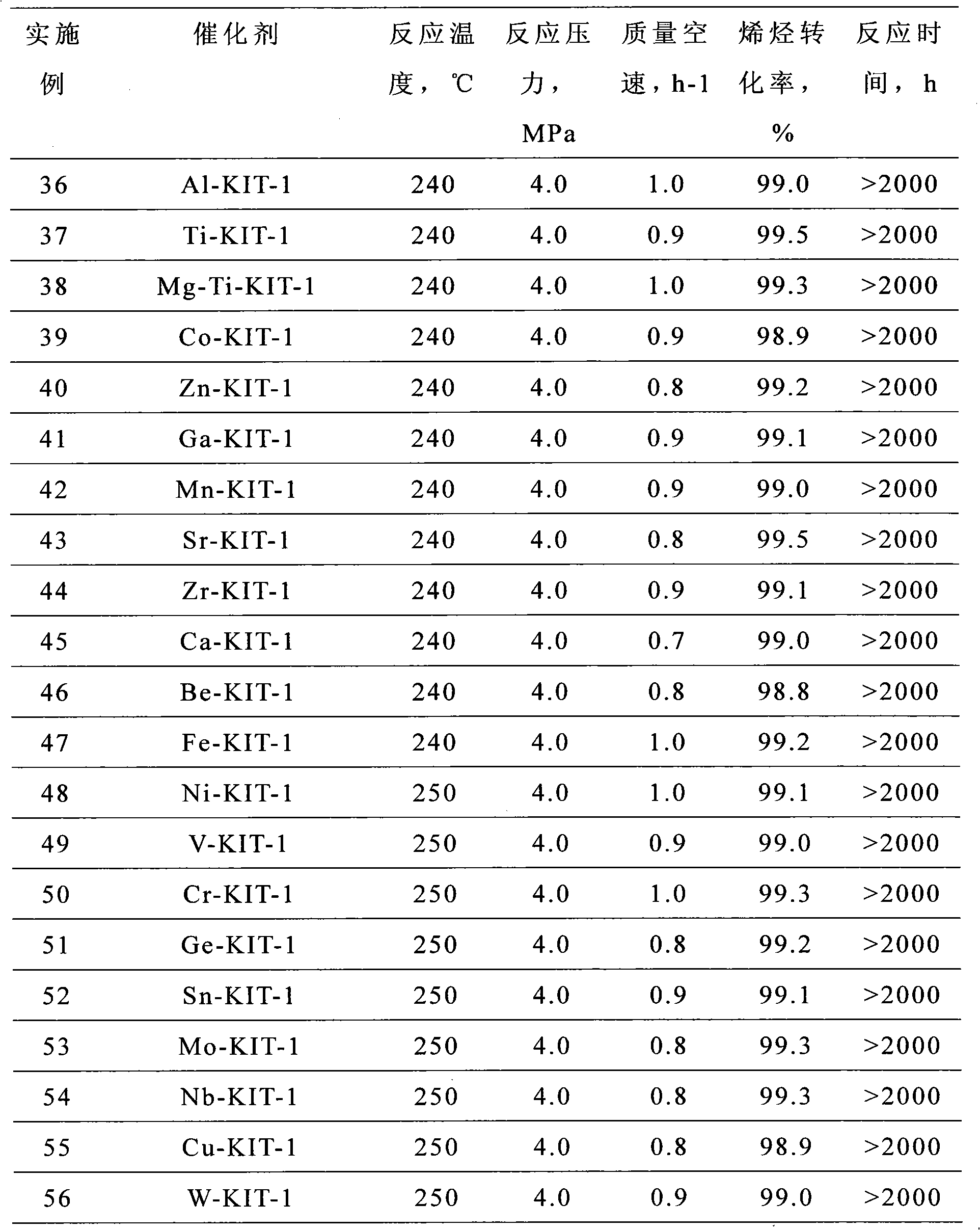

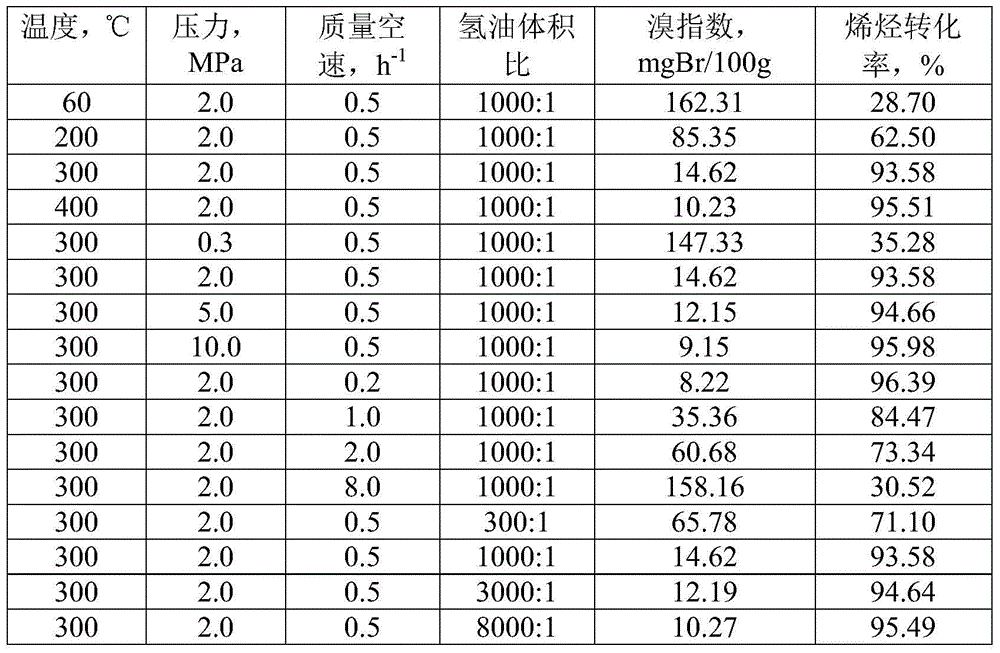

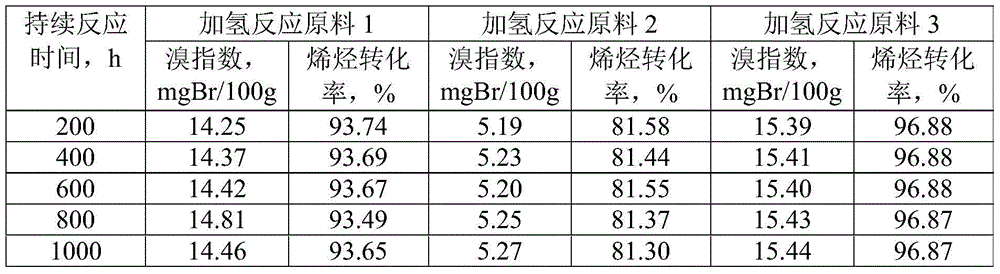

Linear alkylbenzene catalytic hydrofining method

ActiveCN105601463AAvoid pollutionSimple processHydrocarbon purification/separationCatalyst activation/preparationAlkyl transferBenzene

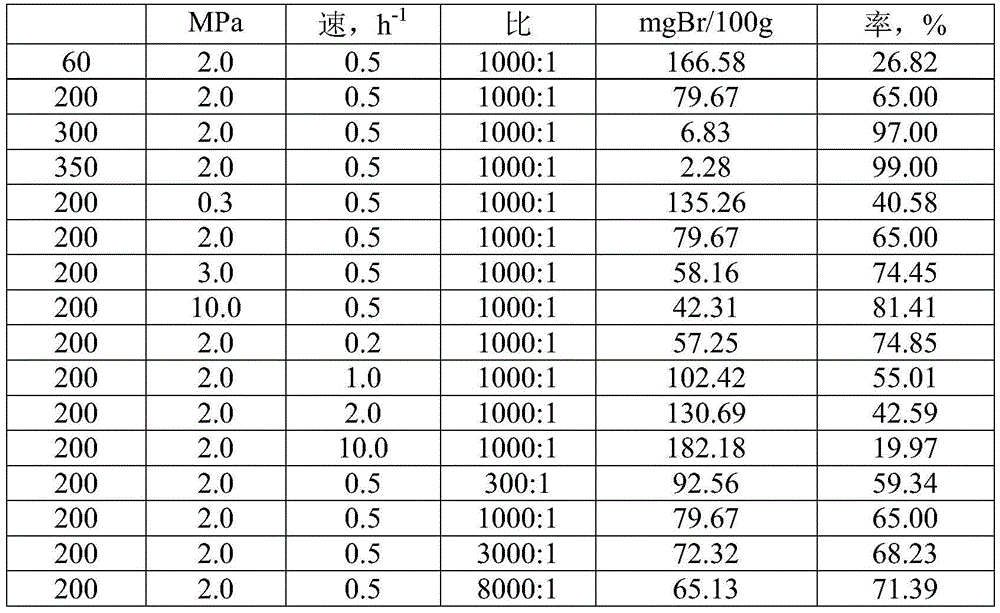

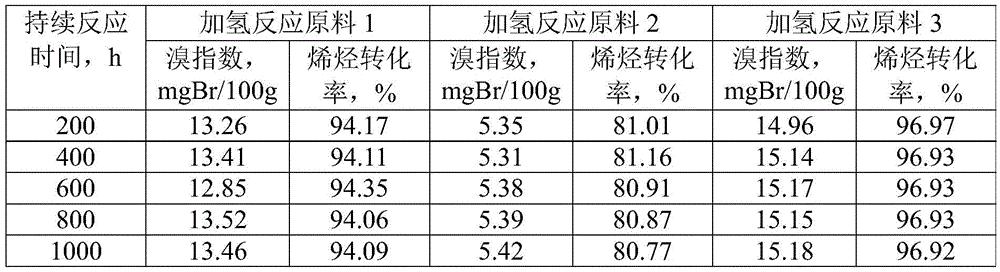

The invention discloses a linear alkylbenzene catalytic hydrofining method. The method comprises the steps that under the conditions that the temperature ranges from 60 DEG C to 350 DEG C, pressure ranges from 0.3 MPa to 10.0 MPa, the mass space velocity ranges from 0.2 h<-1> to 10.0 h<-1>, and the hydrogen and oil volume ratio ranges from 300:1 to 8000:1, a hydrogenation raw material and hydrogen are mixed and react with a palladium supported type catalyst in a contact mode so that olefin can be saturated, and then a trace amount of olefin is removed, the bromine index of linear alkylbenzene is reduced, and the product quality is improved; the hydrogenation raw material is linear alkylbenzene obtained by alkylation of benzene with C10-C14 linear olefins mixture in a distillation separation mode, or is alkylation of benzene with C10-C14 linear olefins mixture. The technological process is simple, the catalyst activity is good in stability, the stable operation time of a device is long, reactor reaction and regeneration frequent switching operation can be avoided, less loss of linear alkylbenzene is realized, the catalyst is reproducible, postprocessing of a large number of catalysts can be avoided, and less influence is caused for an environment.

Owner:ZHEJIANG UNIV OF TECH

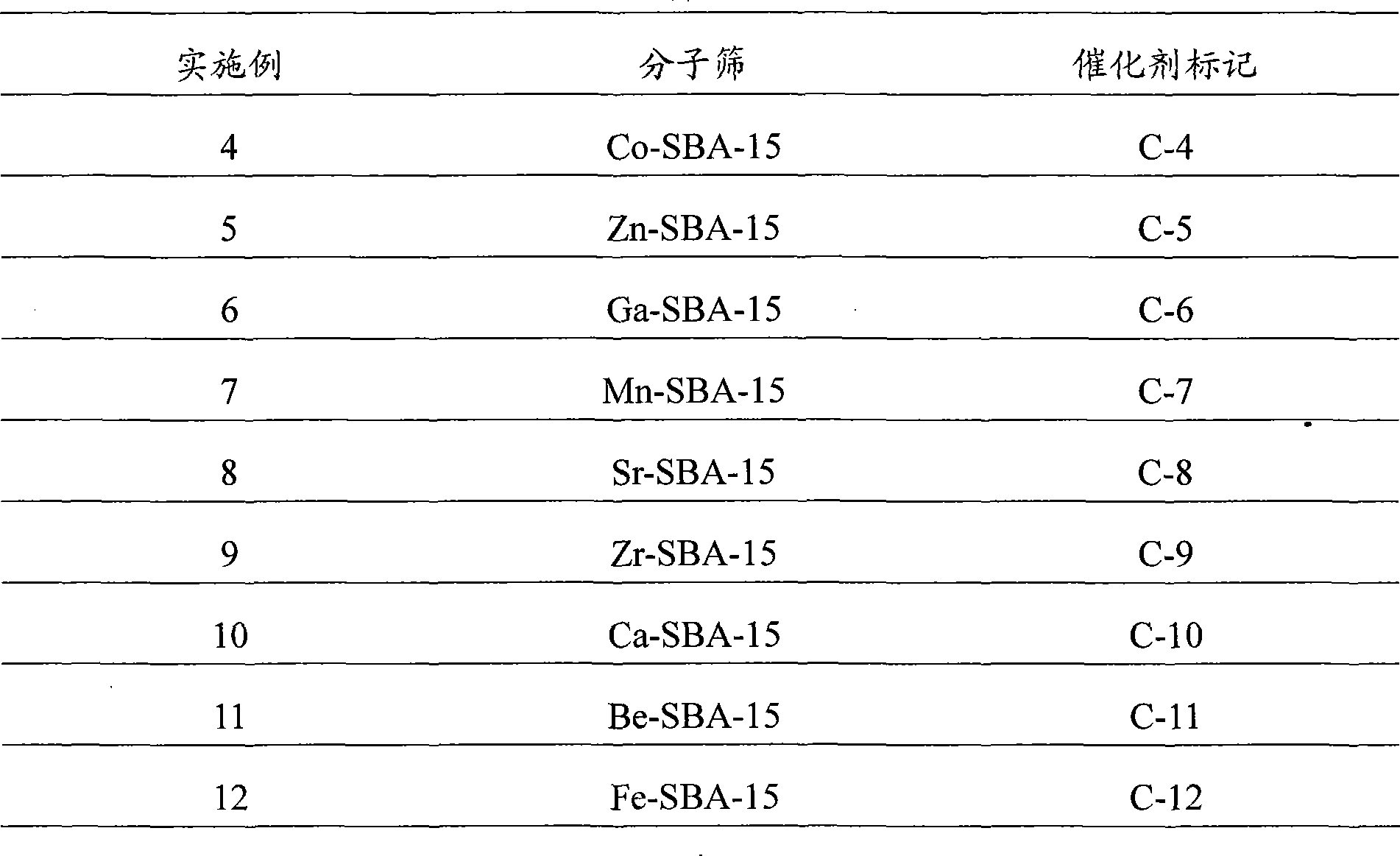

Method for catalytically synthesizing long-chain alkyl aromatic hydrocarbons

ActiveCN111514924AEnvironmentally friendlyGood catalyst activity and stabilityMolecular sieve catalystsMolecular sieve catalystChemistryMolecular sieve

The invention relates to a method for catalytically synthesizing long-chain alkyl aromatic hydrocarbons. The method comprises the following steps: inputting a raw material aromatic hydrocarbon into afixed bed alkylation reactor, and filling the reactor with the raw material aromatic hydrocarbon; inputting a mixture of the raw material aromatic hydrocarbon, raw material C6-C24 long-chain olefins and an additive long-chain alkyl aromatic hydrocarbon solvent or long-chain alkane solvent into the fixed bed reactor, contacting with an SBA-15 type mesoporous molecular sieve alkylation solid acid catalyst, and carrying out an alkylation reaction on the aromatic hydrocarbon and the long-chain olefin to generate a product long-chain alkyl aromatic hydrocarbon; taking one part of an alkylation reactor effluent as a circulating fluid circulating to the reactor, and taking the other part as an effluent fluid for separating excessive raw materials and products in a distillation separation system.The method disclosed by the invention has the characteristics of environmental friendliness, good catalyst activity stability, high conversion rate, high selectivity, high product linearity and low energy consumption.

Owner:ZHEJIANG UNIV OF TECH

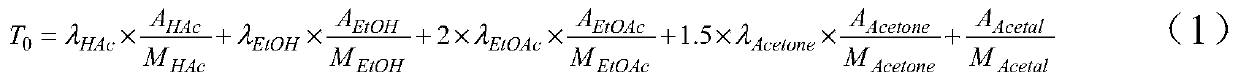

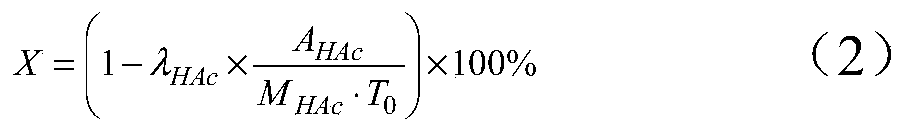

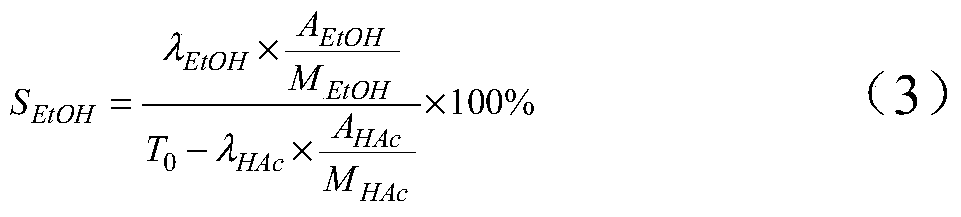

Method for preparing ethanol by hydrogenating acetic acid

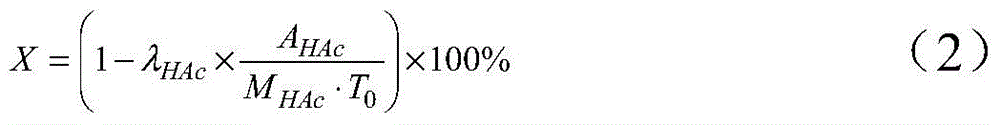

ActiveCN105646148ALow priceReduce manufacturing costPhysical/chemical process catalystsOrganic compound preparationTransition metal carbidesAcetic acid

The invention discloses a method for preparing ethanol by hydrogenating acetic acid. The method comprises the following steps of mixing the acetic acid and hydrogen under the conditions that the temperature is 250 to 400DEG C, the pressure is 0.5 to 10.0MPa, the weight hourly space velocity is 0.2 to 8.0h<-1>, and the feeding mole ratio of the hydrogen to the acetic acid is 1:1 to 20:1; performing contact reaction on a mixture and a loaded transition metal carbide catalyst; hydrogenating the acetic acid to prepare the ethanol. The method disclosed by the invention has the advantages that the process flow is simple, the price of the catalyst is lower, the performance stability of the catalyst is good, and the stable operation time of the device is long; frequent switching operation of reaction and regeneration of a reactor can be avoided, the catalyst can be regenerated, posttreatment of a large amount of waste catalysts can be avoided, and further the influence on the environment is little.

Owner:ZHEJIANG UNIV OF TECH

Solid acid catalytic reaction method for aromatic hydrocarbon long-chain alkylation

ActiveCN111468171AGood activity and stabilityImprove conversion rateMolecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsAlkanePtru catalyst

The invention relates to a solid acid catalytic reaction method for aromatic hydrocarbon long-chain alkylation, which comprises the following steps: feeding raw material aromatic hydrocarbon into a fixed bed alkylation reactor to fill the reactor; feeding a mixture of the raw material aromatic hydrocarbon, the raw material C6-C24 long-chain olefin and an additive long-chain alkyl aromatic hydrocarbon solvent or long-chain alkane solvent into a fixed bed reactor, contacting with an MCM-41 type mesoporous molecular sieve solid acid catalyst, and carrying out an aromatic hydrocarbon long-chain alkylation reaction to generate product long-chain alkyl aromatic hydrocarbon; taking one part of the alkylation reactor effluent as a circulating fluid circulating to the reactor, and taking the otherpart as an effluent fluid for separating excessive raw materials and products in a distillation separation system. The method disclosed by the invention is environment-friendly, good in catalyst activity stability, high in conversion rate, high in selectivity and high in product linearity.

Owner:ZHEJIANG UNIV OF TECH

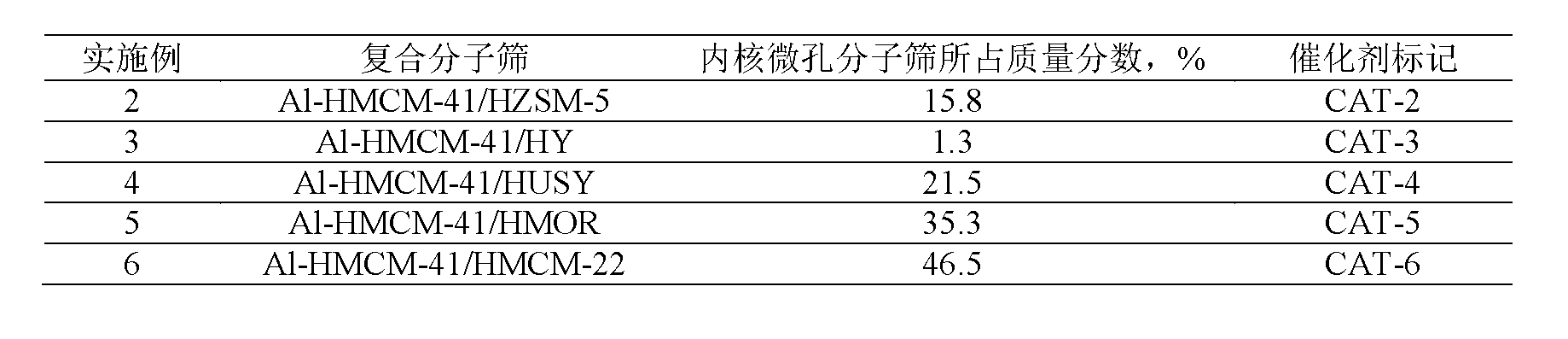

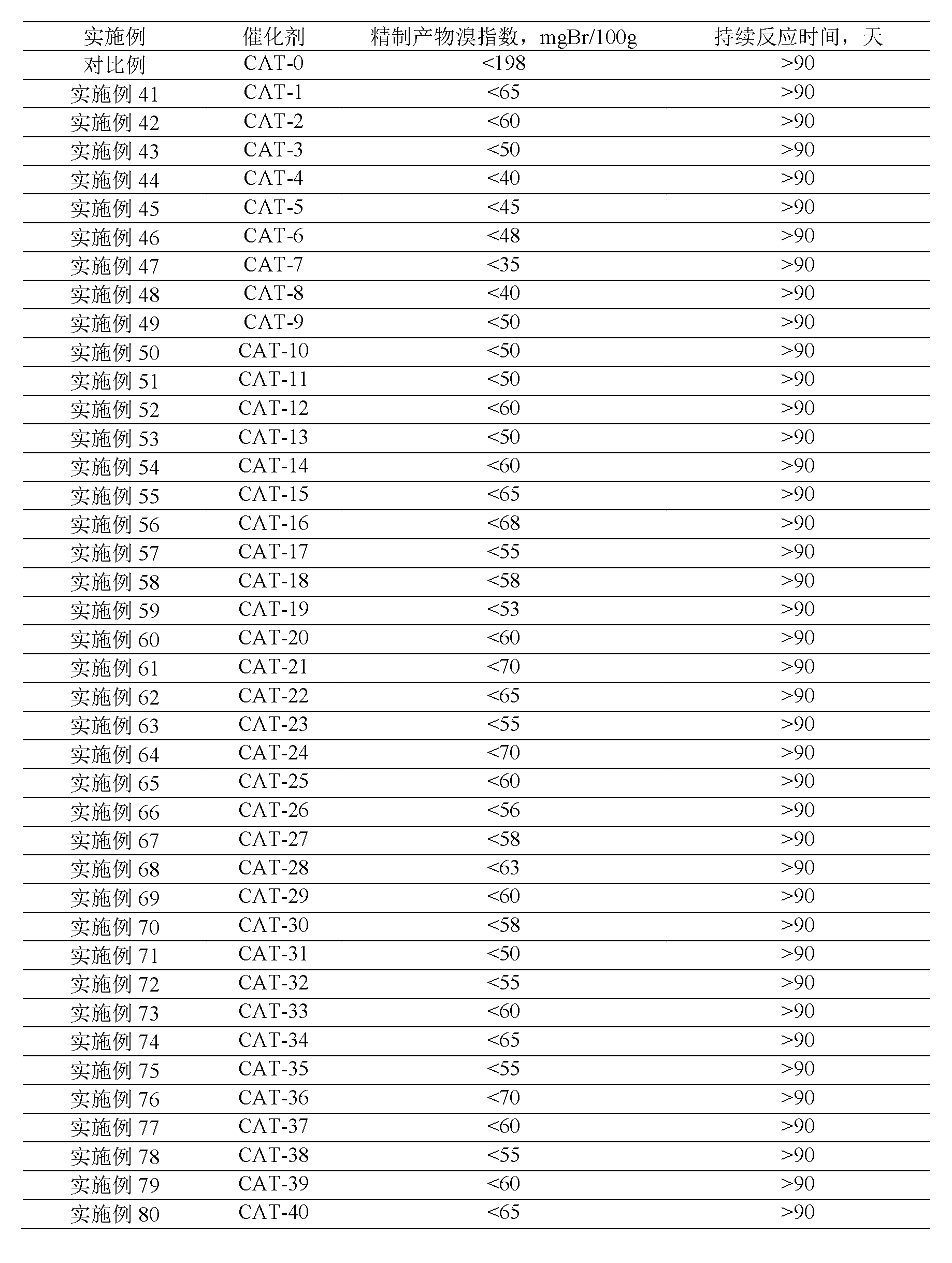

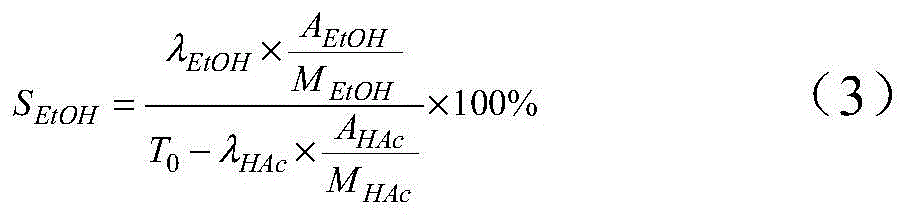

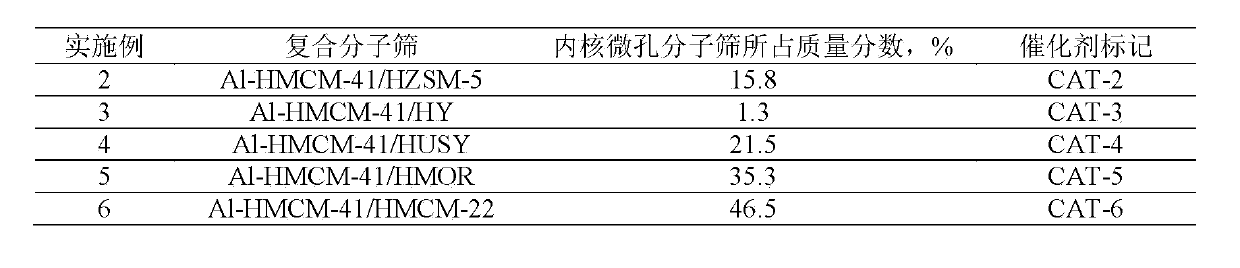

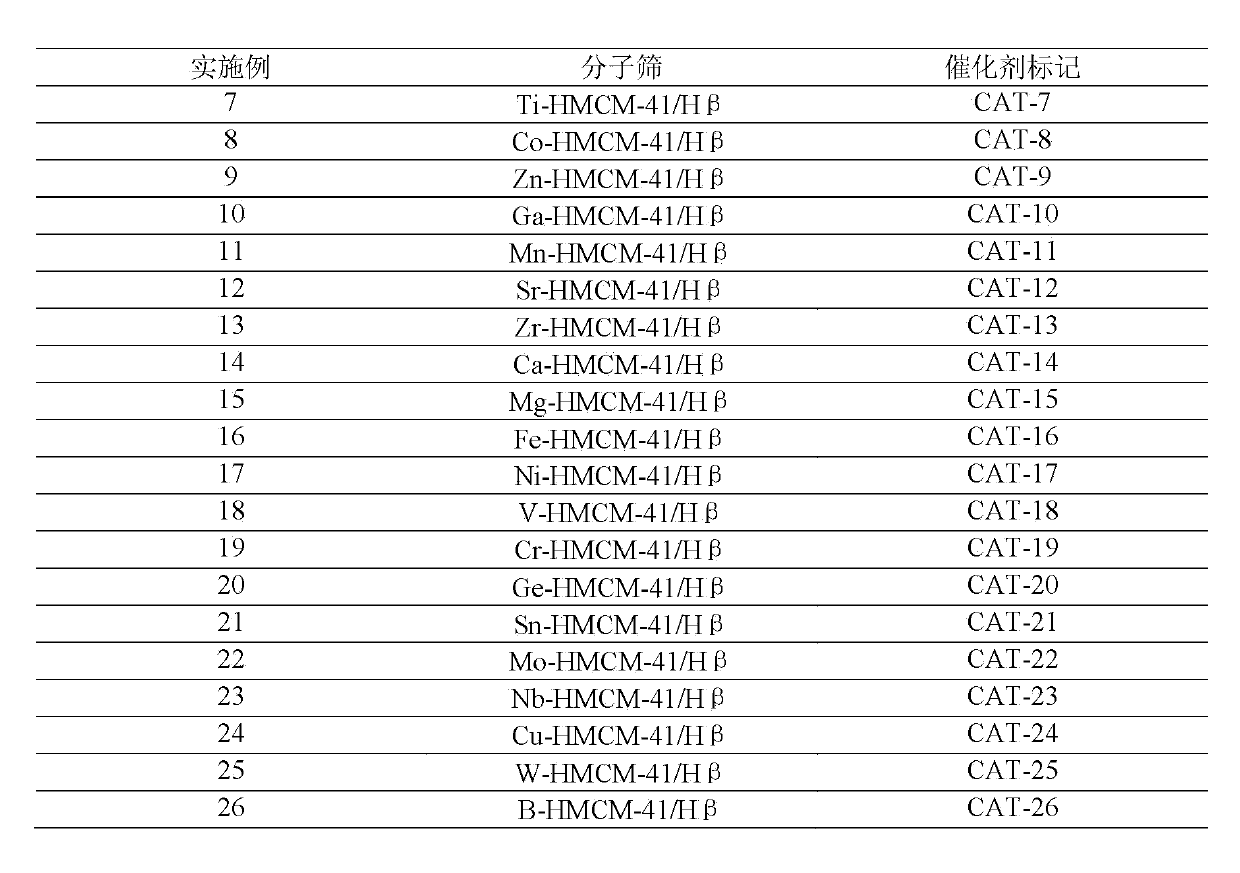

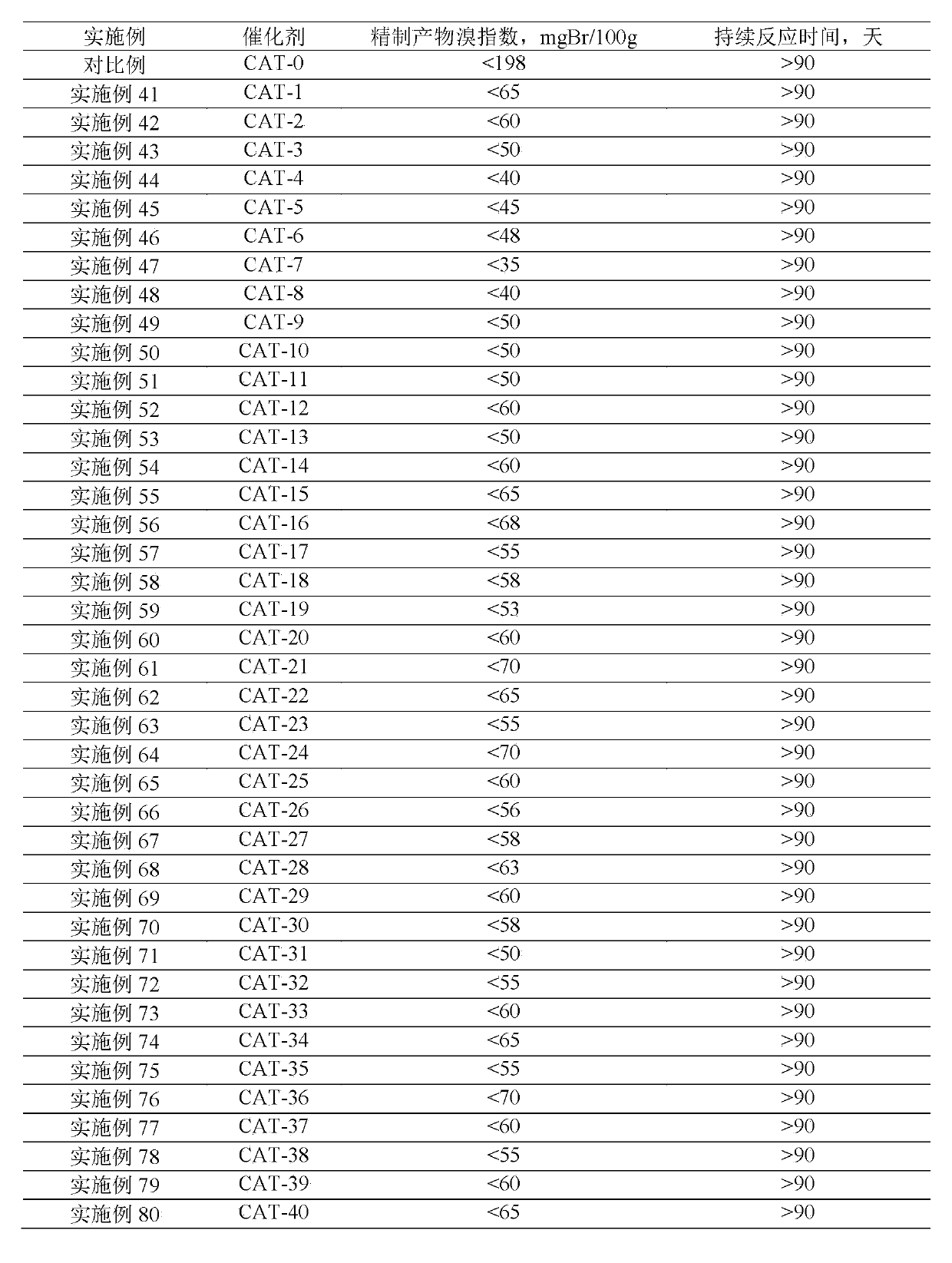

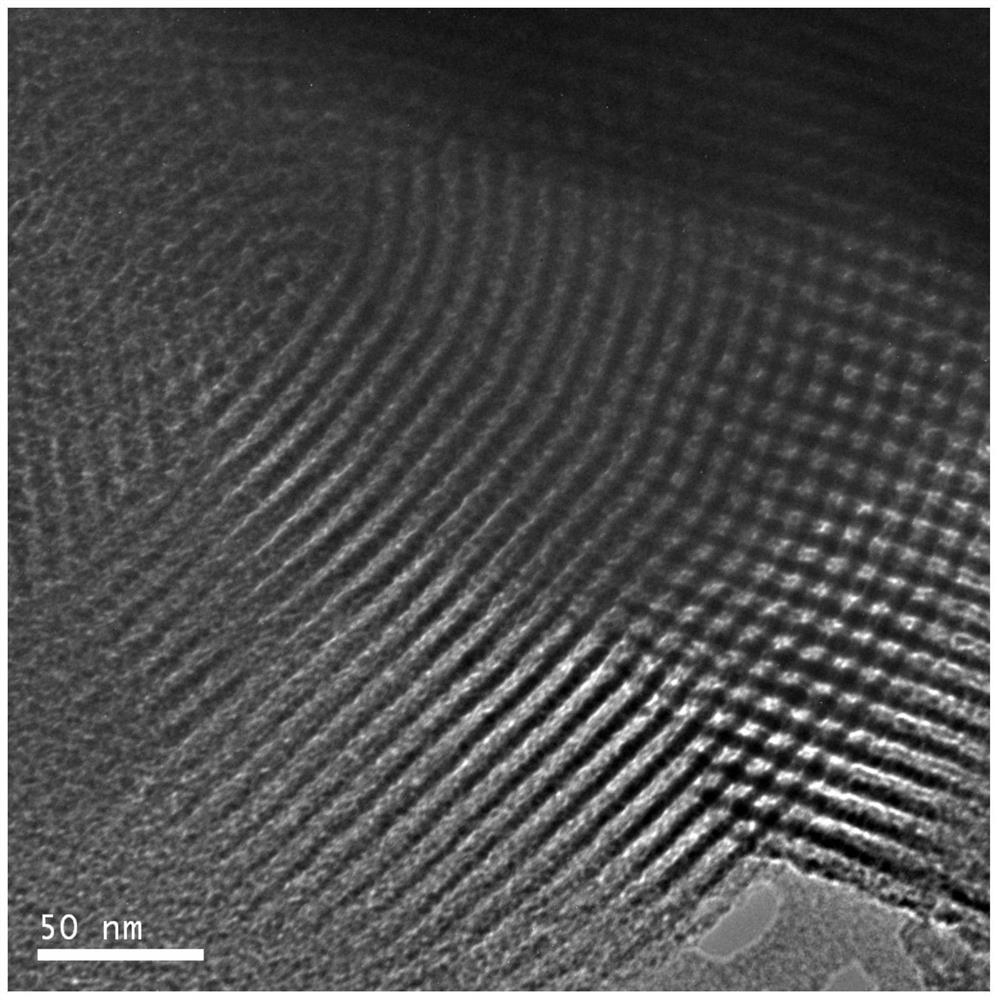

Method for refining aromatic hydrocarbons by using microporous-mesoporous core-shell structure composite molecular sieve

ActiveCN110813370AHigh activityGood activity and stabilityMolecular sieve catalystsMolecular sieve catalystMolecular sievePtru catalyst

The invention discloses a method for refining aromatic hydrocarbons by using a microporous-mesoporous core-shell structure composite molecular sieve. Liquid-phase aromatic hydrocarbons contact and react with a solid acid catalyst at a temperature of 100-300 DEG C under a pressure of 0.2-10 MPa and at a feeding mass space velocity of 0.2-15 h<-1> to carry out alkylation and superposition reactionson a tiny amount of olefins in the aromatic hydrocarbons in order to remove the tiny amount of olefins in the aromatic hydrocarbons, refine the aromatic hydrocarbons and obtain olefin-removed aromatichydrocarbons; the solid acid catalyst is the core-shell structure composite molecular sieve catalyst or a modified mesoporous zirconium phosphate molecular sieve catalyst loaded with a modifying compound; the solid acid catalyst prepared in the invention has a high activity, and the olefin removal rate is 98% or above; the catalyst has a good activity stability, and the activity stabilization time exceeds 3000 h; and the selectivity of the reaction for removing olefins from aromatic hydrocarbons is high, and the generation mass fraction of toluene refined by C8 aromatic hydrocarbons is less than 0.1%, and frequent switching operation of reactor reaction and regeneration can be avoided.

Owner:ZHEJIANG UNIV OF TECH

Method for removing trace olefin from aromatic hydrocarbon

ActiveCN103012037ASimple processLow device investment and operating costsChemical modification purification/separationChemistryEnvironment effect

The invention discloses a method for removing trace olefin from aromatic hydrocarbon. The method comprises the step of carrying out contact reaction on aromatic hydrocarbon and a solid acid catalyst under the conditions that the temperature is 30-400 DEG C, the pressure is 0.1-12MPa and the feeding mass space velocity is 0.1-15h<-1> to obtain aromatic hydrocarbon after the olefin is removed. The method is simple in process without consuming hydrogen, low in device investment and operation cost, good in catalyst activity stability, long in device stable operation time and less in aromatic hydrocarbon loss; and reactor reaction and regeneration frequent switching operation can be avoided and a large quantity of waste catalysts can be prevented from being stacked and embedded, and environment influence is little.

Owner:ZHEJIANG UNIV OF TECH

Method for synthesizing linear alkylbenzene

ActiveCN101289358BNot corrosiveEnvironmentally friendlyMolecular sieve catalystsHydrocarbonsSolid acidLinear alkylbenzene

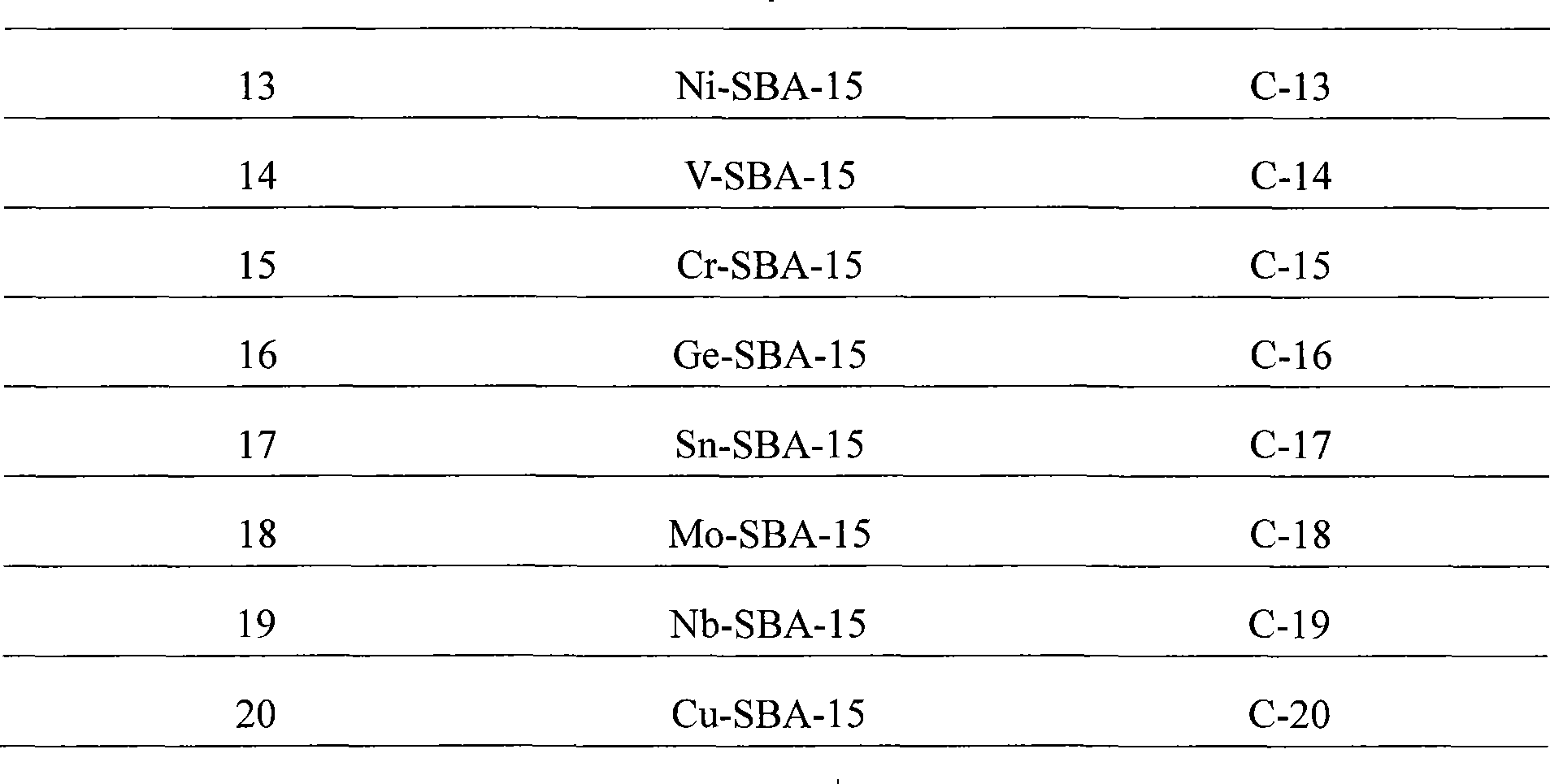

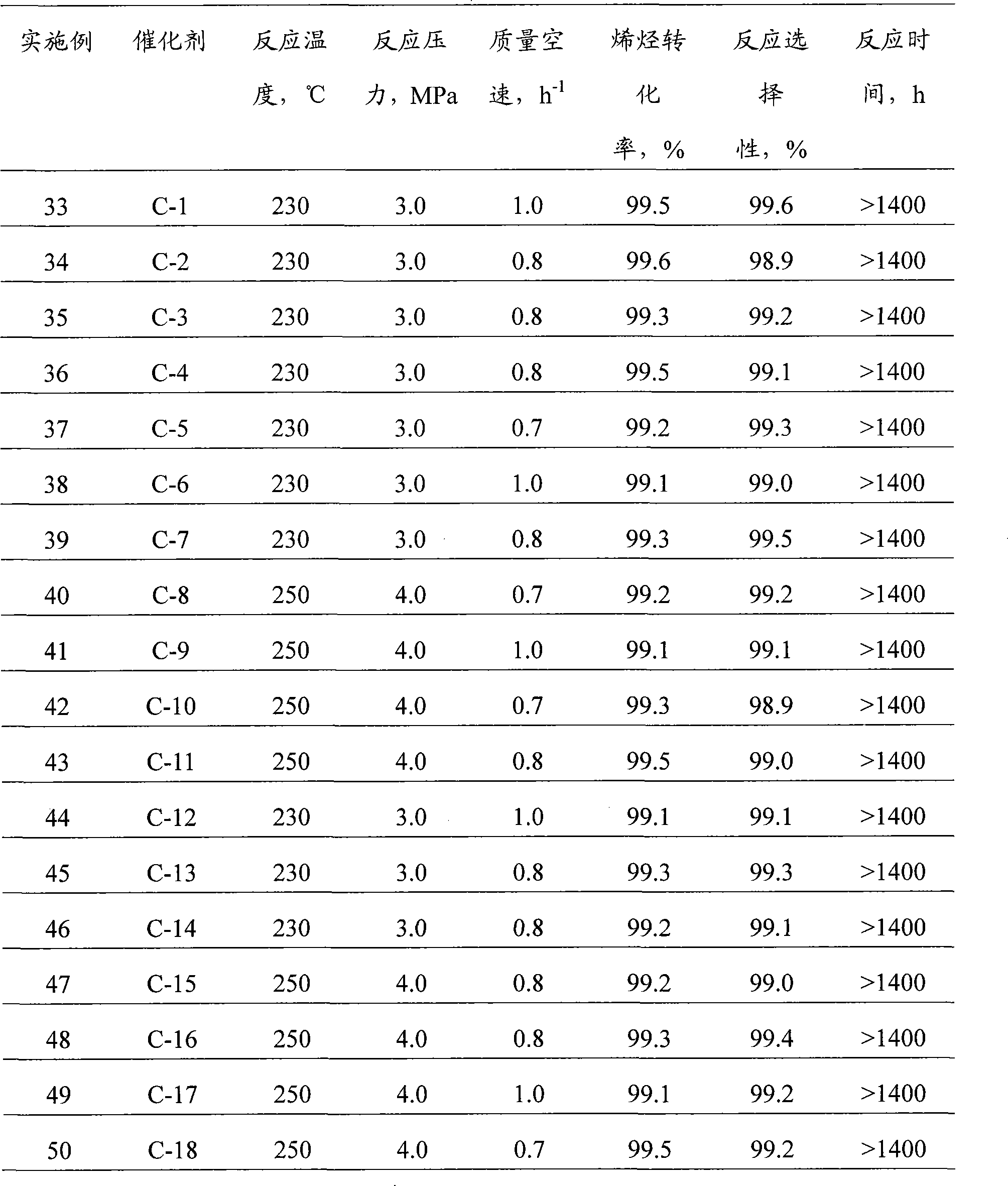

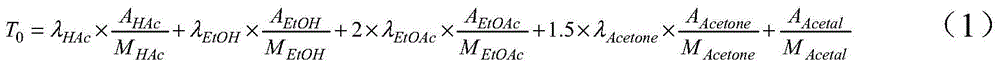

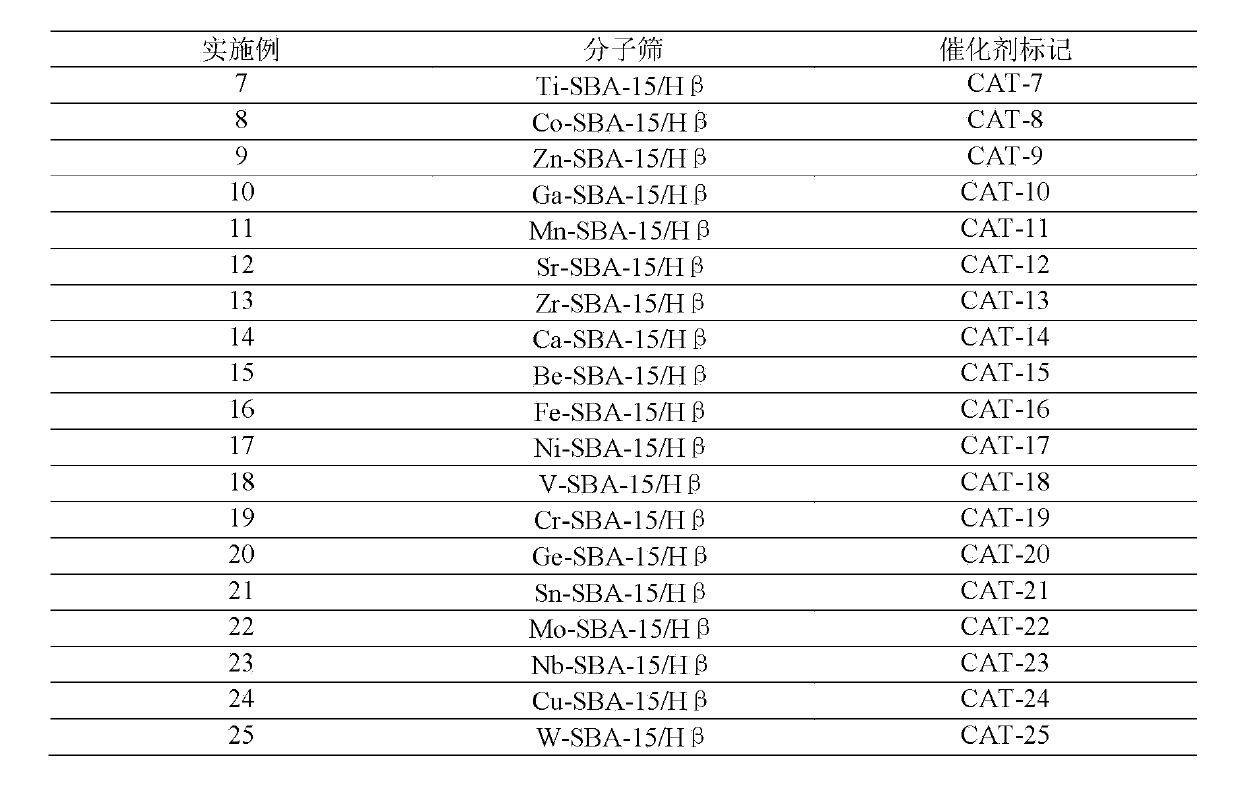

The invention provides a synthetic method for linear alkylbenzene. By taking linear olefin containing 2 to 20 carbon atoms and benzene as raw materials under the reaction condition of a temperature being 10 to 450 DEG C, a pressure being 0.1 to 15MPa, the ratio of the amount of substances of benzene and the olefin is 2 to 100:1 and the airspeed of a feeding total mass is 0.1 to 20 h<-1>, and an alkylation reaction is carried out by catalyzing by a solid acid catalyst, the linear alkylbenzene is obtained. The solid acid catalyst is M-SBA-15 typed mesopore molecular sieve catalyst or compound solid acid catalyst which is obtained by modifying the M-SBA-15 typed mesopore molecular sieve catalyst. The catalyst adopted by the invention has no corrosion, is friendly to environment and has good activity stability; therefore, higher olefin conversion and reaction selectivity can also be obtained even under comparatively lower temperature. Furthermore, the device is stable and has long operation time; therefore, frequent switching operation on the reaction and regeneration of the reactor can be avoided.

Owner:ZHEJIANG UNIV OF TECH

A kind of method of hydrogenation of acetic acid to produce ethanol

ActiveCN105646148BLow priceReduce manufacturing costPhysical/chemical process catalystsOrganic compound preparationTransition metal carbidesAcetic acid

Owner:ZHEJIANG UNIV OF TECH

Method for removing micro-quantity alkene in aromatic hydrocarbon

ActiveCN103012034BGood activity and stabilityReduce lossesChemical recyclingChemical modification purification/separationAlkyl transferEnvironment effect

The invention discloses a method for removing micro-quantity alkene in aromatic hydrocarbon. The method comprises the following steps of: contacting and reacting the aromatic hydrocarbon with a solid acid catalyst under the condition of temperature of 30-350 DEG C, pressure of 0.1-12MPa and feeding quality airspeed of 0.1-15 h<-1>, so that micro-quantity alkene in the aromatic hydrocarbon undergoes adsorbing, overlapping and alkylation reaction so as to remove the micro-quantity alkene in the aromatic hydrocarbon. The method is simple in process procedure, free of oxygen consumption and low in device investment and operation expense; and the catalyst is good in activity stability, the device is long in stable operation time, the aromatic hydrocarbon loss is small, the frequent switching operation between reactor reaction and regeneration is avoided, and the catalyst can be regenerated, so that a great deal of waste catalyst is prevented from being buried, and the environment is less polluted.

Owner:ZHEJIANG UNIV OF TECH

Aromatic hydrocarbon purifying method

ActiveCN103012036BGood activity and stabilityReduce lossesChemical recyclingChemical modification purification/separationHydrogenEnvironment effect

The invention discloses an aromatic hydrocarbon purifying method which comprises the step of carrying out a contact reaction on aromatic hydrocarbon and a solid acid catalyst under the conditions that the temperature is 50-400 DEG C, the pressure is 0.1-12MPa and the feeding mass space velocity is 0.1-15h<-1> to obtain purified aromatic hydrocarbon. The aromatic hydrocarbon purifying method is simple in process without consuming hydrogen, low in device investment and operation cost, good in catalyst activity stability, long in device stable operation time and less in aromatic hydrocarbon loss; and reactor reaction and regeneration frequent switching operation can be avoided, the catalyst can be regenerated, a large quantity of waste catalysts can be prevented from being stacked and embedded, and environment influence is little.

Owner:ZHEJIANG UNIV OF TECH

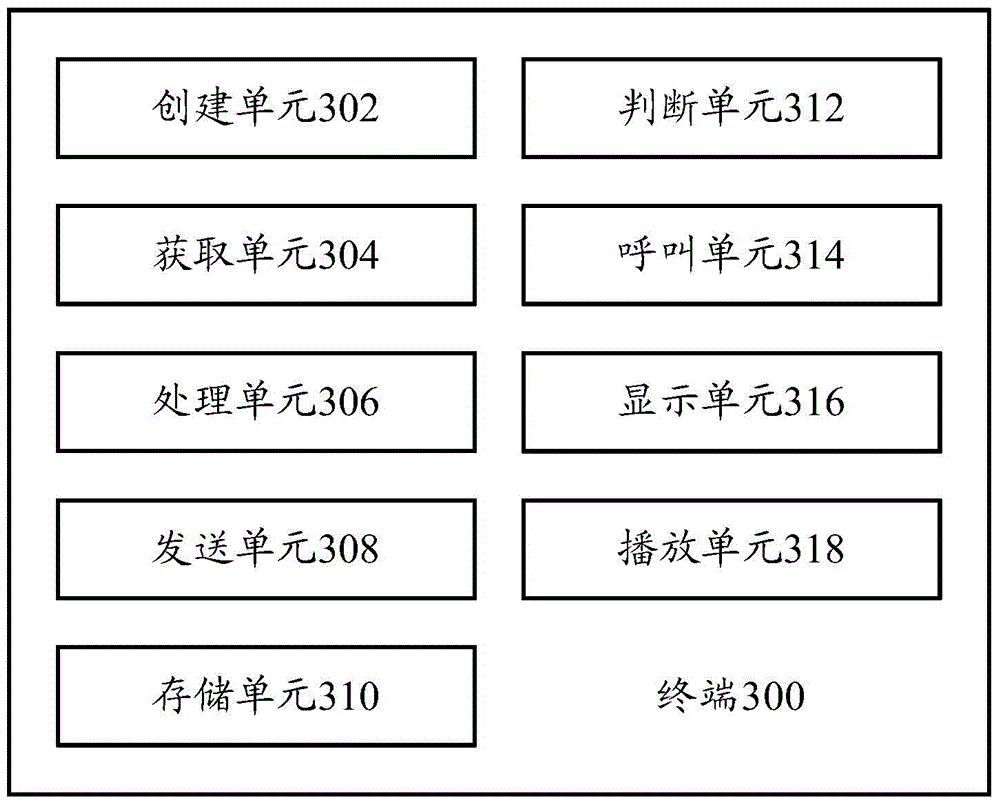

Group management method and terminal

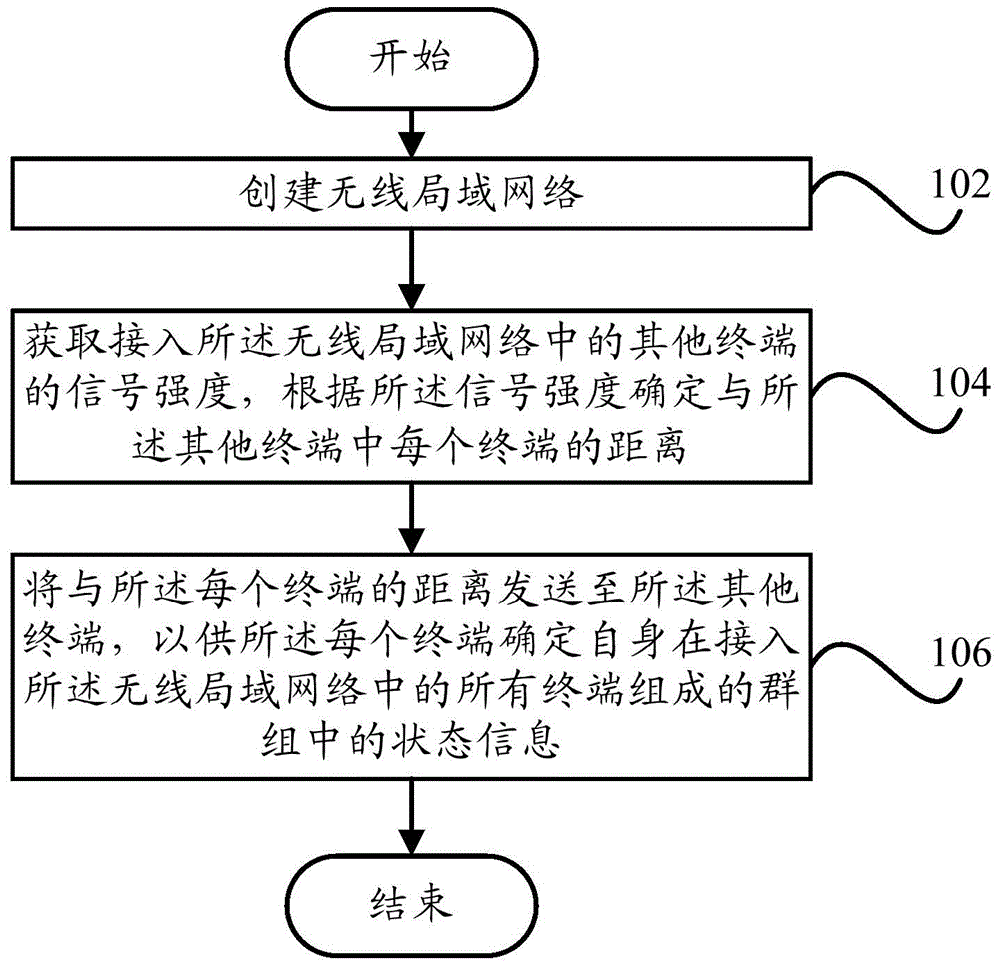

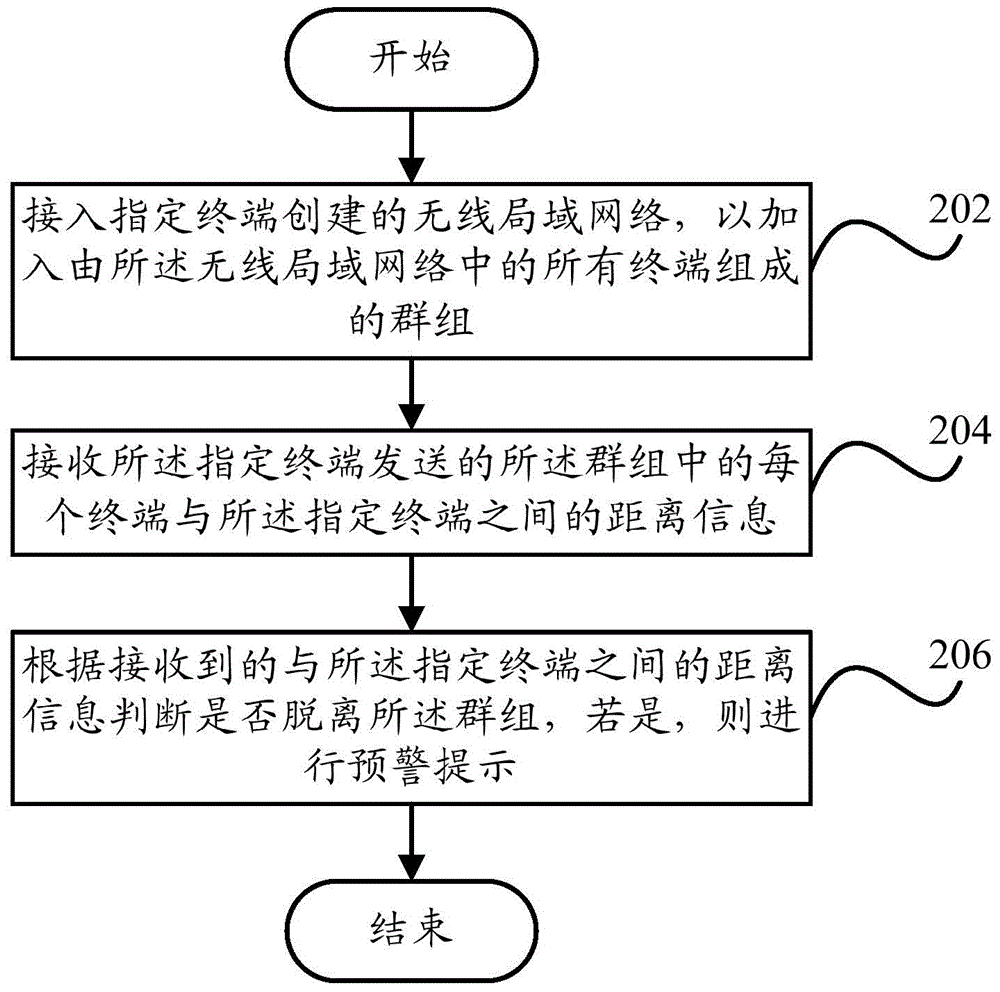

InactiveCN105323727AAvoid frequent switching operationsThe operation process is simpleBroadcast service distributionLocation information based serviceTelecommunicationsLocal area network

The invention provides a group management method and a terminal, wherein the group management method comprises the following steps: creating a wireless local area network; obtaining the signal strength of other terminals accessed to the wireless local area network, and determining the distance between the wireless local area network and each terminal in other terminals according to the signal strength; and sending the distance between the wireless local area network and each terminal to other terminals, such that each terminal determines self state information in a group consisting of all the terminals accessed to the wireless local area network. By means of the technical scheme provided by the invention, on the premise of not increasing the extra cost, the safety condition and the state information of each member in the group can be known in time; simultaneously, the frequent switching operation problem by using an interphone is also avoided; the operation process is simplified; and furthermore, the communication cost is saved.

Owner:YULONG COMPUTER TELECOMM SCI (SHENZHEN) CO LTD

Utilize transition metal phosphide catalyst to catalyze the method for hydrogenation of acetic acid to produce ethanol

ActiveCN105669372BGood activity and stabilityLong stable operation timePhysical/chemical process catalystsOrganic compound preparationAcetic acidHydrogen

The invention discloses a method for catalyzing the hydrogenation of acetic acid to produce ethanol by using a transition metal phosphide catalyst. Under the condition that the molar ratio of hydrogen to acetic acid is 1:1 to 20:1, acetic acid and hydrogen are mixed, and contacted and reacted with a supported transition metal phosphide catalyst to hydrogenate acetic acid to produce ethanol; the process of the invention is simple, and the catalyst price Lower, the catalyst performance stability is good, the stable operation time of the device is long, the frequent switching operation of the reactor reaction and regeneration can be avoided, the catalyst can be regenerated, the post-treatment of a large number of spent catalysts can be avoided, and the impact on the environment is small.

Owner:ZHEJIANG UNIV OF TECH

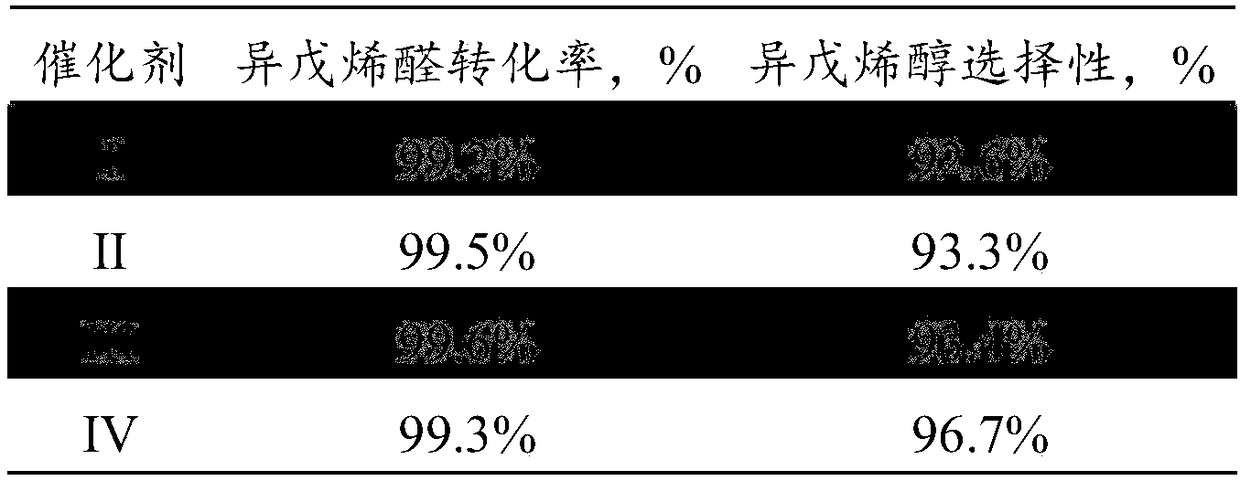

Method for preparing methyl-2-buten-1-ol from 3-methylcrotonaldehyde by selective hydrogenation

InactiveCN109369329AReduce manufacturing costHigh catalytic activityOrganic compound preparationHydroxy compound preparationHydrogenation reactionSubstance amount

The invention discloses a method for preparing methyl-2-buten-1-ol from 3-methylcrotonaldehyde by selective hydrogenation. The method comprises steps as follows: 3-methylcrotonaldehyde and hydrogen are mixed under the conditions of temperature being 50-80 DEG C, pressure being 0.1-3.0 MPa, mass space velocity being 5-8 h<-1> and a ratio of feeding substance amount of hydrogen to 3-methylcrotonaldehyde being 1:1-20:1, a mixture is contacted with a supported Al-Zn / CeO2 catalyst for a hydrogenation reaction, and methyl-2-buten-1-ol is obtained. The catalyst is cheaper and has high selective activity, methyl-2-buten-1-ol can be prepared under the conditions of low temperature, low pressure and high space velocity, and production cost of methyl-2-buten-1-ol is reduced.

Owner:杭州更蓝生物科技有限公司

Method for lowering bromine index of linear alkylbenzene

ActiveCN105503495AAvoid pollutionSimple processHydrocarbon purification/separationCatalystsBenzeneAlkyl transfer

The invention discloses a method for lowering bromine index of linear alkylbenzene, which comprises the following steps: mixing a hydrogenation raw material and hydrogen gas at 60-350 DEG C under the pressure of 0.3-10.0 MPa at the weight hourly space velocity of 0.2-10.0 hour<-1> under the condition that the hydrogen / oil volume ratio is 300:1-8000:1, carrying out contact reaction with a Pt-Sn / SiO2 supported catalyst until olefins are saturated, thereby lowering the bromine index of the linear alkylbenzene and the improving the product quality, wherein the hydrogenation raw material is linear alkylbenzene prepared by carrying out distillation separation on a benzene-C10-C14 linear olefin alkylation mixture, or a benzene-C10-C14 linear olefin alkylation mixture. The method has the advantages of simple technical process, high catalyst activity and stability, long stable operation time of the device, low loss of linear alkylbenzene, renewable catalyst and low influence on the environment, can avoid frequent switching operation between reactor reaction and regeneration, and can avoid abundant spent catalyst after-treatment.

Owner:ZHEJIANG UNIV OF TECH

A method for refining aromatics using a microporous mesoporous core-shell structure composite molecular sieve

ActiveCN110813370BHigh activityGood activity and stabilityMolecular sieve catalystsMolecular sieve catalystMolecular sievePtru catalyst

The invention discloses a method for refining aromatics by using a composite molecular sieve with a microporous mesoporous core-shell structure. ‑1 Under certain conditions, the liquid-phase aromatics are contacted with a solid acid catalyst, so that the trace olefins in the aromatics undergo alkylation and superimposition reactions, and the trace olefins in the aromatics are removed, thereby refining the aromatics and obtaining aromatics from which olefins have been removed The solid acid catalyst is a core-shell structure composite molecular sieve catalyst or a modified core-shell structure composite molecular sieve catalyst loaded with tungsten trioxide; the solid acid catalyst prepared by the present invention has high activity, and the removal rate is above 98%; the catalyst activity is stable Good stability, activity stability time over 3000h; high selectivity of aromatics deolefination reaction, the mass fraction of toluene produced from C8 aromatics refining is less than 0.1%, which can avoid frequent switching operation of reactor reaction and regeneration.

Owner:ZHEJIANG UNIV OF TECH

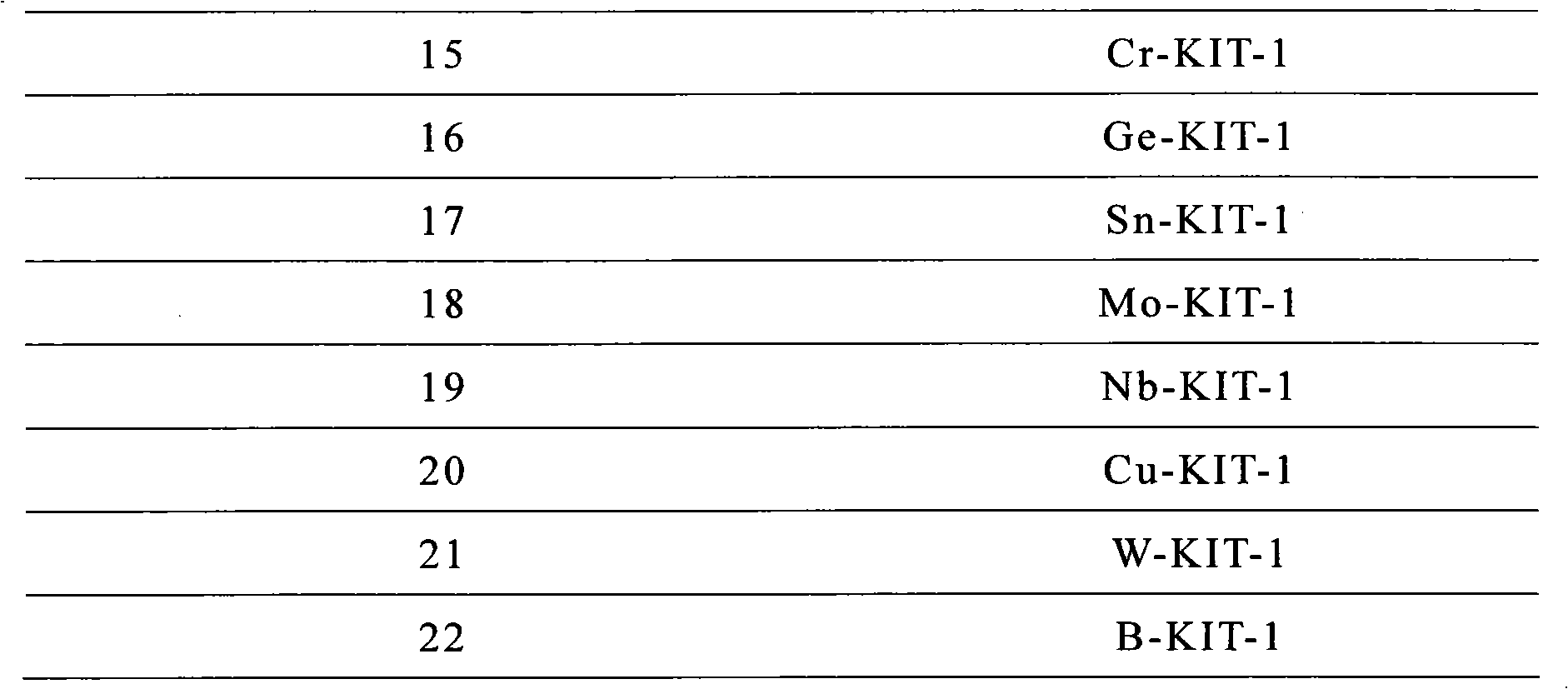

Solid-acid-catalyzed method for synthesizing straight-chain alkyl-benzene

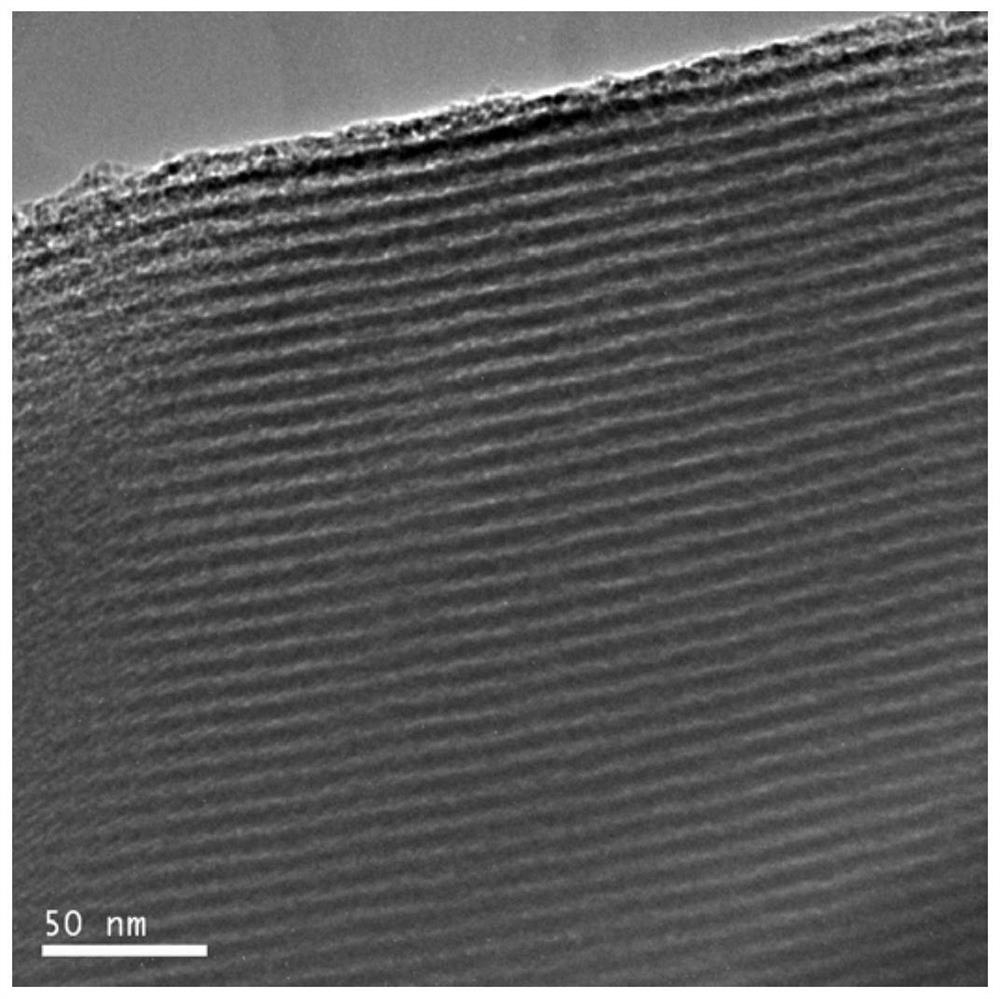

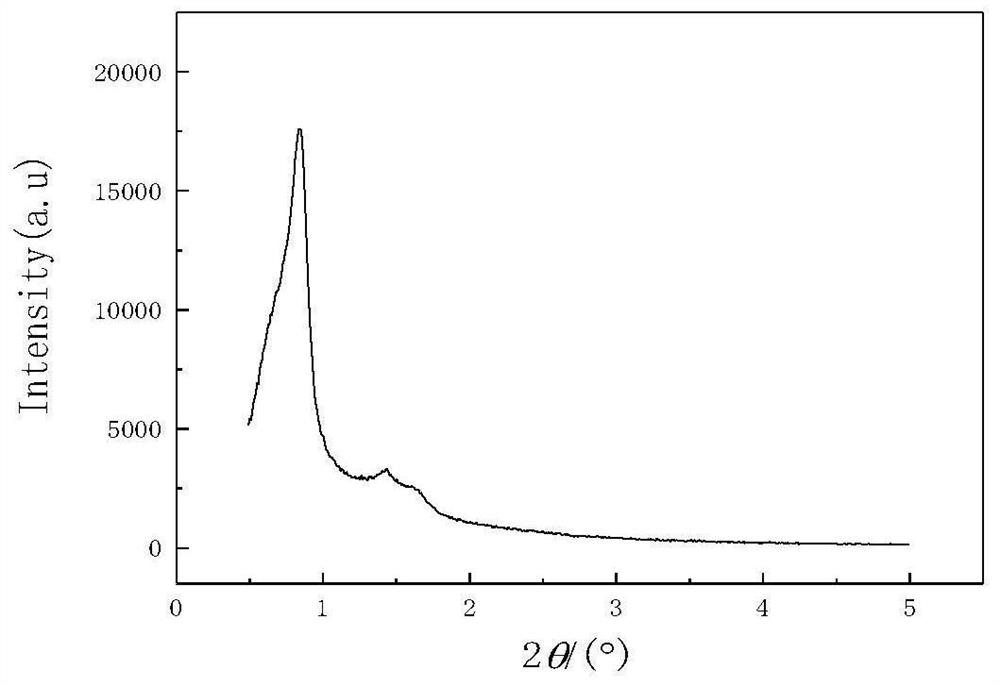

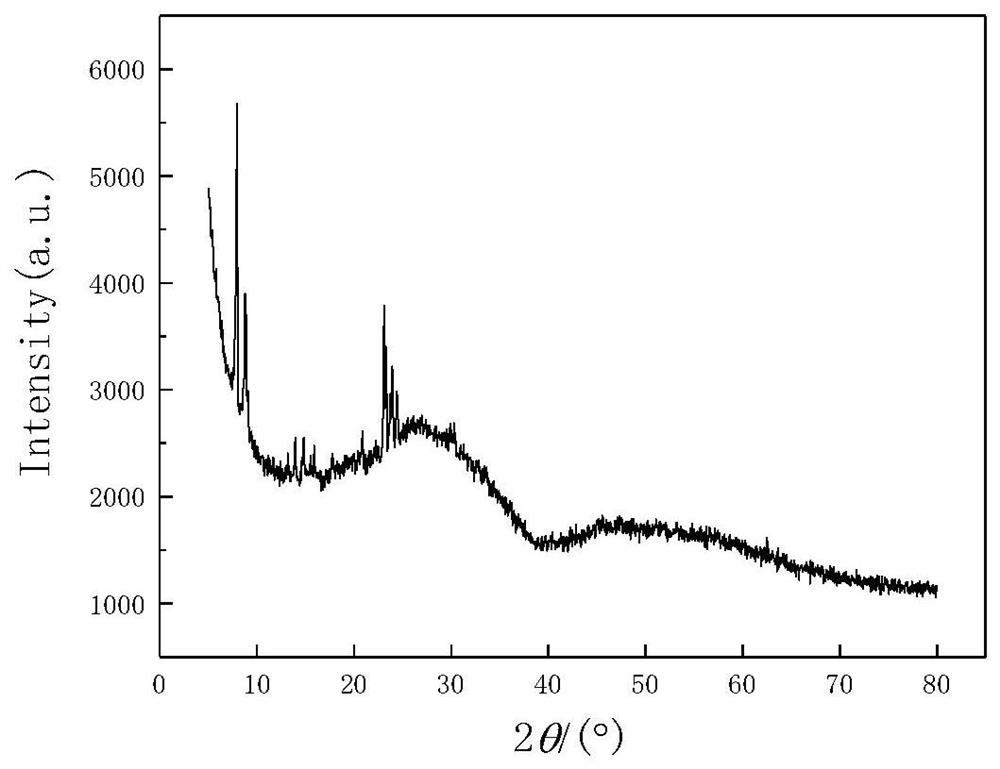

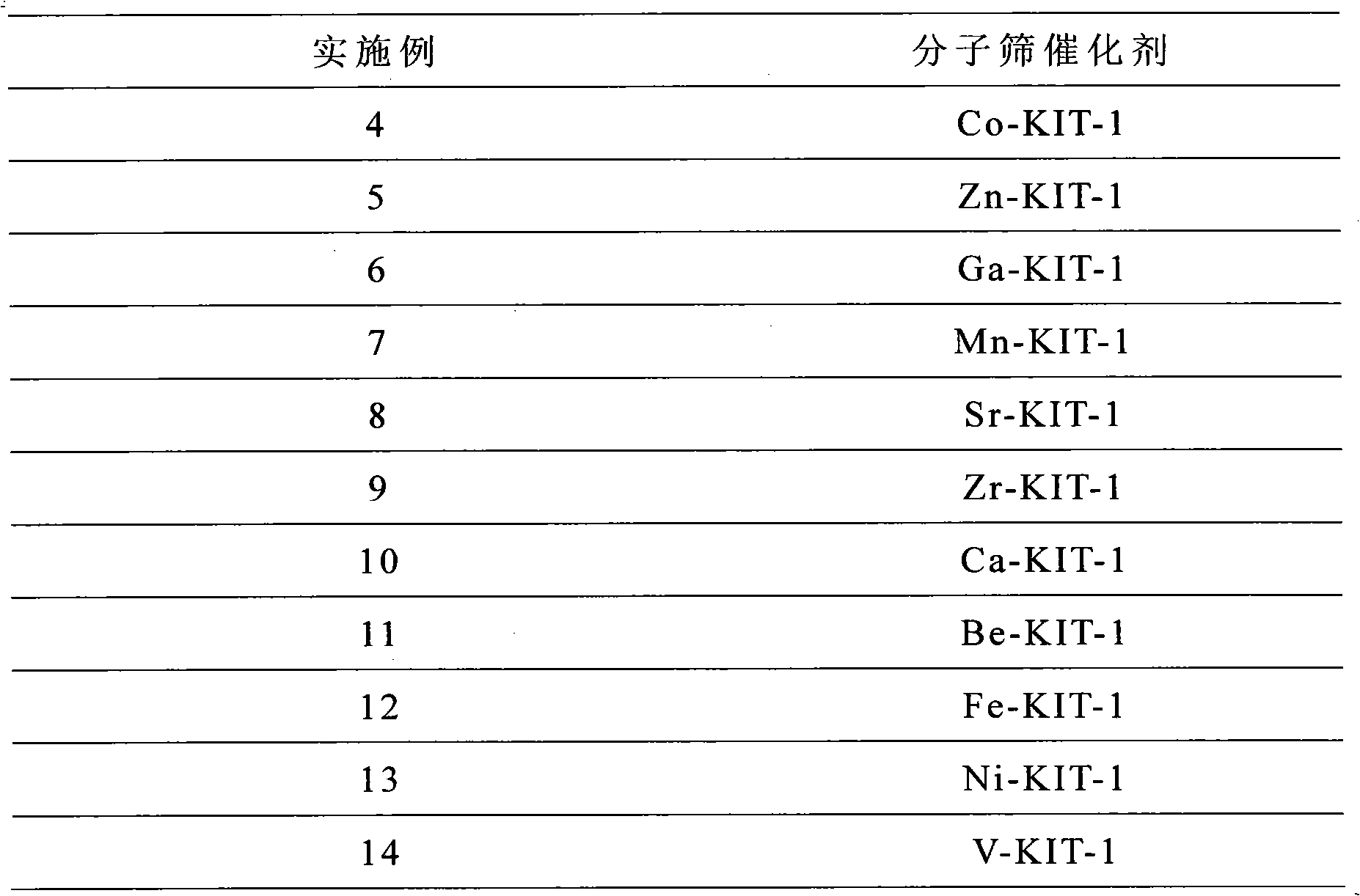

ActiveCN102464539BShort processGood activity and stabilityMolecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsSolid acidLinear alkylbenzene

The invention relates to a solid-acid-catalyzed method for synthesizing straight-chain alkyl-benzene, comprising the steps of: with straight-chain olefin having 10 to 14 carbon atoms and benzene as raw materials, and carrying out alkylation reaction with catalysis of a solid acid catalyst to obtain the straight-chain alkyl-benzene under the reaction condition that the temperature is 10-450 DEG C, the pressure is 0.1-15MPa, the mass ratio of the benzene to olefin substance is (2-100):1 and the total mass airspeed of feedstock is 0.1-20h<-1>, wherein the solid acid catalyst is mesoporous molecular sieve catalyst of M-KIT-1 type or a composite solid acid catalyst obtained by loading a modified compound on the mesoporous molecular sieve catalyst of M-KIT-1 type. The catalyst adopted in the method disclosed by the invention is free of corrosiveness, friendly to environment and has good activity stability. Stable operation time of a device is long so that a reactor is prevented from being switched between reaction and regeneration frequently.

Owner:PETROCHINA CO LTD +1

Method of preparing linear alkylbenzene

InactiveCN101058523BGood activity and stabilityImprove conversion rateMolecular sieve catalystsHydrocarbonsAlkyl transferMolecular sieve

The invention discloses a synthesizing method of straight-line alkyl benzene, which comprises the following steps: adopting straight-line olefin with carbon atom number between 2 and 20 and benzene as raw material; inputting in the reactor; reacting benzene and olefin with molar rate at 2-100:1 at 290-450 deg. c under 5-15Mpa hypercritical condition; setting the air speed at 0. 1-20h-1; making solid acid as catalyst; adopting one of loaded modified (1) SBA-15 typed molecular sieve, (2) HY typed molecular sieve, (3) USY typed molecular sieve, (4) H beta typed molecular sieve, (5) H-Moderite typed molecular sieve, (6) HZSM-20 typed molecular sieve as composite typed solid acid catalyst. The invention improves transmitting rate of olefin with stable operation, which possesses good using prospect.

Owner:ZHEJIANG UNIV OF TECH

A kind of catalytic hydrogenation method that reduces linear alkylbenzene bromide index

ActiveCN105601464BAvoid pollutionSimple processHydrocarbon purification/separationCatalyst activation/preparationPtru catalystDistillation

The invention discloses a catalytic hydrogenation method for reducing the linear alkylbenzene bromine index. The method is as follows: at a temperature of 60-400°C, a pressure of 0.3-10.0MPa, and a mass space velocity of 0.2-8.0 hours-1, hydrogen Under the condition of oil volume ratio of 300:1~8000:1, the hydrogenation raw material is mixed with hydrogen, and reacted with transition metal phosphide supported catalyst to saturate olefins, thereby reducing the linear alkylbenzene bromide index and improving product quality The raw material for hydrogenation is linear alkylbenzene obtained by distillation and separation of the alkylation mixture of benzene and C10-C14 linear olefins, or the alkylation mixture of benzene and C10-C14 linear olefins; the process flow of the present invention is simple, The catalyst has good activity and stability, and the stable operation time of the device is long, which can avoid the frequent switching operation of reactor reaction and regeneration, the loss of linear alkylbenzene is small, the catalyst can be regenerated, and the post-treatment of a large amount of spent catalyst can be avoided, and the impact on the environment is small.

Owner:ZHEJIANG UNIV OF TECH

A kind of production method of hrb500e high-strength earthquake-resistant steel bar

ActiveCN109554613BAvoid frequent switching operationsAvoid idle waits for operationsChemical compositionRebar

The invention provides a production method of HRB500E high-strength anti-seismic steel bar, comprising the following steps: making a steel billet, the components of which are: C: 0.20-0.25%, Si: 0.40-0.70%, Mn: 1.30-1.60%, P≤0.045 %, S≤0.045%, V: 0.020‑0.050%, N: 0.0050‑0.0120%, and the rest are Fe and unavoidable impurities; Multi-grade steel: that is, the same chemical composition formula, by adjusting the rolling process, can produce both HRB500E and HRB400E. Therefore, a unified production process can be adopted when preparing raw materials and blanks, which is beneficial to improve production efficiency, and reduces the frequency of adjusting preparation parameters such as temperature and component ratio, improves product stability, and is conducive to improving production efficiency.

Owner:SHANDONG SHIHENG SPECIAL STEEL GROUP

A kind of method utilizing solid acid catalyst to remove trace olefins in aromatics

ActiveCN110813371BHigh activityGood activity and stabilityMolecular sieve catalystsTreatment with plural serial stages onlyMolecular sievePtru catalyst

Owner:ZHEJIANG UNIV OF TECH

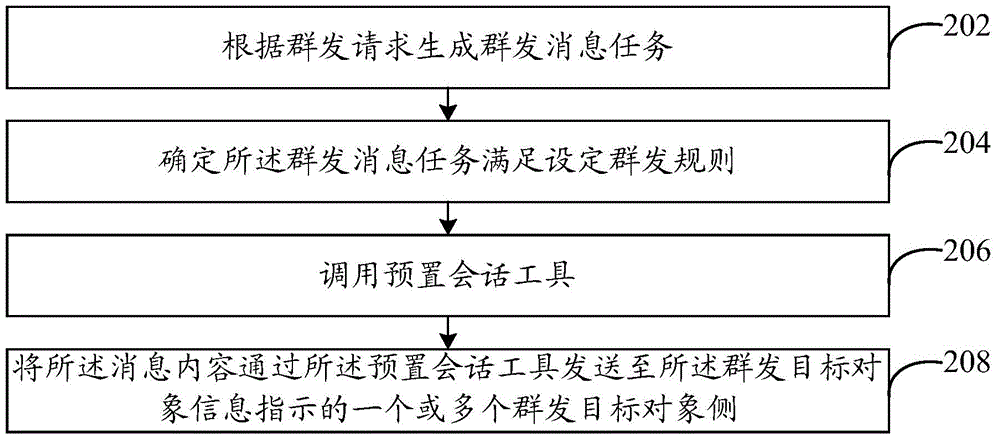

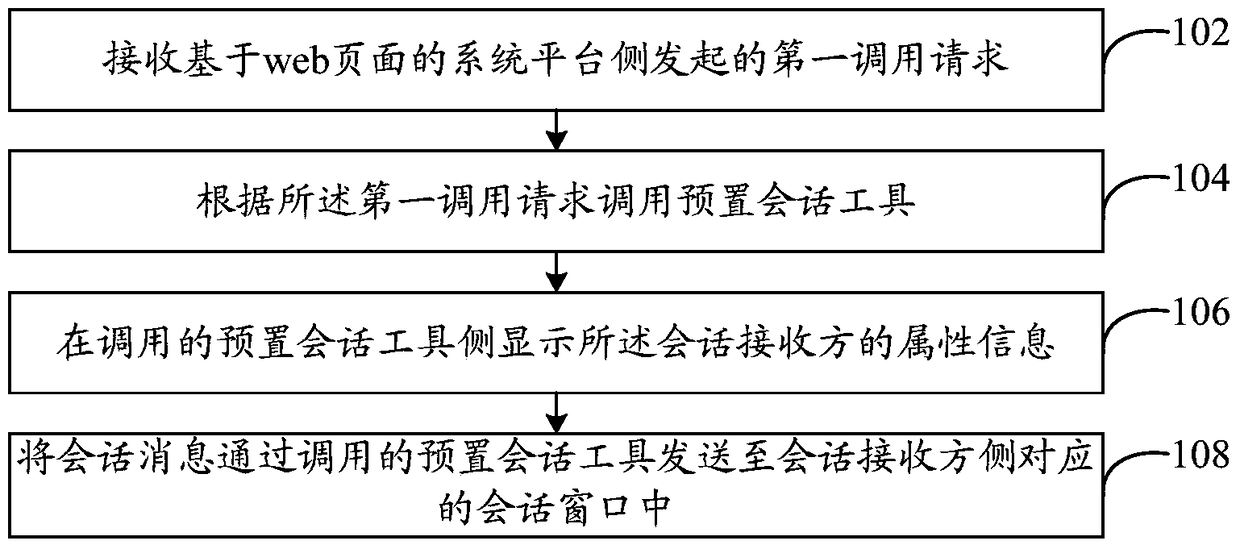

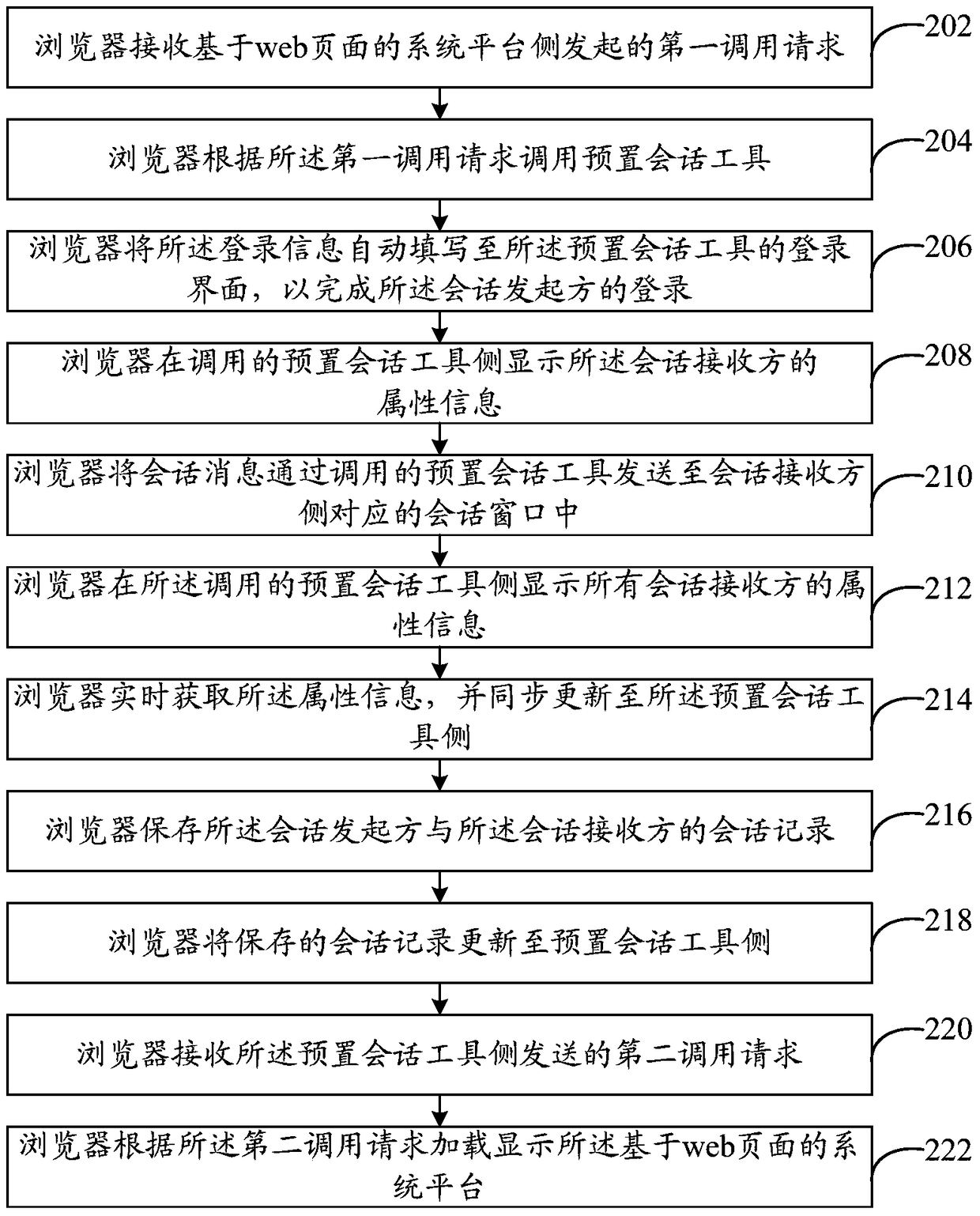

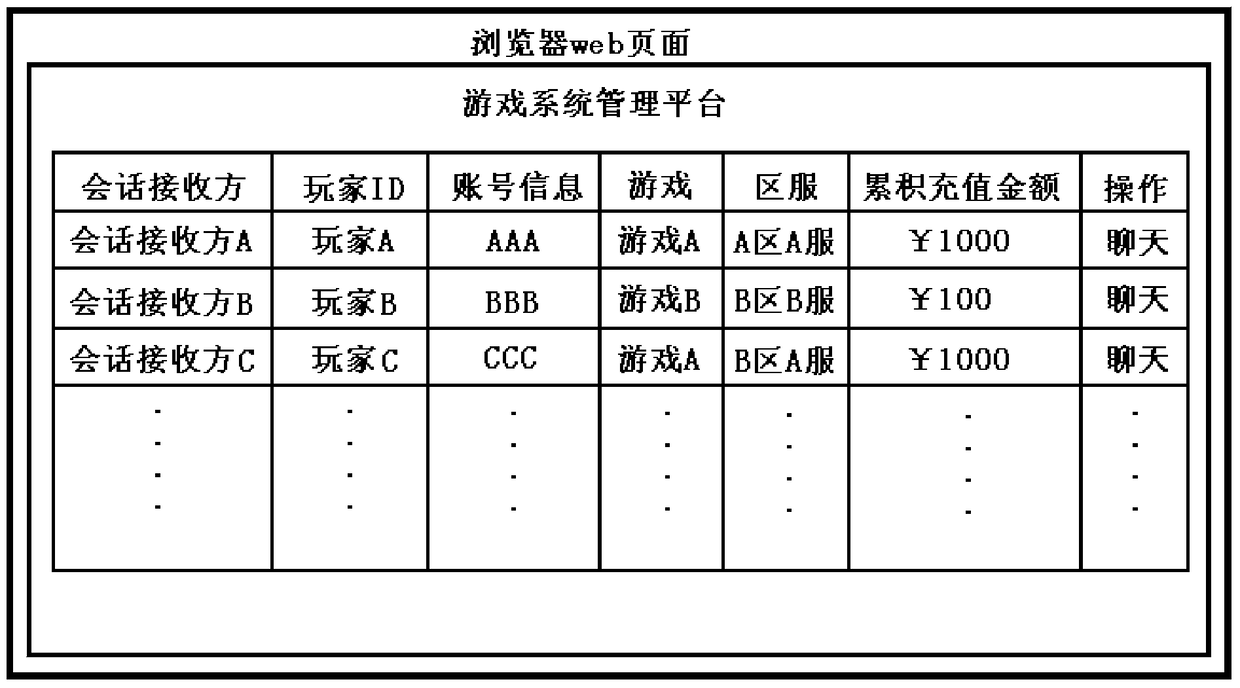

Conversation method and system of system platform, and electronic device

ActiveCN105791363BAvoid frequent switching operationsGuaranteed accuracyData switching networksThird partySystem of systems

The invention discloses a session method and system of a system platform based on a web page and an electronic device; wherein the method comprises following steps of receiving a first invoking request initiated by the system platform side based on the web page, wherein login information of a session initiator and / or attribute information of a session receiver is carried in the first invoking request; invoking a preset session tool according to the first invoking request, wherein the preset session tool comprises a web session tool based on the web page and / or an independent client session tool; displaying the attribute information of the session receiver at the invoked preset session tool side; sending the session message to the corresponding session window of the session receiver side through the invoked preset session tool, wherein the session window is the instant session window loaded in third party software. Through adoption of the method, the system and the electronic device, the problem of low session efficiency is solved.

Owner:BEIJING QIHOO TECH CO LTD

Method for removing olefin in aromatic hydrocarbon by M-SBA-15 type mesoporous molecular sieve

ActiveCN102992932BSimple processDoes not consume hydrogenChemical modification purification/separationMolecular sieveAlkene

The invention discloses a method for removing olefin in aromatic hydrocarbon by an M-SBA-15 type mesoporous molecular sieve. The method comprises the step of carrying out contact reaction of aromatic hydrocarbon with a solid acid catalyst to obtain aromatic hydrocarbon without olefin at 30-350 DEGC, at a pressure of 0.1-10MPa, and at an air speed of 0.1-15 / h for feed quality, wherein the aromatic hydrocarbon is aromatic hydrocarbon generated by reforming generated oil, reforming aromatic hydrocarbon or steam cracking. The method is simple in process flow, free of hydrogen consumption and low in device investment and operating cost. The catalyst activity is good in stability, the stable operation of the device is long and the aromatic hydrocarbon loss is small, so that the frequency switching operation between reaction and regeneration of a reactor is avoided. The catalyst is reproducible, so that a great amount of dead catalysts is not buried, therefore, the environmental influence is small.

Owner:ZHEJIANG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com