Method for removing tiny amount of olefins in aromatic hydrocarbons by using solid acid catalyst

A solid acid catalyst, catalyst technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of catalyst pore blockage, catalyst deactivation, etc., to optimize reaction conditions, improve activity and activity stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

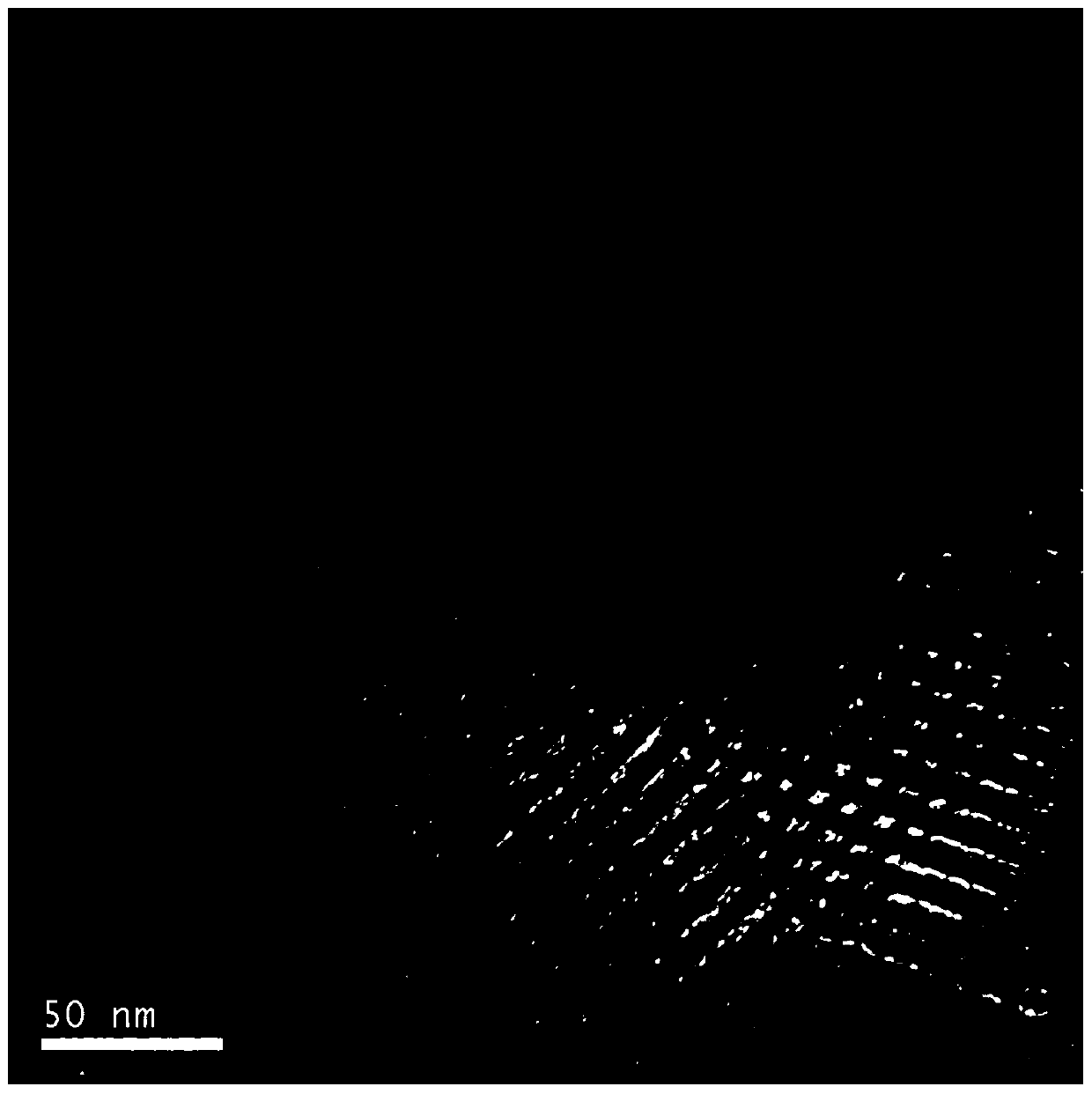

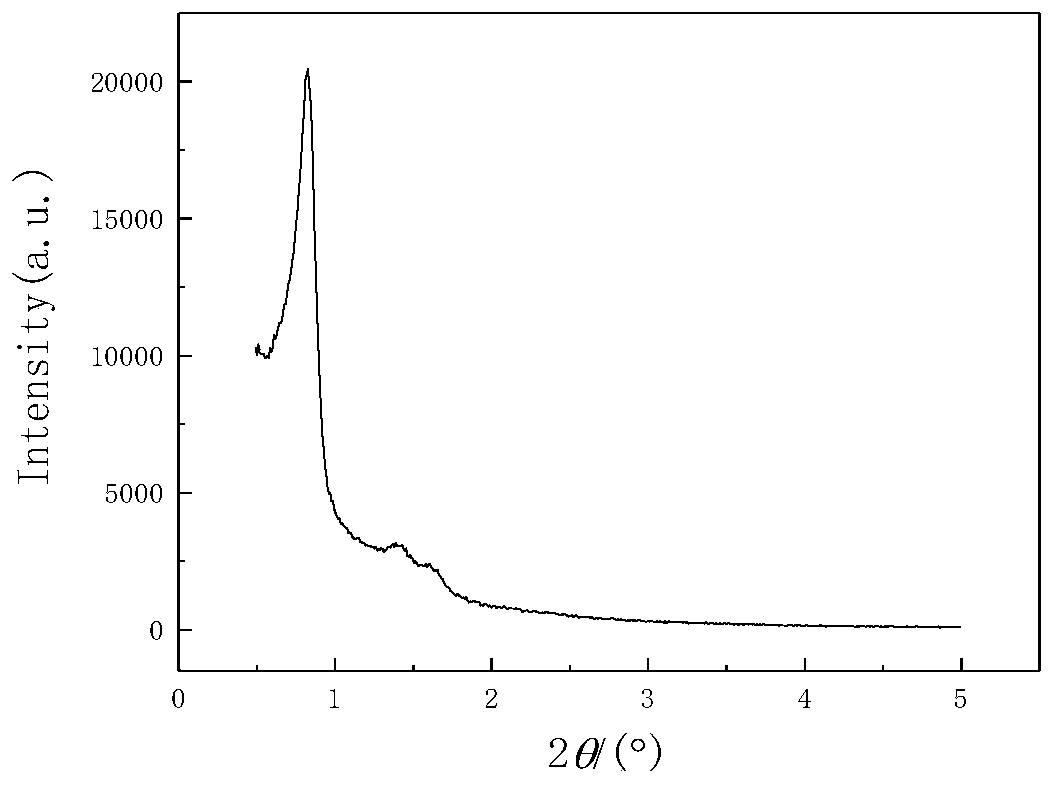

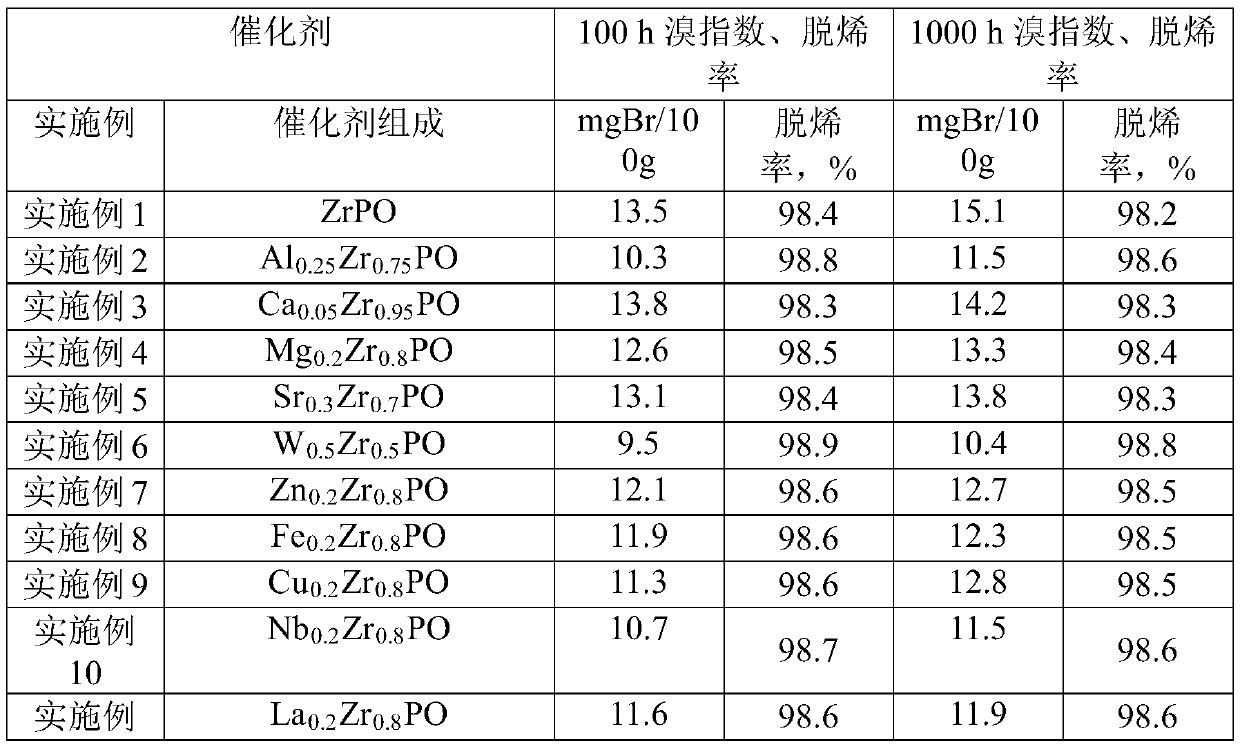

[0045] Example 1: Preparation of ZrPO mesoporous zirconium phosphate molecular sieve catalyst

[0046] (1) Synthesis of ZrPO Mesoporous Zirconium Phosphate Molecular Sieve: Dissolve 57.6g (4.57mmol) of F127 in 600mL of absolute ethanol, stir at 40℃ for 30min to obtain F127 ethanol solution; add 58.0g (180.0mmol) of oxygen chloride The zirconium was dissolved in 300 mL of absolute ethanol, and stirred at 40°C for 30 minutes to obtain an ethanol solution of zirconium oxychloride; then 20.2 g (144.2 mmol) of trimethyl phosphate was dissolved in 200 mL of absolute ethanol and stirred at 40°C 30min, obtain trimethyl phosphate ethanol solution; under 40℃ temperature and stirring conditions, add zirconium oxychloride ethanol solution and trimethyl phosphate ethanol solution dropwise to F127 ethanol solution, continue to stir for 6h to obtain total solute concentration 0.3 A mixture of mmol / mL ethanol solution, the molar ratio of P to Zr n P / n Zr =0.8, F127 and P+Zr molar ratio n F127 / ...

Embodiment 2

[0048] Example 2: Al 0.25 Zr 0.75 Preparation of PO Mesoporous Zirconium Phosphate Molecular Sieve Catalyst

[0049] (1)Al 0.25 Zr 0.75 Synthesis of PO Mesoporous Zirconium Phosphate Molecular Sieve: Dissolve 63.0g (5.0mmol) of F127 in 600mL of absolute ethanol, and stir at 30°C for 60min to obtain F127 ethanol solution; use 43.5g (135.0mmol) of zirconium oxychloride Dissolve in 300 mL of absolute ethanol, stir at 30°C for 60 minutes to obtain an ethanol solution of zirconium oxychloride; dissolve 6.0 g (45.0 mmol) of anhydrous aluminum chloride in 150 mL of absolute ethanol, and stir at 30°C for 60 minutes to obtain Aluminum chloride ethanol solution; then 18.9g (135.0mmol) of trimethyl phosphate was dissolved in 150mL of absolute ethanol, and stirred at 30°C for 60min to obtain a trimethyl phosphate ethanol solution; at 30°C under stirring conditions, The ethanol solution of zirconium oxychloride, the ethanol solution of aluminum chloride, and the ethanol solution of trimethyl ...

Embodiment 3

[0051] Example 3: Ca 0.05 Zr 0.95 Preparation of PO Mesoporous Zirconium Phosphate Molecular Sieve Catalyst

[0052] (1)Ca 0.05 Zr 0.95 Synthesis of PO Mesoporous Zirconium Phosphate Molecular Sieve: Dissolve 126.0g (10.0mmol) of F127 in 800mL of absolute ethanol, stir at 40℃ for 30min to obtain F127 ethanol solution; use 43.5g (135.0mmol) of zirconium oxychloride Dissolve in 300 mL of absolute ethanol and stir at 40°C for 30 min to obtain an ethanol solution of zirconium oxychloride; dissolve 0.79 g (7.1 mmol) of anhydrous calcium chloride in 100 mL of absolute ethanol, and stir at 30°C for 60 min to obtain Calcium chloride ethanol solution; then 18.9g (135.0mmol) of trimethyl phosphate was dissolved in 100mL of absolute ethanol, and stirred at 40°C for 30 min to obtain trimethyl phosphate ethanol solution; at 30°C under stirring conditions, The ethanol solution of zirconium oxychloride, the ethanol solution of calcium chloride, and the ethanol solution of trimethyl phosphate we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molar mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com