Linear alkylbenzene catalytic hydrofining method

A technology for catalytic hydrogenation of straight-chain alkylbenzenes, applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc., capable of solving problems such as environmental pollution and large loss of straight-chain alkylbenzenes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

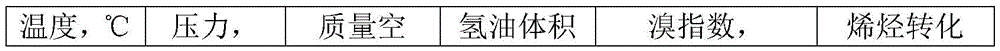

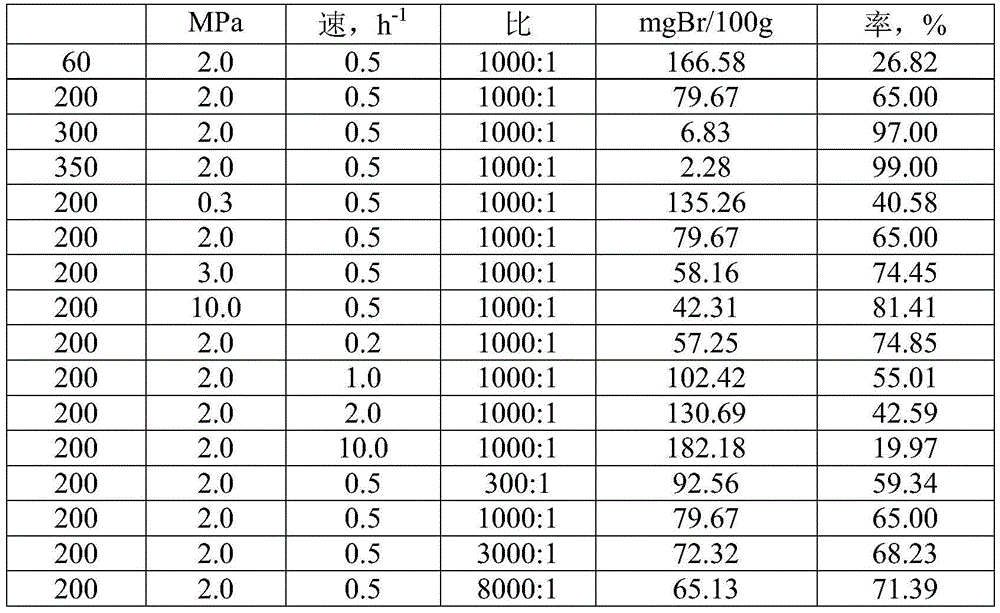

Method used

Image

Examples

Embodiment 1

[0038] Example 1: 5% Pd / Al 2 o 3 Catalyst preparation

[0039] Weigh 12g of Al 2 o 3Carrier (its specific surface area is 302m 2 / g). 1g (5.6398mmol) PdCl 2 Dissolve in 15% hydrochloric acid aqueous solution with HCl mass fraction, obtain 10mL impregnating solution, its palladium concentration is 5.6398×10 -4 mol / mL, the volume of the impregnation solution is equal to the volume of the maximum adsorption water of the catalyst support. Carry out impregnation at room temperature according to the equal volume impregnation method, add 10mL impregnation solution dropwise to 12g carrier, and keep stirring. After the dropwise addition, stand at room temperature for 3h. Then, it was dried at 70°C for 24 hours, put into a muffle furnace and fired at 100°C, 200°C, 300°C, and 400°C for 1 hour, and at 500°C for 4 hours to obtain a catalyst precursor. Under the condition of 10:1 volume ratio of water to solid (that is, catalyst precursor), 240 mL of distilled water was stirred and...

Embodiment 2

[0040] Example 2: 5% Pd / γ-Al 2 o 3 Catalyst preparation

[0041] Weigh 12g of γ-Al 2 o 3 As a carrier (its specific surface area is 296m 2 / g), 1.3g (5.6421mmol) palladium nitrate dihydrate was dissolved in distilled water to prepare 10mL impregnating solution, and its palladium concentration was 5.6421×10 -4 mol / mL, the volume of the impregnation solution is equal to the volume of the maximum adsorption water of the catalyst support. Carry out impregnation at room temperature according to the equal volume impregnation method, add 10mL impregnation solution dropwise to 12g carrier, and keep stirring. After the dropwise addition, it was allowed to stand at room temperature for 24h. Then, it was dried at 95°C for 3 hours, put into a muffle furnace and fired at 100°C, 200°C, 300°C, and 400°C for 1 hour, and at 600°C for 2 hours to obtain a catalyst precursor. Take the method of reduction in the reactor tube, under the pressure of 0.2MPa, the hydrogen volume space velocity ...

Embodiment 3

[0042] Example 3: 5% Pd / SiO 2 Catalyst preparation

[0043] The porous silica gel that takes by weighing 12g is as carrier (its specific surface area is 480m 2 / g), 1.3g (5.6421mmol) palladium nitrate dihydrate was dissolved in distilled water to prepare 15mL impregnating solution, and its palladium concentration was 3.7614×10 -4 mol / mL, the volume of the impregnation solution is equal to the volume of the maximum adsorption water of the catalyst support. Carry out impregnation at room temperature according to the equal volume impregnation method, add 15mL impregnation solution dropwise to 12g carrier, and keep stirring. After the dropwise addition, it was allowed to stand at room temperature for 20 h. Then, it was dried at 70°C for 24 hours, put into a muffle furnace and fired at 100°C, 200°C, 300°C, and 400°C for 1 hour, and at 450°C for 6 hours to obtain a catalyst precursor. Take the method of reduction in the reactor tube, under the pressure of 2.0MPa, the hydrogen vo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bromine index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com