A kind of method utilizing solid acid catalyst to remove trace olefins in aromatics

A solid acid catalyst and catalyst technology, applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of catalyst pore blockage, catalyst deactivation, etc., and achieve catalytic performance recovery, regeneration performance, and reaction highly selective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

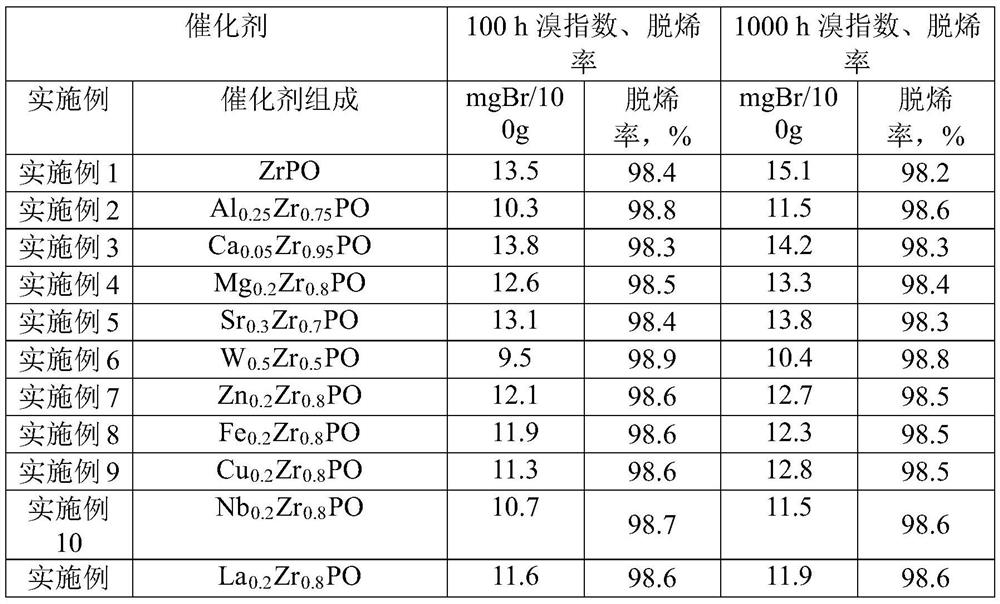

Embodiment 1

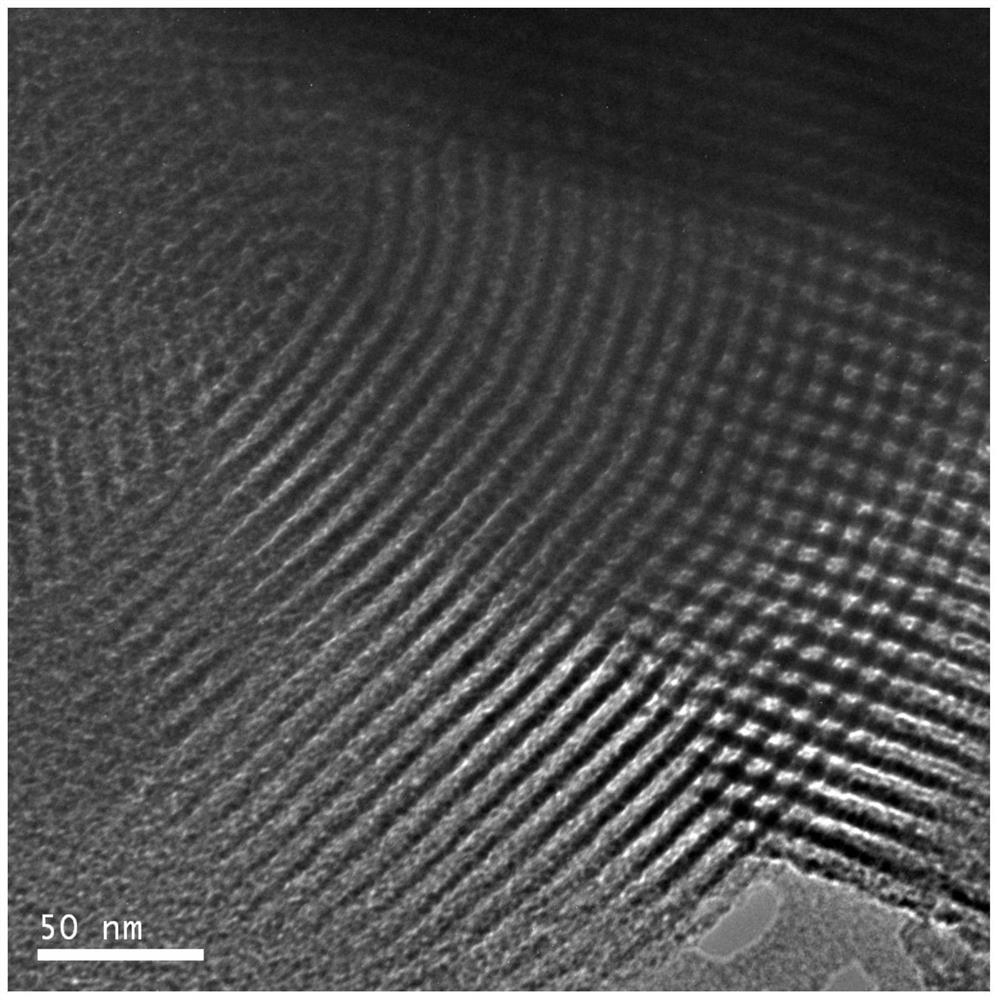

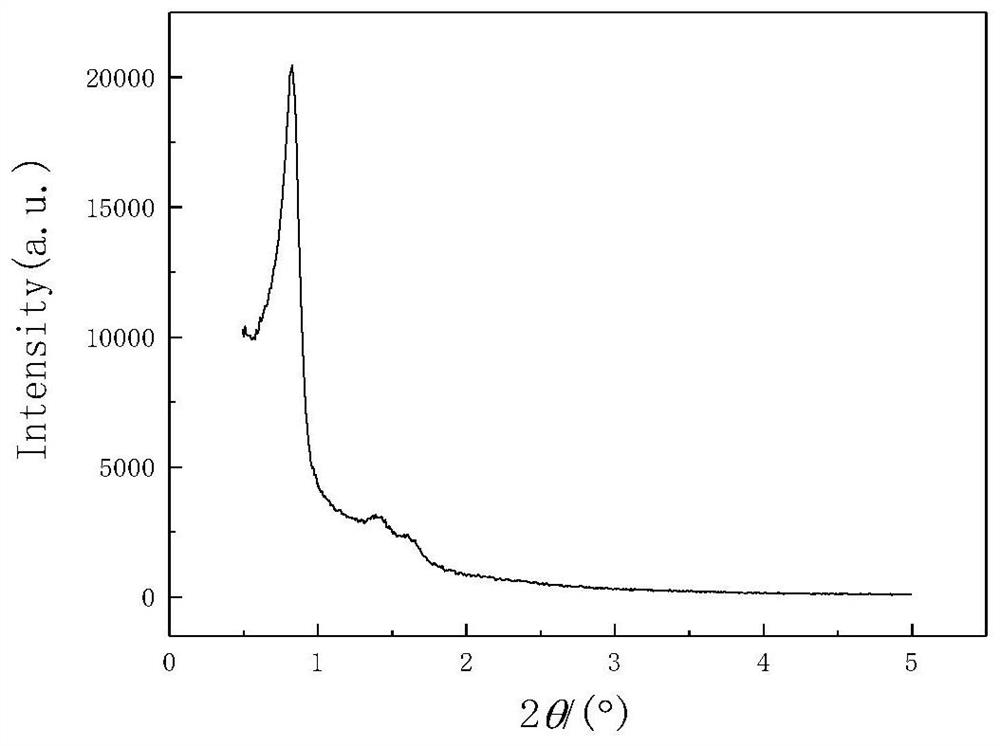

[0040] Example 1: Preparation of ZrPO Mesoporous Zirconium Phosphate Molecular Sieve Catalyst

[0041] (1) Synthesis of ZrPO mesoporous zirconium phosphate molecular sieve: dissolve 57.6 g (4.57 mmol) of F127 in 600 mL of absolute ethanol, and stir at 40°C for 30 min to obtain an ethanolic solution of F127; 58.0 g (180.0 mmol) of oxychlorine Zirconium was dissolved in 300 mL of absolute ethanol, and stirred at 40°C for 30 minutes to obtain a zirconium oxychloride ethanol solution; then 20.2 g (144.2 mmol) of trimethyl phosphate was dissolved in 200 mL of absolute ethanol, and stirred at 40°C. 30min to obtain a trimethyl phosphate ethanol solution; under the temperature of 40 ° C and stirring conditions, the zirconium oxychloride ethanol solution and the trimethyl phosphate ethanol solution were added dropwise to the F127 ethanol solution in turn, and stirring was continued for 6h to obtain a total solute concentration of 0.3 mmol / mL mixture ethanol solution, its P and Zr molar...

Embodiment 2

[0043] Example 2: Al 0.25 Zr 0.75 Preparation of PO Mesoporous Zirconium Phosphate Molecular Sieve Catalyst

[0044] (1) Al 0.25 Zr 0.75Synthesis of PO mesoporous zirconium phosphate molecular sieve: Dissolve 63.0g (5.0mmol) F127 in 600mL absolute ethanol, stir at 30°C for 60min to obtain F127 ethanol solution; 43.5g (135.0mmol) zirconium oxychloride is used Dissolve 300 mL of anhydrous ethanol, stir at 30 °C for 60 min to obtain an ethanolic solution of zirconium oxychloride; dissolve 6.0 g (45.0 mmol) of anhydrous aluminum chloride in 150 mL of anhydrous ethanol, and stir at 30 °C for 60 min to obtain Aluminum chloride ethanol solution; then 18.9g (135.0mmol) trimethyl phosphate was dissolved in 150mL absolute ethanol, stirred at 30 ℃ for 60min to obtain trimethyl phosphate ethanol solution; under 30 ℃ temperature and stirring conditions, Add zirconium oxychloride ethanol solution, aluminum chloride ethanol solution, and trimethyl phosphate ethanol solution dropwise to F...

Embodiment 3

[0046] Example 3: Ca 0.05 Zr 0.95 Preparation of PO Mesoporous Zirconium Phosphate Molecular Sieve Catalyst

[0047] (1)Ca 0.05 Zr 0.95 Synthesis of PO mesoporous zirconium phosphate molecular sieve: Dissolve 126.0 g (10.0 mmol) F127 in 800 mL of absolute ethanol, and stir at 40°C for 30 min to obtain an ethanolic solution of F127; 43.5 g (135.0 mmol) of zirconium oxychloride was used Dissolve 300 mL of anhydrous ethanol, stir at 40 °C for 30 min to obtain a zirconium oxychloride ethanol solution; dissolve 0.79 g (7.1 mmol) of anhydrous calcium chloride in 100 mL of anhydrous ethanol, stir at 30 °C for 60 min to obtain Calcium chloride ethanol solution; then 18.9g (135.0mmol) trimethyl phosphate was dissolved in 100mL absolute ethanol, and stirred at 40°C for 30min to obtain trimethylphosphate ethanol solution; under 30°C temperature and stirring conditions, Add zirconium oxychloride ethanol solution, calcium chloride ethanol solution, and trimethyl phosphate ethanol solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molar mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com