Aromatic hydrocarbon purifying method

A refining method and technology of aromatics, applied in the direction of chemical recovery, chemical change purification/separation, etc., can solve the problems of hydrothermal stability and poor acidity, hindering application, etc., achieve good activity stability, small environmental impact, and less loss of aromatics Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Synthesis of Al-SBA-15 Mesoporous / Hβ Microporous Composite Molecular Sieve Catalyst

[0036] 5 g of Hβ microporous molecular sieve powder was used as the inner core, and stirred and mixed with 50 g of distilled water for 1.0 hour to obtain a mixture A. According to the molar ratio of raw materials P123:Al 2 o 3 :SiO2 2 :HCl:H 2 O is calculated as 1:3.1:62.5:300:10000, weigh 20 grams of P123, mix with the calculated amount of distilled water and hydrochloric acid, stir and mix at 40°C for 1.0 hour, add 1.3 grams of monohydrate alumina and continue to stir and mix for 1.0 hour ; 45.0 grams of ethyl orthosilicate was added under stirring conditions to obtain a mixture B. Then, the mixture A was added to the mixture B, and the mixture was stirred and mixed at a temperature of 40° C. for 5.0 hours to obtain a mixed slurry. The mixed slurry was placed in a plastic container, crystallized at 100°C and autogenous pressure for 48 hours, filtered, washed, and dried, and fire...

Embodiment 2~6

[0038] Using the same synthesis method as in Example 1, the difference is that HZSM-5 molecular sieves, HY molecular sieves, HUSY molecular sieves, HMOR molecular sieves, and HMCM-22 molecular sieves are used as cores, and the core microporous molecular sieves are obtained through hydrothermal synthesis and extrusion molding. The Al-SBA-15 mesoporous / microporous core-shell composite molecular sieve catalyst, which accounts for 27.8% of the total mass of the catalyst, is listed in Table 1.

[0039] Table 1

[0040]

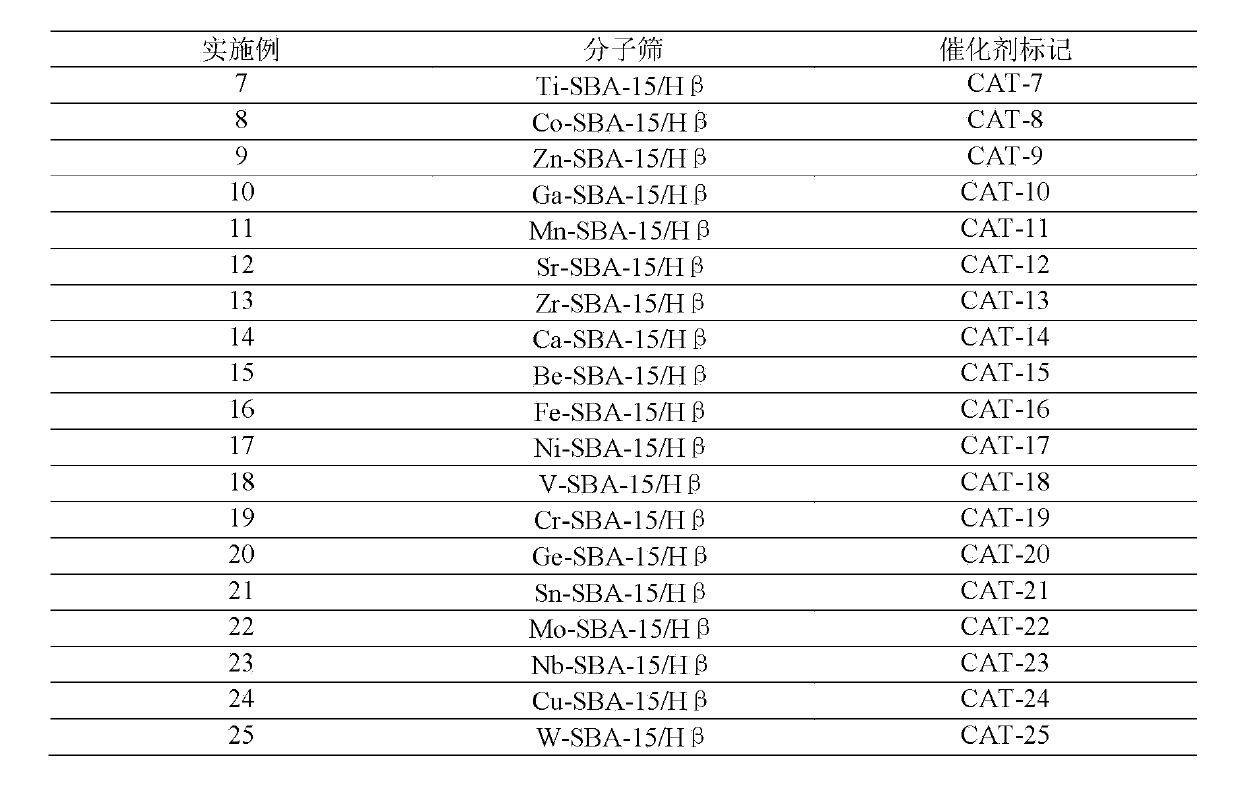

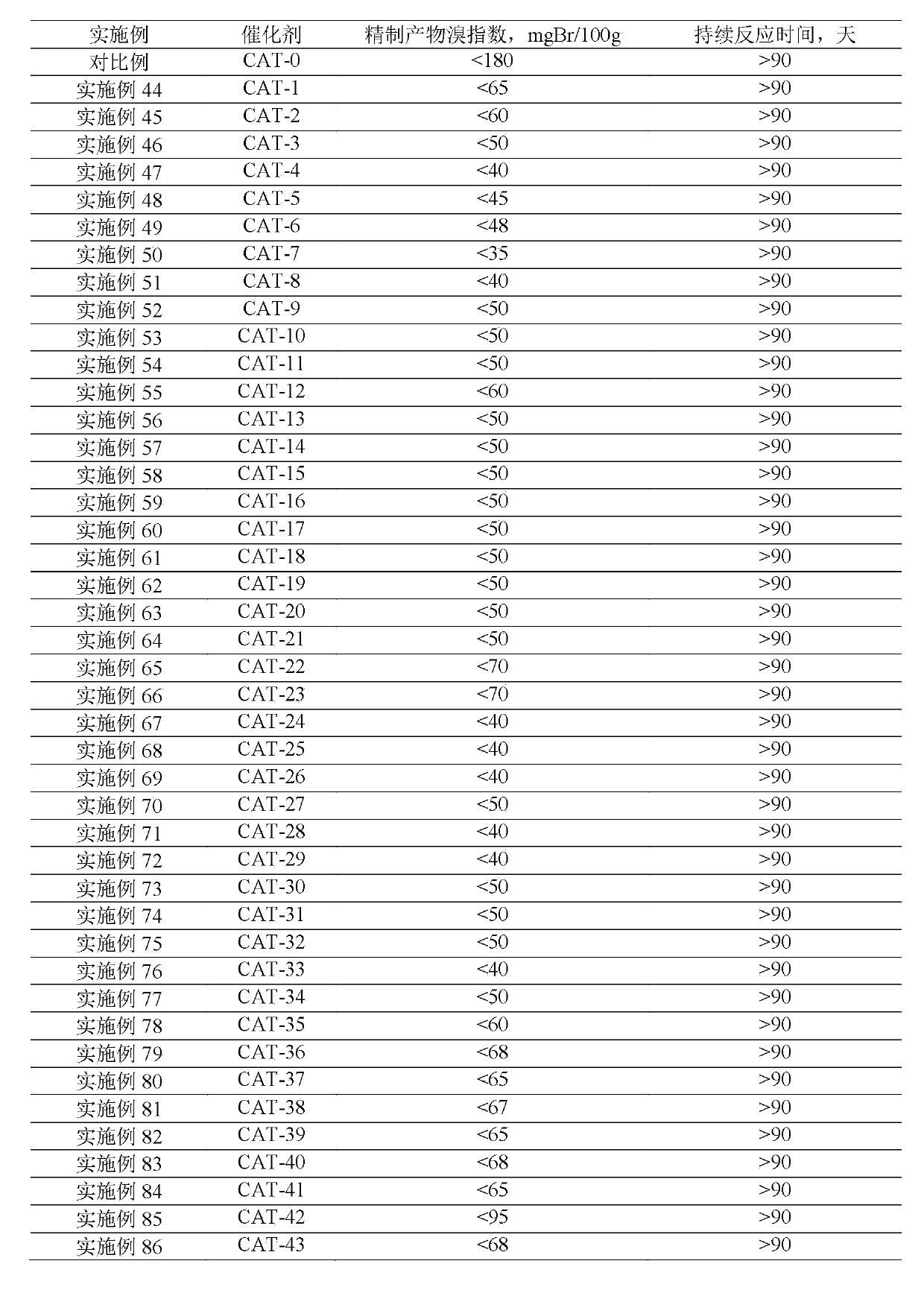

Embodiment 7~25

[0042] Using the same synthesis method as in Example 1, the difference is that the three-block polymer P123 is used as a template, and butyl titanate, cobalt nitrate, zinc nitrate, gallium nitrate, manganese nitrate, strontium nitrate, zirconium nitrate, nitric acid Calcium, beryllium nitrate, iron nitrate, nickel nitrate, vanadium nitrate, chromium nitrate, germanium nitrate, tin nitrate, molybdenum nitrate, niobic acid, copper nitrate, tungstic acid as precursors of the substituting element M, according to P123:MO n / 2 :SiO2 2 :HCl:H 2 O is 1:6.25:62.5:300:10000 molar ratio of raw materials to synthesize M-SBA-15 molecular sieve powder containing substituting elements. After extruding and crushing, 20-40 mesh catalyst particles are obtained, which are listed in Table 2.

[0043] Table 2

[0044]

PUM

| Property | Measurement | Unit |

|---|---|---|

| bromine number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com