Integrated process for recovering acetic acid and methyl acetate in production process of aromatic carboxylic acid

A technology of aromatic carboxylic acid and methyl acetate, which is applied in the field of azeotropic distillation, can solve the problems of large reflux flow rate of entrainer, affecting the stable oxidation reaction, and high energy consumption in the recovery process of acetic acid, so as to avoid complicated process and reduce The reflux rate of entrainer and the effect of reducing the content of acetic acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Terephthalic acid is produced by catalytic oxidation of p-xylene (PX) under a catalyst and a certain temperature and pressure. During the production process, the acetic acid aqueous solution cooled by the steam at the top of the reactor enters the upper part of the dehydration tower T1.

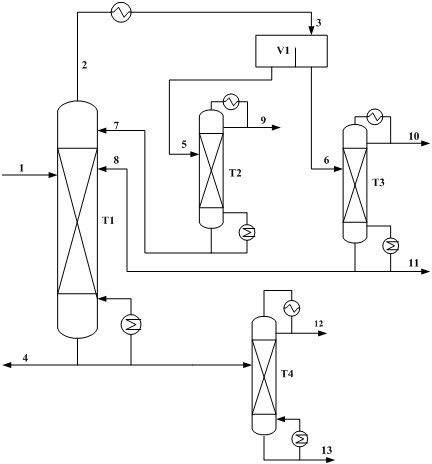

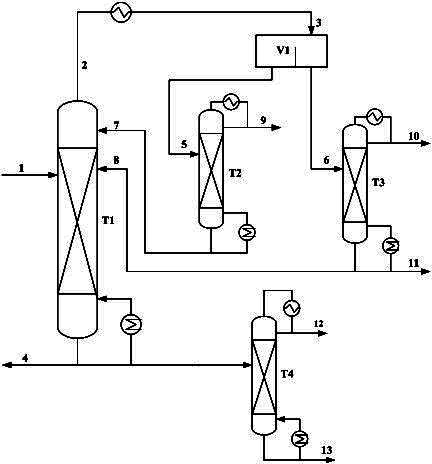

[0027] Such as figure 1 As shown, the theoretical plate number of the dehydration tower T1 is 40, the theoretical plate number of the entrainer refining column is 15, the theoretical plate number of the methyl acetate recovery tower is 10, and the theoretical plate number of the azeotropic agent separation tower is 20. The acetic acid aqueous solution flow rate that enters dehydration tower is 1000kg / hr, wherein contains 75 wt% of acetic acid, contains water 24.5 wt%, contains the quality 0.5 wt% of methyl acetate, feeds from the 10th plate of dehydration tower, tower top steam (2 ) after condensation, the condensate (3) enters the phase separator V1, and the oil phase (5) in the phase...

Embodiment 4

[0031] Keep other conditions in Example 1 unchanged, change the entrainer PX reflux rate to 900kg / hr, the oil phase reflux rate and the total amount ratio entering the dehydration tower water are 3.3, and the PX content in the extraction of the dehydration tower tower kettle is 12.9% , the material first enters the 8th tray of the entrainer separation tower T4, and the acetic acid produced at the top contains 1.2% water and 2.0% PX; after separation, the methyl acetate recovery tower still contains 0.01% acetic acid in the water phase, The content of methyl acetate extracted from the top of the entrainer refining tower is 98.1%, and the content of methyl acetate recovered from the top of the methyl acetate recovery tower is 96.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com