Method for removing small amount of acetic acid or methanoic acid and refining DMF

A technology of acetic acid and formic acid, applied in the chemical industry, can solve the problems such as hydrolysis of DMF, and achieve the effects of simplifying the operation process, reducing energy consumption, and improving economic value and social value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

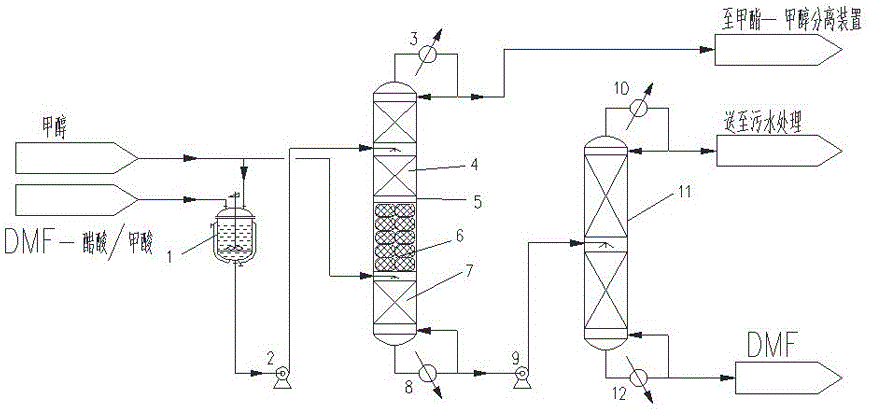

[0038] process such as figure 1 As shown, a DMF solution containing 15% acetic acid, methanol with a molar ratio of 1:1 to acetic acid, and NKC-9 catalyst with 20% acetic acid weight were added to the pre-reactor, and the reaction temperature was 70°C.

[0039] After the pre-reaction, the mixed liquid is sent to the feed port of the upper section of the reactive distillation column, the ratio of the methanol feed flow rate at the lower end of the reactive distillation column to the mixed liquid feed flow rate at the upper section is 0.3:1, and the reactive distillation column is operated at normal pressure, with a theoretical plate number of 30 , the reflux ratio is 0.5, the top components are methyl acetate: 34.1%, methanol: 59.3%, water: 6.6%, and the bottom components are DMF: 98.9%, acetic acid: 0.1%, water: 1%.

[0040]The bottom component enters the DMF dehydration tower, the operating pressure is 20kPa, the number of theoretical plates is 20, the reflux ratio is 3, the ...

Embodiment 2

[0042] process such as figure 1 As shown, a DMF solution containing 30% acetic acid, methanol with a molar ratio of 2:1 to acetic acid, and NKC-9 catalyst with 15% acetic acid weight were added to the pre-reactor, and the reaction temperature was 65°C.

[0043] After the pre-reaction, the mixed liquid is sent to the feed port of the upper section of the reactive distillation column. The ratio of the methanol feed flow rate at the lower end of the reactive distillation column to the mixed liquid feed flow rate at the upper section is 0.4:1. The reactive distillation column is operated at normal pressure, and the number of theoretical plates is 30. , the reflux ratio is 0.5, the top components are methyl acetate: 34.1%, methanol: 59.7%, water: 6.2%, and the bottom components are DMF: 96.5%, acetic acid: 0.4%, water: 3.1%.

[0044] The bottom component enters the DMF dehydration tower, the operating pressure is 20kPa, the number of theoretical plates is 20, the reflux ratio is 2,...

Embodiment 3

[0046] process such as figure 1 As shown, a DMF solution containing 40% acetic acid, methanol with a molar ratio of 3:1 to acetic acid, and NKC-9 catalyst with 15% acetic acid weight were added to the pre-reactor, and the reaction temperature was 65°C.

[0047] After the pre-reaction, the mixed liquid is sent to the feed port of the upper section of the reactive distillation column. The ratio of the methanol feed flow rate at the lower end of the reactive distillation column to the mixed liquid feed flow rate at the upper section is 0.4:1. The reactive distillation column is operated at normal pressure, and the number of theoretical plates is 30. , the reflux ratio is 0.5, the top components are methyl acetate: 29.7%, methanol: 64.7%, water: 5.6%, and the bottom components are DMF: 95.4%, acetic acid: 0.4%, water: 4.2%.

[0048] The bottom component enters the DMF dehydration tower, the operating pressure is 20kPa, the number of theoretical plates is 20, the reflux ratio is 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com