Catalyst for catalytic decomposition of hydrogen iodide and preparation method thereof

A catalytic decomposition and catalyst technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of complex preparation process, poor stability and high cost, and achieve Simple preparation process, high stability and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

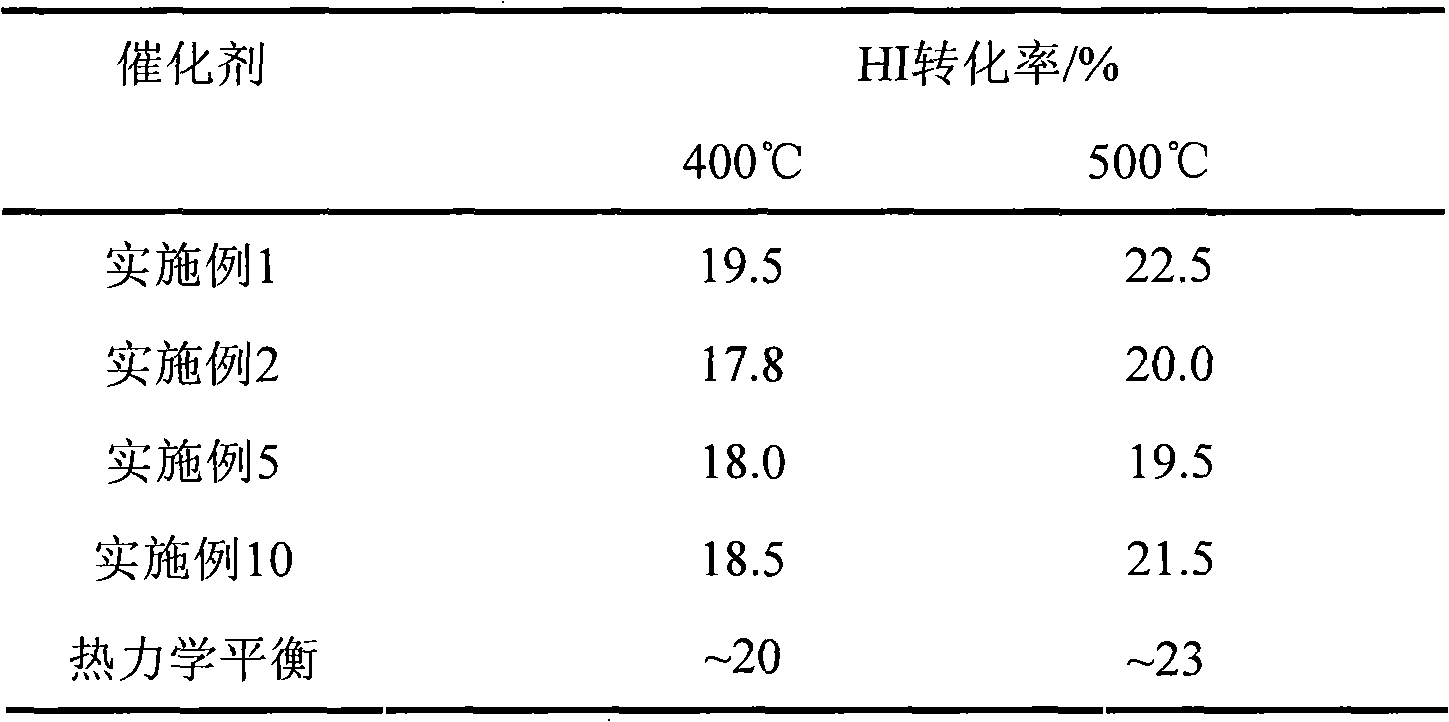

Examples

Embodiment 1

[0024] The impregnation method is adopted to impregnate the aqueous solution containing platinum nitrate and palladium nitrate on the carbon molecular sieve, the platinum element accounts for 0.05% of the mass of the carrier, and the palladium element accounts for 0-20% of the mass of the carrier. The impregnated carrier was dried at 200° C. for 1 hour to obtain the target catalyst.

Embodiment 2

[0026] An impregnation method is adopted to impregnate the carbon nanotubes with an acetone aqueous solution containing chloroplatinic acid and iridium nitrate, the platinum element accounts for 50% of the mass of the carrier, and the iridium element accounts for 1.0% of the mass of the carrier. The impregnated carrier was dried at 120° C. for 4 hours to obtain the target catalyst.

Embodiment 3

[0028] An impregnation method is adopted to impregnate the carbon fiber with an aqueous solution containing platinum acetate and ruthenium nitrate, the platinum element accounts for 50% of the mass of the carrier, and the iridium element accounts for 1.0% of the mass of the carrier. The impregnated carrier was dried at 120° C. for 4 hours to obtain the target catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com