Hydrogen sulfide slow-release inhibitor as well as preparation method and application thereof

A slow-release agent and hydrogen sulfide technology, applied in the direction of botanical equipment and methods, applications, biocides, etc., can solve the problems of difficult concentration control and low utilization rate, and achieve low product cost, increase the duration of efficacy, and reduce the use of pesticides. The effect of drug frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

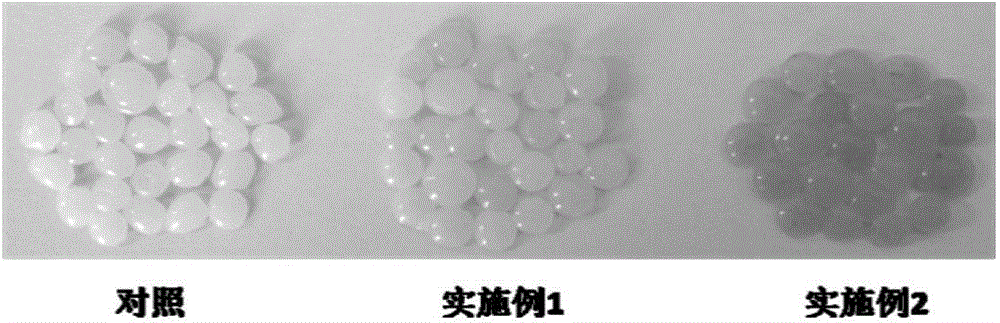

[0025] Embodiment 1. Weigh 10g of sliced paraffin (melting point 68°C) and place it in a small beaker, heat it in a water bath to 70-80°C to fully melt it; weigh 0.03g of NaHS and 0.1g of PEG-8000 in Add 1ml of absolute ethanol to two 2ml centrifuge tubes, heat the metal bath to 70-80°C to fully dissolve; combine the two solutions and vortex until fully mixed; add the mixture to the molten paraffin , select the power of 300W ultrasonic for 10 minutes to disperse evenly in the paraffin liquid. This process ensures that the temperature of the mixed liquid is greater than 68°C; absorb the paraffin liquid with a pipette gun, quickly inject it into cold water to obtain paraffin pellets, cool it, and remove it to room temperature dry to get H 2 S sustained release agent (see attached figure 1 ).

Embodiment 2

[0026] Embodiment 2. Weigh 10g of sliced paraffin (melting point 68°C) and place it in a small beaker, heat it to 70-80°C in a water bath to fully melt it; weigh 0.05g of NaHS and 0.2g of PEG-8000 in the Add 1ml of absolute ethanol to two 2ml centrifuge tubes, heat the metal bath to 70-80°C to fully dissolve; combine the two solutions and vortex until fully mixed; add the mixture to the molten paraffin , select the power of 300W ultrasonic for 15 minutes to make it uniformly dispersed in the paraffin liquid, this process ensures that the temperature of the mixed liquid is greater than 68 °C; use a pipette gun to absorb the paraffin liquid, quickly inject it into cold water to obtain paraffin pellets, cool, and remove it to room temperature dry to get H 2 S sustained release agent (see attached figure 1 ).

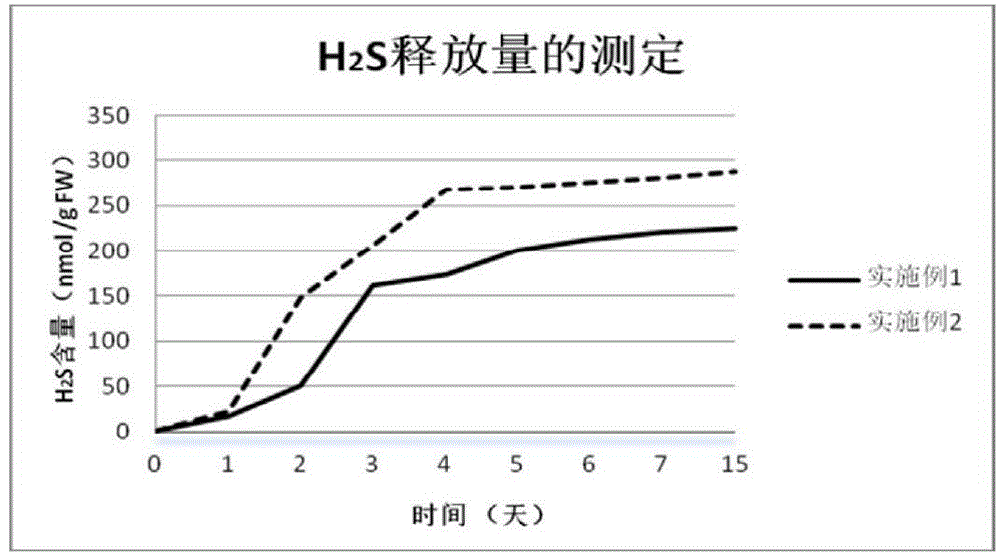

[0027] Get the pellet slow-release preparation prepared by embodiment 1 and 2 and carry out release rate measurement:

[0028] Preparation of working curve: Accurately...

Embodiment 3

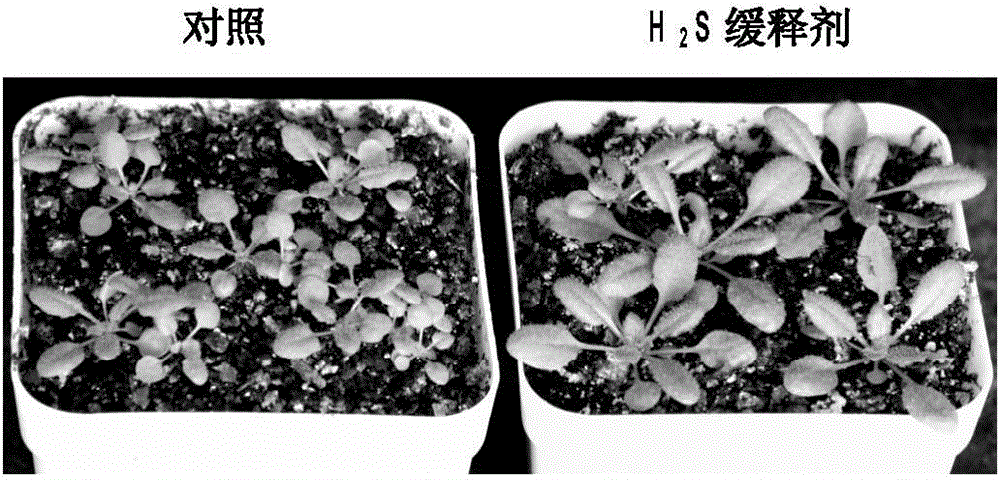

[0032] Embodiment 3. get 2 slow-release agent pellets that make in embodiment 1, place the Arabidopsis thaliana cultivation pot that grows for 2 weeks, keep the soil that it covers moist, compare with control after 10 days, individual plant obviously Larger, better growth and development (see attached image 3 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com