Processing method and processing device of production waste gas containing hydrogen sulfide

A treatment method, hydrogen sulfide technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of high power consumption of treatment devices, unsatisfactory treatment effect, low concentration of sodium hydrosulfide, etc., and achieve saving Alkali consumption, simple structure, high concentration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below with reference to the accompanying drawings.

[0014] There are many treatment methods for waste gas containing hydrogen sulfide. The treatment method disclosed in the present invention is to collide the waste gas containing lye and hydrogen sulfide with high-pressure impact technology, and absorb the lye to absorb the hydrogen sulfide in the waste gas.

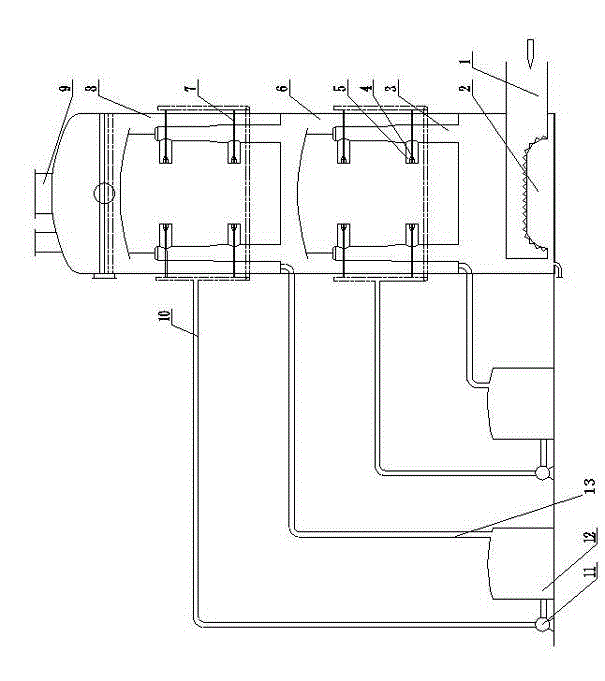

[0015] see attached figure 1 , the device disclosed in the present invention for treating hydrogen sulfide in waste gas using impinging flow technology includes an absorption tower and a lye circulation tank. The top of the absorption tower 8 is provided with an exhaust port 9 , and the bottom of the first-stage absorption tower 6 arranged at the lower part is connected with the intake main pipe 1 . Each absorption tower is respectively provided with an air inlet pipe 3, an alkali inlet pipe 10 and an alkali discharge pipe 13. The intake pipes 3 are respectively p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com