Membrane absorption method and device for producing sodium bisulfide with refinery acid gases

A sodium hydrosulfide and membrane absorption technology, applied in chemical instruments and methods, sulfur compounds, separation methods, etc., can solve the problems of low profit, inconvenient production, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

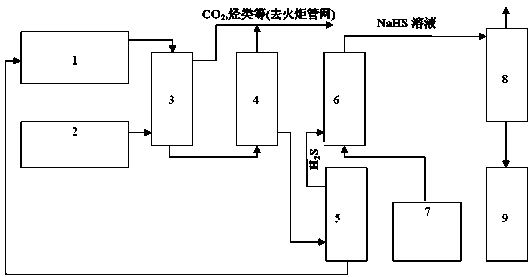

[0011] In conjunction with the accompanying drawings, the membrane absorption device used for the production of sodium hydrosulfide from acid gas in refineries, wherein the outlet of the MDEA (N-methyldiethanolamine) storage tank is connected to the inlet of the primary membrane absorption module, and the outlet of the acid gas buffer tank is connected to a The shell-side inlet of the first-stage membrane absorption module is connected, the tube-side outlet of the first-stage membrane absorption module is connected to the inlet of the hydrogen sulfide purification device, the shell-side outlet of the first-stage membrane absorption module is connected to the flare pipe network, and the outlet of the hydrogen sulfide purification device goes all the way to the flare pipe network. All the way to the solvent regeneration tower, the outlet 1 of the solvent regeneration tower is connected to the shell side inlet of the secondary membrane absorption module, the outlet 2 of the solvent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com