Process for preparing 3-mercaptopropyl acid

A technology of mercaptopropionic acid and hydrochloric acid, which is applied in the field of preparation of 3-mercaptopropionic acid, can solve the problems of difficult marketization of products, high cost, low yield, etc., and achieves low production cost, convenient wastewater treatment, and low price. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

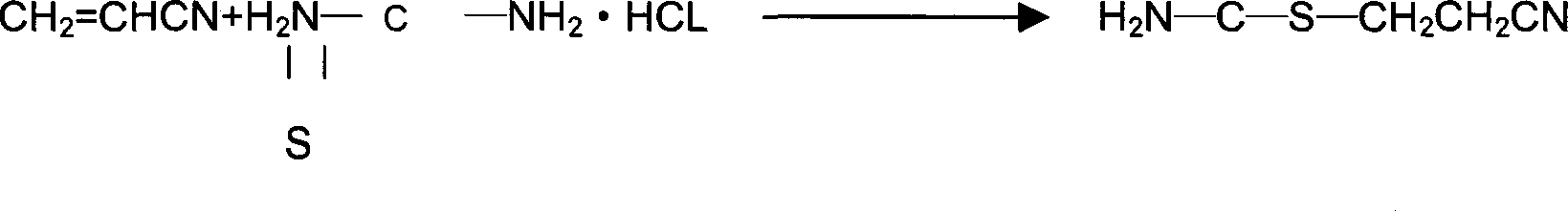

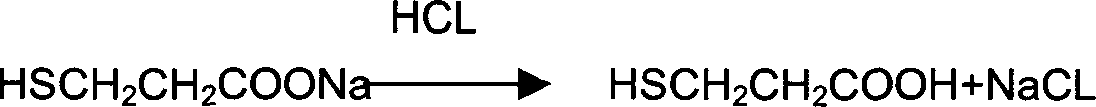

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with embodiment, but does not limit the present invention.

[0027] Preparation of synthetic solution:

[0028] 250 grams of 30% sodium hydrosulfide, 12 grams of caustic soda, 20 grams of water, and 3 grams of catalyst sodium disulfide were added to the reaction pot and stirred, and 54 grams of acrylonitrile was added at 25°C for reaction, and the reaction was carried out for 10 hours after adding.

[0029] acidification:

[0030] Adding concentration is 450 grams of industrial hydrochloric acid of 30% to above-mentioned synthesis liquid, heats up and refluxes for 3 hours.

[0031] reduction:

[0032] The temperature of the above acidified solution was lowered to 30°C, 40 grams of zinc powder was added to react, and the temperature was raised to 100°C for 0.5 hours.

[0033] Extraction, Distillation:

[0034] Add 500 g of toluene to the above reducing solution, stir and separate layers, distill the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com