Treatment method of waste gas containing nitride oxides

A technology of nitrogen oxides and treatment methods, which is applied in chemical instruments and methods, separation methods, and separation of dispersed particles, etc., can solve the problems of inability to remove nitrogen oxides and low treatment effect of nitrogen oxides, and achieve the effect of improving treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

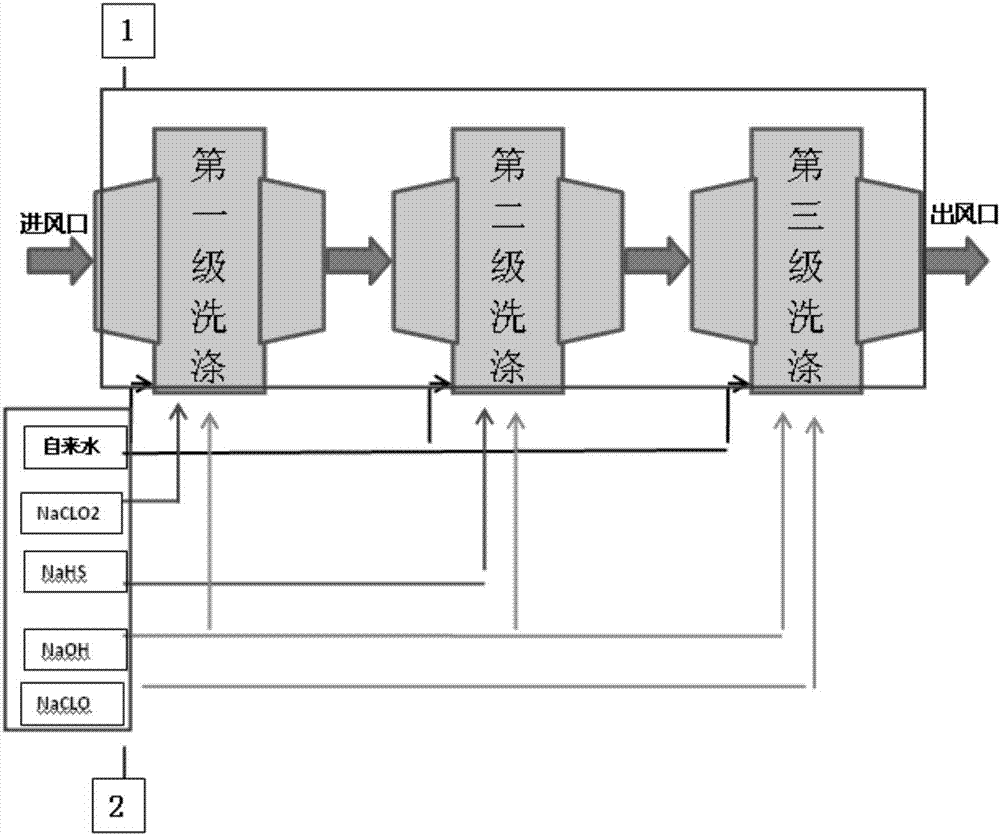

[0071] according to figure 1 In the process flow shown, the gas is drawn into the three-stage wet (packed) scrubber through the fan, and under the condition of pH value of 5-6, the waste gas containing nitrogen oxides is oxidized and washed (the first stage of washing) to obtain The first scrubbing gas; the first scrubbing gas is subjected to reduction water washing (second stage scrubbing) to obtain the second scrubbing gas; the second scrubbing gas is subjected to oxidation and deodorization water washing (third stage scrubbing) to obtain purification treatment The gas is discharged through the chimney.

[0072] Dosing through the treatment agent addition device: add NaOH, NaClO in the first scrubber 2 ; NaOH, NaHS are added to the second washing tower; NaOH and NaClO are added to the third washing tower. Each washing section adopts tap water spray purification treatment; in addition, the present invention cooperates with an automatic dosing device to make the entire dosin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com