Large blocked TS-1 molecular sieve with high catalytic activity and synthetic method thereof

A high catalytic activity, TS-1 technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc. Catalytic activity, loss reduction, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: the synthesis of bulk TS-1 molecular sieve

[0021] The ratio of the reaction raw materials is as follows, SiO 2 :0.015~0.025TBOT:0.28TPAOH:40H 2 O: 0.33 Isopropanol: 1.3H 2 o 2 . First, mix TBOT with isopropanol evenly, then add TPAOH, H 2 O, mix evenly, then add TEOS while stirring vigorously, after adding TEOS, continue to stir until the solution is clear, replenish the water evaporated from the solution in time, and finally add H 2 o 2 , Stir evenly, add the reaction raw materials into a polytetrafluoroethylene stainless steel reaction kettle, crystallize at 180°C for 48-72 hours, and then take out the product and separate it by suction filtration.

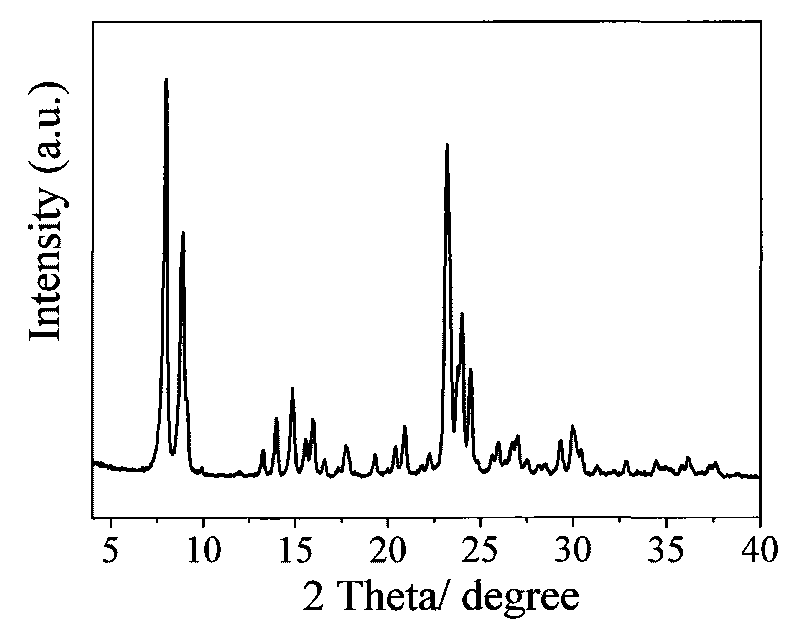

[0022] figure 1 It is the XRD characterization result of the product. From the XRD point of view, the product has a typical MFI zeolite molecular sieve structure, and the sample has a high degree of crystallinity.

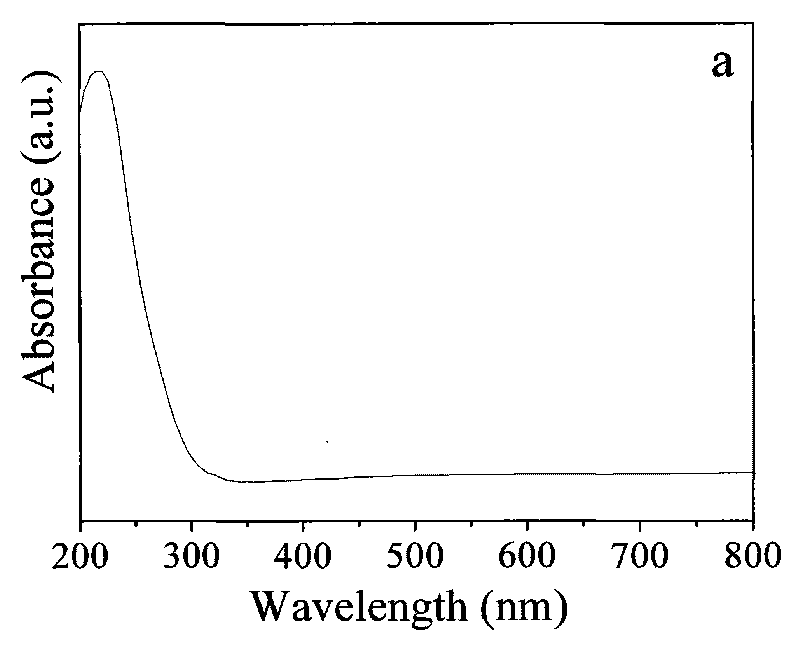

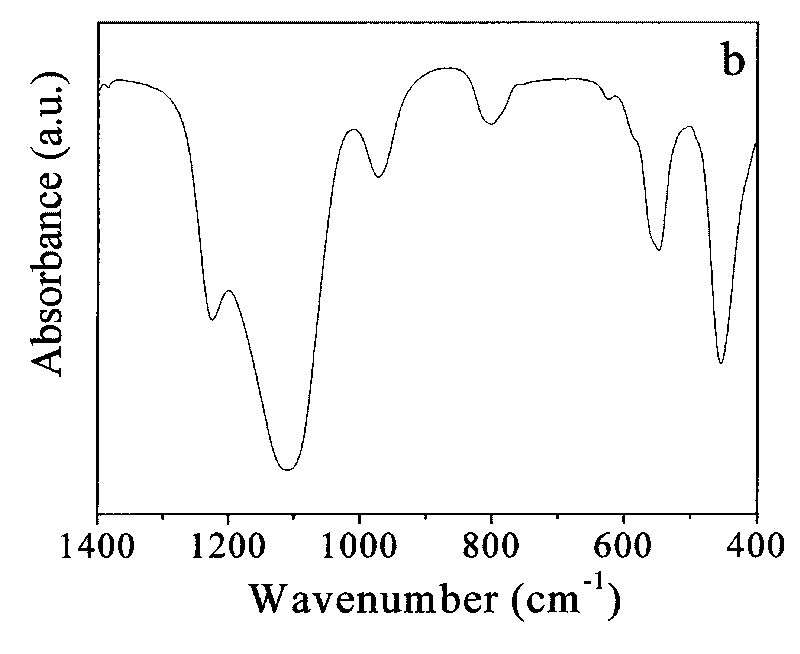

[0023] figure 2 , image 3 UV and IR spectra of the samples, respectively. From...

Embodiment 2

[0027] Example 2: Reduction of H 2 o 2 Addition amount, synthesis of block TS-1 molecular sieve

[0028] The ratio of the reaction raw materials is as follows, SiO 2 :0.015~0.025TBOT:0.28TPAOH:40H 2 O: 0.33 Isopropanol: 0.85H 2 o 2 . First, mix TBOT with isopropanol evenly, then add TPAOH, H 2 O, mix evenly, then add TEOS while stirring vigorously, after adding TEOS, continue to stir until the solution is clear, replenish the water evaporated from the solution in time, and finally add H 2 o 2 , Stir evenly, add the reaction raw materials into a polytetrafluoroethylene stainless steel reaction kettle, crystallize at 180°C for 48-72 hours, and then take out the product and separate it by suction filtration.

[0029] The product has no big difference compared with Example 1, except that the size of the bulk product is slightly smaller.

Embodiment 3

[0030] Example 3: Increase H 2 o 2 Addition amount, synthesis of block TS-1 molecular sieve

[0031] The ratio of the reaction raw materials is as follows, SiO 2:0.015-0.025TBOT:0.28TPAOH:40H 2 O: 0.33 Isopropanol: 2.0H 2 o 2 . First, mix TBOT with isopropanol evenly, then add TPAOH, H 2 O, mix evenly, then add TEOS while stirring vigorously, after adding TEOS, continue to stir until the solution is clear, replenish the water evaporated from the solution in time, and finally add H 2 o 2 , Stir evenly, add the reaction raw materials into a polytetrafluoroethylene stainless steel reaction kettle, crystallize at 180°C for 48-72 hours, and then take out the product and separate it by suction filtration.

[0032] The product has no big difference compared with Example 1, except that the size of the bulk product is slightly larger.

[0033] In Examples 1-3, if the crystallization time is shortened to 6 hours or increased to 96 hours, bulk TS-1 molecular sieves can also be o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com