Refining method of xylose in hemicellulose hydrolysate

A technology of hemicellulose and refining method, which is applied in the field of chemical production to achieve the effects of simple operation, increasing product income and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

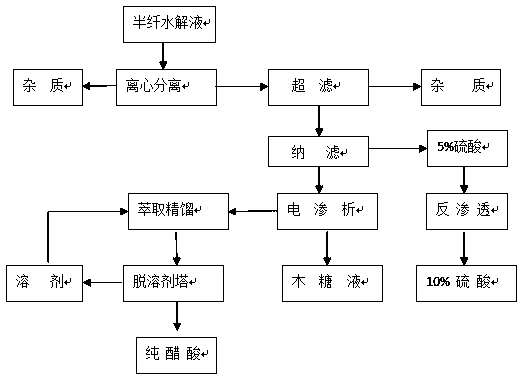

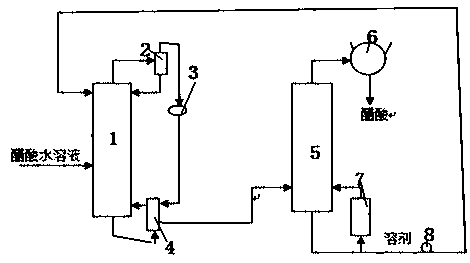

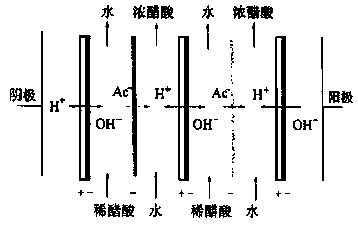

[0037] The hemicellulose hydrolyzate is passed through a high-speed disc centrifuge to separate solid impurities. The aqueous phase is composed of 2% sulfuric acid, 1.5% acetic acid, and 15% xylose, and then passes through Da2000 ultrafiltration membrane to remove lignin and macromolecular substances. Obtain the permeate solution containing xylose, sulfuric acid and acetic acid; the permeate solution containing xylose, sulfuric acid and acetic acid passes through the Da500 nanofiltration membrane to intercept sulfate ions, and the sulfuric acid concentration obtained is 5%, which is directly reused; The osmotic membrane is concentrated to a concentration of 10% for reuse; the nanofiltration permeate is separated from acetic acid and xylose in the biomass hydrolyzate by a homogeneous membrane electrodialysis method. According to the difference in the physical and chemical properties of the sulfuric acid and acetic acid ions, under the action of a direct current electric field, t...

Embodiment 2

[0041] The hemicellulose hydrolyzate is passed through a high-speed disc centrifuge to separate solid impurities, and the water phase is composed of 2% sulfuric acid, 1.5% acetic acid, and 15% xylose, and then passes through a Da1000 ultrafiltration membrane to remove lignin and macromolecular substances The permeate containing xylose, sulfuric acid and acetic acid is obtained; the permeate is passed through a Da500 nanofiltration membrane to intercept sulfate ions, and the sulfuric acid concentration obtained is 5%, which is directly reused; Use; nanofiltration permeate with homogeneous membrane electrodialysis to separate acetic acid and xylose in biomass hydrolyzate. According to the difference in the physical and chemical properties of the sulfuric acid and acetic acid ions, under the action of a direct current electric field, the device is called the treatment chamber between the anion exchange membrane and the cation exchange layer, and the acid recovery chamber between t...

Embodiment 3

[0044] Pass the hemicellulose hydrolyzate through a high-speed disc centrifuge to separate solid impurities. The water phase is composed of 2% sulfuric acid, 1.5% acetic acid, and 15% xylose, and then pass through Da1000 ultrafiltration membrane to remove lignin and macromolecular substances. Obtain the permeate containing xylose, sulfuric acid and acetic acid; the permeate passes through the Da500 nanofiltration membrane to intercept sulfate ions, and the mass concentration of the obtained sulfuric acid is 5%, which can be directly reused; or concentrated to 10wt by reverse osmosis membrane The % concentration is reused; the nanofiltration permeate is separated from acetic acid and xylose in the biomass hydrolyzate by homogeneous membrane electrodialysis. According to the difference in the physical and chemical properties of the sulfuric acid and acetic acid ions, under the action of a direct current electric field, the device is called the treatment chamber between the anion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com