Etching liquid for TFT (thin film transistor)array substrate copper conductor

An array substrate and etching solution technology, applied in the field of etching solution, can solve the problems of increased engineering control difficulty, short process window, short service life, etc., so as to improve the short process window, reduce the difficulty of engineering control, and improve the service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

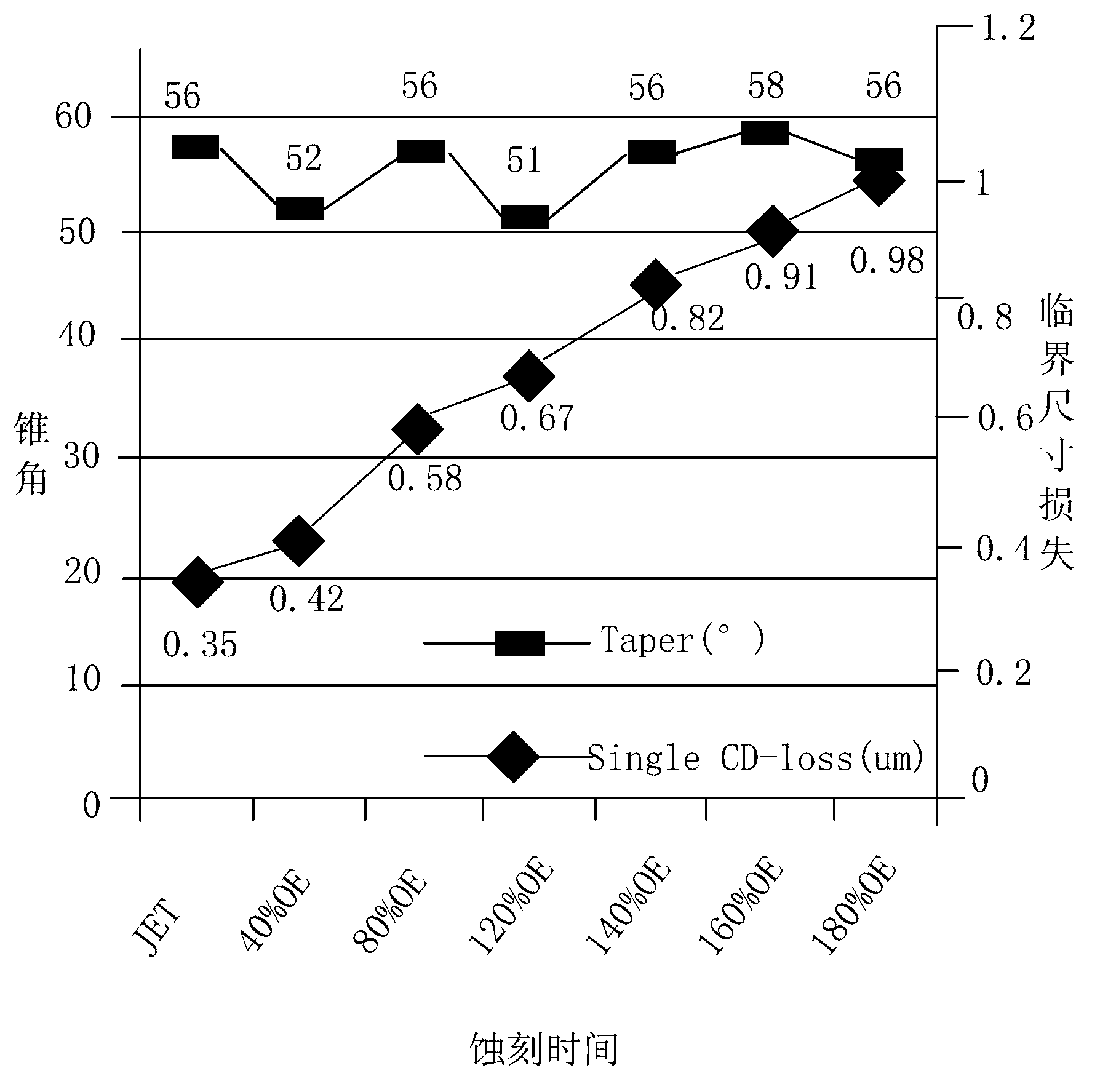

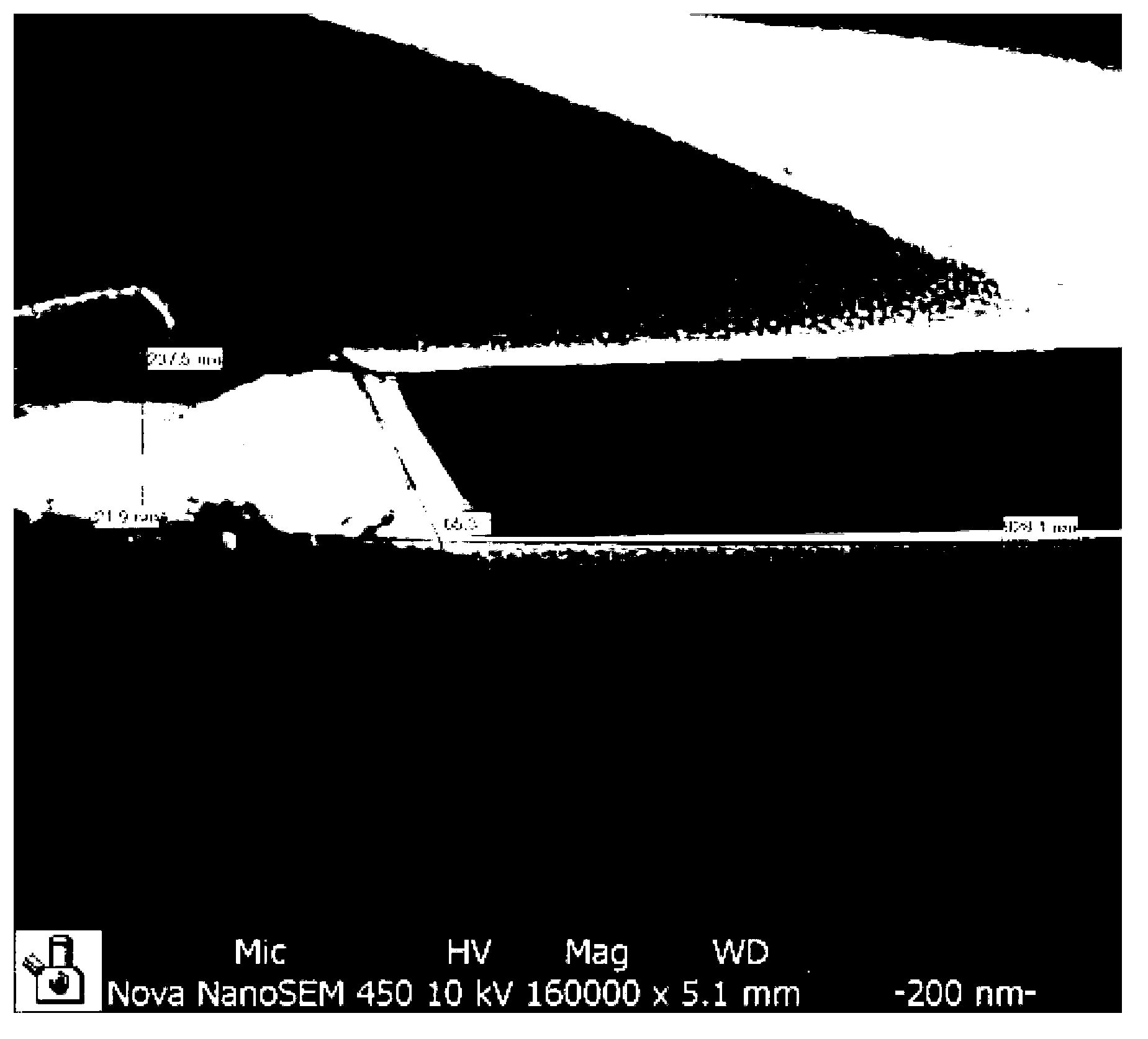

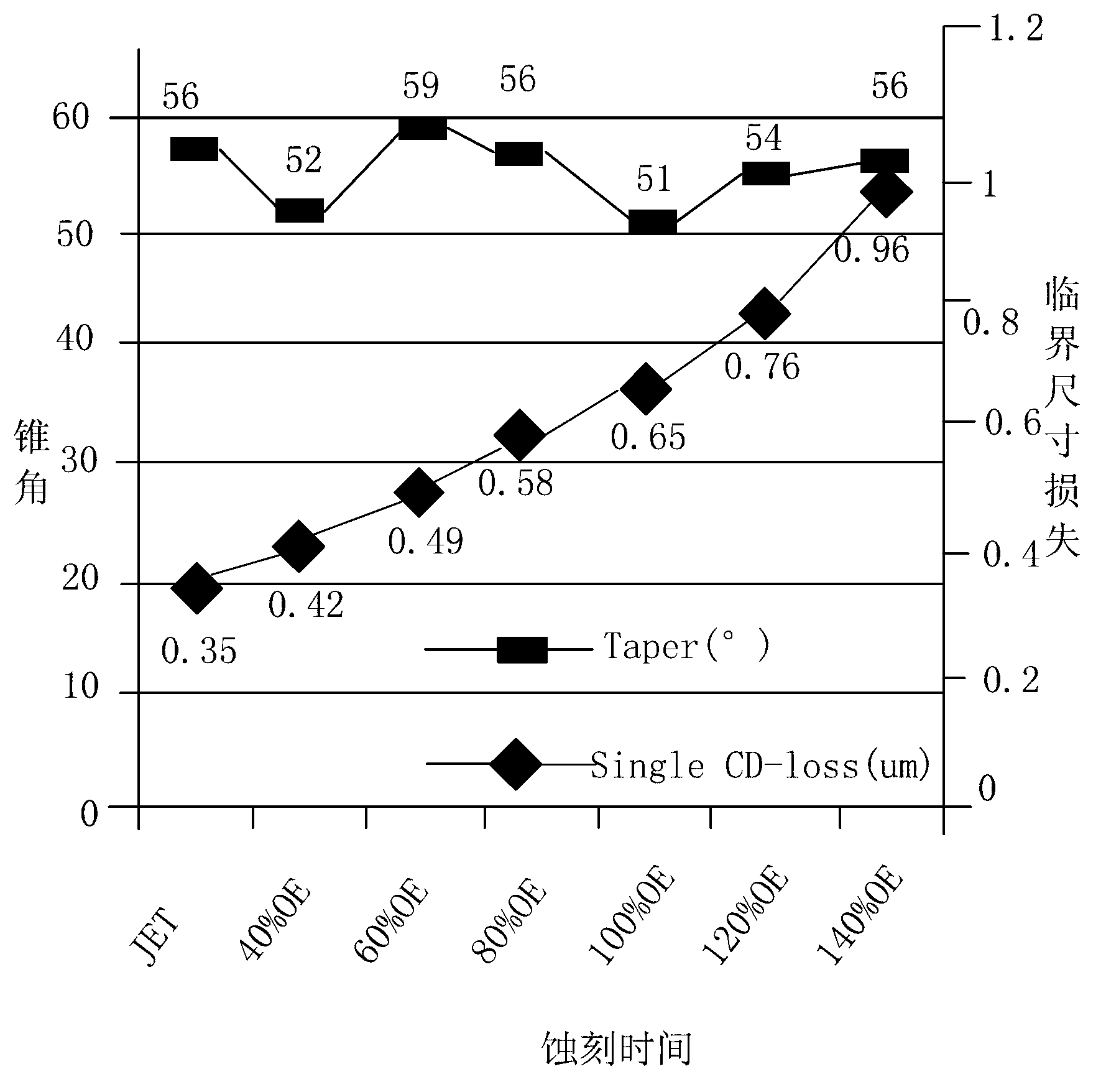

[0034] The invention provides an etchant for copper wires of a TFT array substrate, which is mainly aimed at metal structures such as Cu / Mo and Cu / Mo-alloys. The metal alloy can include materials such as Mg, Al, Ni, V, Mn or Si, and a molybdenum layer is used. Or the molybdenum alloy layer is used as the lower layer metal to improve the adhesion and barrier effect of the lower layer metal to the glass and to stabilize the electrode potential of the barrier metal layer in the etching solution. The etching solution comprises: a main oxidant, a secondary oxidant, a chelating agent, an inhibitor, and an additive, the main oxidant is hydrogen peroxide, the secondary oxidant is phosphoric acid, sulfuric acid, and nitric acid; the chelating agent is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com