Patents

Literature

137 results about "Engineering tool" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

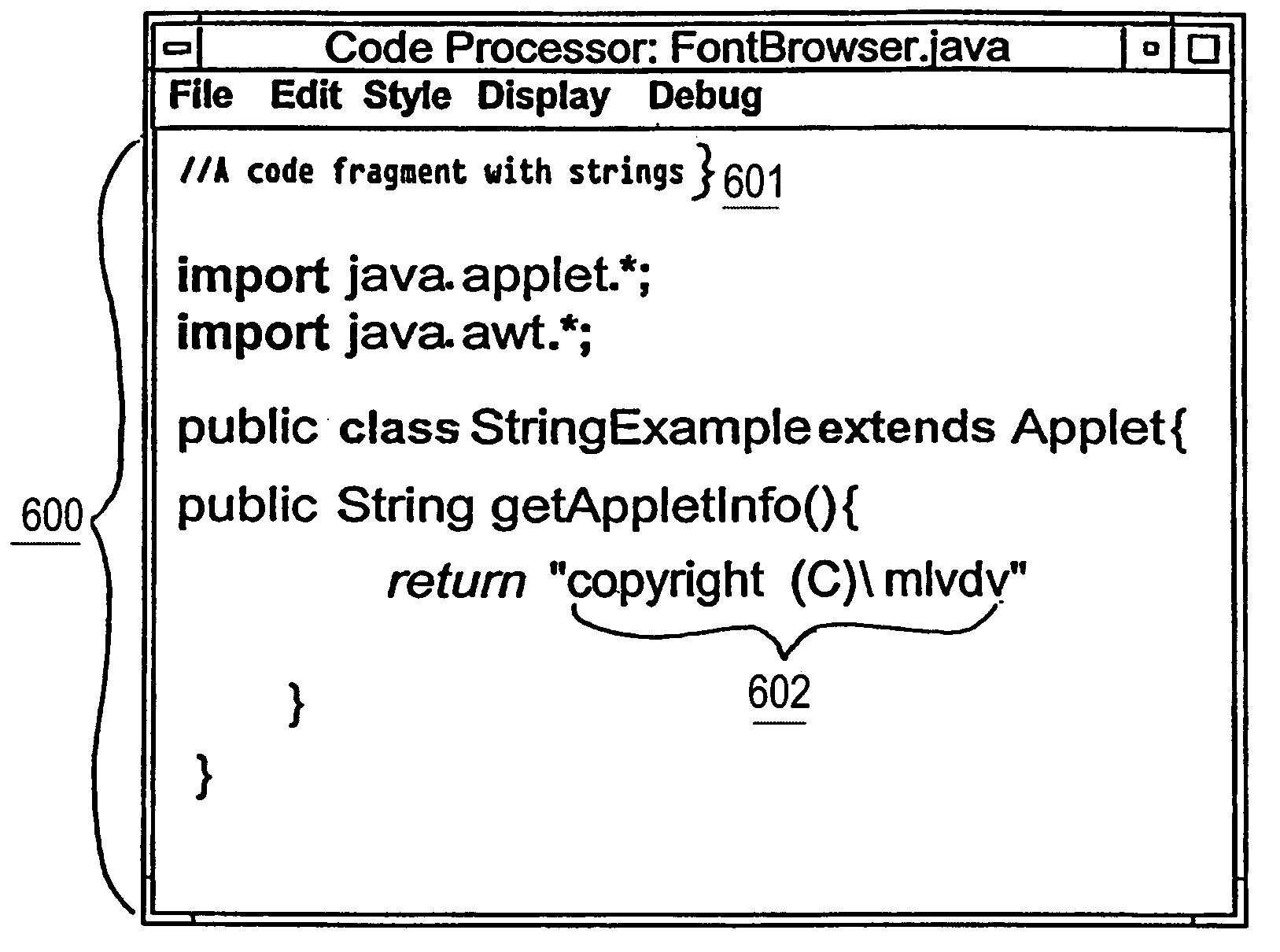

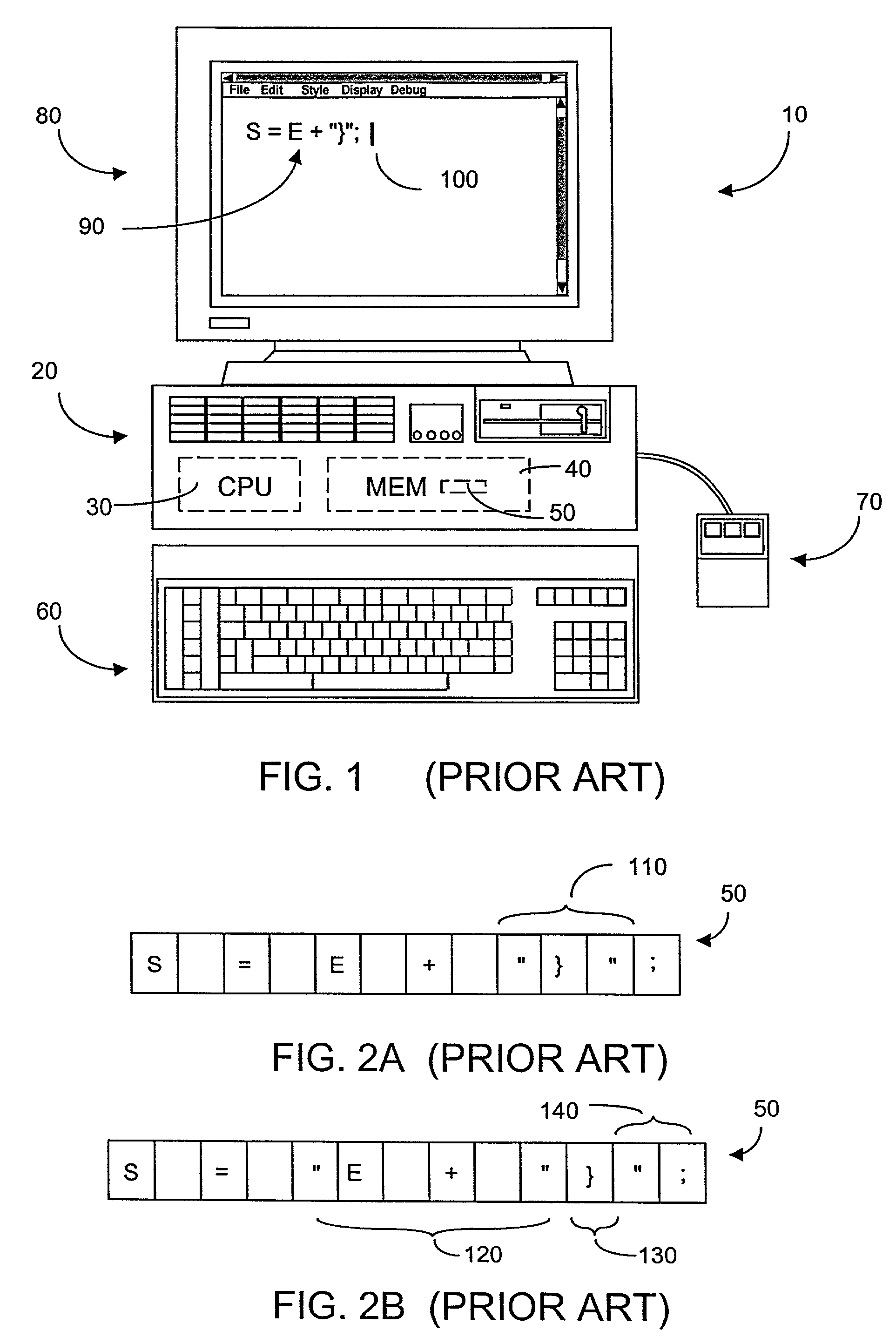

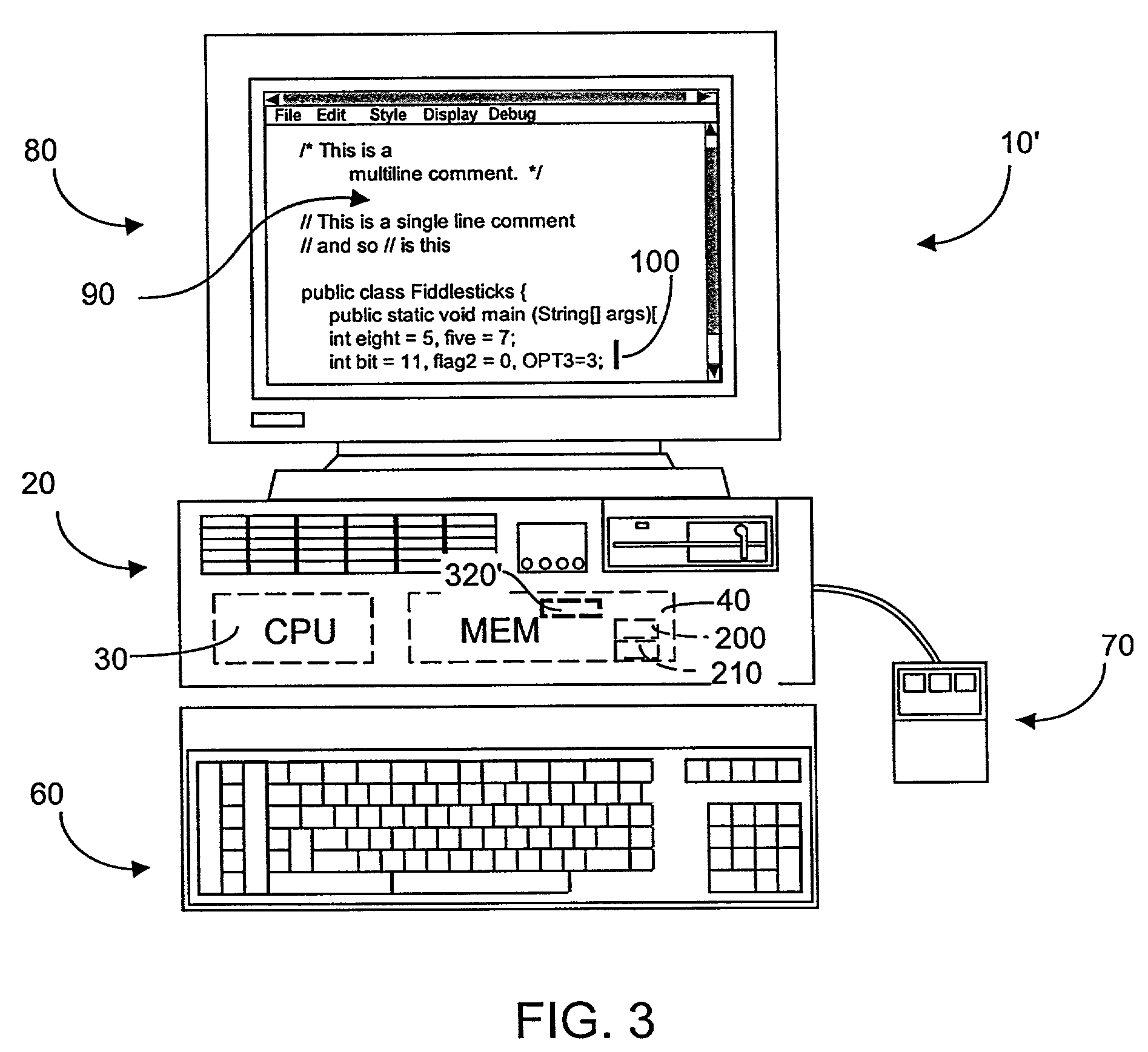

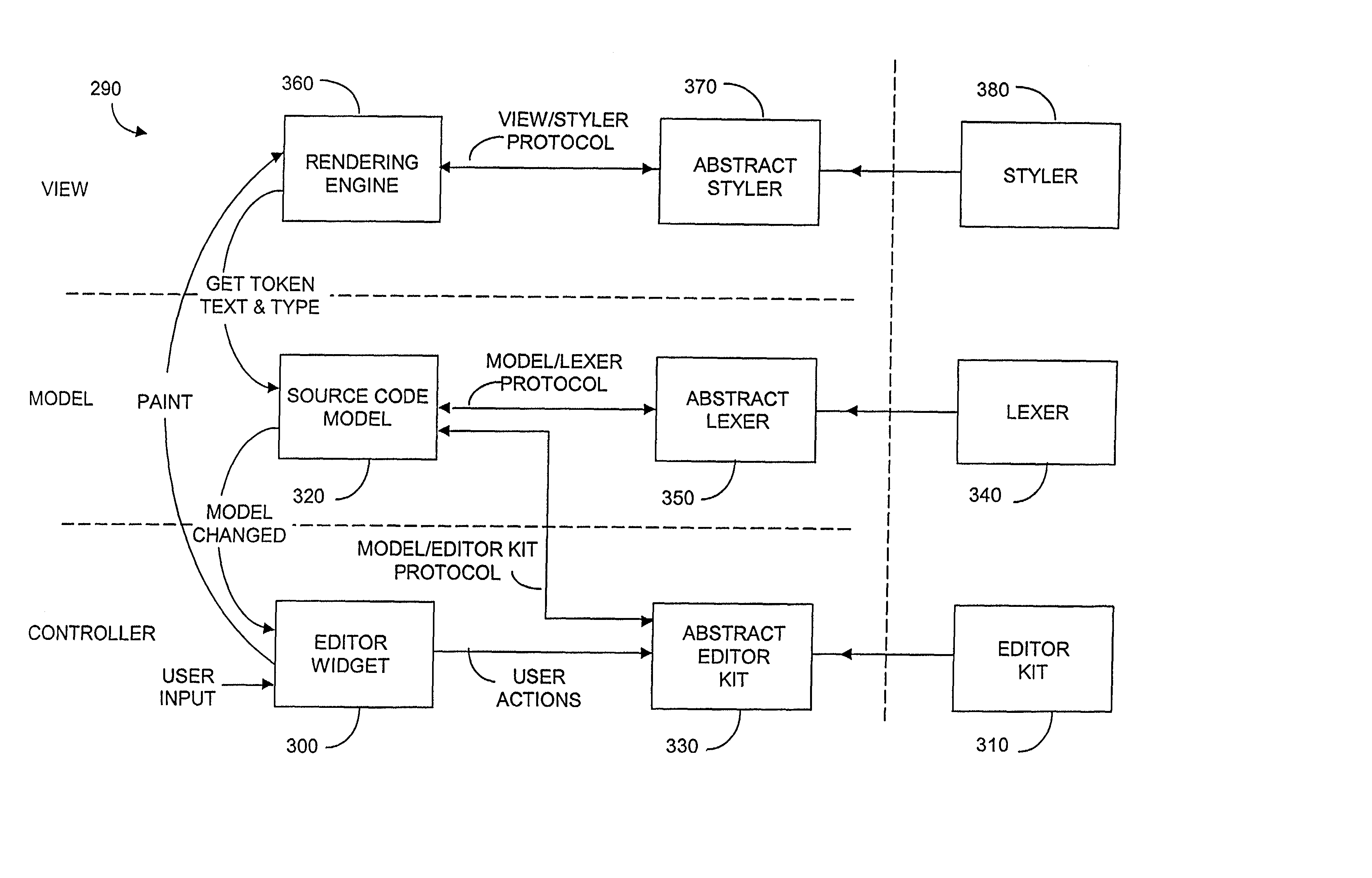

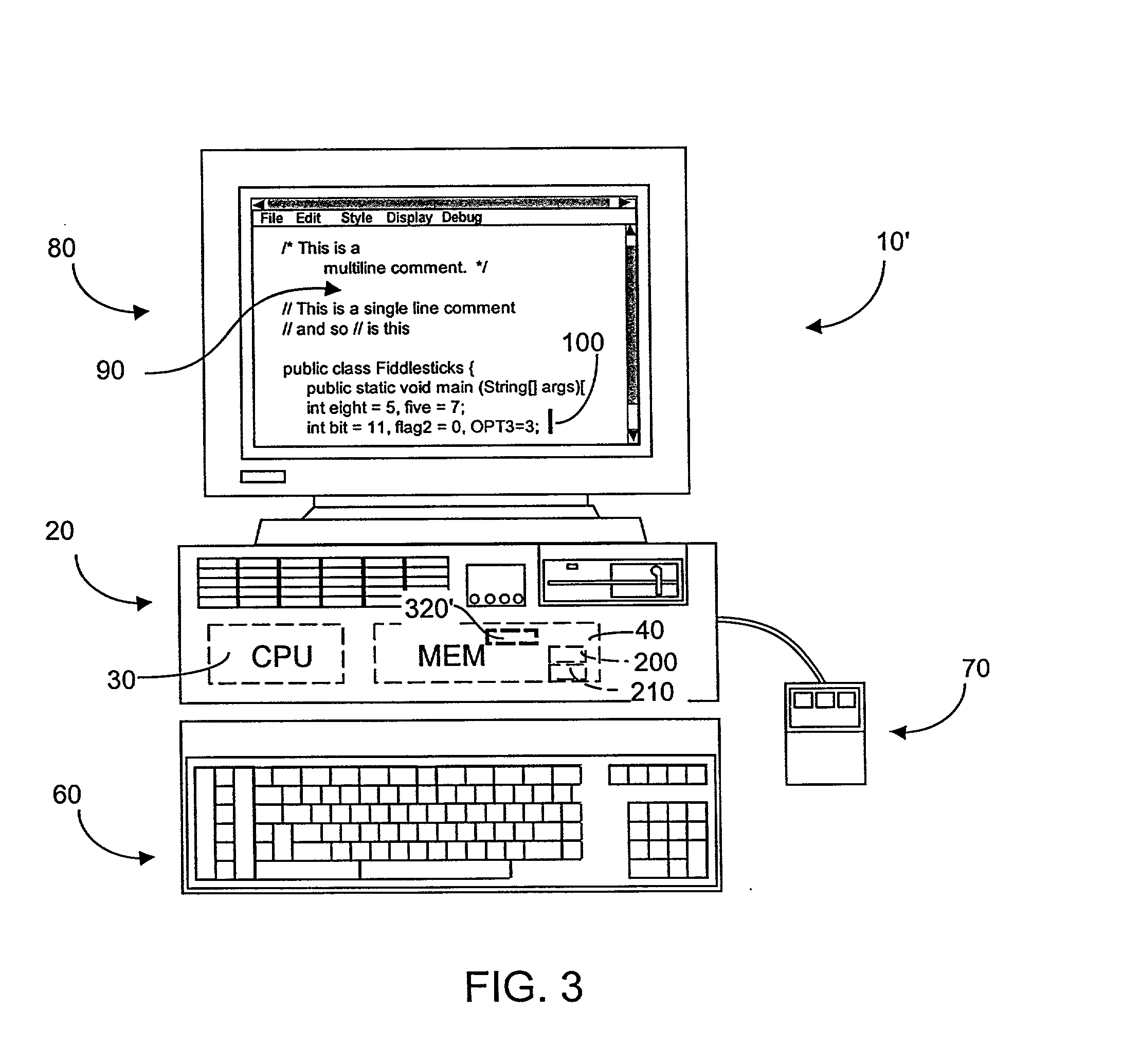

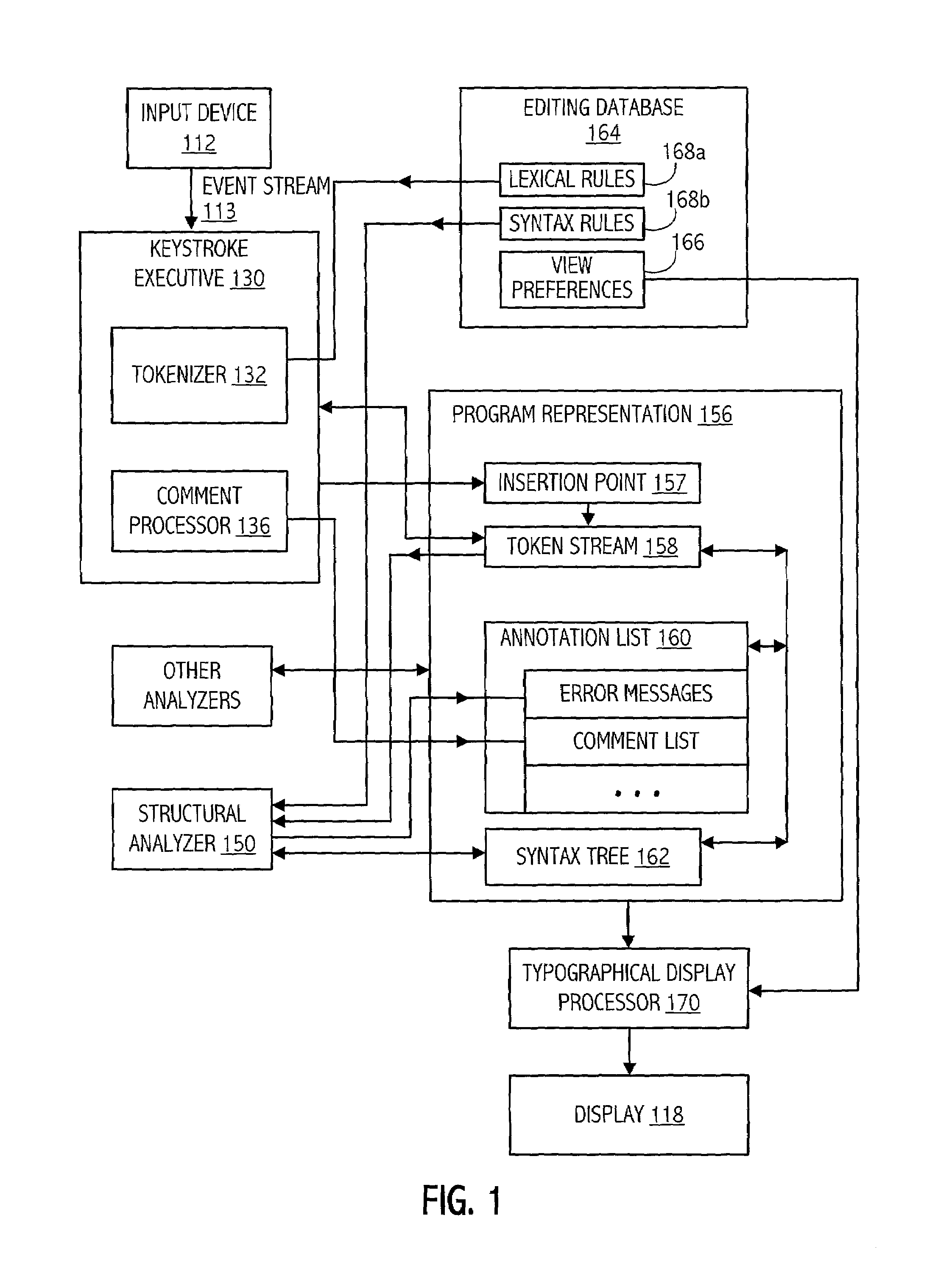

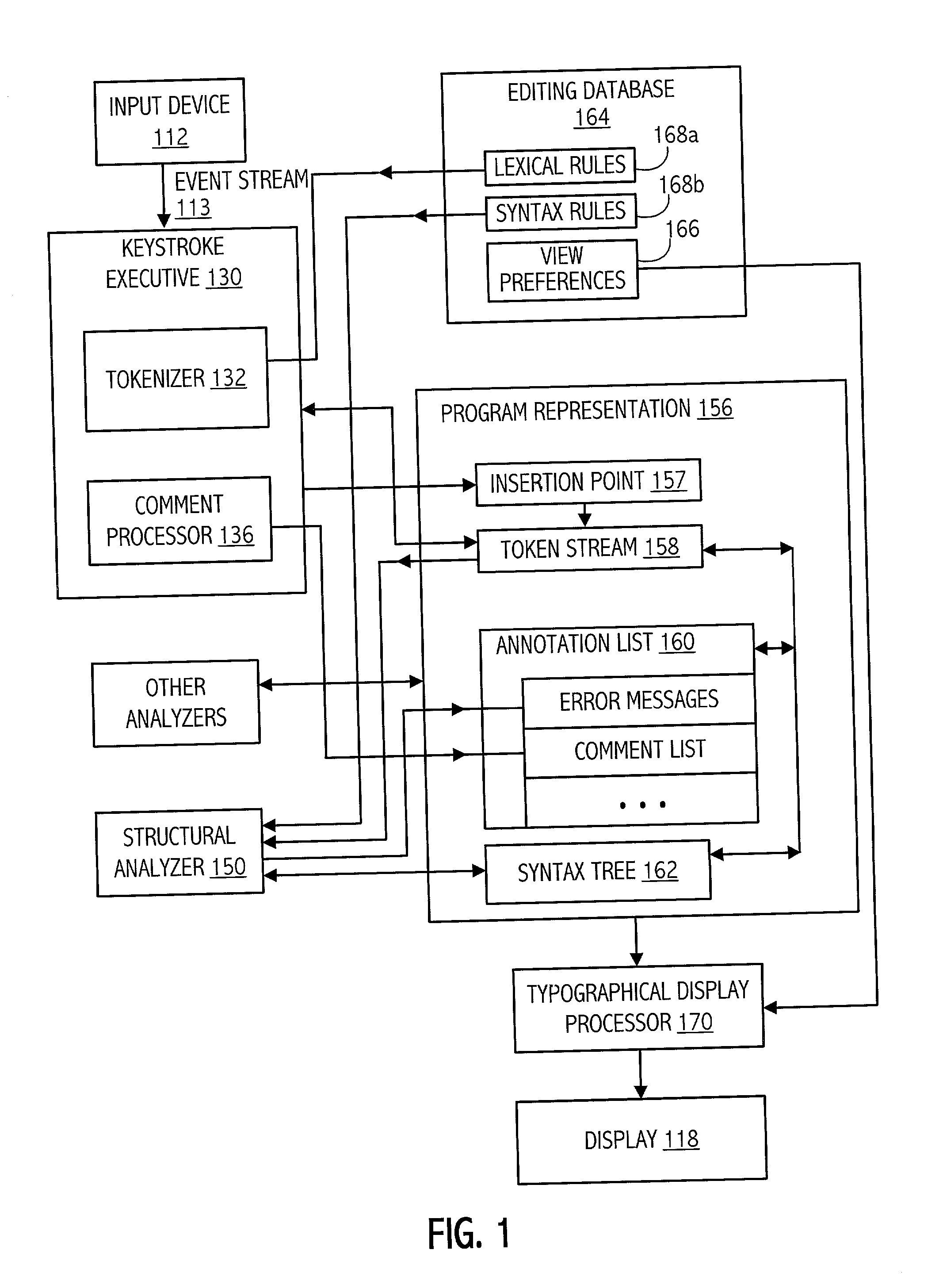

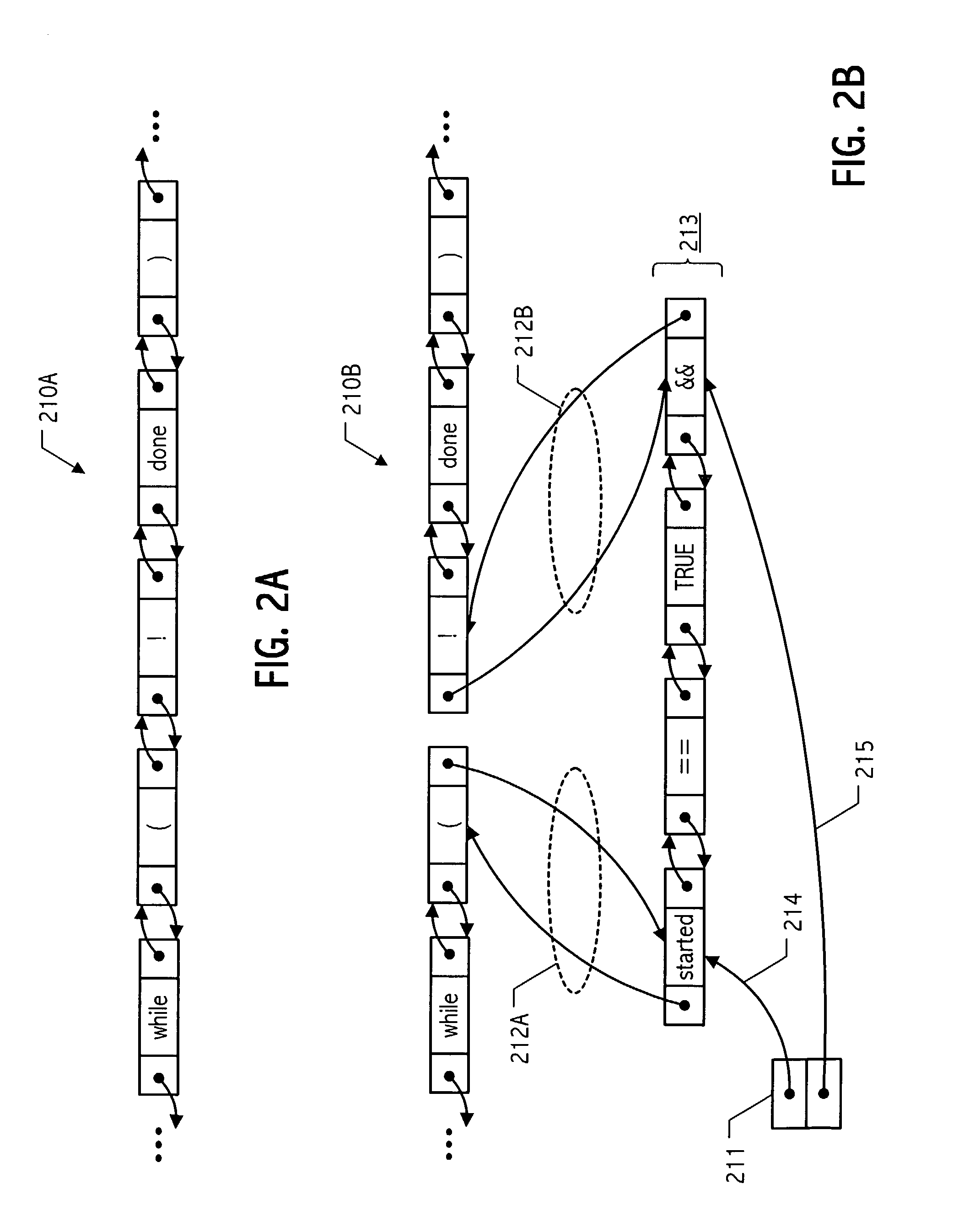

Interactive software engineering tool with support for embedded lexical contexts

InactiveUS7127704B2Avoid deletionIntelligent editorsSpecial data processing applicationsInteractive softwareProgramming language

In response to programmer input of a trigger token, a program editor creates a pair of boundary tokens encapsulating an embedded lexical context and positions an insertion point within the embedded lexical context. The operations on the embedded lexical context are preferably performed using an embeddable sub-editor specialized to the task at hand. Since boundary tokens are generated in pairs, stability of lexical boundaries is enforced. Accordingly, stable implementations of certain desirable behaviors, including language-oriented advanced program typography that is robust to user edits, are facilitated using the invented techniques.

Owner:ORACLE INT CORP

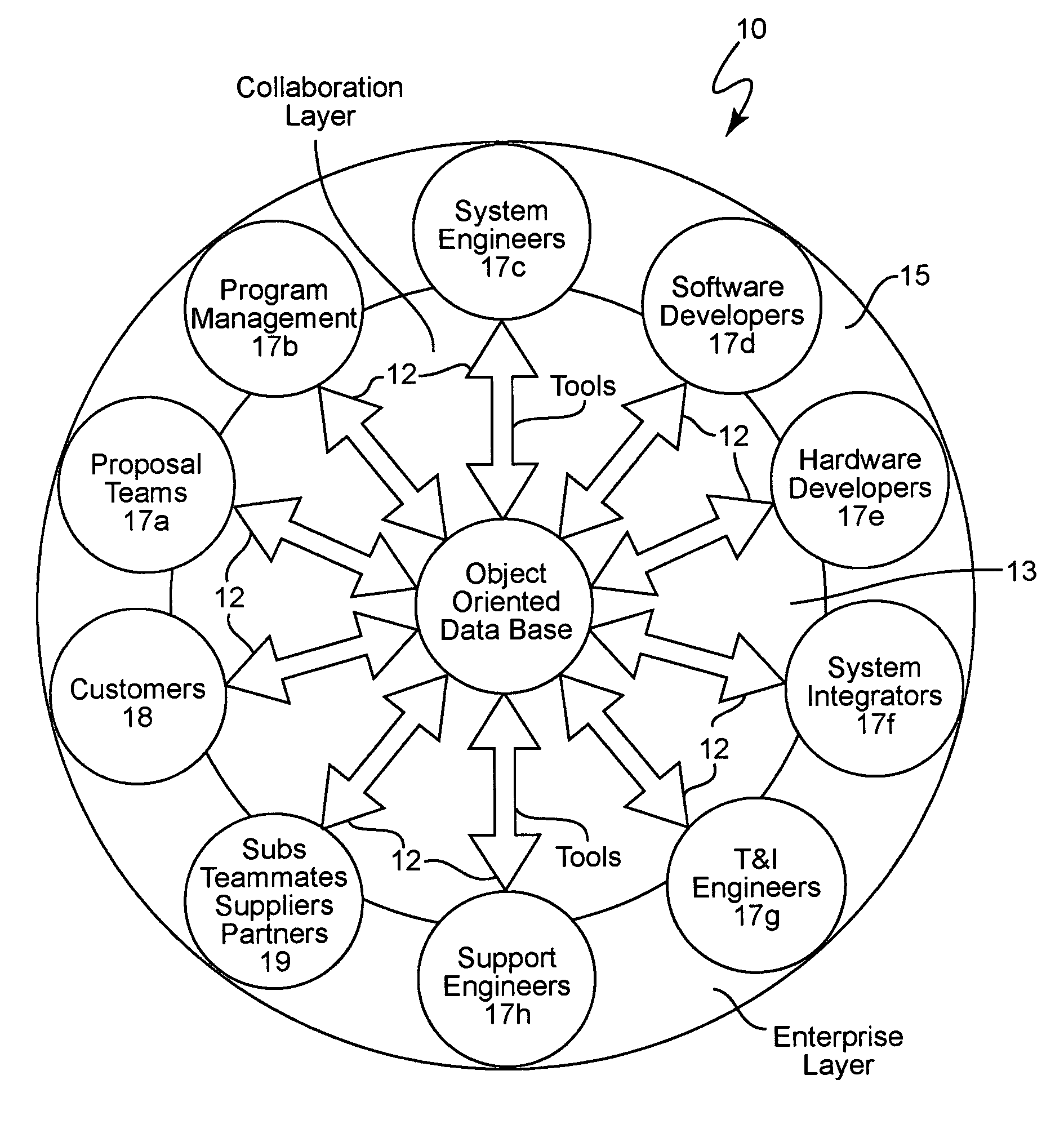

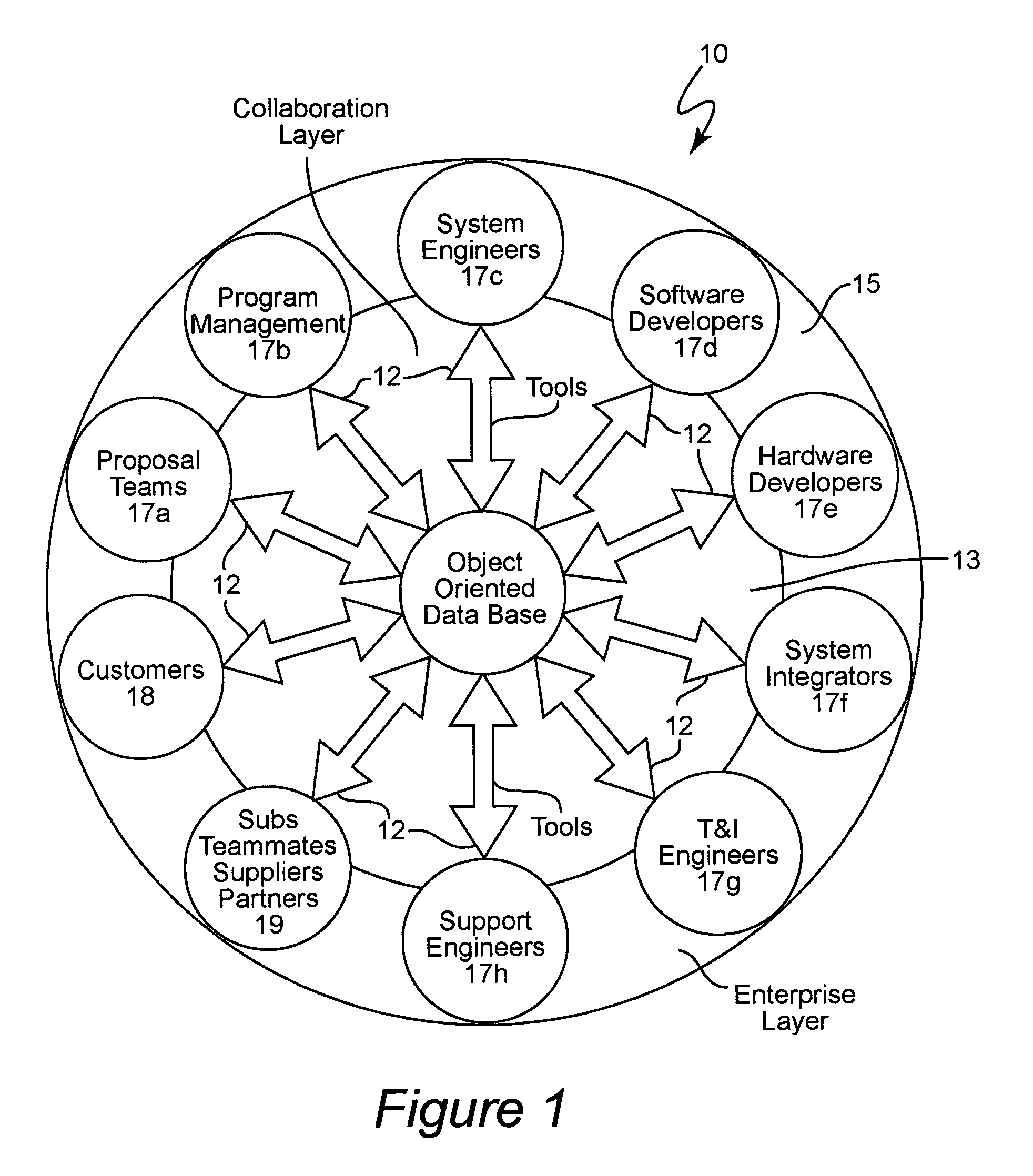

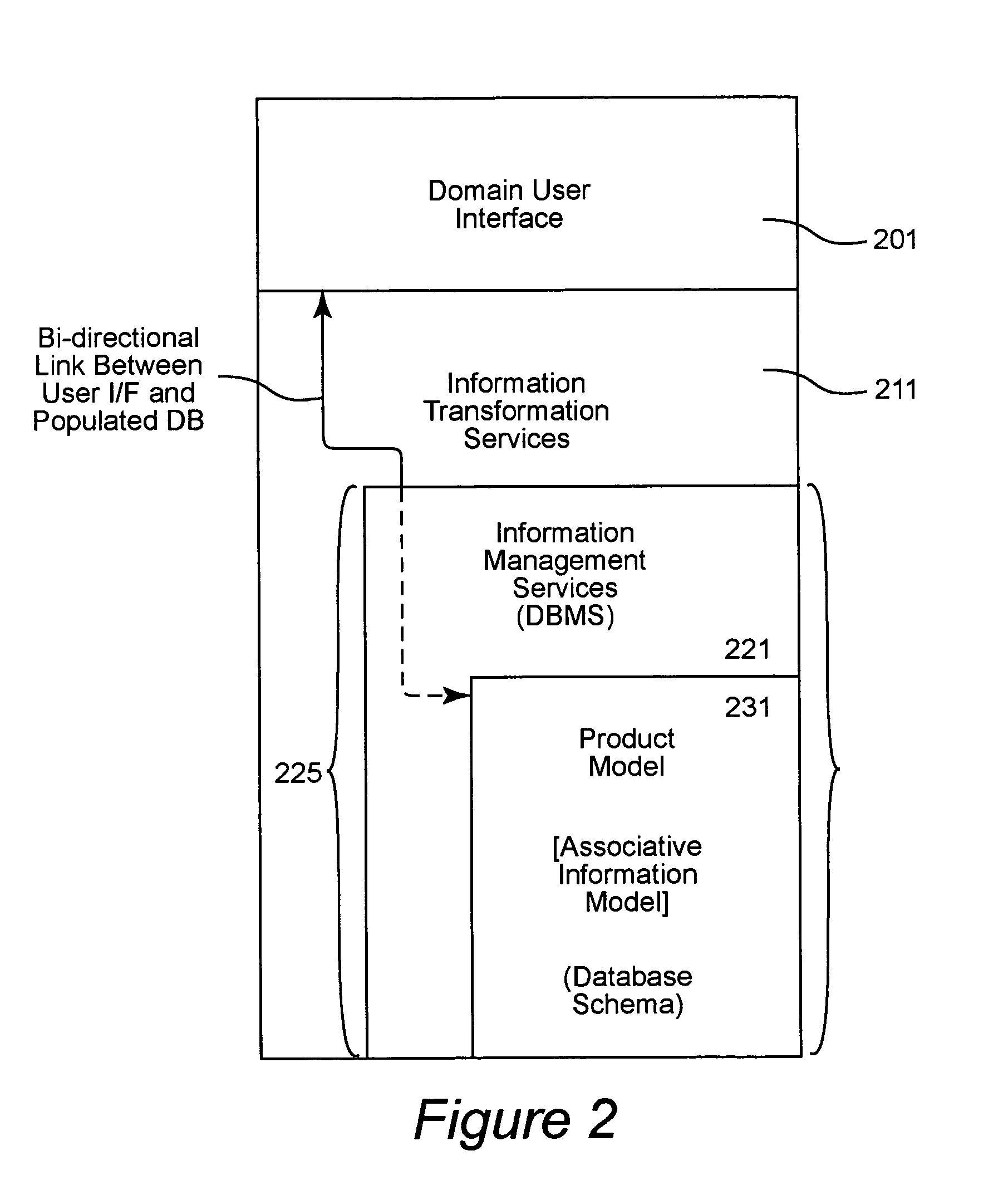

Internet based product data management (PDM) system

InactiveUS6961687B1Defect informationImprove visibilityMultiple digital computer combinationsSound input/outputSystems designApplication software

An integrated product data environment for system design and optimization, e.g., a Collaborative Engineering Environment (CEE). The CEE provides a multi-disciplinary engineering team with immediate access to all relevant product information. It is an enterprise system at the program as well as the company levels, managing product information as a program and corporate asset. Product-centric collaborative capabilities for the CEE are provided by extending the functionality of a commercial Product Data Management (PDM) System. Emerging web-centric commercial-off-tho-shelf (COTS) PDM capabilities, object-oriented technologies, associated rapid application development environments, sophisticated engineering toolsets, and COTS computing and communications technologies have been leveraged to establish the CEE for the complex electronic systems integration domain. The CEE offers substantial improvements in productivity, cost savings, cycle time reductions, product integrity and lifetime support of a system.

Owner:LOCKHEED MARTIN CORP

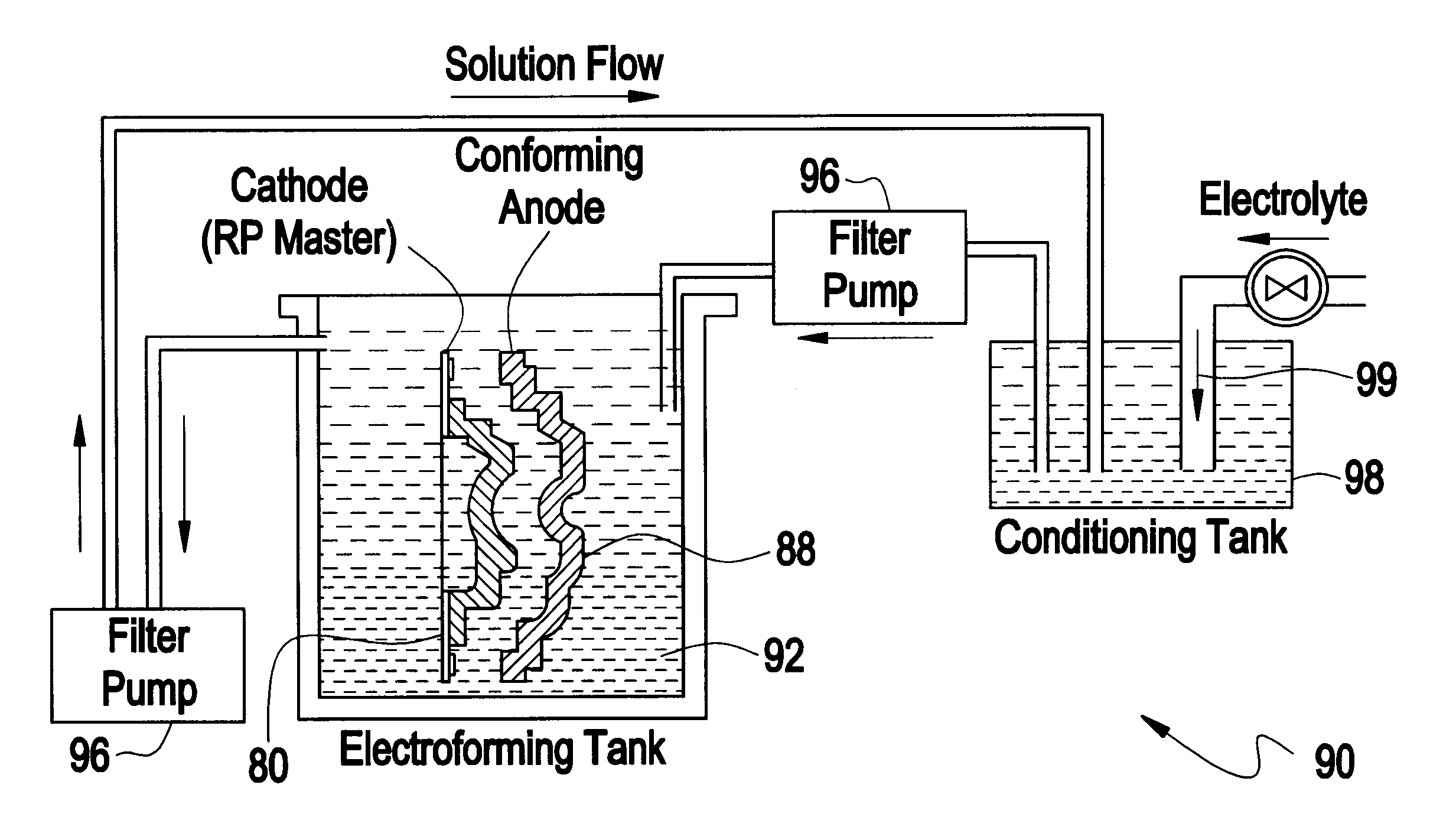

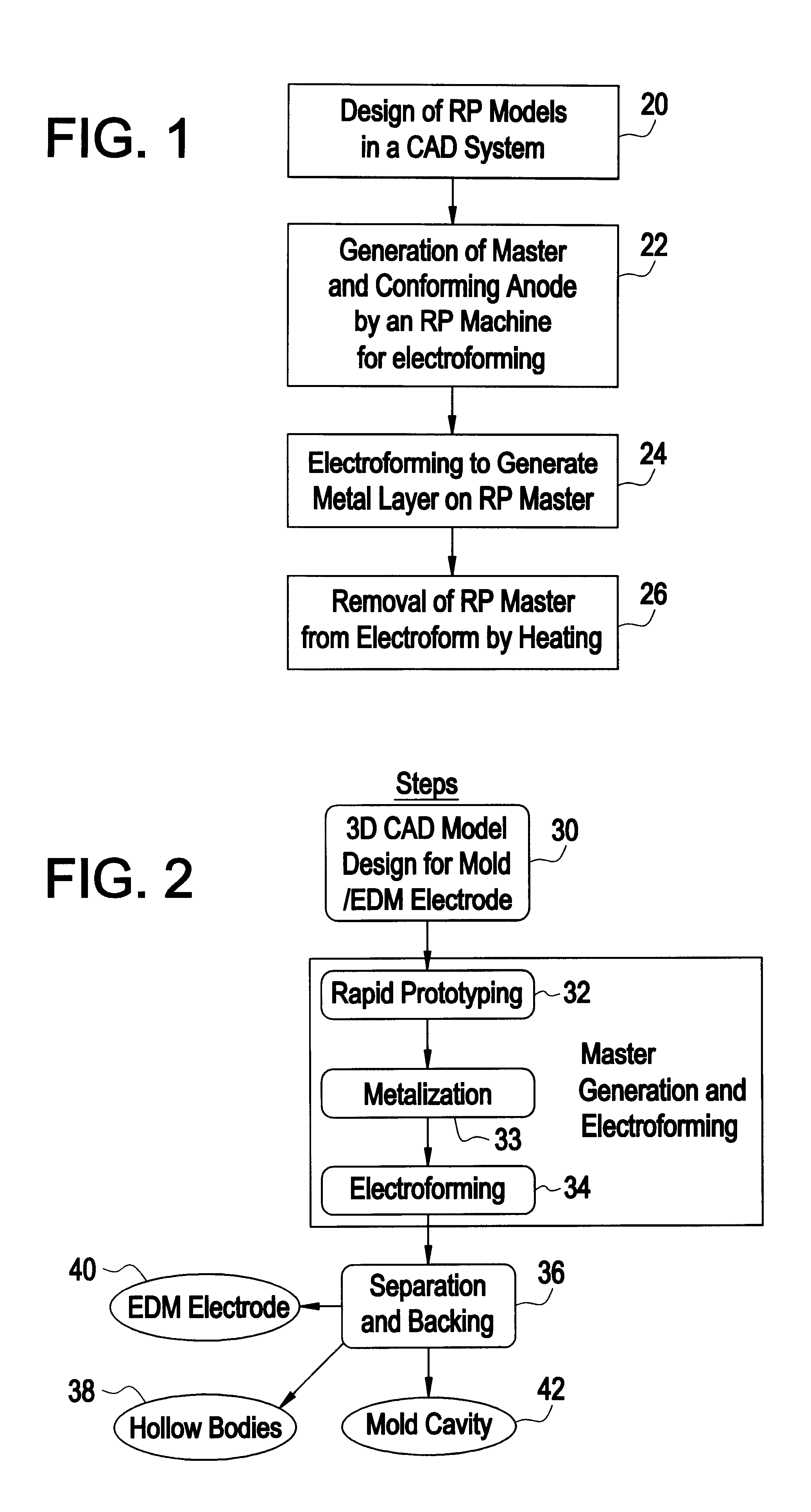

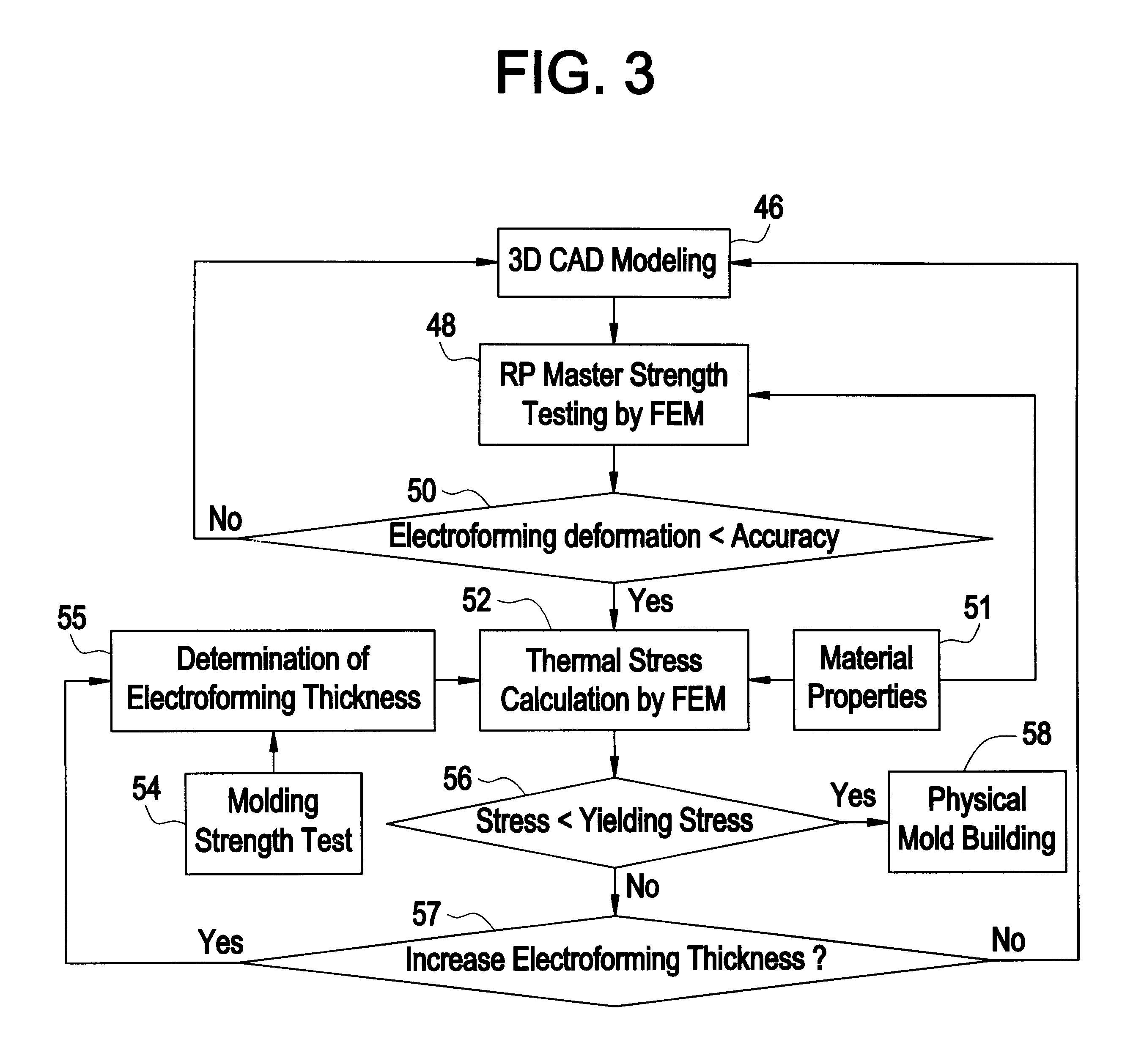

Rapid production of engineering tools and hollow bodies by integration of electroforming and solid freeform fabrication

InactiveUS6409902B1Stay in shapeAvoid insufficient thicknessAdditive manufacturing apparatusFoundry mouldsElectrolysisElement analysis

This invention describes a rapid tooling process that integrates solid freeform fabrication (SFF) with electroforming to produce metal tools including molds, dies, and electrical discharge machining (EDM) electrodes. An SFF part is metalized by electroless plating and then placed in an electroplating solution, where metal is deposited upon the part by electrolysis. When the desired thickness of metal has been reached, the SFF part is removed from the metal shell. The shell is then optionally backed with other materials to form a mold cavity, and EDM electrode, or other desired parts for tooling. Thermomechanical modeling and numerical simulation with finite element analysis (FEA) is used to determine the geometry of the SFF part and the electroform thickness for minimizing the manufacturing time and cost while satisfy the tooling requirement.

Owner:NEW JERSEY INSTITUTE OF TECHNOLOGY

Interactive software engineering tool with support for embedded lexical contexts

InactiveUS20020100016A1Improve stabilityIntelligent editorsSpecial data processing applicationsInteractive softwareProgramming language

In response to programmer input of a trigger token, a program editor creates a pair of boundary tokens encapsulating an embedded lexical context and positions an insertion point within the embedded lexical context. The operations on the embedded lexical context are preferably performed using an embeddable sub-editor specialized to the task at hand. Since boundary tokens are generated in pairs, stability of lexical boundaries is enforced. Accordingly, stable implementations of certain desirable behaviors, including language-oriented advanced program typography that is robust to user edits, are facilitated using the invented techniques.

Owner:ORACLE INT CORP

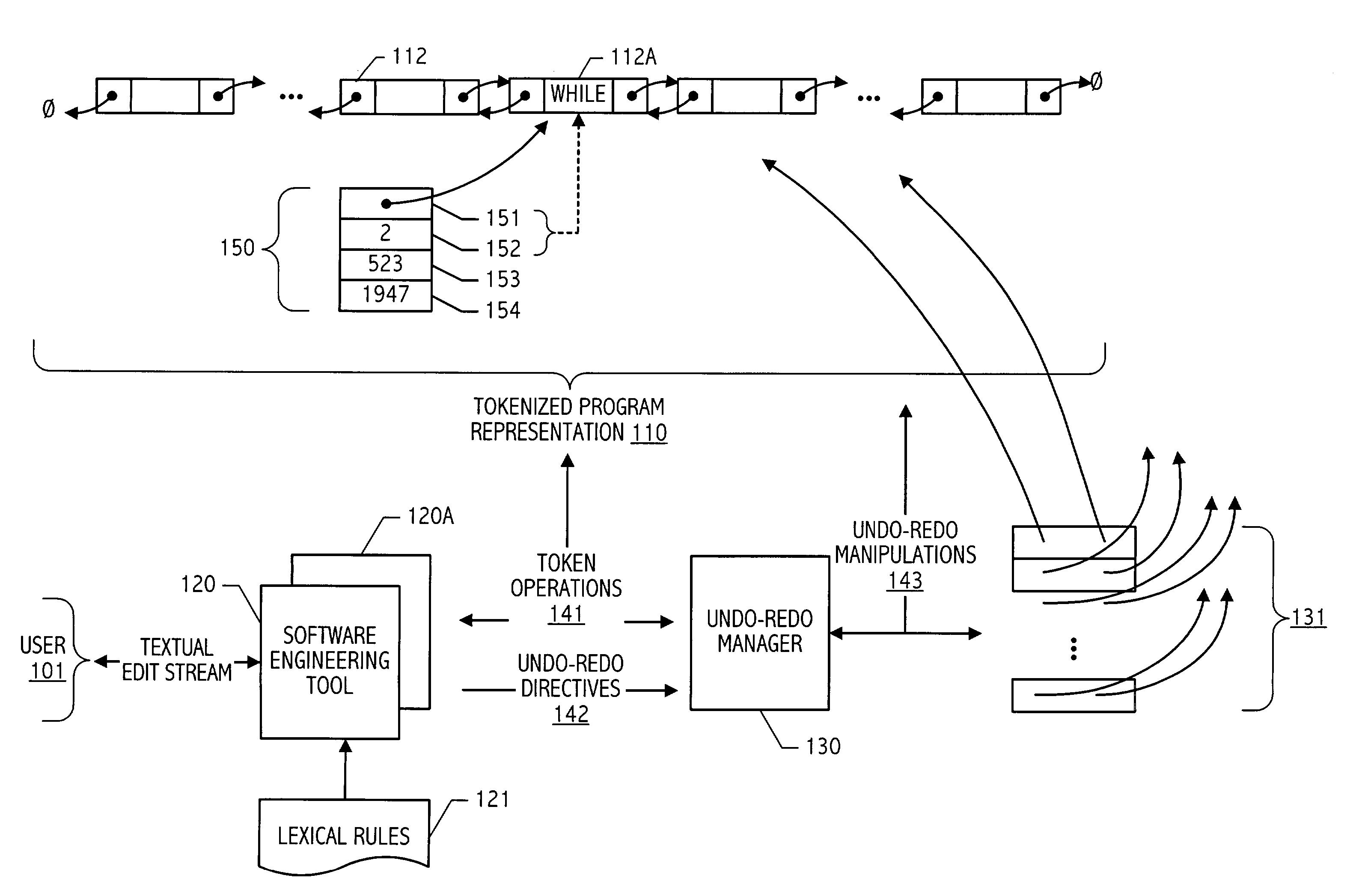

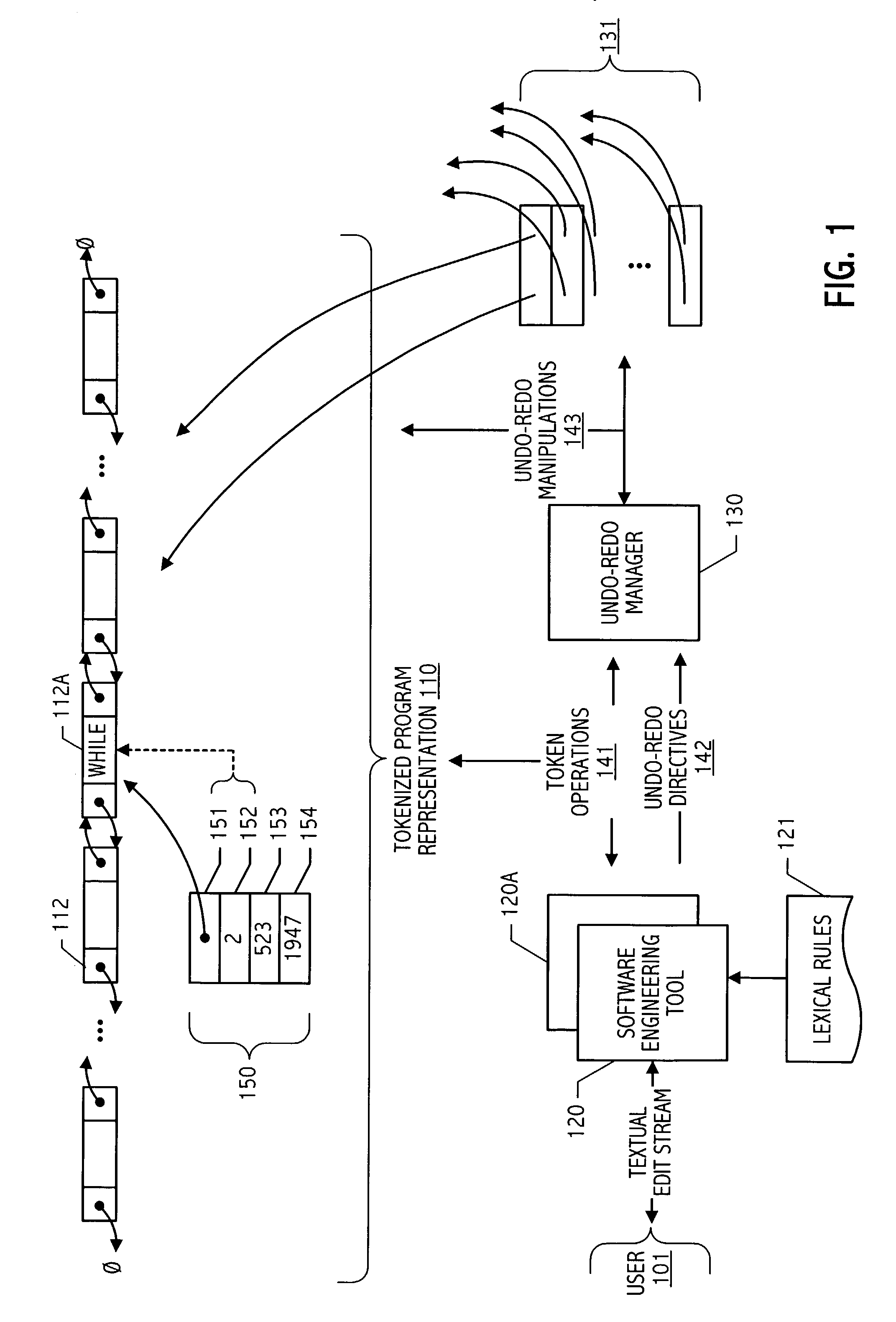

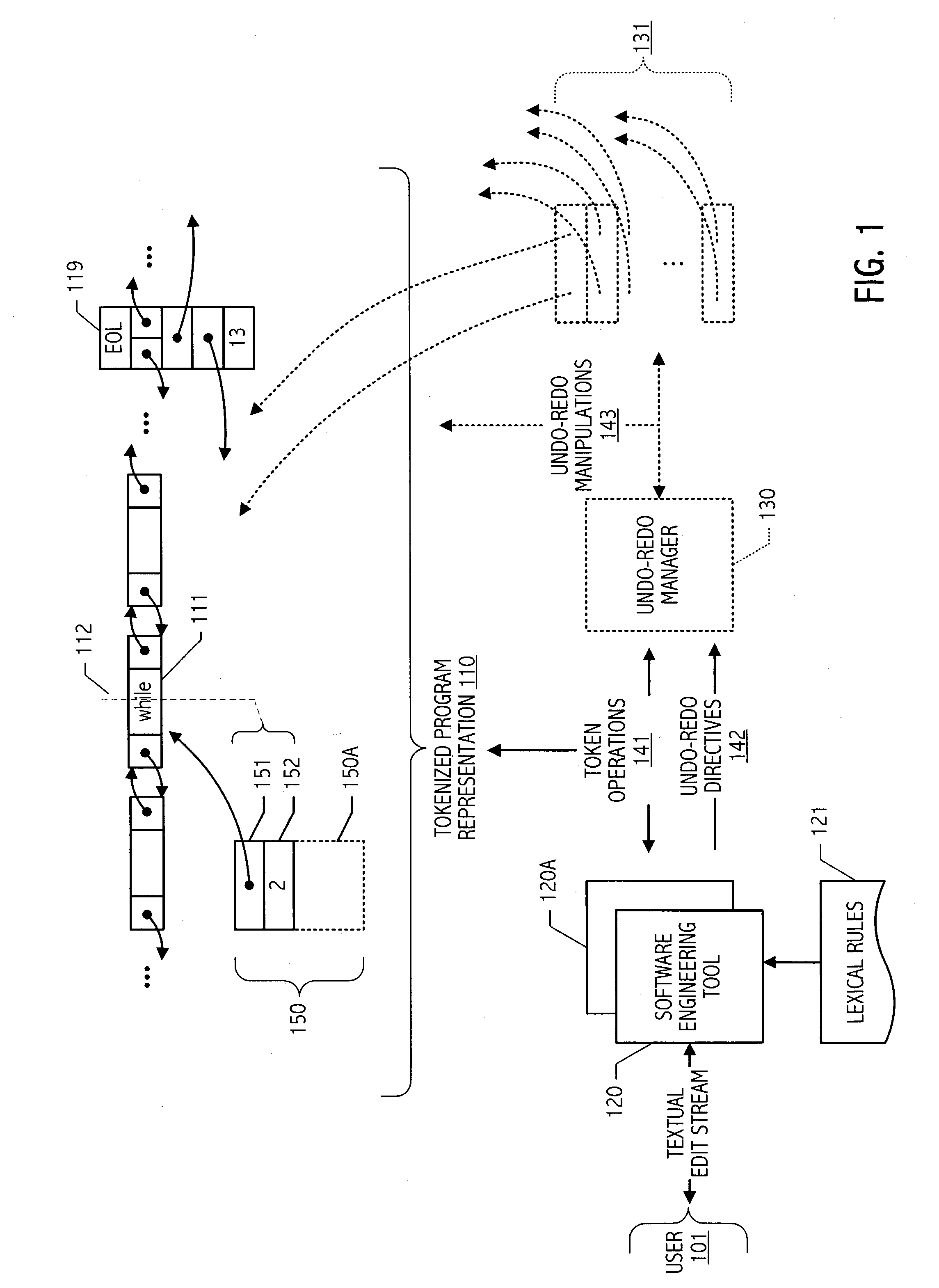

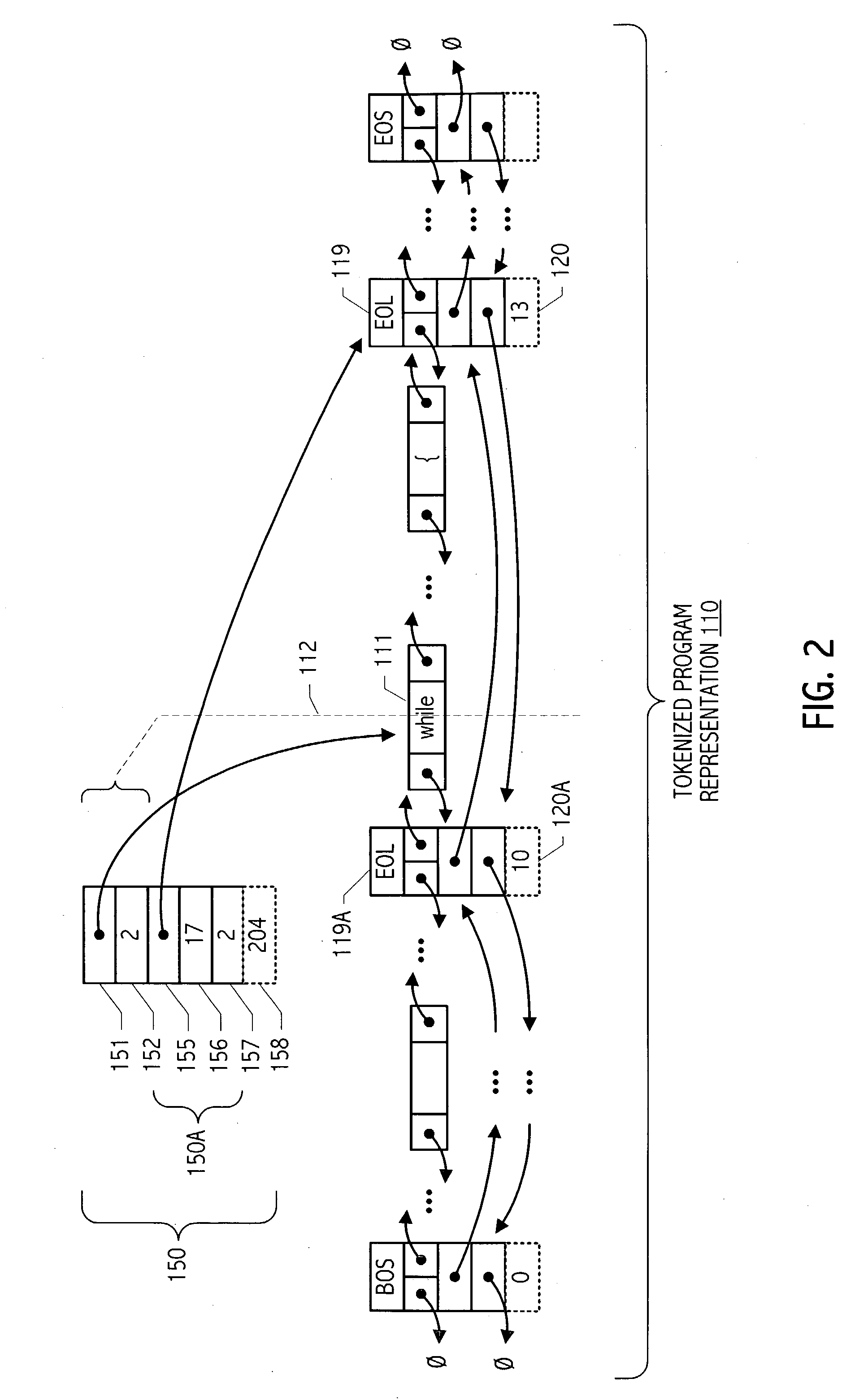

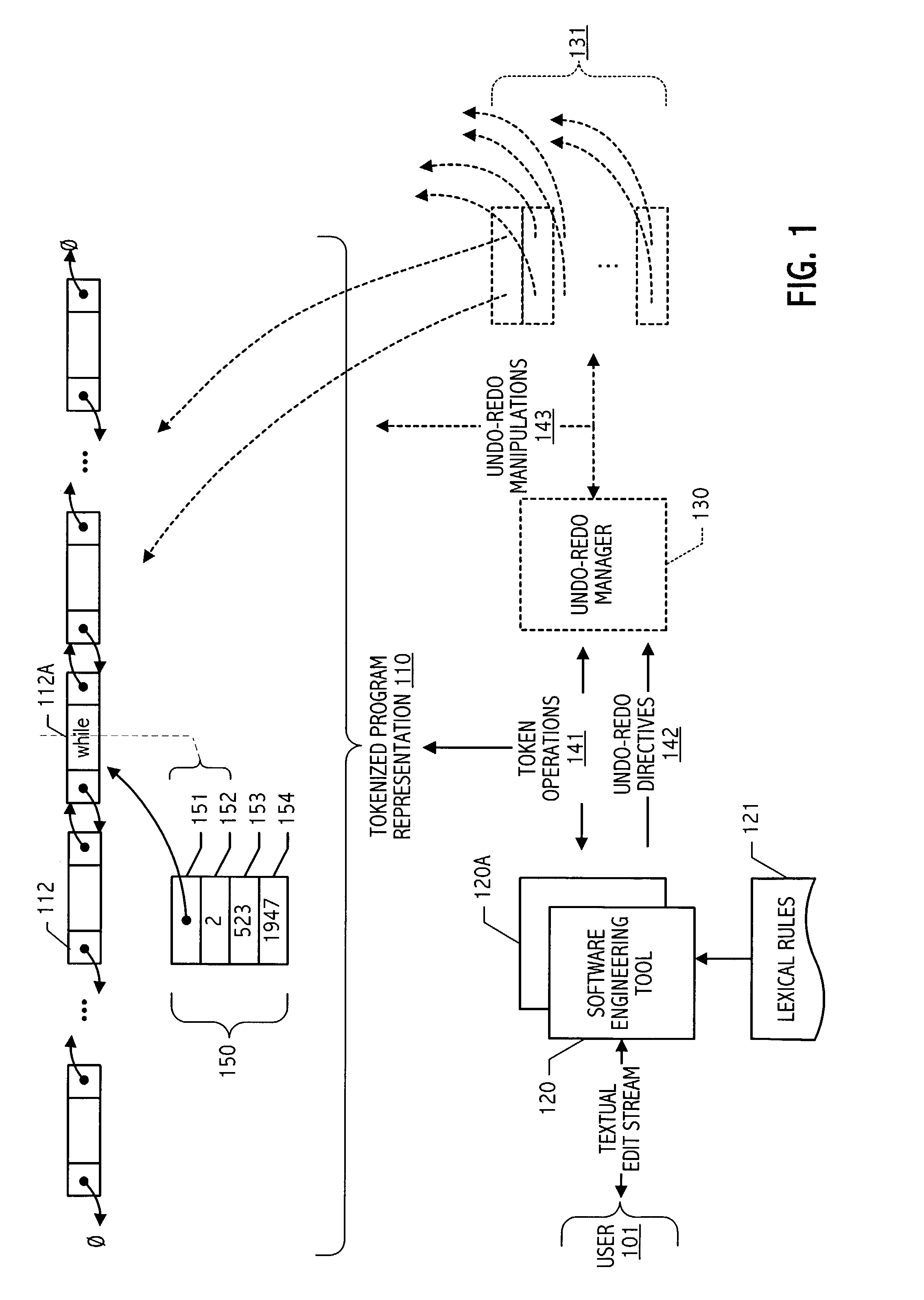

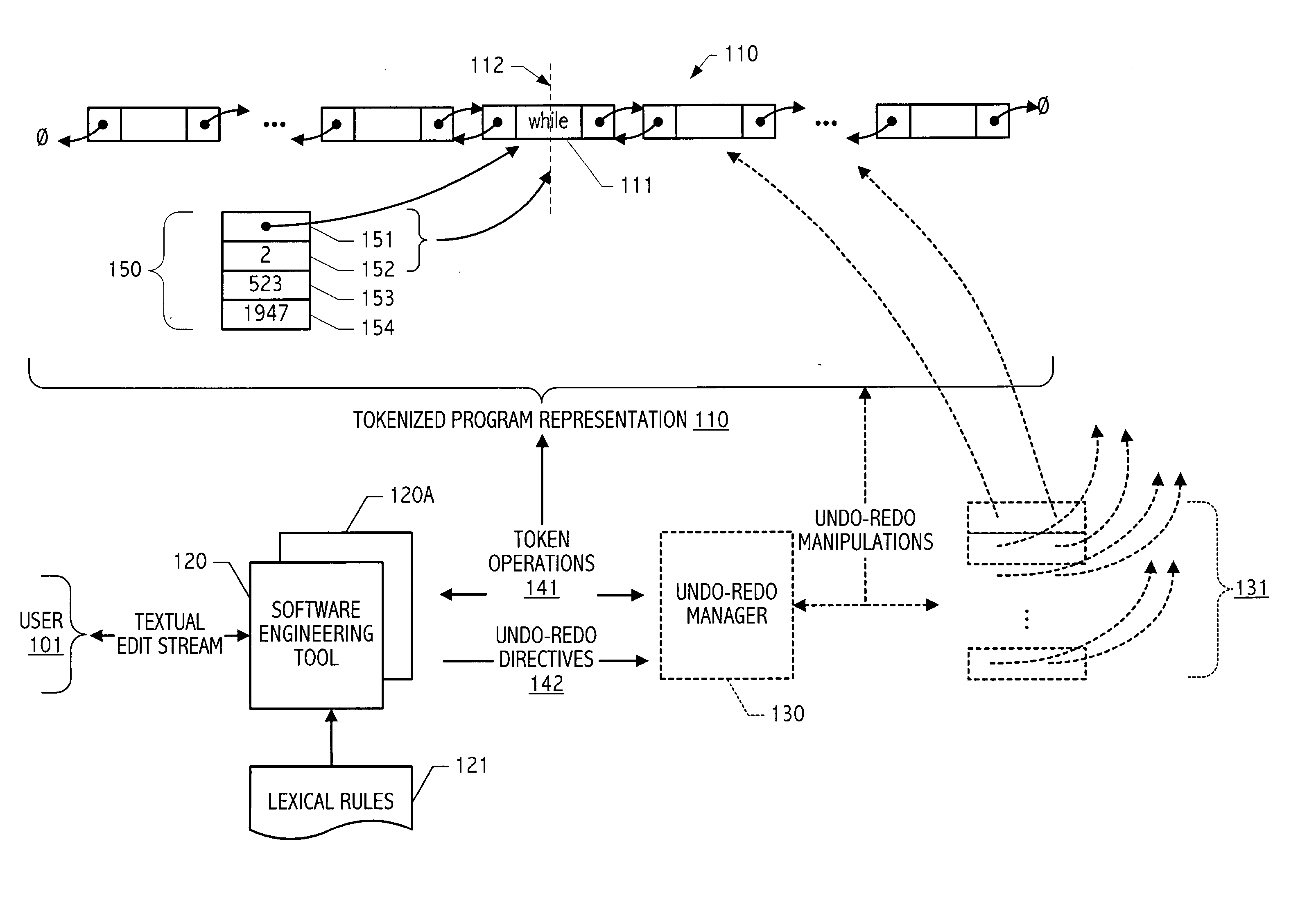

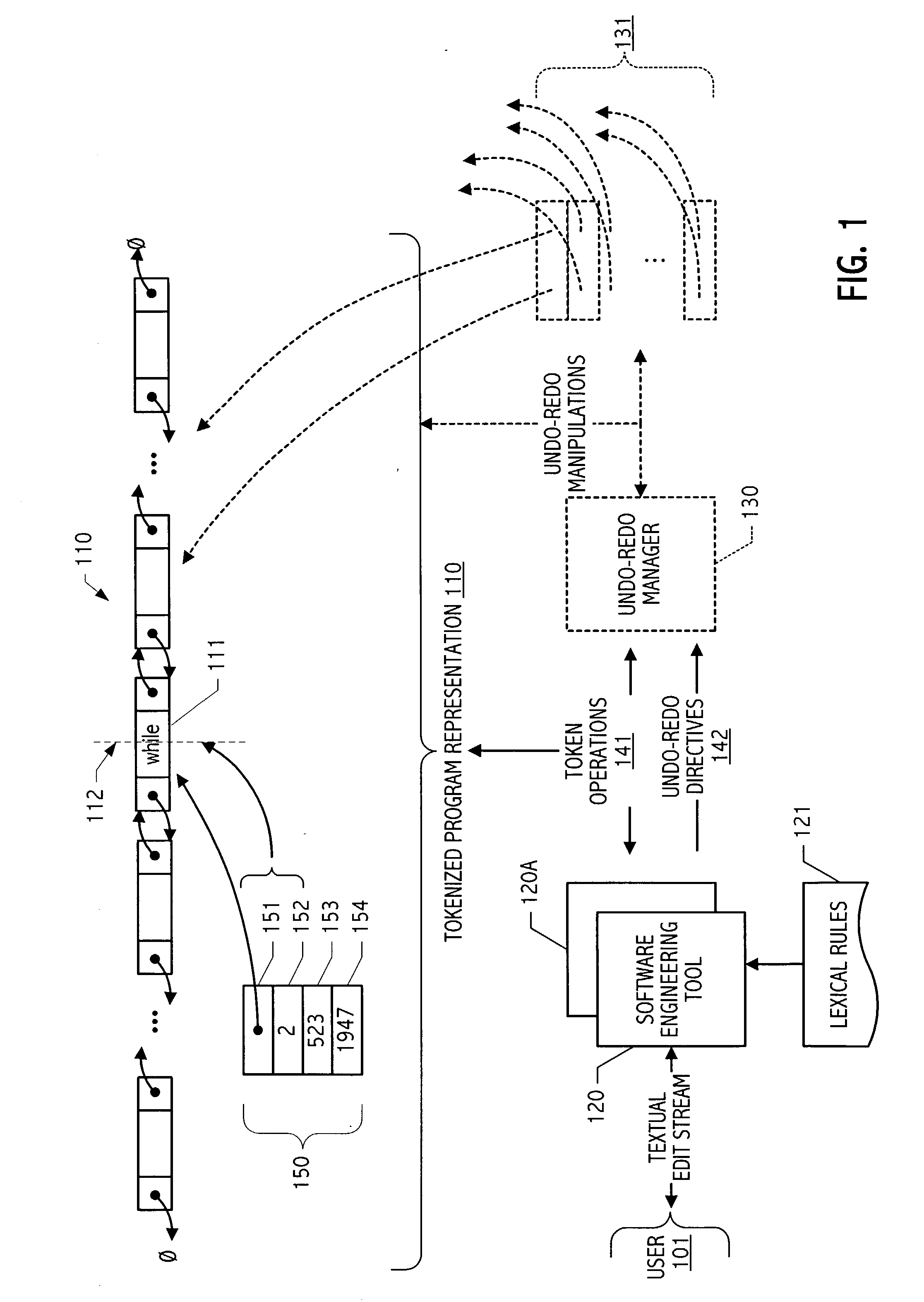

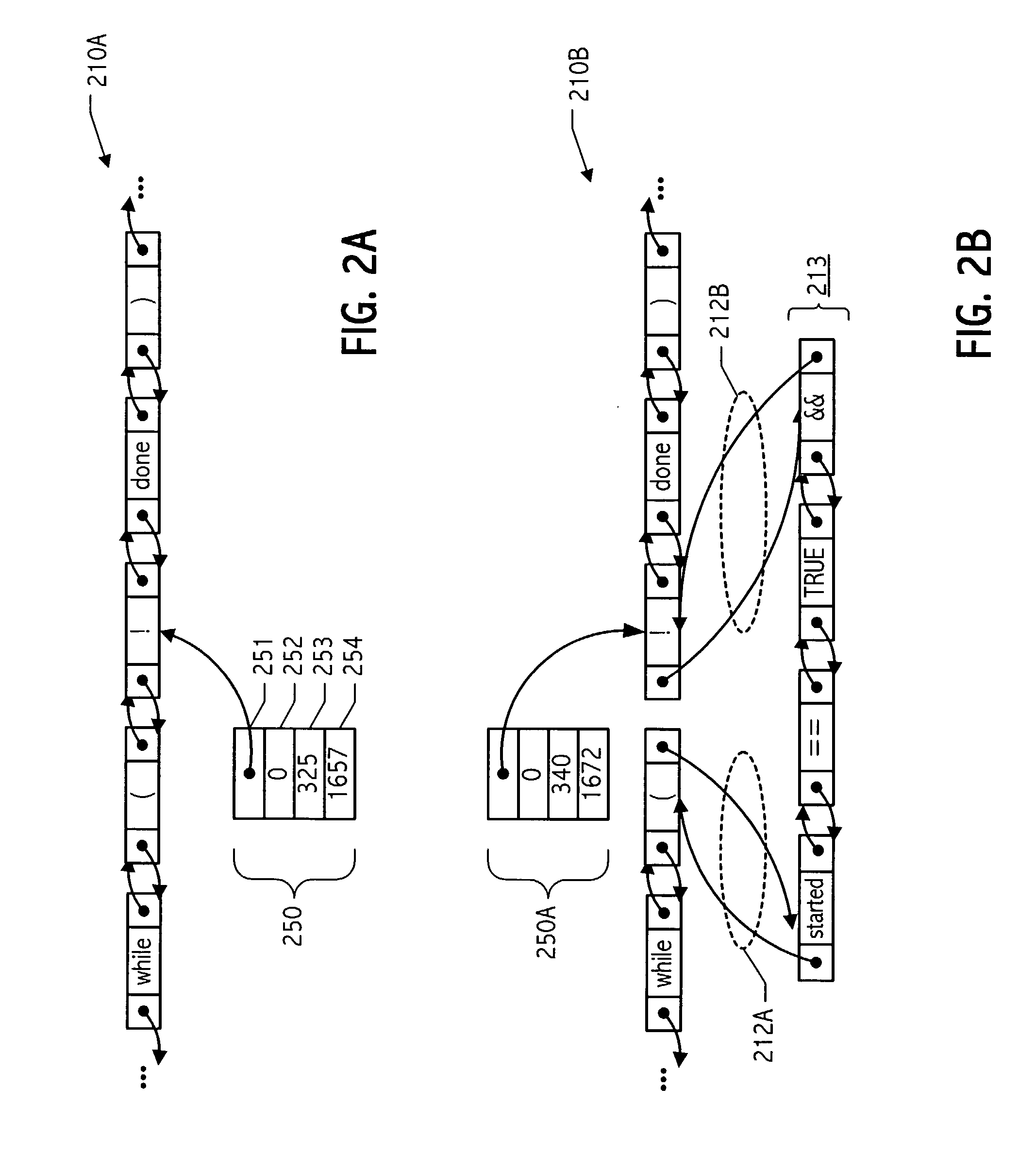

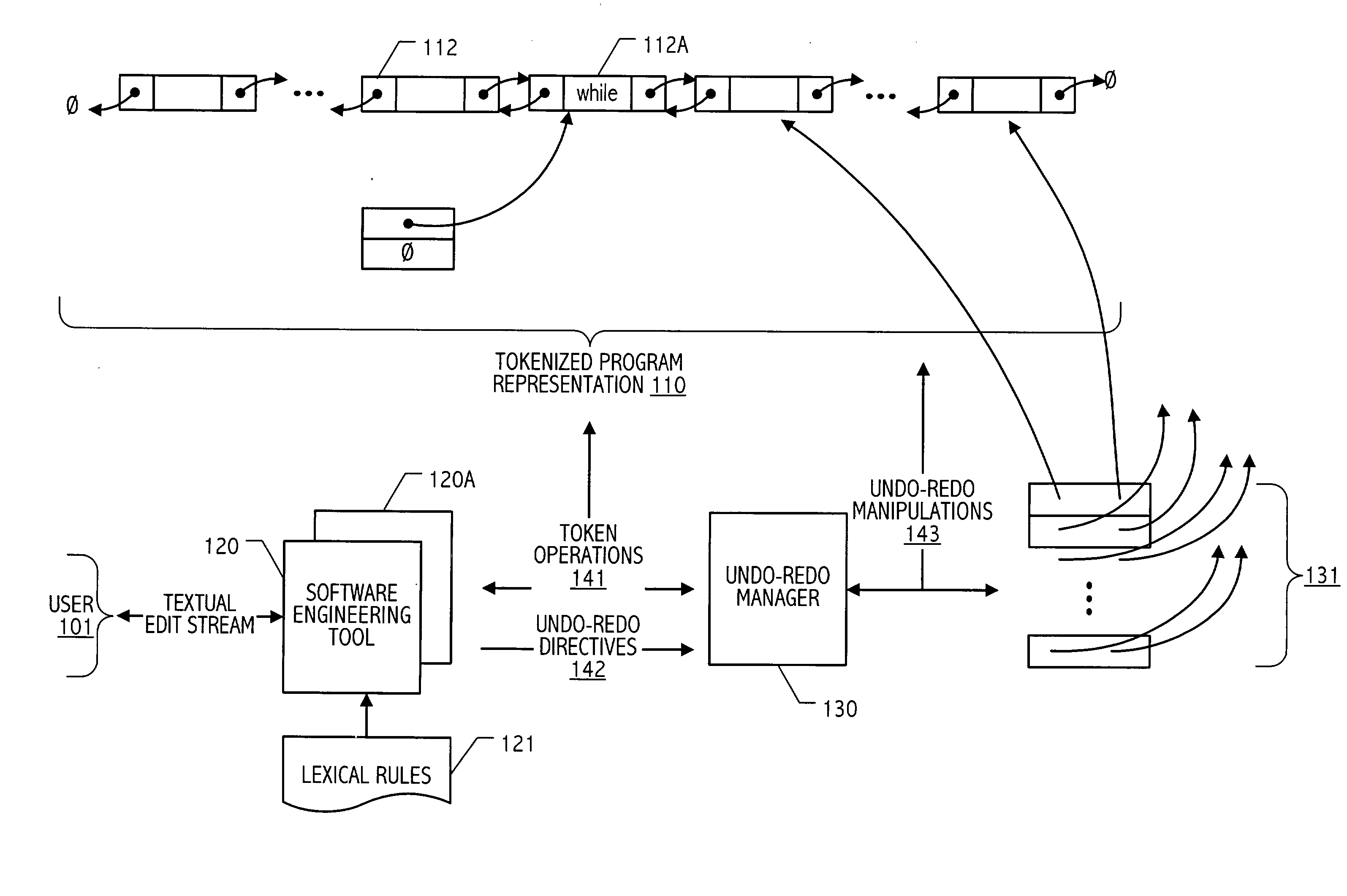

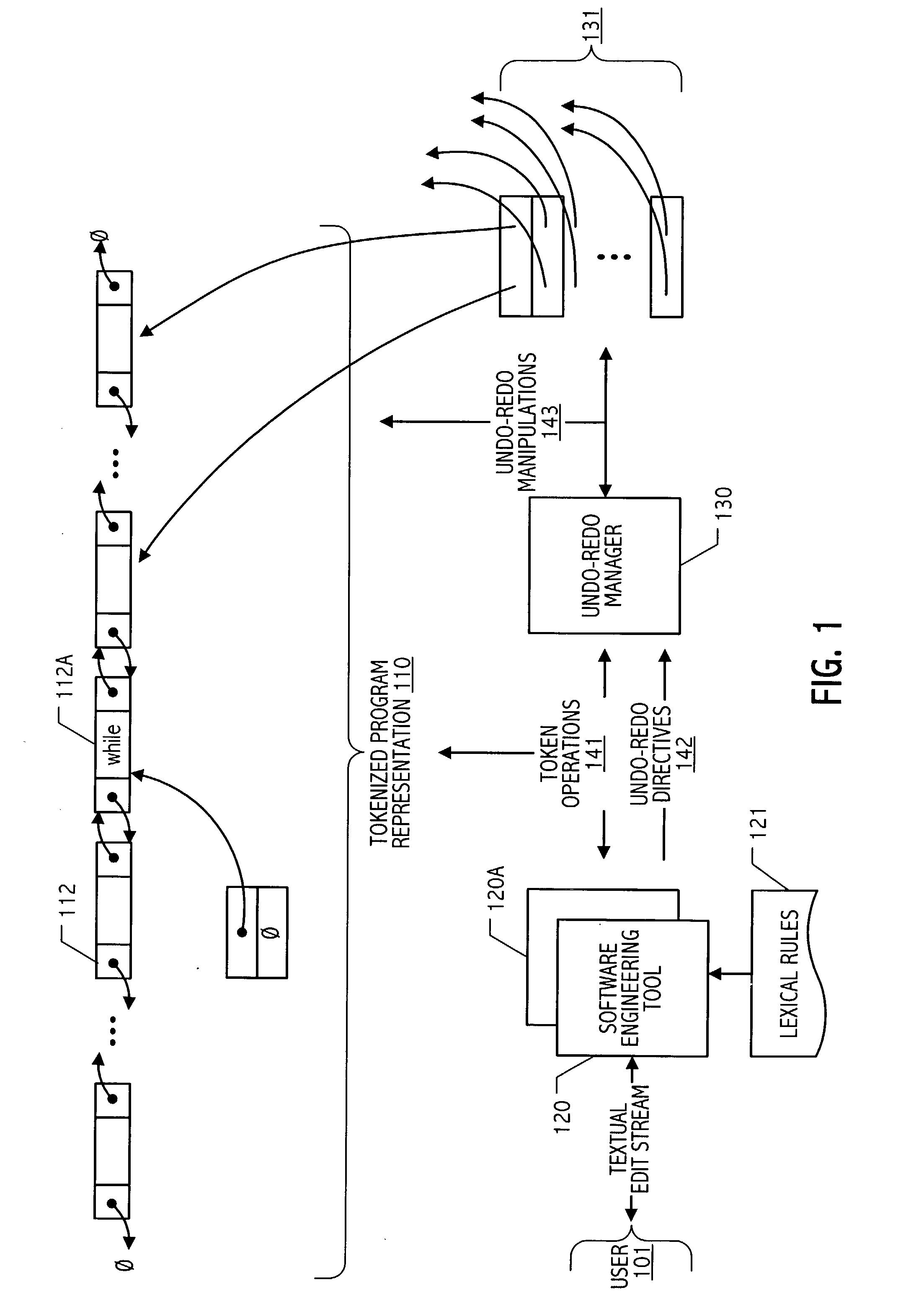

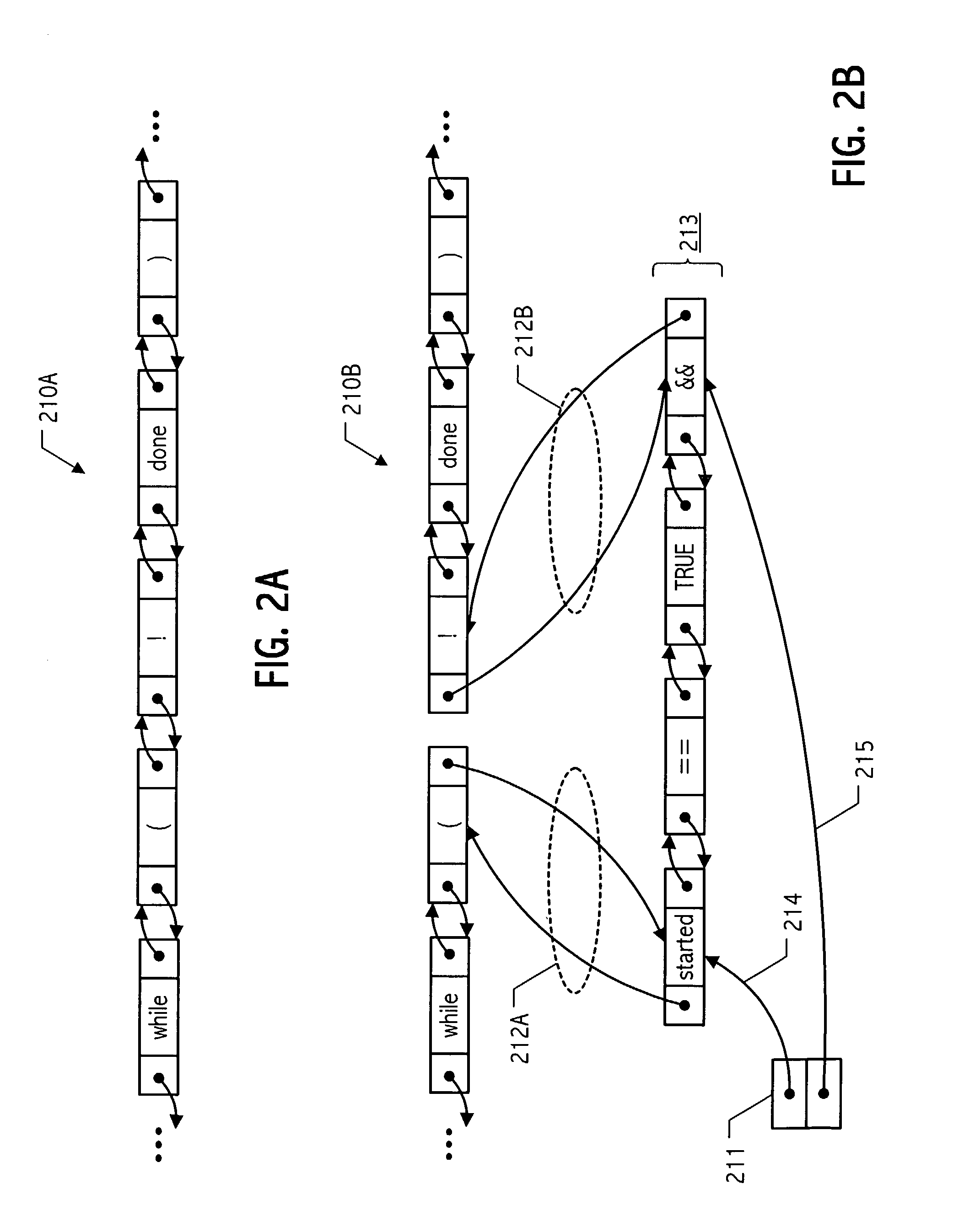

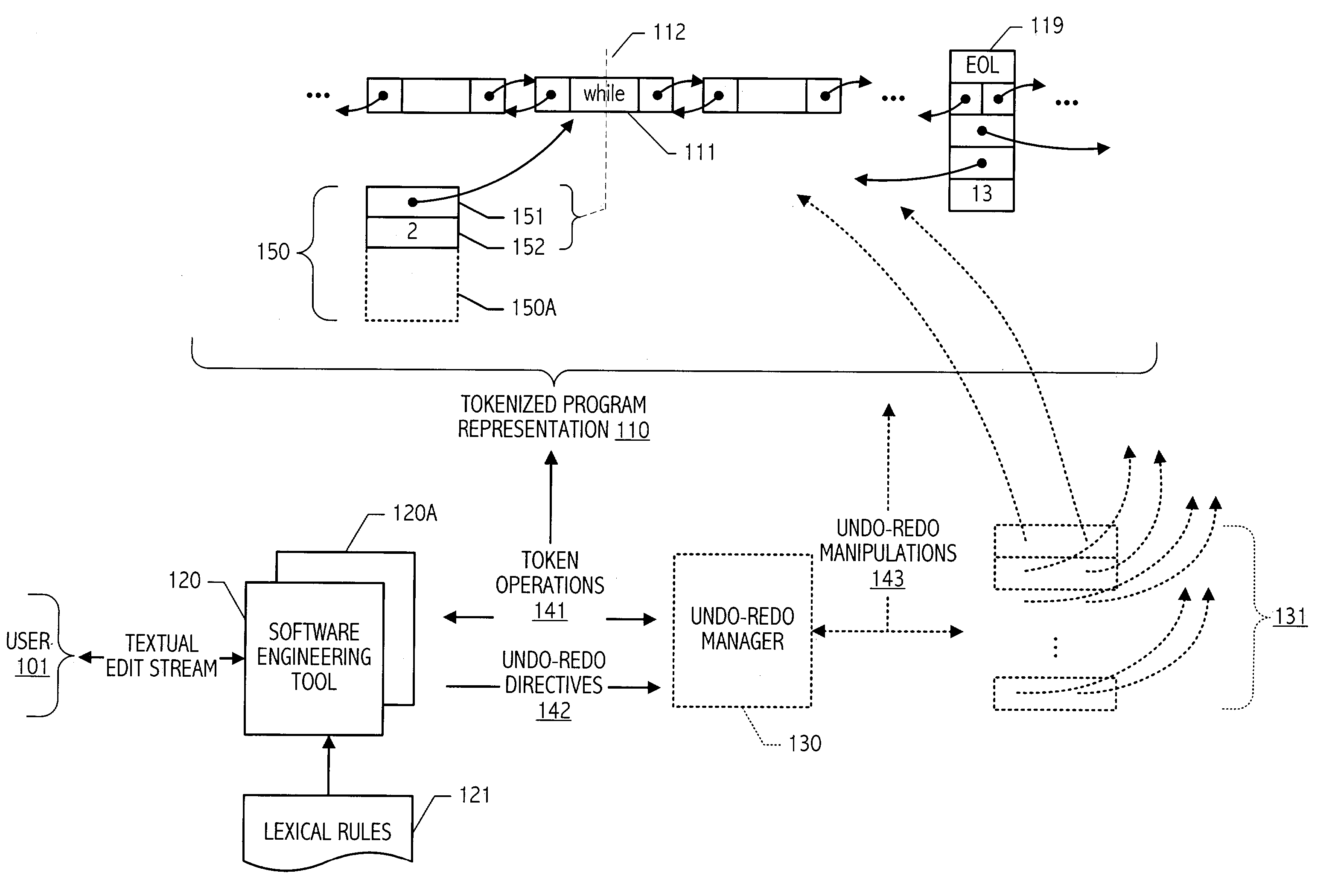

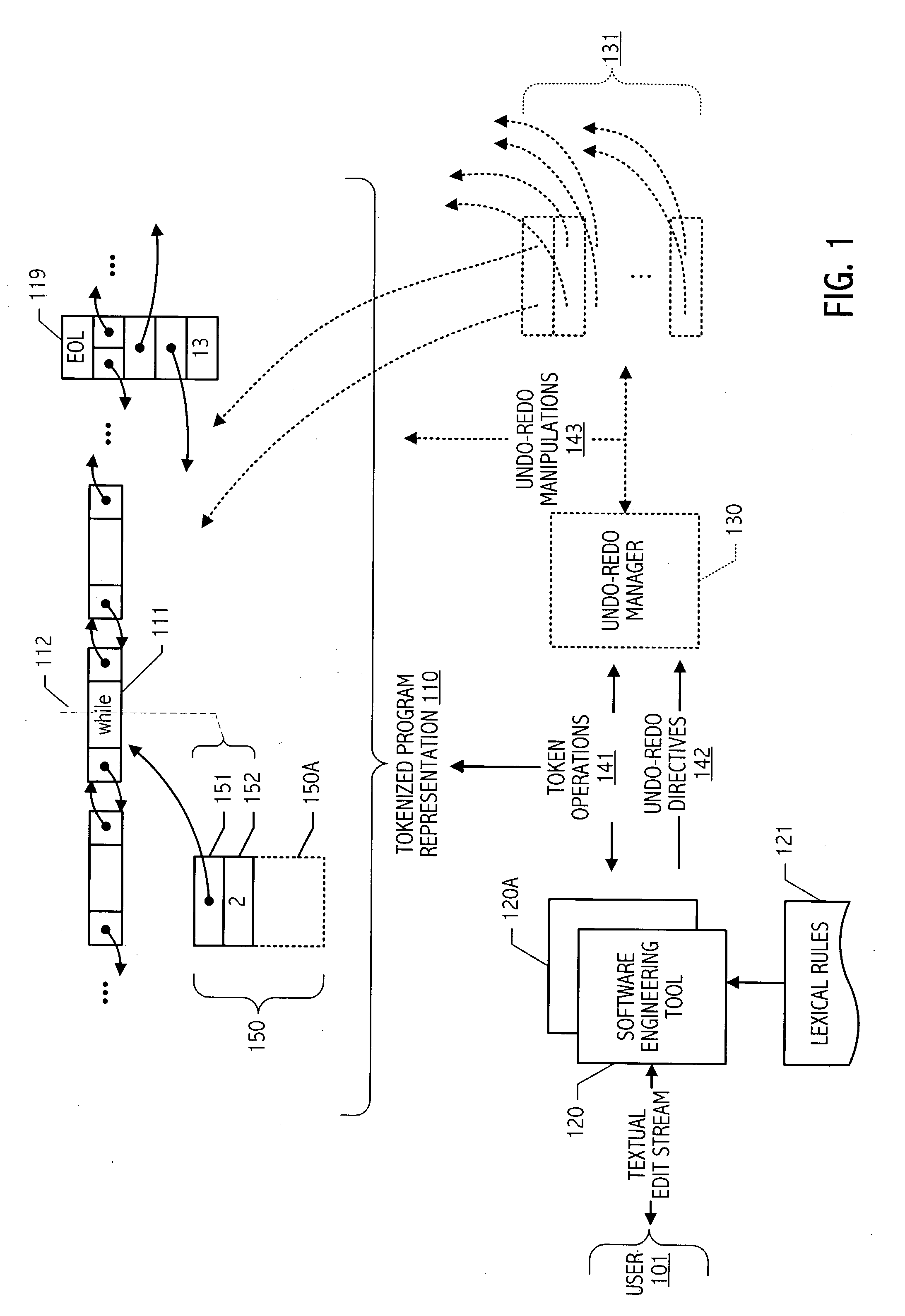

Undo/redo technique with insertion point state handling for token-oriented representation of program code

InactiveUS20040006763A1Efficient undo-redo supportNatural language data processingIntelligent editorsEngineering toolInsertion point

An editor or other software engineering tool may be configured to represent program code as an ordered set of lexical tokens and to maintain, coincident with an operation that modifies contents of the set, an undo object that identifies a pre-modification state of an insertion point. Often, the pre-modification state includes both a token coordinates and a character coordinates representation of the insertion point and storage of pre-modification state in, or in association with, the undo object facilitates efficient implementation of a undo operation, e.g., generally without recomputation of a coordinate representation that would otherwise scale with buffer size. In this way, lexical tokens corresponding to an inserted substring can be readily and efficiently excised to restore a pre-insertion tokenized list and insertion point state. Similarly, lexical tokens corresponding to a removed substring can be readily and efficiently reinstated to restore a pre-deletion tokenized list and insertion point state.

Owner:SUN MICROSYSTEMS INC

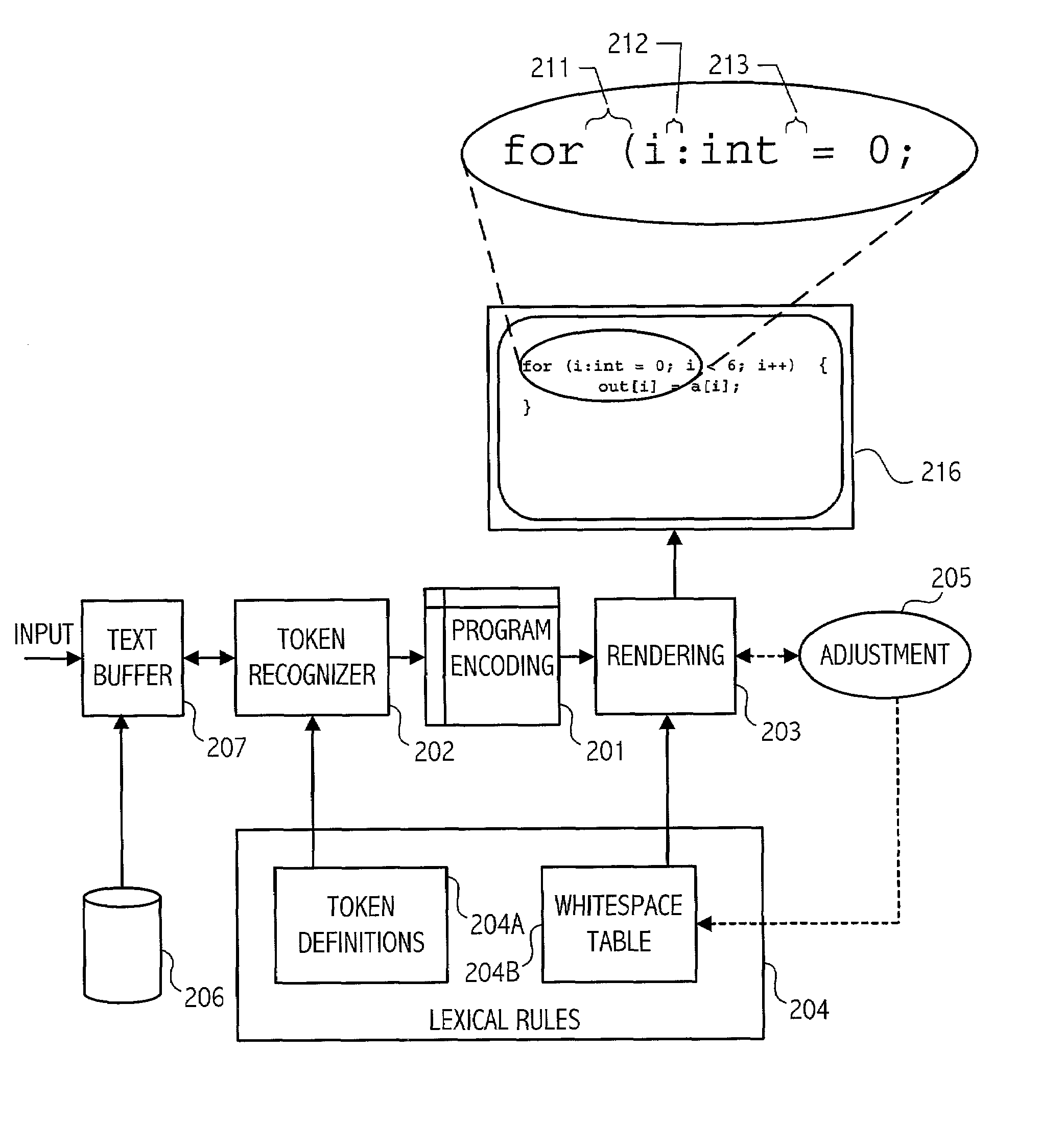

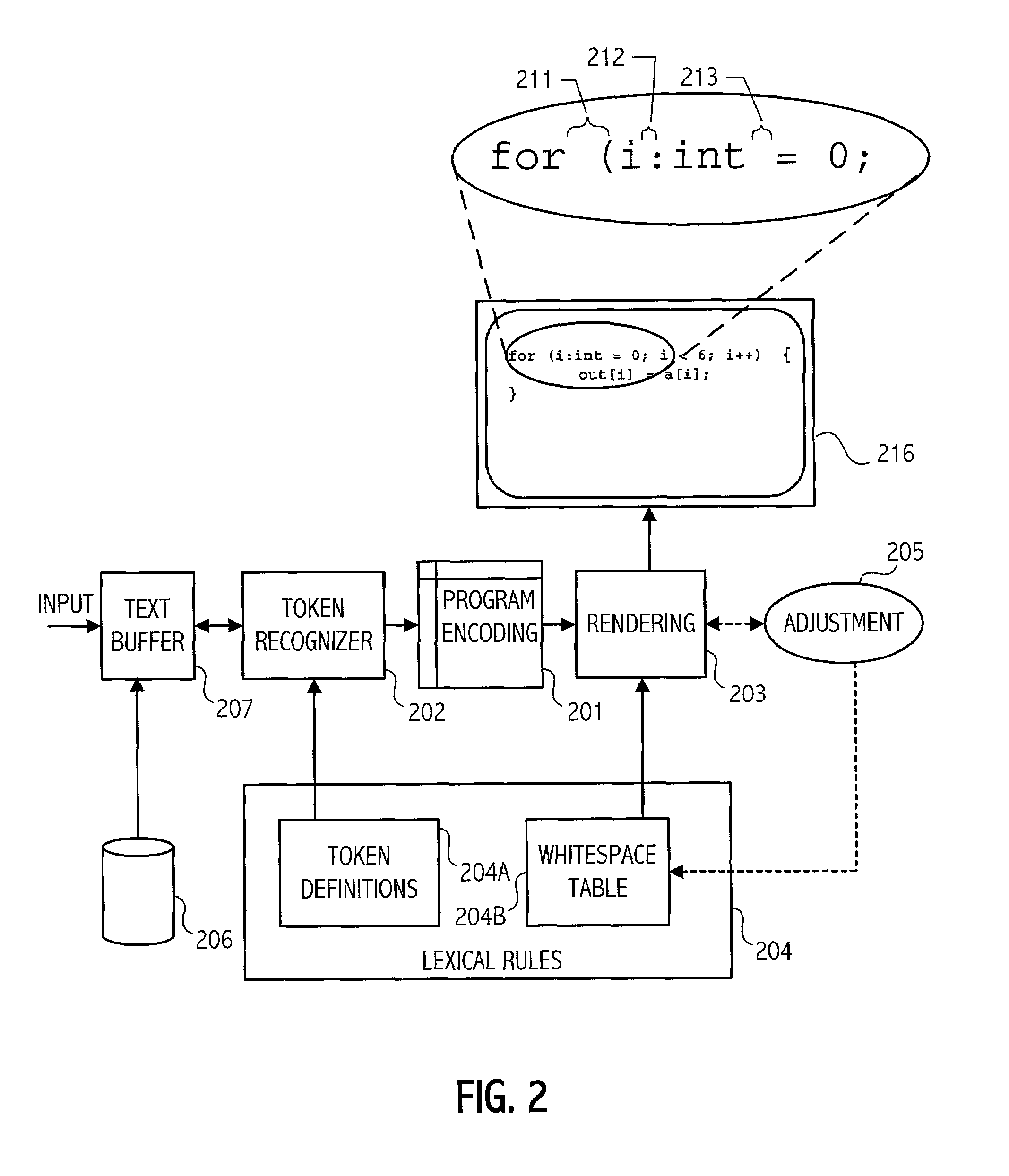

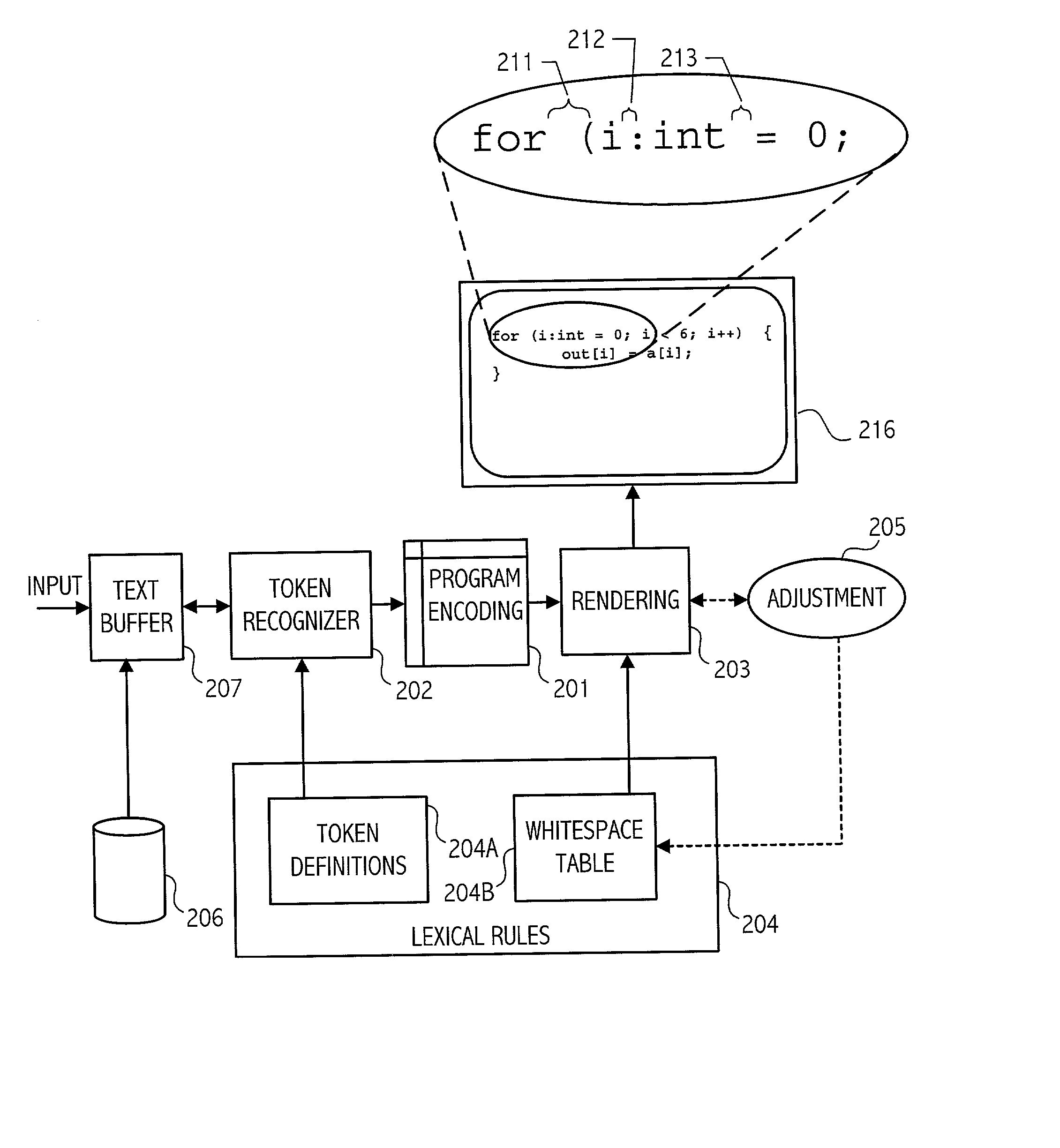

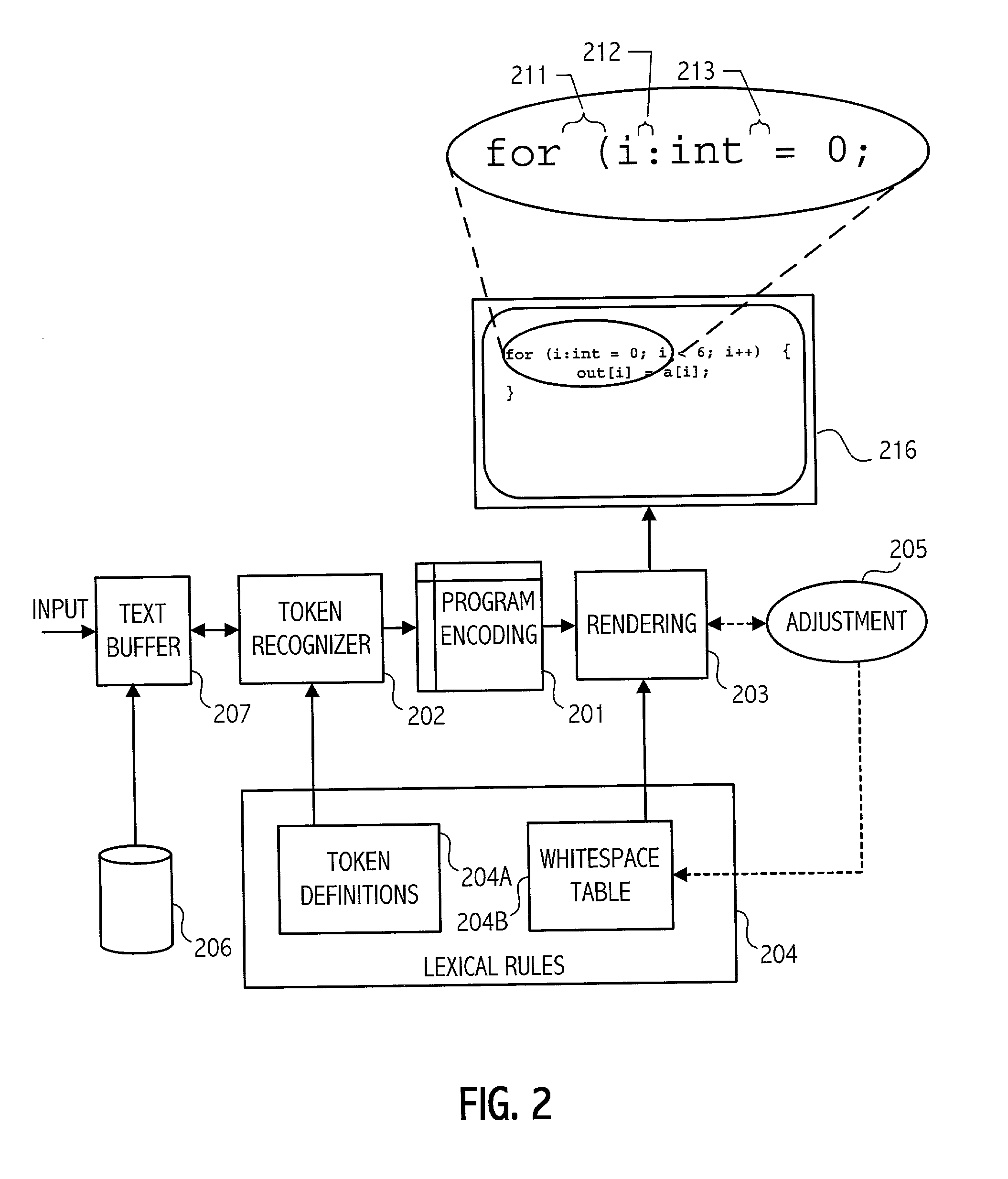

Language-sensitive whitespace adjustment in a software engineering tool

InactiveUS7117479B2Intelligent editorsSpecific program execution arrangementsAlgorithmEngineering tool

An editor or software engineering tool may be configured to render whitespace between adjacent tokens, wherein the amount of whitespace between any two adjacent tokens is determined according to language-specific style rules and scaled in accordance with display considerations. In some realizations, the operative scaling is selected or defined by a user according to the user's visual preferences. In some realizations, the operative scaling relates to requirements or constraints of an automated layout mechanism. For example, a particular scaling may be calculated to adjust line length in conformance with a desired margin alignment or to optimize layout when long lines are automatically wrapped (or folded) in some automatic way.

Owner:ORACLE INT CORP

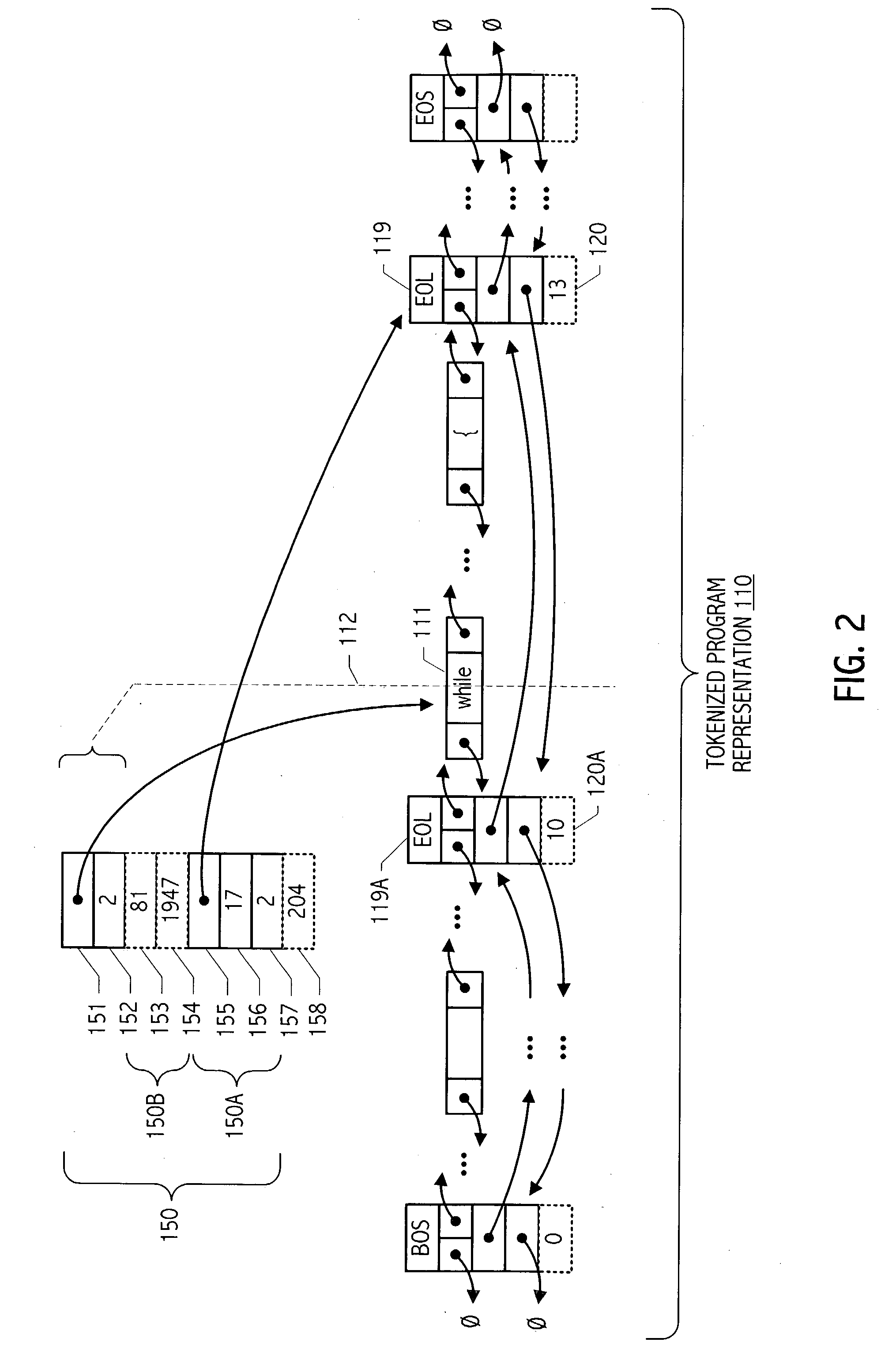

Undo/Redo technique with computed of line information in a token-oriented representation of program code

InactiveUS20040225998A1Efficient undo-redo supportIntelligent editorsSpecific program execution arrangementsEngineering toolInsertion point

An editor, software engineering tool or collection of such tools may be configured to encode (or employ an encoding of) an insertion point representation that identifies a particular token of a token-oriented representation and offset thereinto, together with at least some line-oriented coordinates. Such a tool (or tools) may be further configured to maintain, coincident with an operation that modifies contents of the token-oriented representation, an undo object that identifies pre-modification line demarcation state. Often, the pre-modification state also includes both a token coordinates and a line-coordinates representation of the insertion point and storage of pre-modification state in, or in association with, the undo object facilitates efficient implementation of a undo operation, e.g., generally without recomputation of a coordinate representation or line demarcation state, which would otherwise scale with buffer size. In this way, lexical tokens corresponding to an inserted substring can be readily and efficiently excised to restore a pre-insertion tokenized list and insertion point state. Similarly, lexical tokens corresponding to a removed substring can be readily and efficiently reinstated to restore a pre-deletion tokenized list and insertion point state.

Owner:SUN MICROSYSTEMS INC

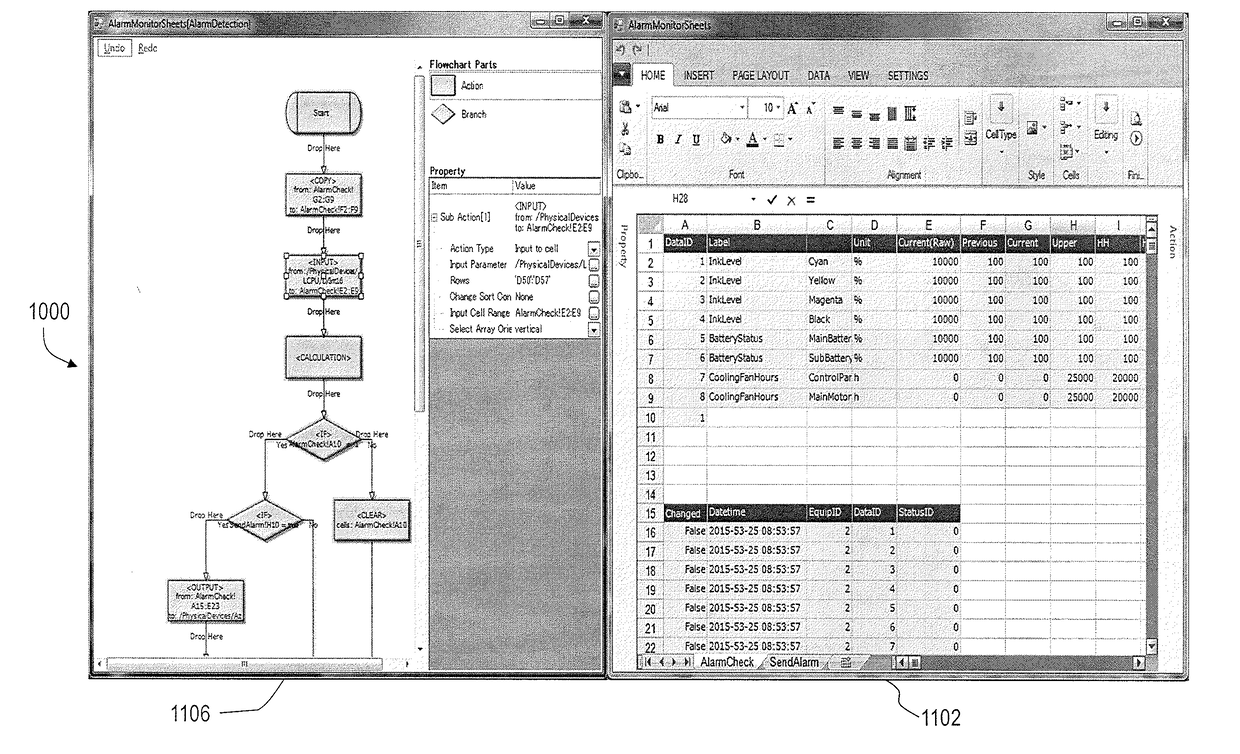

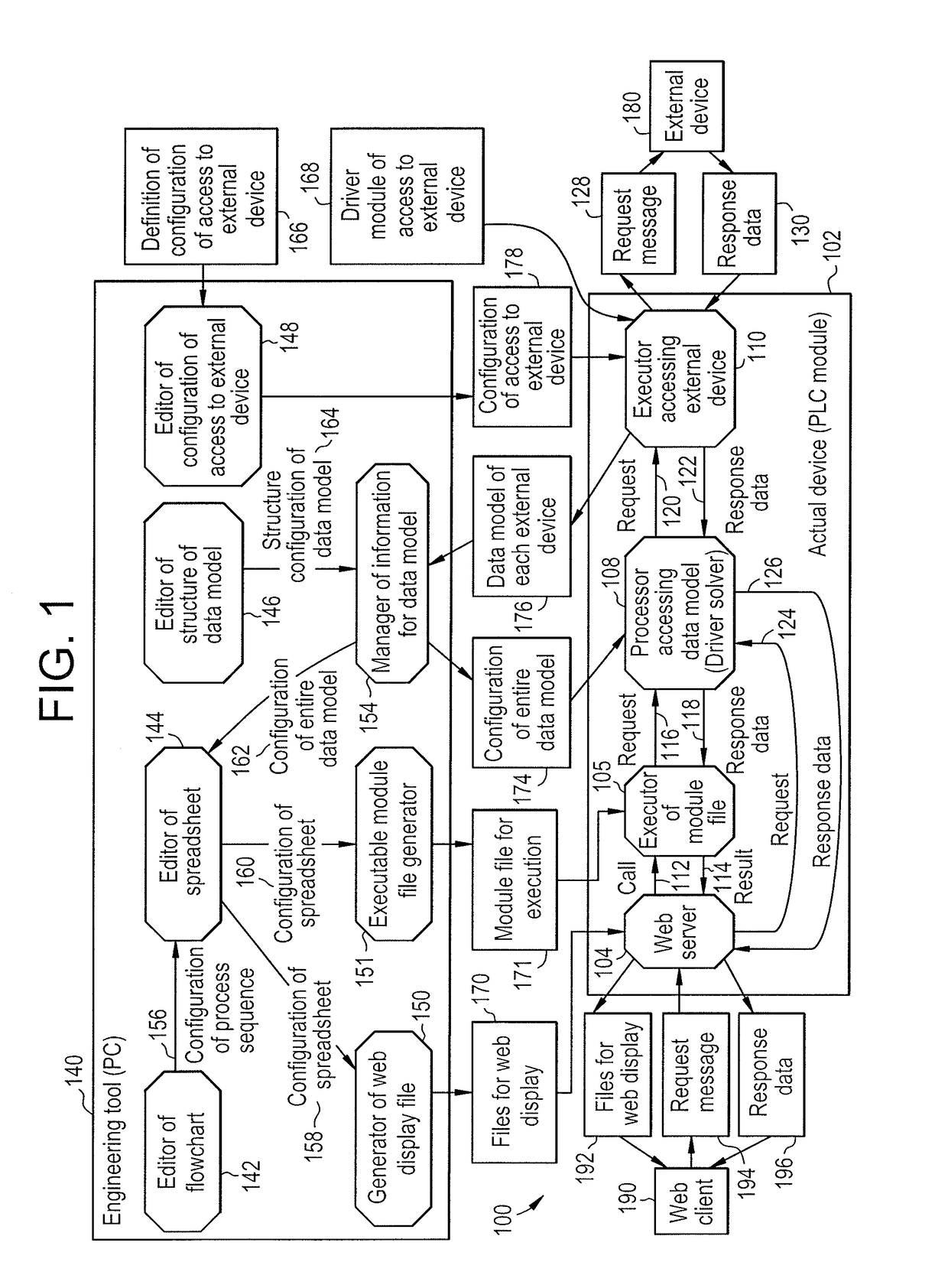

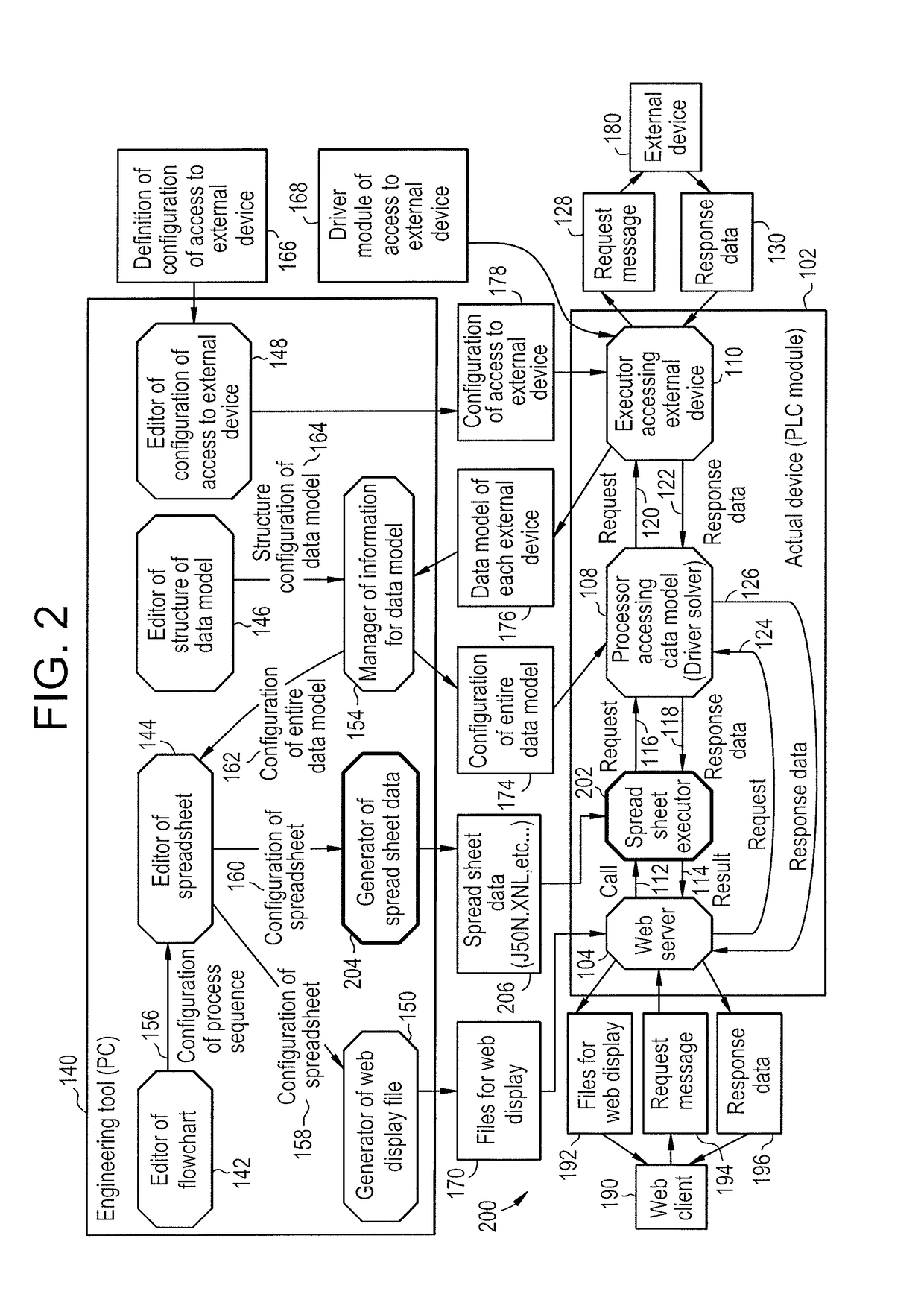

Information-processing equipment based on a spreadsheet

An engineering tool includes a spreadsheet editor configured to display a definition in cells of a spreadsheet, and to edit the definition by setting allocation data of a device to a cell among the cells of the spreadsheet or by setting a calculation defined in some cells among the cells of the spreadsheet in reference to other cells among the cells of the spreadsheet; and an executable module file generator configured to generate, based on the edited definition, an executable module file configured to be executed in an execution environment of a controller in order for the controller to control the device.

Owner:MITSUBISHI ELECTRIC CORP

Language-sensitive whitespace adjustment in a software engineering tool

ActiveUS20030066058A1Intelligent editorsSpecific program execution arrangementsAlgorithmEngineering tool

An editor or software engineering tool may be configured to render whitespace between adjacent tokens, wherein the amount of whitespace between any two adjacent tokens is determined according to language-specific style rules and scaled in accordance with display considerations. In some realizations, the operative scaling is selected or defined by a user according to the user's visual preferences. In some realizations, the operative scaling relates to requirements or constraints of an automated layout mechanism. For example, a particular scaling may be calculated to adjust line length in conformance with a desired margin alignment or to optimize layout when long lines are automatically wrapped (or folded) in some automatic way.

Owner:ORACLE INT CORP

Novel tubular hard surfacing material

ActiveCN101380698ANot easy to fall offImprove wear resistanceWelding/cutting media/materialsSoldering mediaEngineering toolAlloy

The invention provides a novel tubular hard-surface resurfacing welding material which includes a tubular skin and filling powder. The novel tubular hard surface resurfacing welding material includes the components as follows: 20 to 40 percent of steel as well as 60 to 80 percent of filling powder; the components of the filling powder is as follows: 35 to 75 percent of spherical hard alloy grains, 15 to 40 percent of carbonated casting tungsten grains, the surface of which are processed, 5 to 20 percent of spherical carbonated casting tungsten grains, 2 to 6 percent of SiMn alloy powder, 0.2 to 0.6 percent of resin powder as well as 0.1 to 2 percent of metal Nb. The spherical hard alloy grains, the carbonated casting tungsten grains and the spherical carbonated casting tungsten grains with thermal stability are adopted, thus remarkably improving the wear resistance and the impact resistance of a resurfacing welding layer; less Nb element is added to improve the resurfacing welding manufacturability, thereby improving the intensity and the toughness of a substrate metal, enhancing the anti-impact capacity of the resurfacing welding layer and the fixing capacity to the hard grains as well as prolonging the service life of the resurfacing welding layer. The tubular hard surface resurfacing welding material is widely applied to the wear-resistance reinforcement on the working surfaces like the gear surface of a steel gear roller bit, a back cone, a palm tip and the other engineering tools.

Owner:SHAREATE TOOLS

Token-oriented representation of program code with support for textual editing thereof

InactiveUS20040003373A1Digital computer detailsNatural language data processingTheoretical computer scienceEngineering tool

An editor, software engineering tool or collection of such tools may be configured to encode (or employ an encoding of) an insertion point representation that identifies both a particular token of a token-oriented representation and a character offset thereinto. Efficient implementations of insert, remove and replace operations that employ such a representation are described herein. Computational costs of such operations typically scale at worst with the size of fragments inserted into and / or removed from such a token-oriented representation, rather than with buffer size. Accordingly, such implementations are particularly well-suited to providing efficient support for programming tool environments in which a token stream is updated incrementally in correspondence with user edits.

Owner:SUN MICROSYSTEMS INC

Efficient computation of character offsets for token-oriented representation of program code

InactiveUS20040003374A1Digital computer detailsIntelligent editorsTheoretical computer scienceEngineering tool

An editor, software engineering tool or collection of such tools may be configured to encode (or employ an encoding of) an insertion point in both token-coordinates and character-coordinates. Efficient implementations of insert, remove and replace operations that employ and maintain such a representation are described herein. Some realizations further maintain a total buffer size encoding consistent with each such operations. Computational costs of such operations typically scale at worst with the size of fragments inserted into and / or removed from such a token-oriented representation, rather than with buffer size. Accordingly, such implementations are particularly well-suited to providing efficient support for programming tool environments in which a token stream is updated incrementally in correspondence with user edits.

Owner:SUN MICROSYSTEMS INC

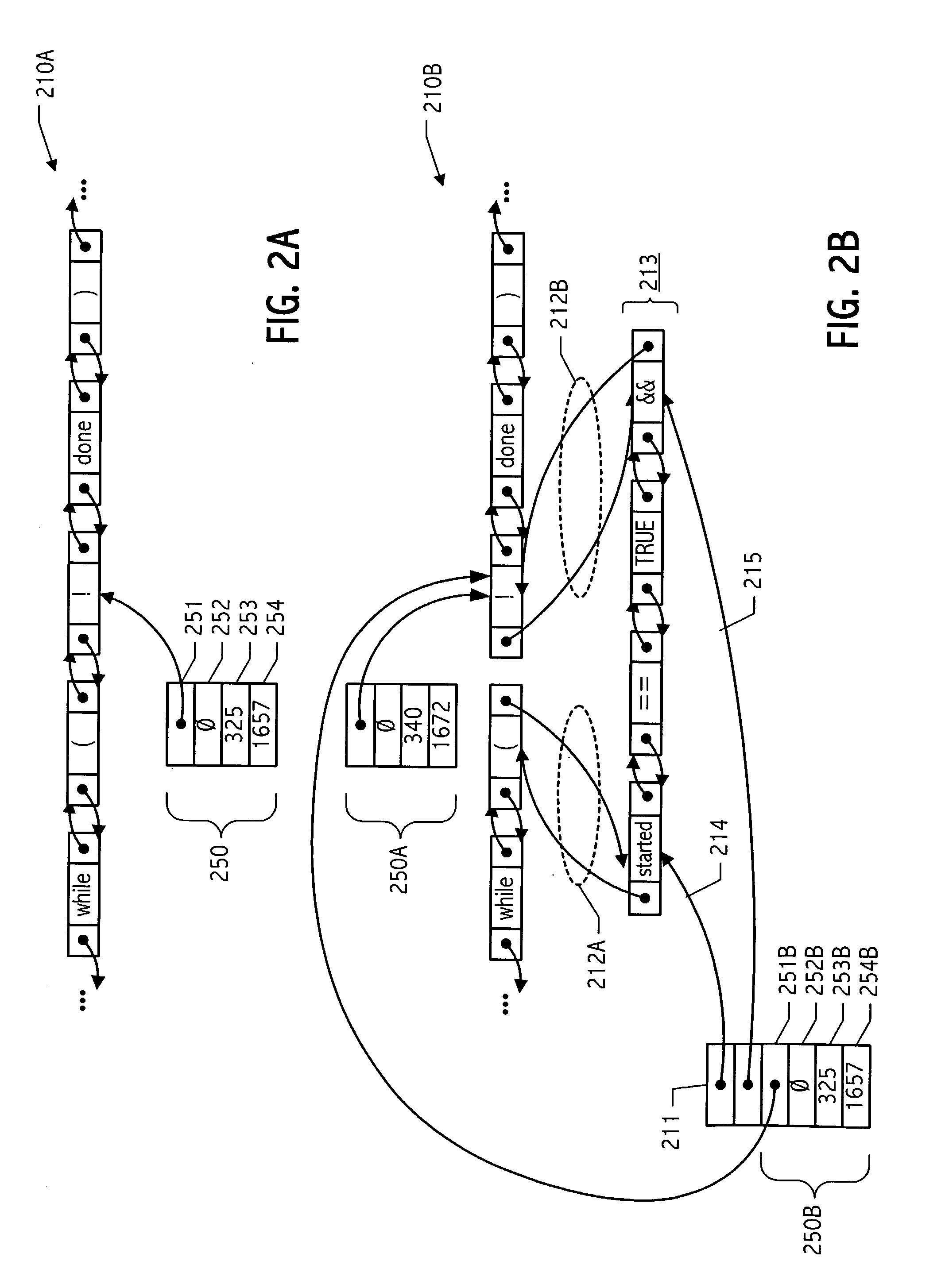

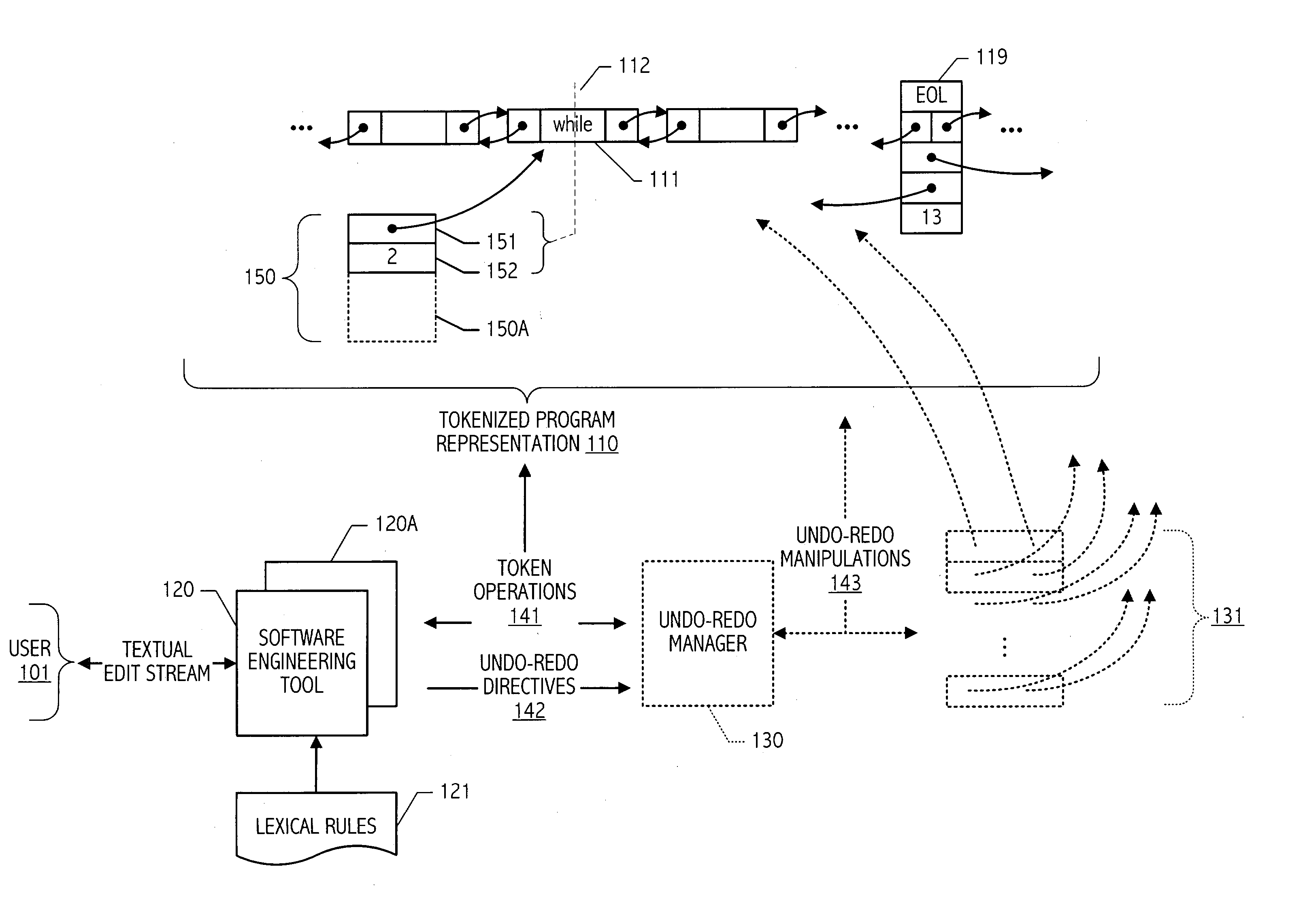

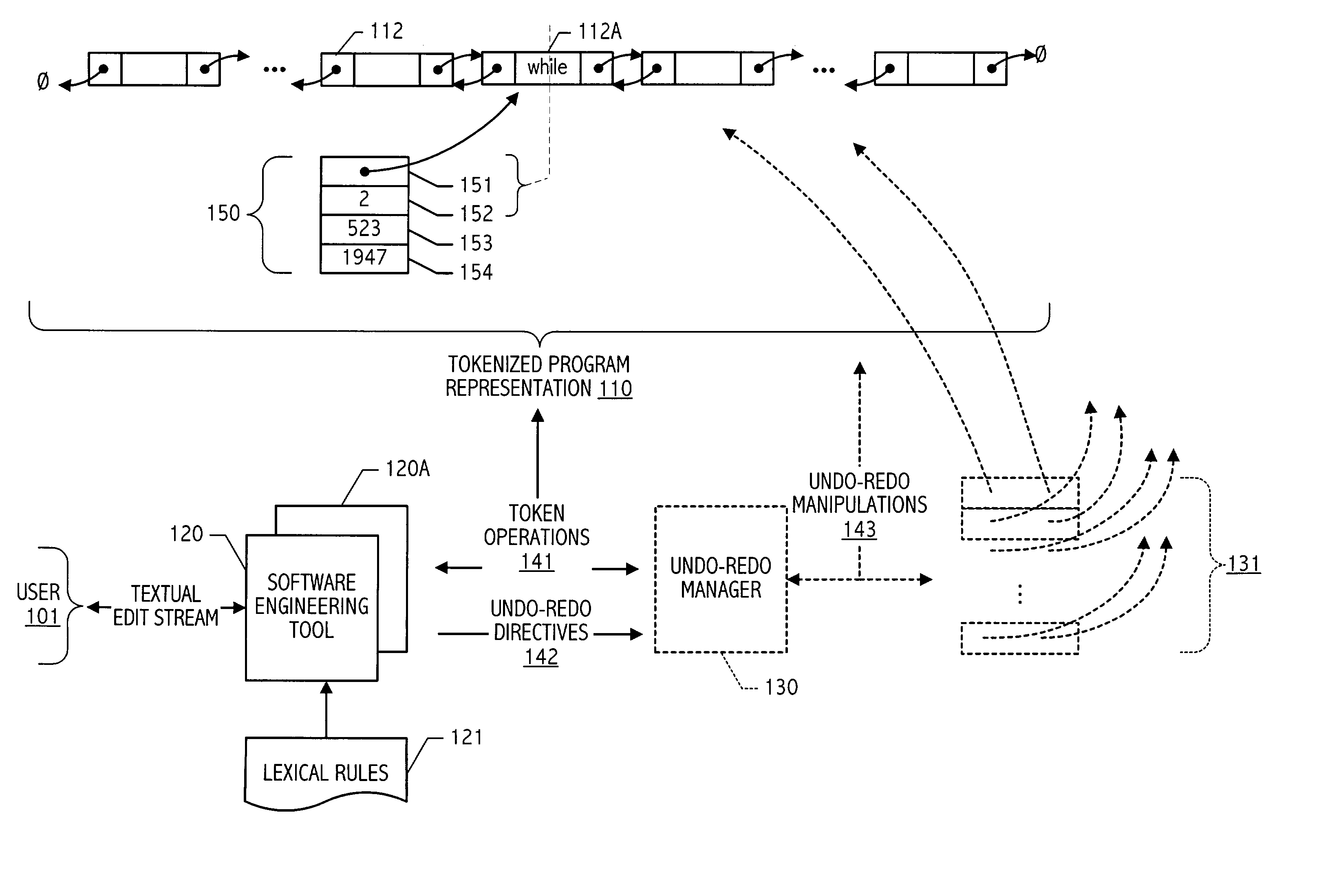

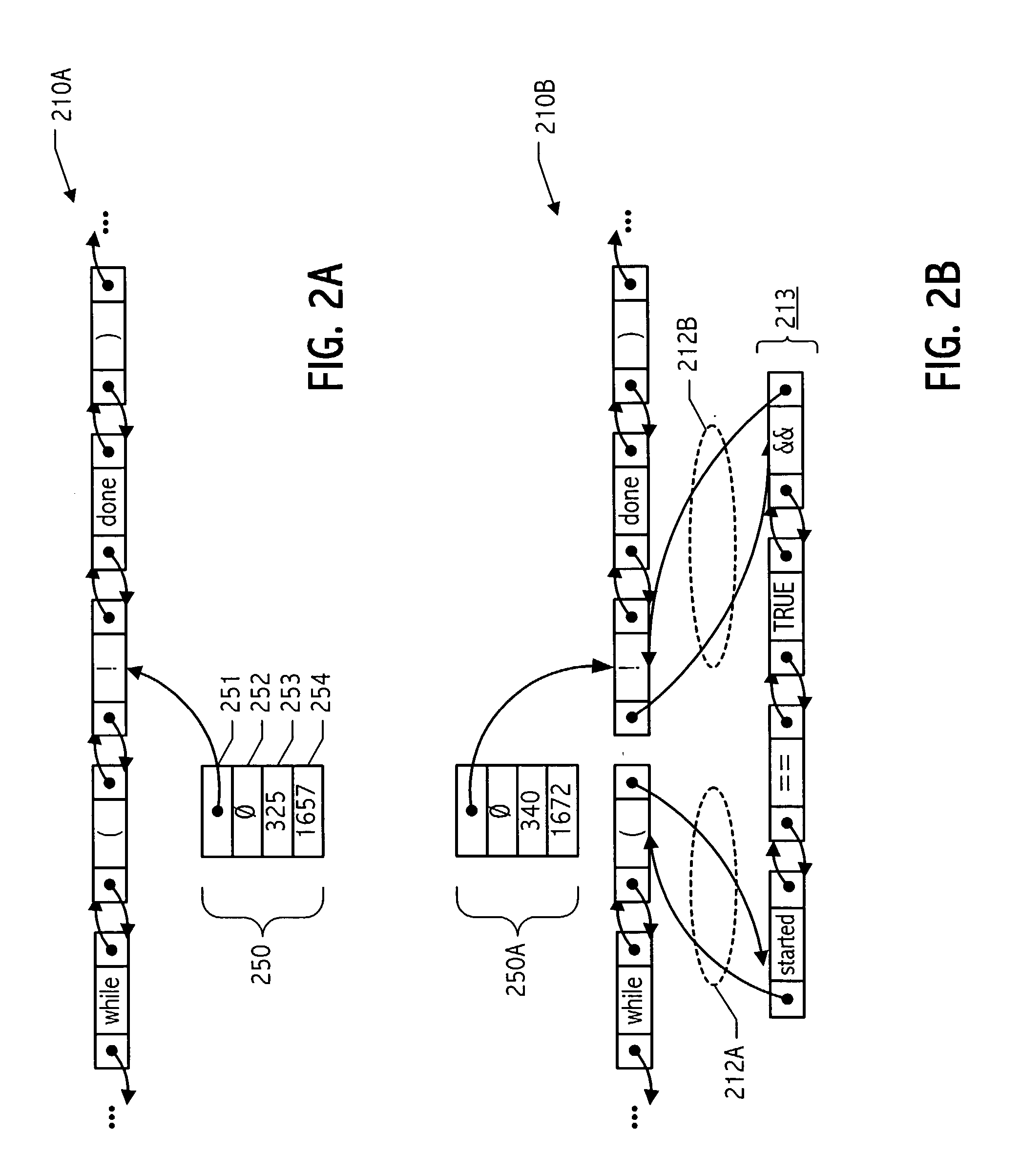

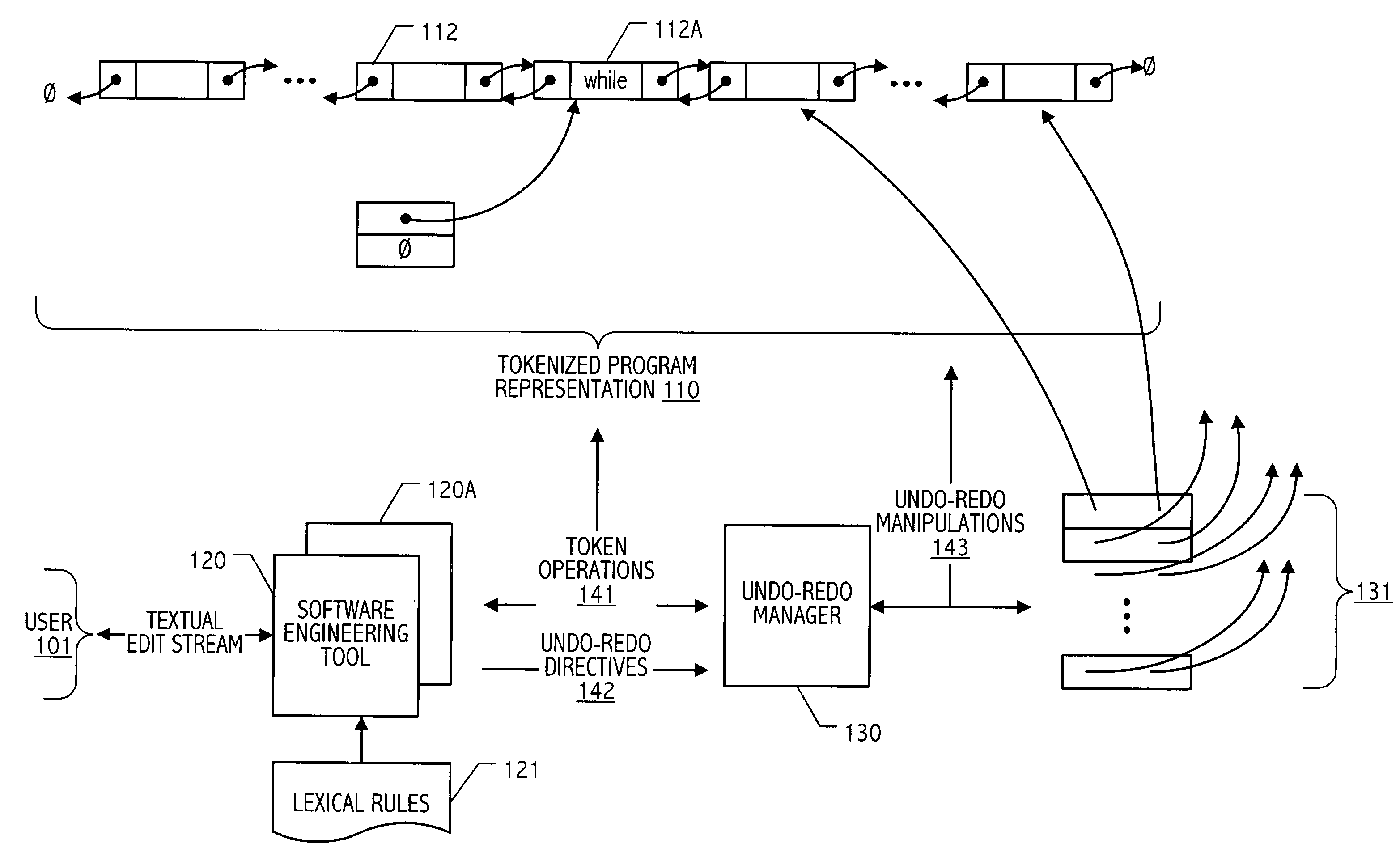

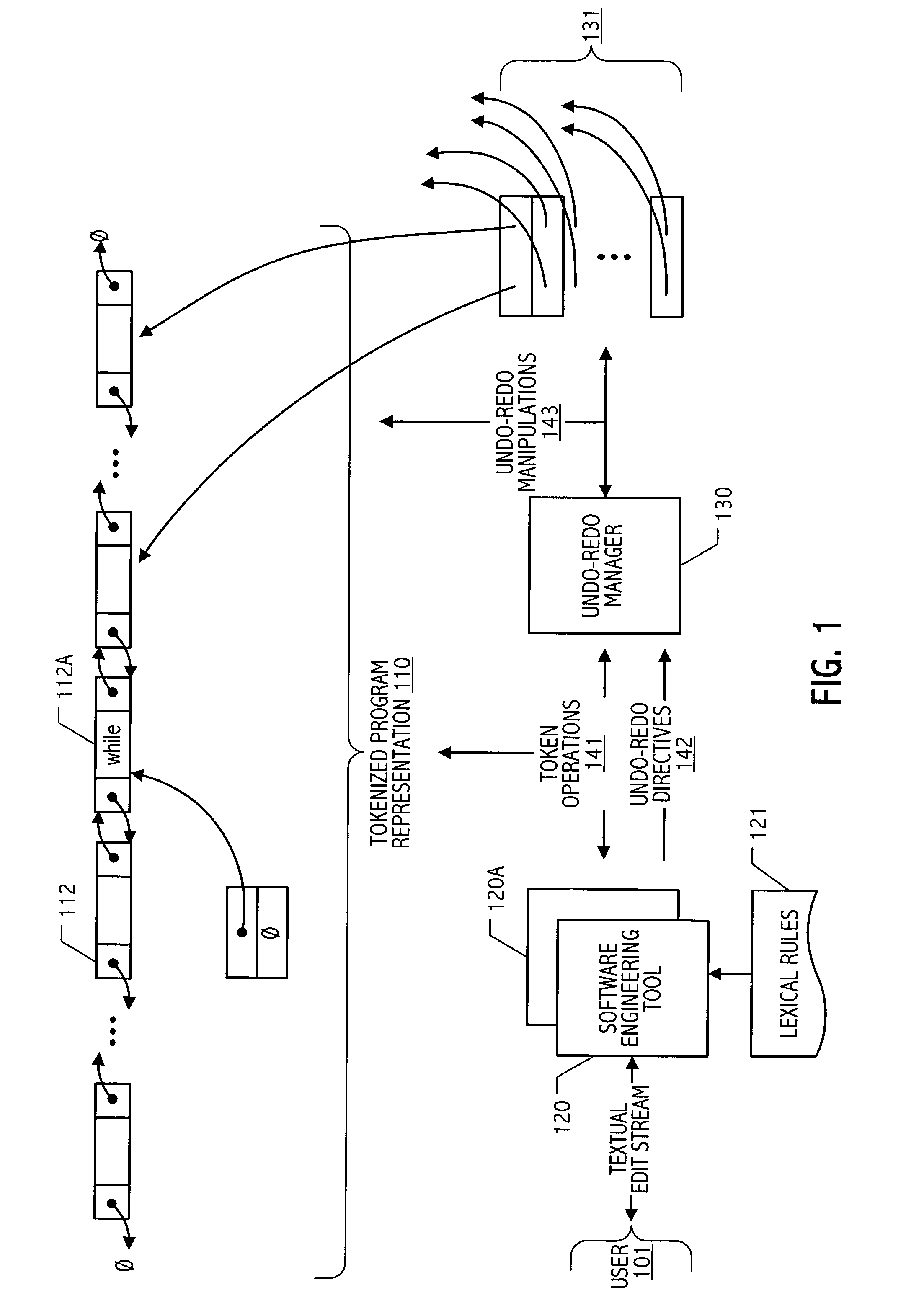

Undo/redo technique for token-oriented representation of program code

ActiveUS20040006764A1Efficient undo-redo supportDigital computer detailsIntelligent editorsEngineering toolDoubly linked list

An editor or software engineering tool may be configured to represent program code as a doubly-linked list of lexical tokens and to maintain, coincident with an operation that modifies contents of the list, an undo object that identifies opposing end nodes of a sublist of one or more lexical tokens corresponding to a substring that is either inserted into or removed from the list by the operation. In this way, lexical tokens corresponding to an inserted substring can be readily and efficiently excised to restore a pre-insertion tokenized list state. Similarly, lexical tokens corresponding to a removed substring can be readily and efficiently reinstated to restore a pre-deletion tokenized list state. Advantageously, undo support once employed to restore a prior tokenized list state is symmetrically available to support redo operations. In some embodiments in accordance with the present invention, undo-redo entries are maintained in an operation ordered set that is traversed to support one or more operations in either the undo or redo directions. In some realizations, such an ordered set of undo-redo entries is maintained by, or in conjunction with, an undo-redo manager.

Owner:ORACLE INT CORP

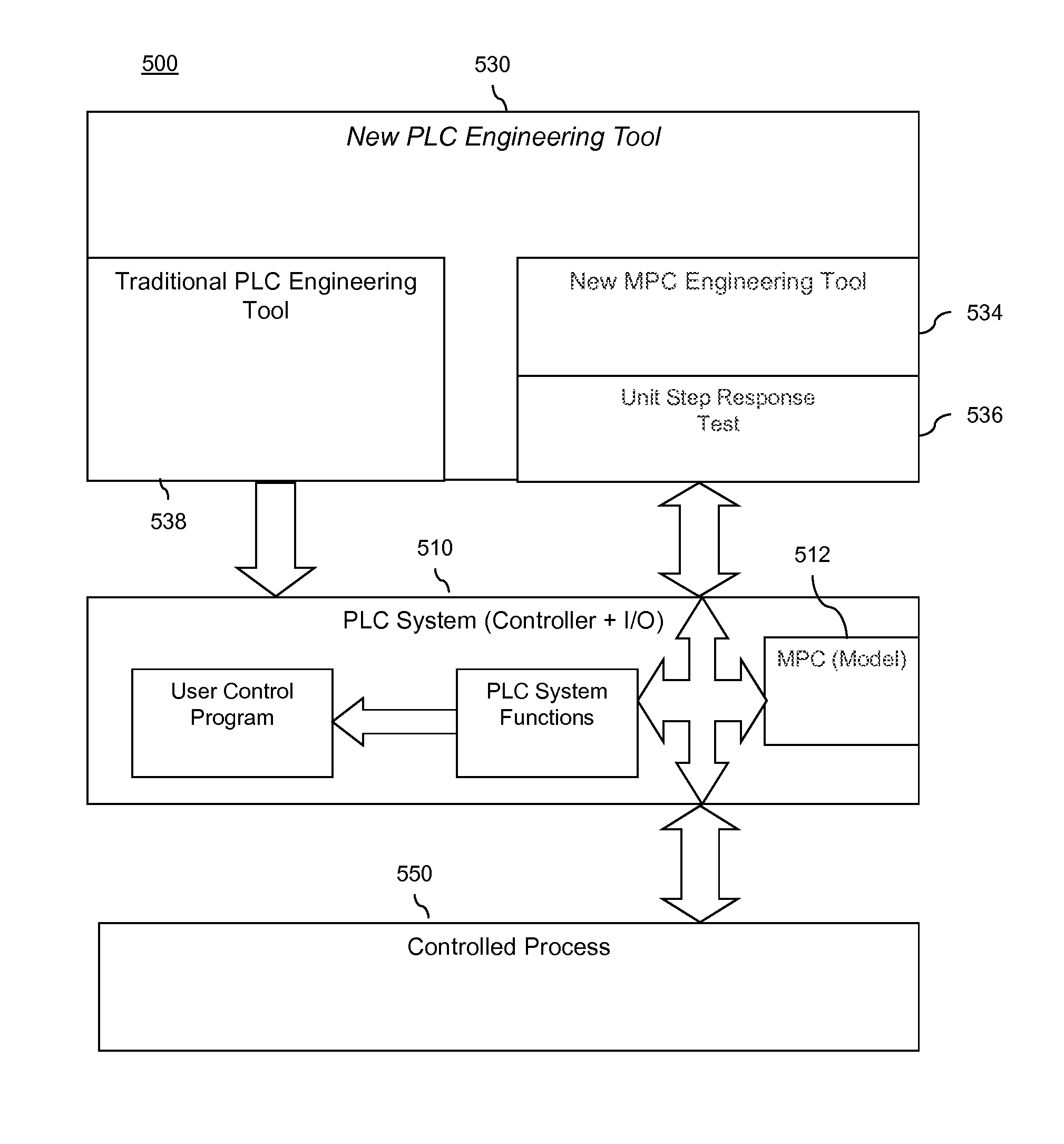

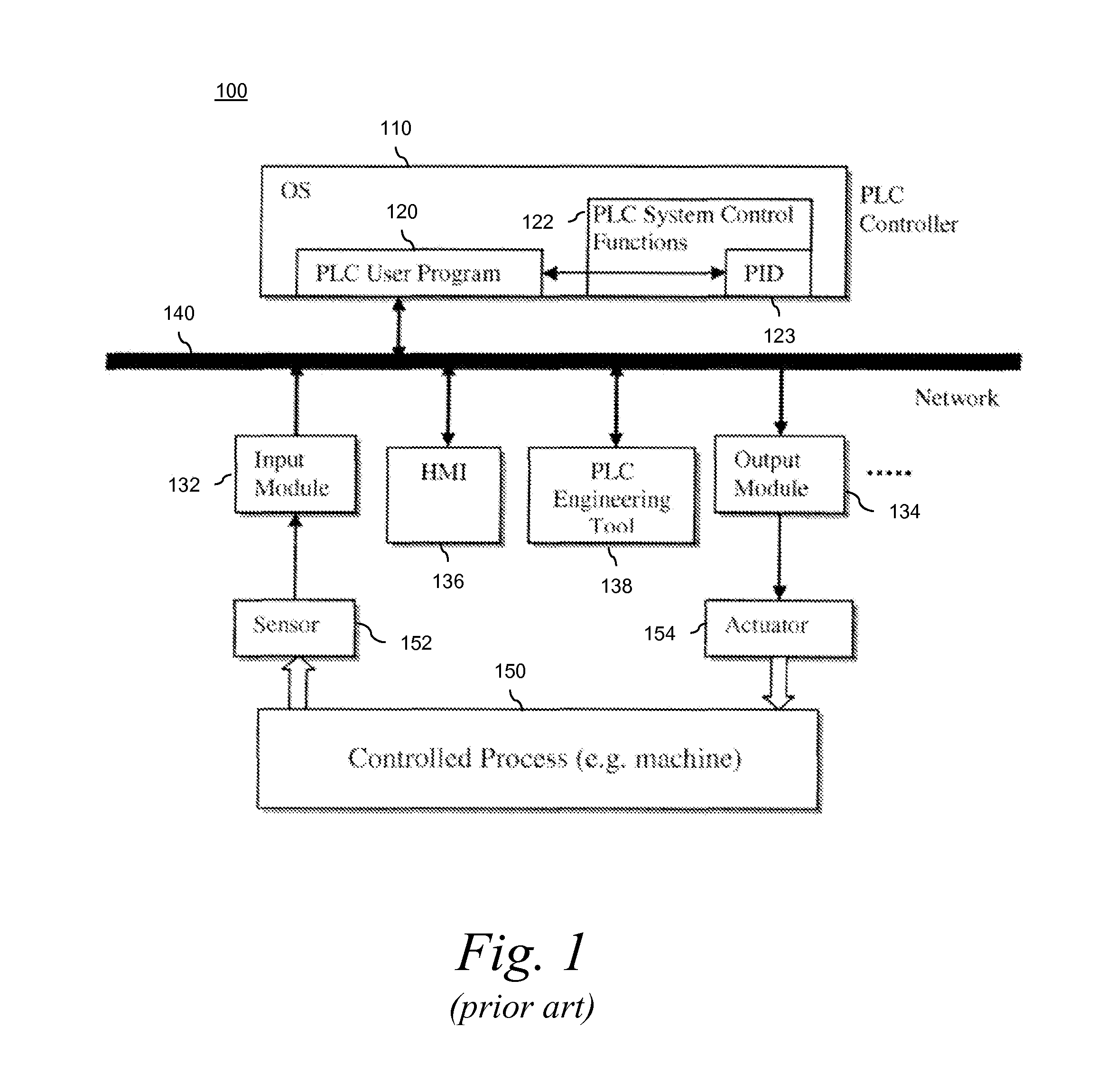

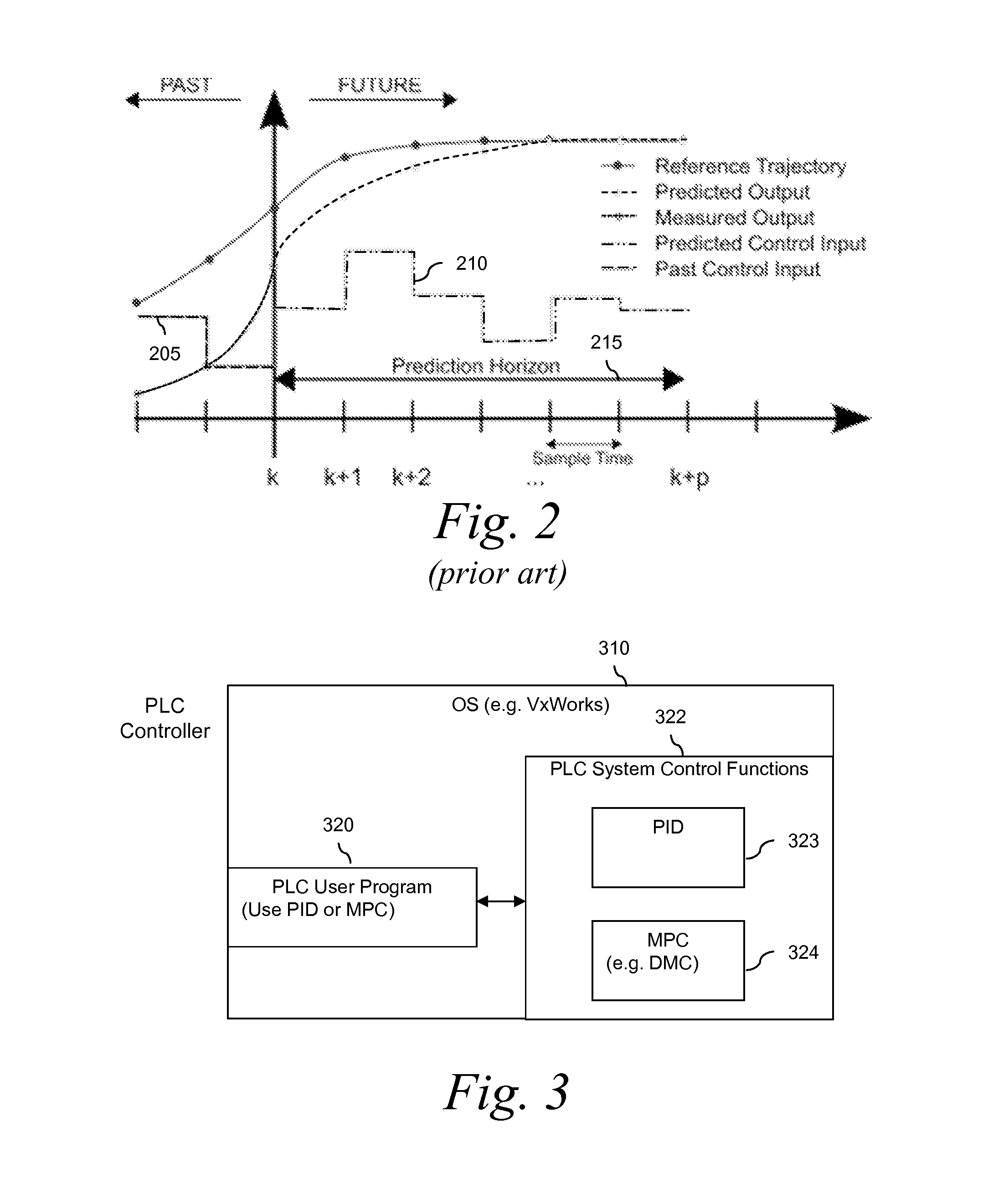

System and method for implementing model predictive control in PLC

A Model Predictive Control (MPC) framework is implemented as part of the run-time system function features of a Programmable Logic Controller (PLC) system. Optimal control calculations are performed in the run-time MPC function block of the PLC. The optimal control function is determined by an MPC block in an engineering tool of the PLC, using a system dynamic matrix containing measurements from a unit step response test performed by the PLC.

Owner:SIEMENS AG

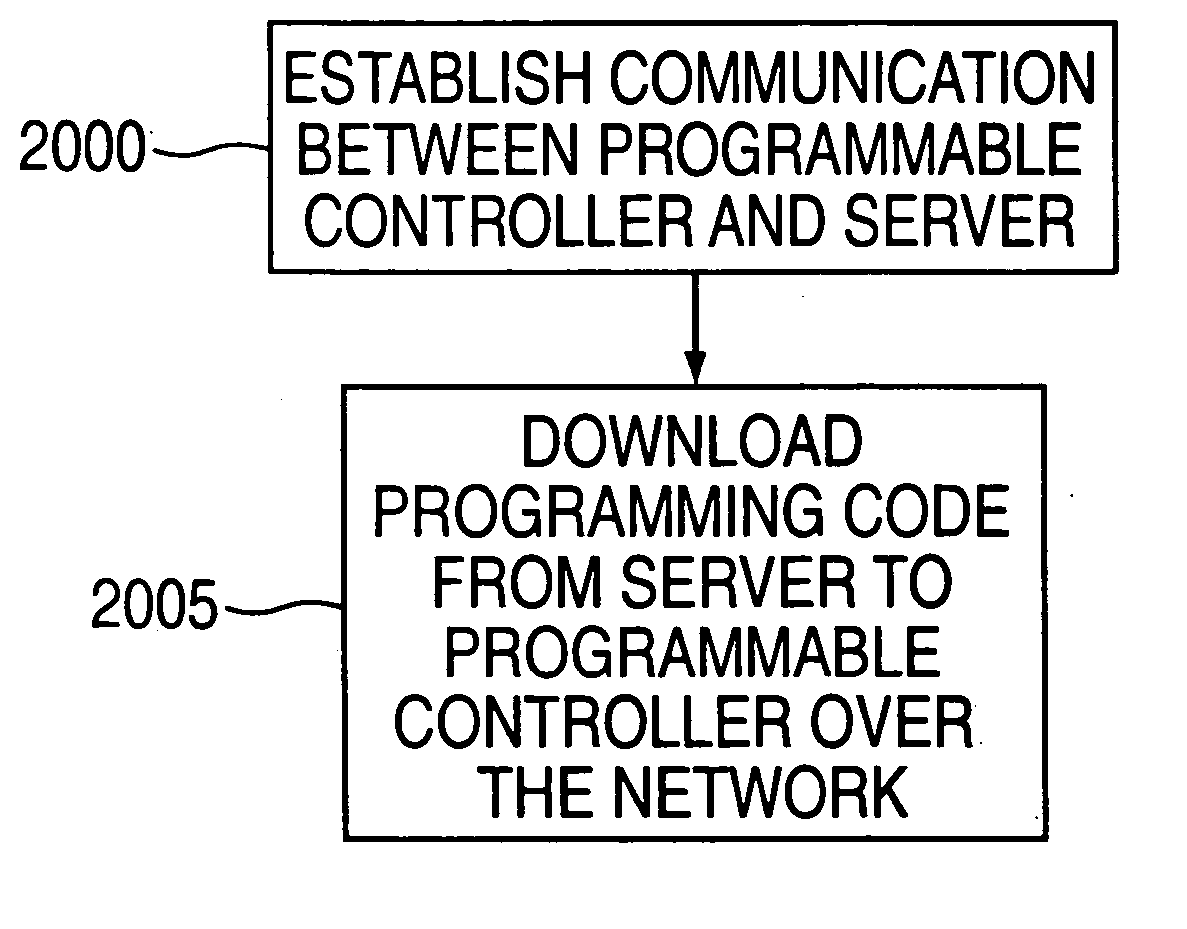

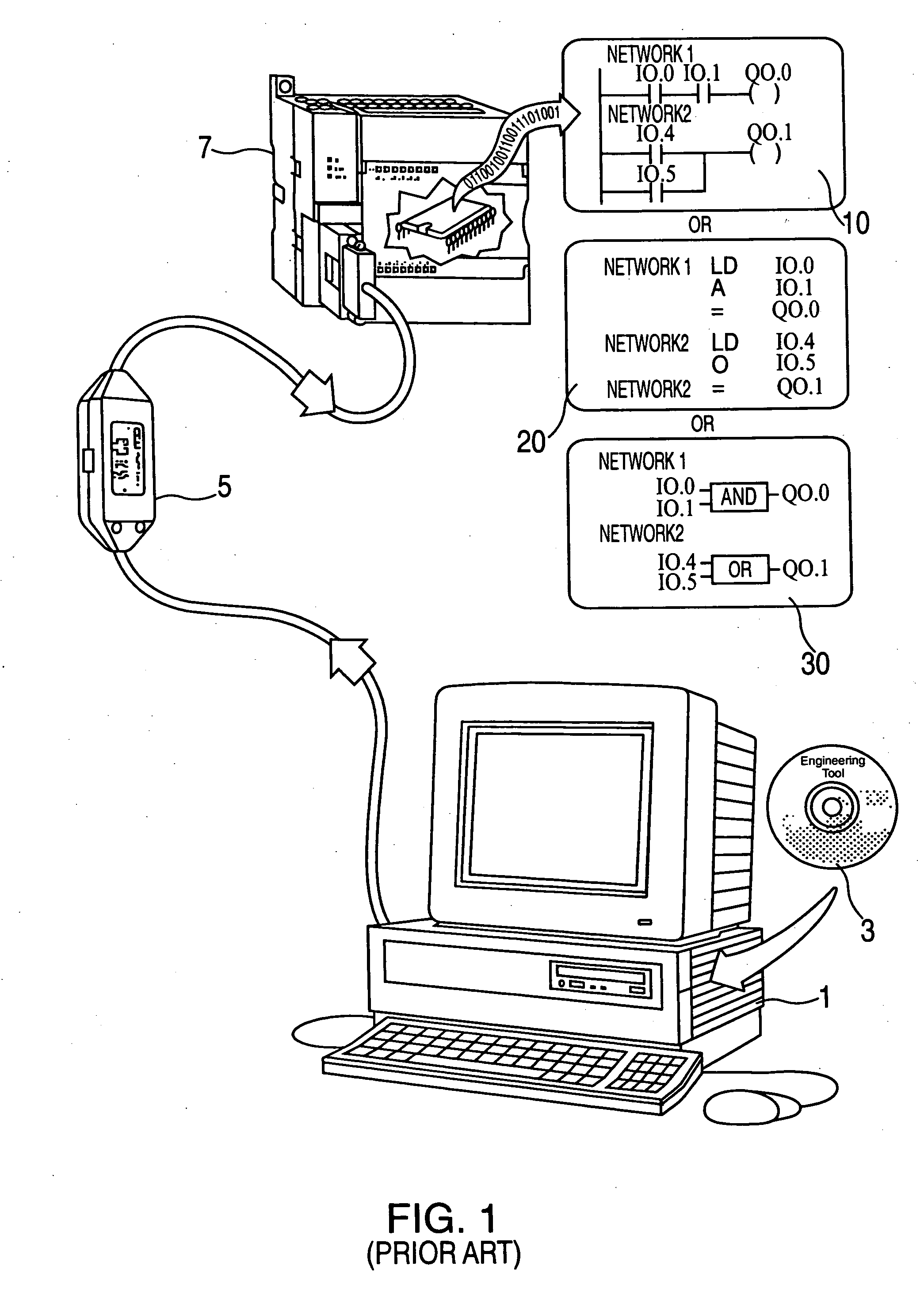

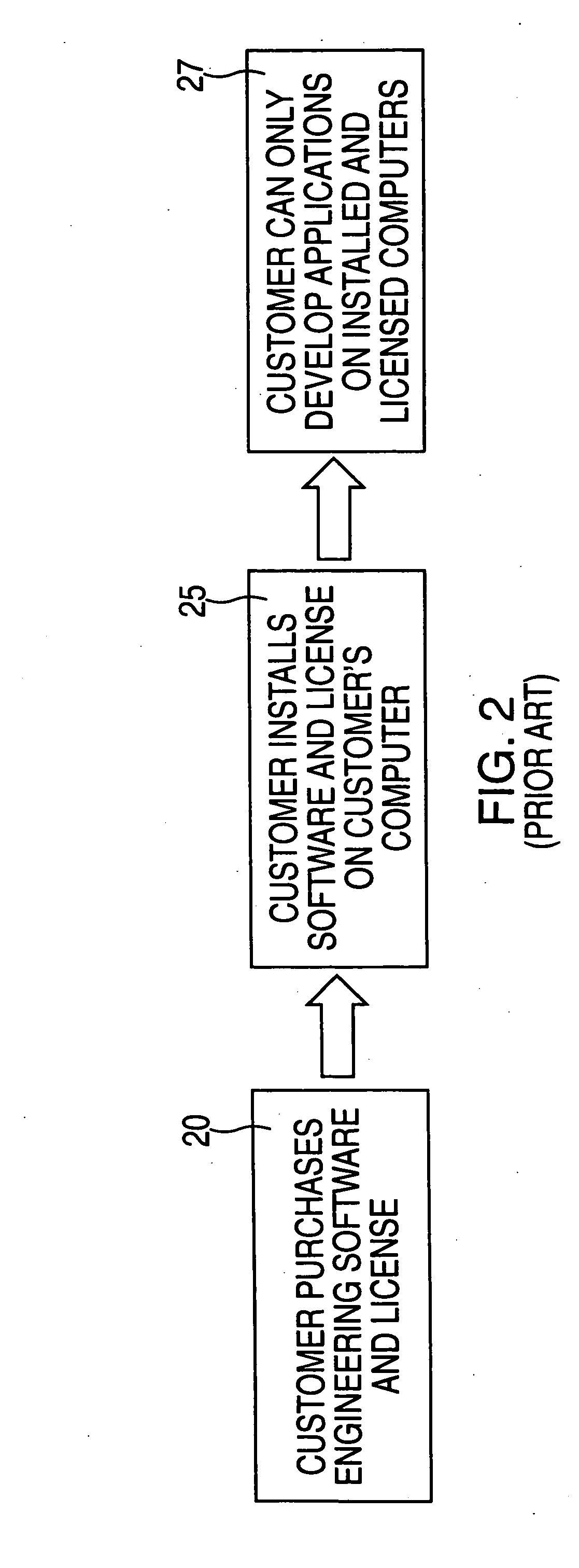

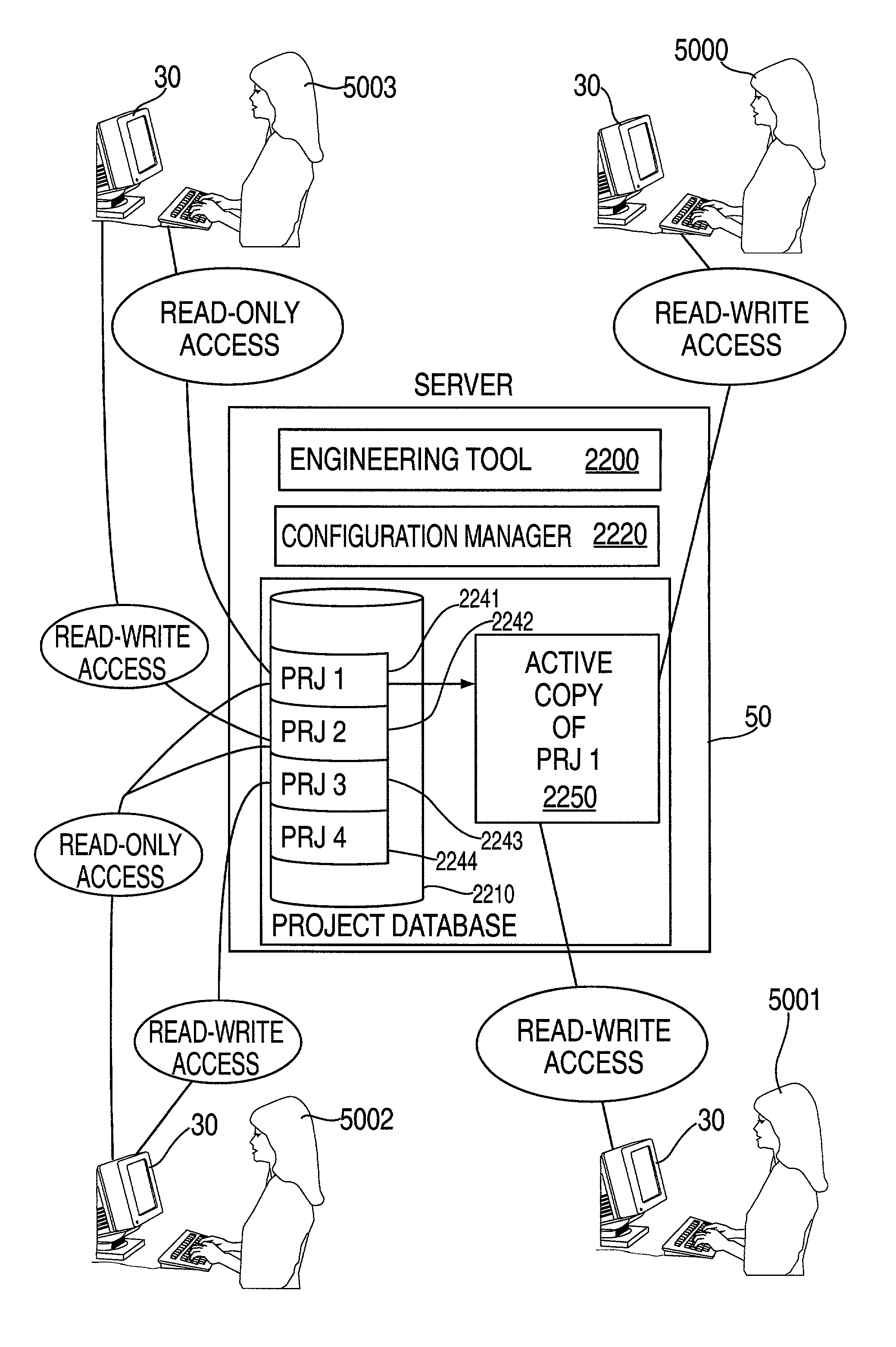

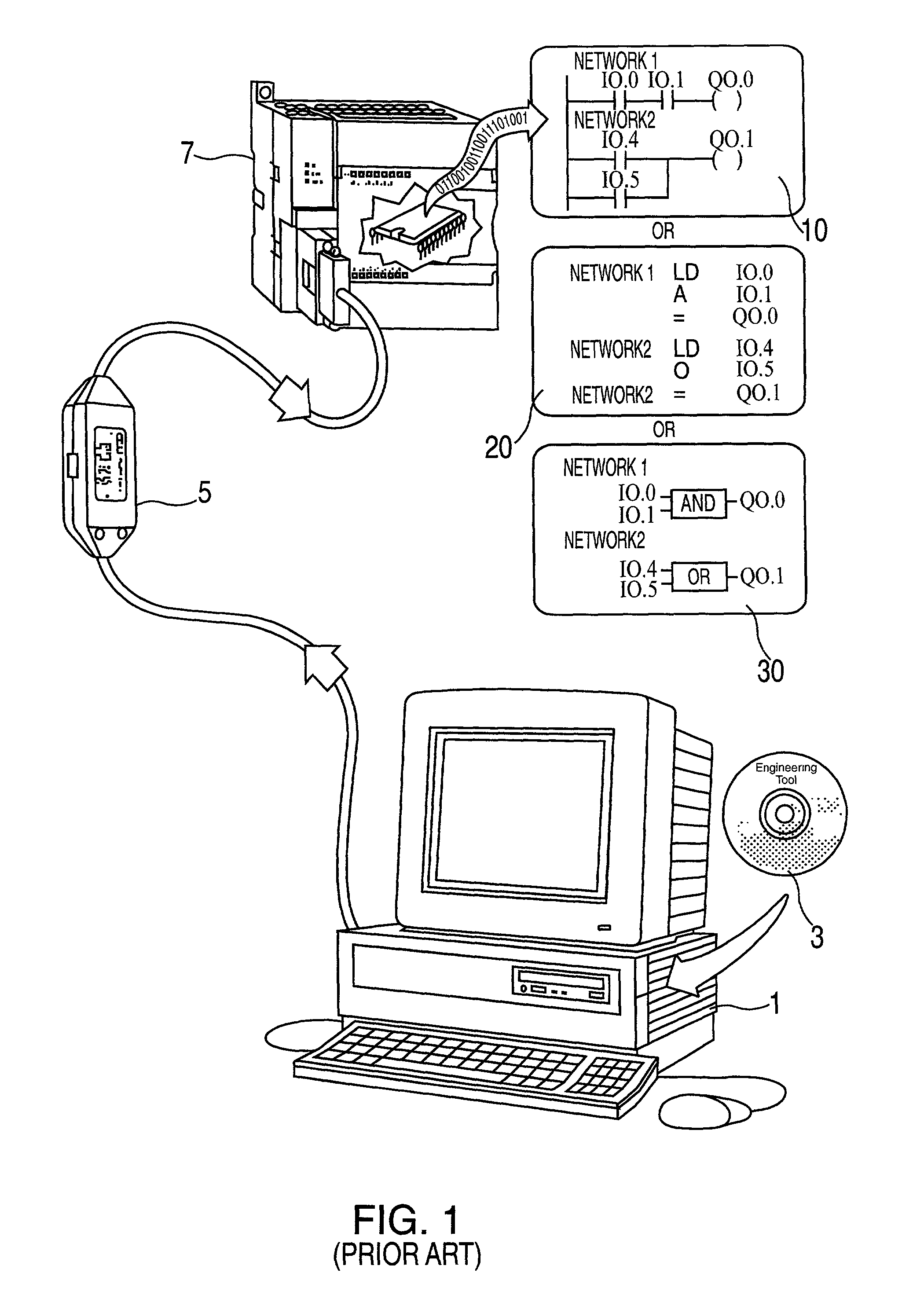

Method for utilizing remote data access to provide engineering tool services

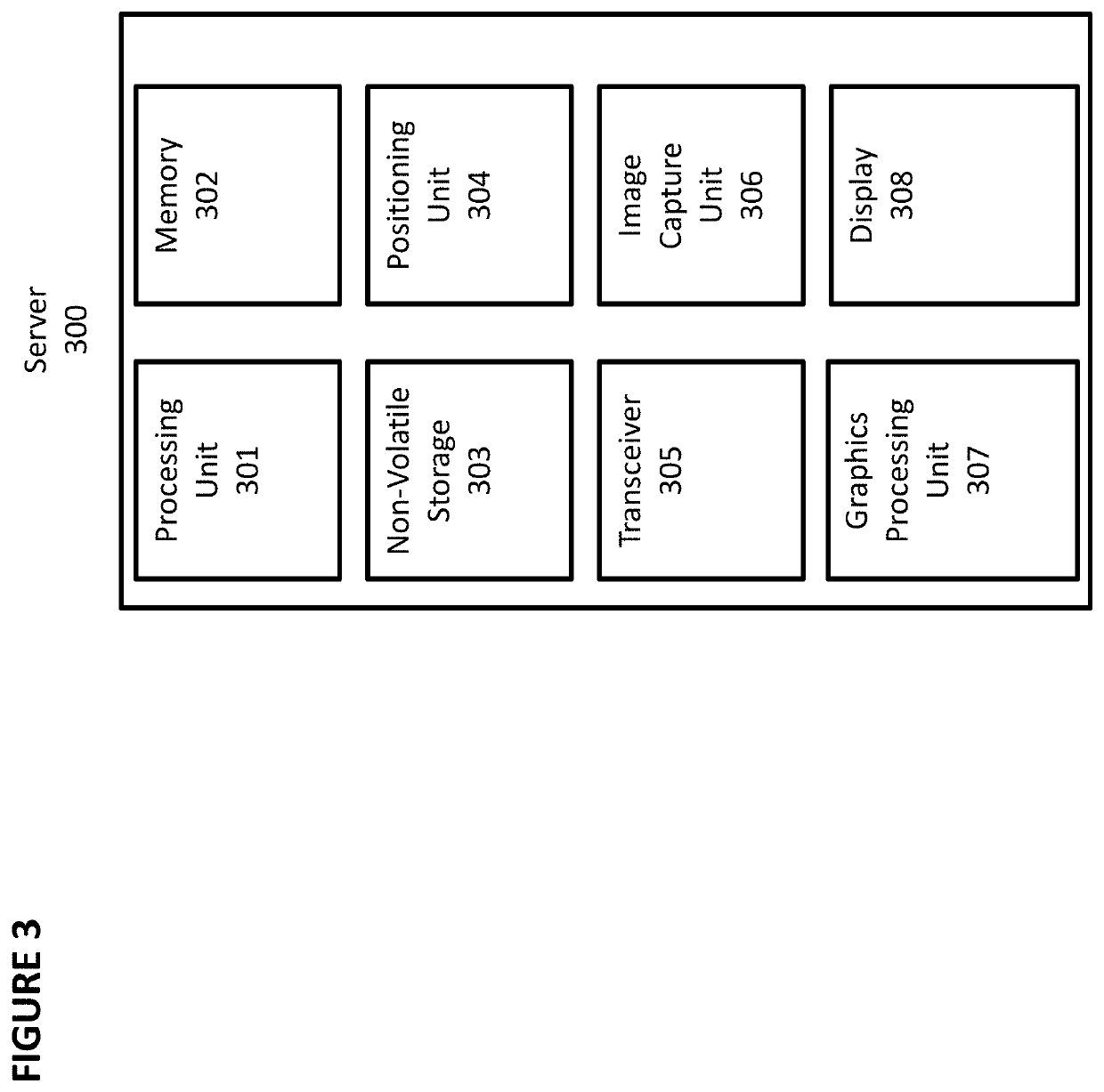

InactiveUS20050144601A1Way of increaseSignalling system detailsMultiple digital computer combinationsNetwork generationData access

A method and system for generating programming code and / or configuration data for programmable controller and the networks on which they operate is disclosed. In one embodiment, programming code is generated on a centralized server having a web-enabled engineering tool. The engineering tool operates on client devices that are in communication with the server over a network, such as the Interntet. Preferably, the engineering tool runs in a browser application (or other network-interfacing-application) on the client device and a user generates the programming code on the server with the aid of the client device. By centralizing the engineering tool, which may contain a configuration editor and a configuration management tool having version management functionality, a new business paradigm for providing engineering tool services to customers having programmable controllers. In addition, new methods and tools for collaborative engineering of programming code are enabled.

Owner:SIEMENS AG

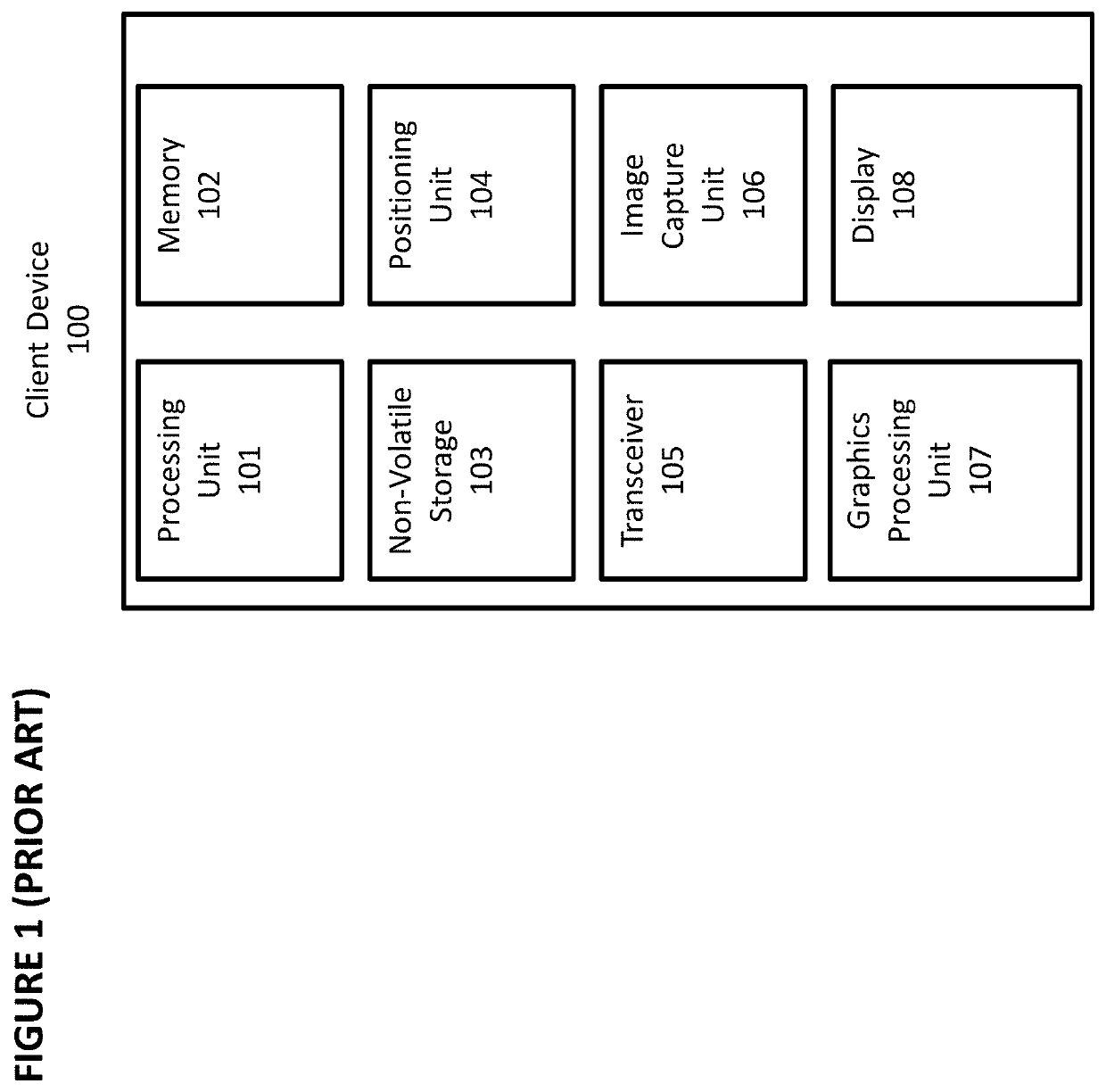

Method and apparatus for programming programmable controllers and generating configuration data from a centralized server

ActiveUS8086664B2Efficient and cost-effectiveComputer controlMultiple digital computer combinationsNetwork generationProgrammable logic controller

A method and system for generating programming code and / or configuration data for programmable controller and the networks on which they operate is disclosed. In one embodiment, programming code is generated on a centralized server having a web-enabled engineering tool. The engineering tool operates on client devices that are in communication with the server over a network, such as the Interntet. Preferably, the engineering tool runs in a browser application (or other network-interfacing-application) on the client device and a user generates the programming code on the server with the aid of the client device. By centralizing the engineering tool, which may contain a configuration editor and a configuration management tool having version management functionality, a new business paradigm for providing engineering tool services to customers having programmable controllers. In addition, new methods and tools for collaborative engineering of programming code are enabled.

Owner:SIEMENS AG

Undo/redo technique for token-oriented representation of program code

ActiveUS7386834B2Readily and efficiently excisedReadily and efficiently reinstatedDigital computer detailsIntelligent editorsEngineering toolDoubly linked list

An editor or software engineering tool may be configured to represent program code as a doubly-linked list of lexical tokens and to maintain, coincident with an operation that modifies contents of the list, an undo object that identifies opposing end nodes of a sublist of one or more lexical tokens corresponding to a substring that is either inserted into or removed from the list by the operation. In this way, lexical tokens corresponding to an inserted substring can be readily and efficiently excised to restore a pre-insertion tokenized list state. Similarly, lexical tokens corresponding to a removed substring can be readily and efficiently reinstated to restore a pre-deletion tokenized list state. Advantageously, undo support once employed to restore a prior tokenized list state is symmetrically available to support redo operations. In some embodiments in accordance with the present invention, undo-redo entries are maintained in an operation ordered set that is traversed to support one or more operations in either the undo or redo directions. In some realizations, such an ordered set of undo-redo entries is maintained by, or in conjunction with, an undo-redo manager.

Owner:ORACLE INT CORP

Efficient computation of line information in a token-oriented representation of program code

InactiveUS20040225997A1Intelligent editorsSpecific program execution arrangementsTheoretical computer scienceEngineering tool

An editor, software engineering tool or collection of such tools may be configured to encode (or employ an encoding of) an insertion point representation that identifies a particular token of a token-oriented representation and offset thereinto, together with at least some line-oriented coordinates. Efficient implementations of insert and remove operations that employ such a representation are described herein. Computational costs of such operations typically scale at worst with the size of fragments inserted into and / or removed from such a token-oriented representation, rather than with buffer size. Accordingly, such implementations are particularly well-suited to providing efficient support for programming tool environments in which a token stream is updated incrementally in correspondence with user edits.

Owner:SUN MICROSYSTEMS INC

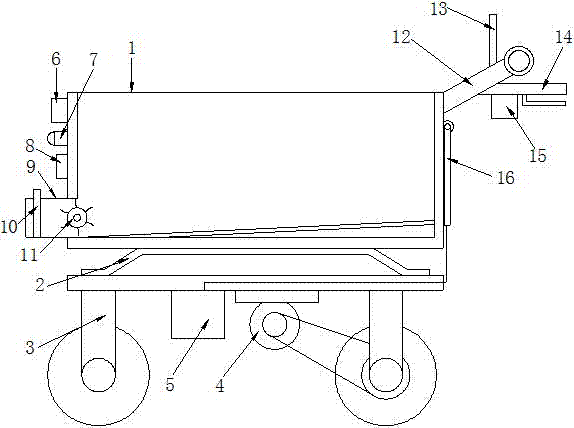

Electric mortar transport cart

PendingCN107458443AAccurate observationAccurate operabilitySupporting partsHand carts with multiple axesElectric machineryEngineering tool

The invention discloses an electric mortar transport cart, and relates to the technical field of constructional engineering tools. A damping plate spring is installed at the bottom of a cart body, a walking wheel mechanism is installed at the lower end of the damping plate spring, a storage battery and a drive motor are installed on the walking wheel mechanism, and the drive motor is connected with the walking wheel mechanism through a belt; an image camera, a wide-angle camera and a lighting lamp are installed at the front end of the cart body; a discharging pipe is installed at the lower left end of the cart body, an installing groove is formed in the front side of the discharging pipe, a gate segment is installed in the installing groove, a material guiding plate is obliquely installed at the lower end in the cart body, the left portion is lower than the right portion of the material guiding plate, a discharging roller mechanism is arranged at the connecting position of the discharging pipe and the cart body, and a push handle is installed on the upper right end of the cart body. The electric mortar transport cart is capable of being accurately observed and operate and improving safety, electric operation is adopted, time can be saved, and the electric mortar transport cart is high in efficiency and easy to operate.

Owner:JINLING INST OF TECH

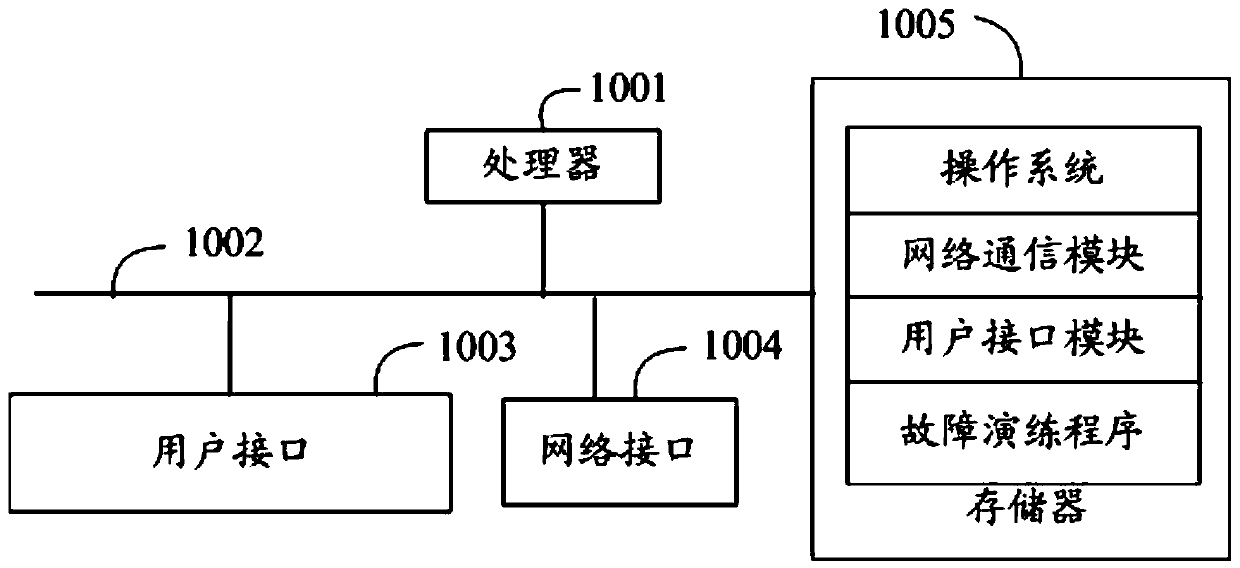

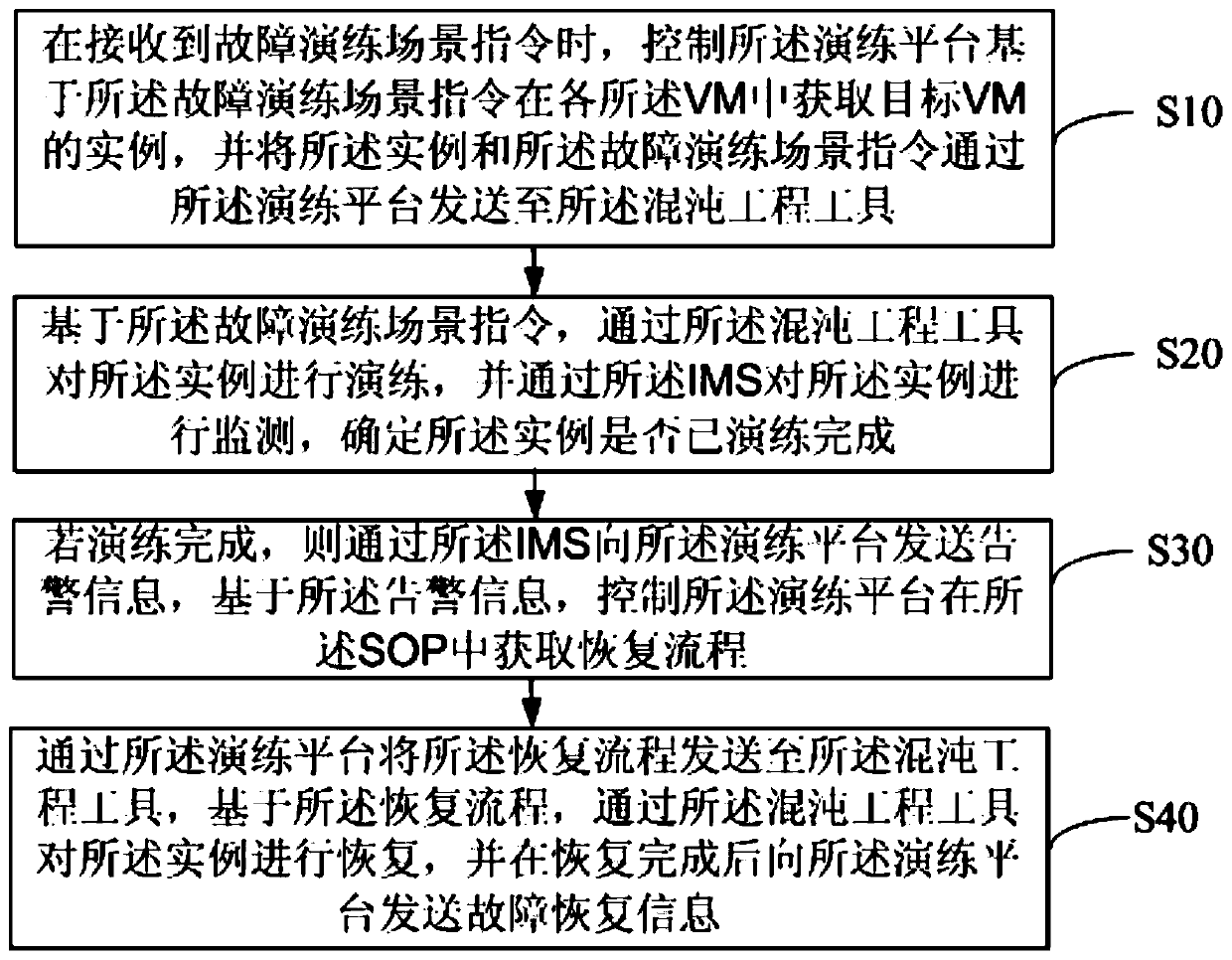

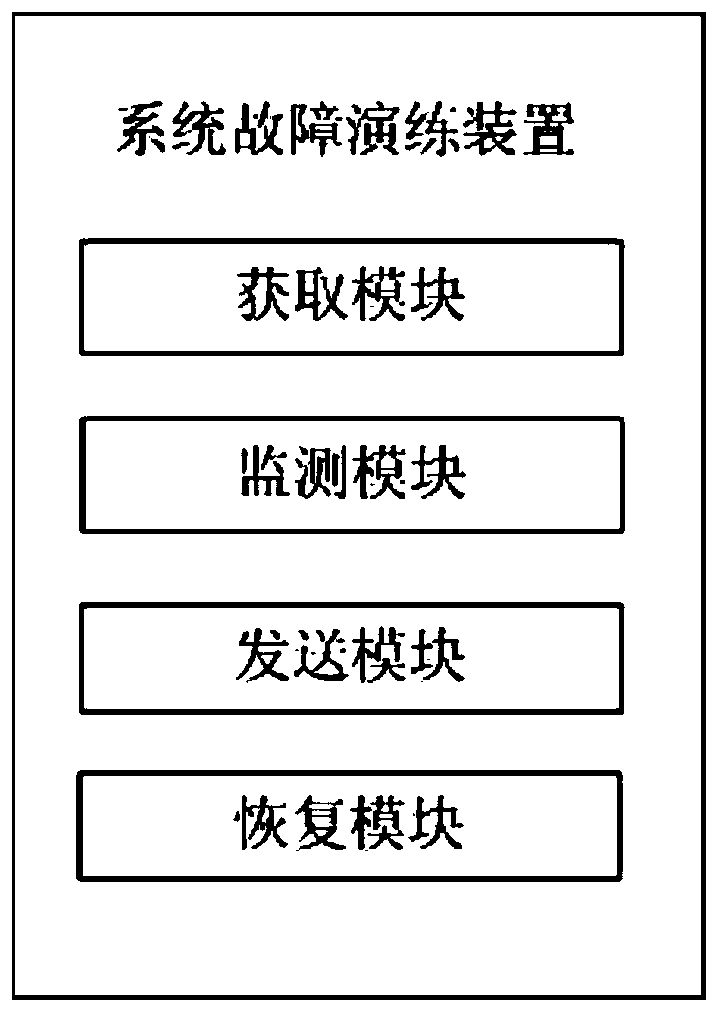

Fault exercise method and device, apparatus and computer storage medium

PendingCN110308969AImprove the efficiency of failure drillsWith fault self-healing abilityNon-redundant fault processingSoftware simulation/interpretation/emulationEngineering toolSystem failure

The invention relates to the technical field of finance technology (Fintech), and discloses a fault exercise method. The method comprises the steps of when a fault exercise scene instruction is received, controlling an exercise platform to obtain the instances of the target VMs in the VMs based on the fault exercise scene instruction, and sending the instances and the fault exercise scene instruction to a chaotic engineering tool through the exercise platform; performing exercise on the instance through the chaotic engineering tool, and monitoring whether the instance is exercised or not through an IMS; if the exercise is completed, sending the alarm information to the exercise platform through the IMS, and controlling the exercise platform to obtain a recovery process in the SOP; and sending the recovery process to the chaotic engineering tool through the exercise platform, recovering the examples through the chaotic engineering tool, and sending the fault recovery information to theexercise platform after the recovery is completed. The invention further discloses a fault exercise device, an apparatus and a computer storage medium. According to the invention, the efficiency of the financial system fault exercise is improved.

Owner:WEBANK (CHINA)

Real options based iterative development program metrics

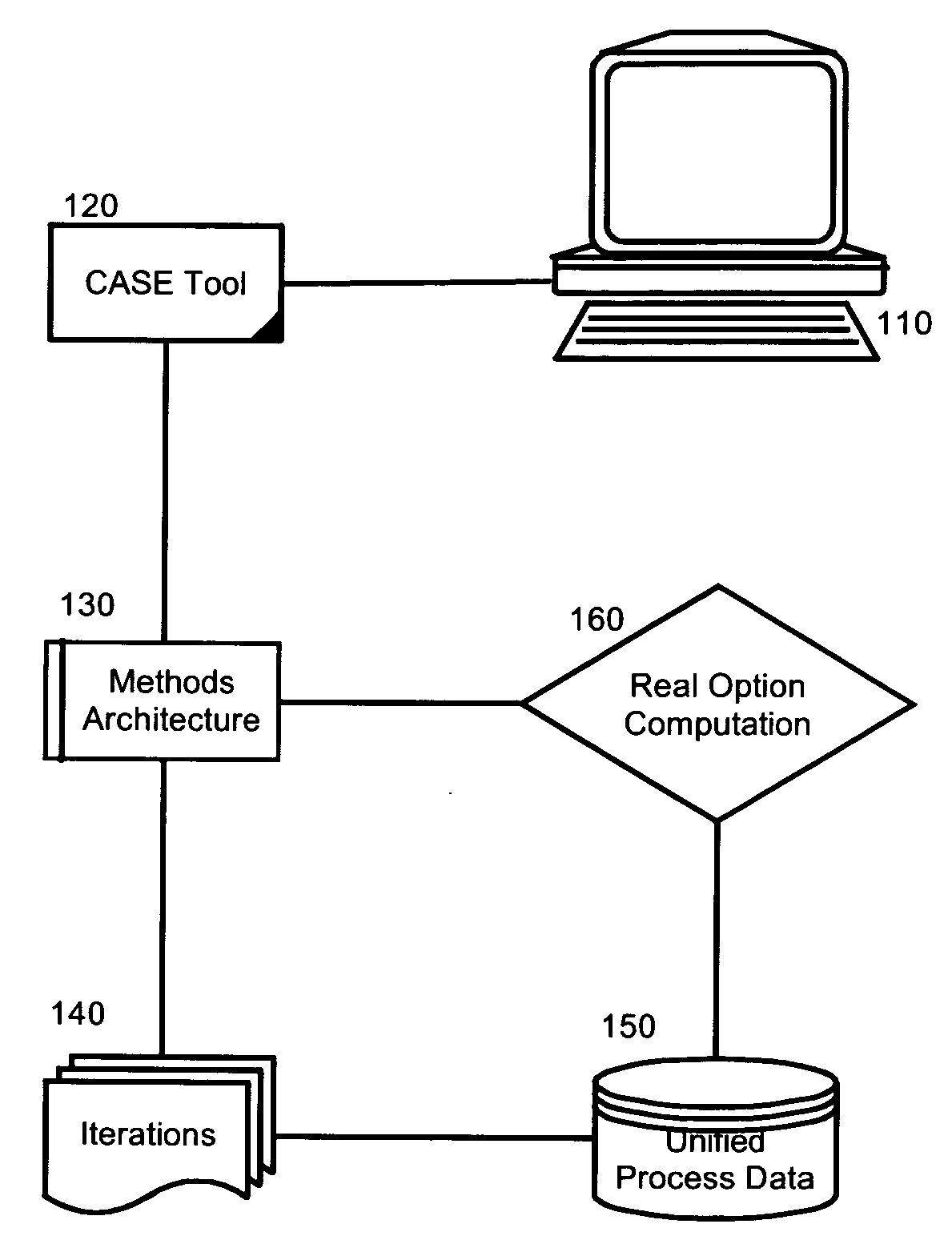

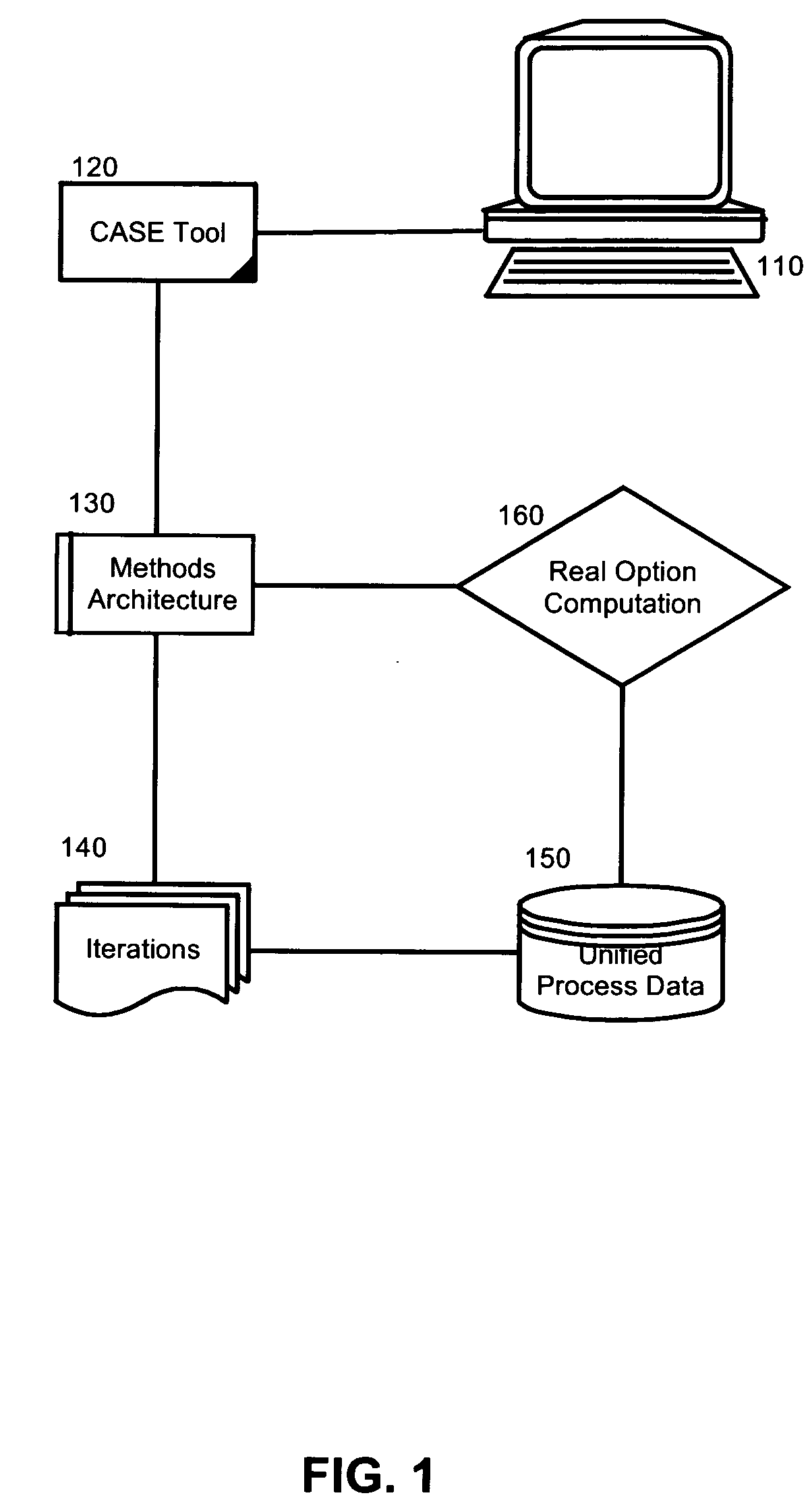

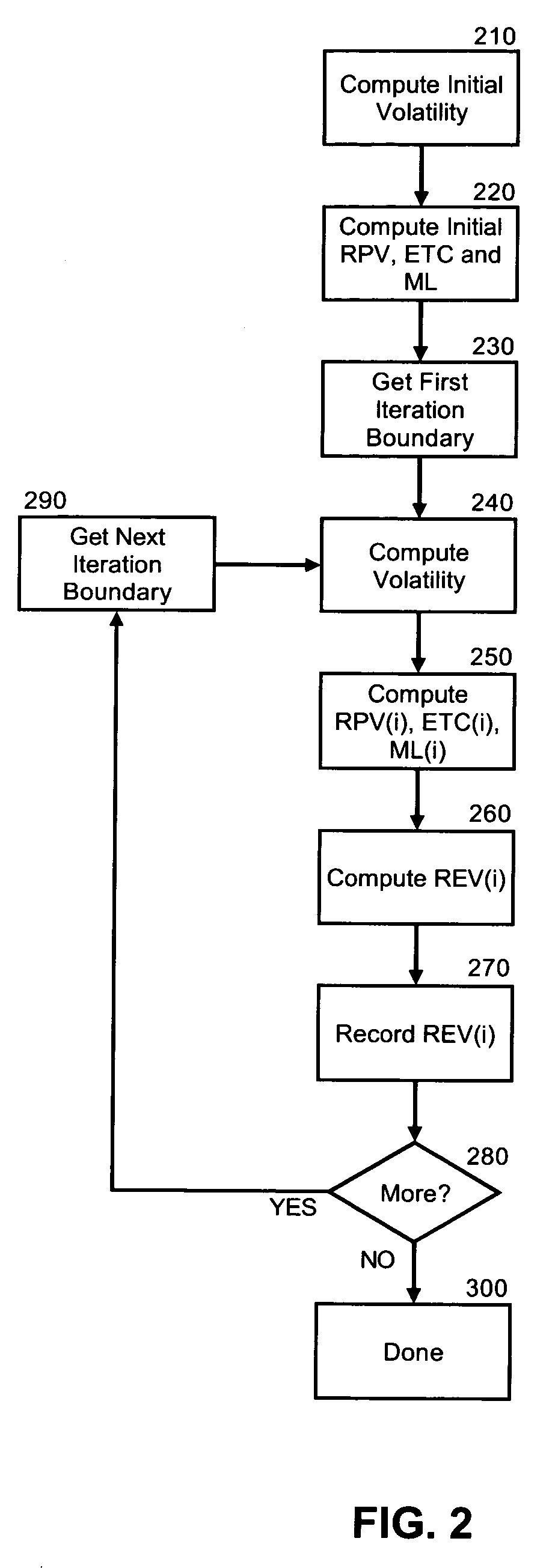

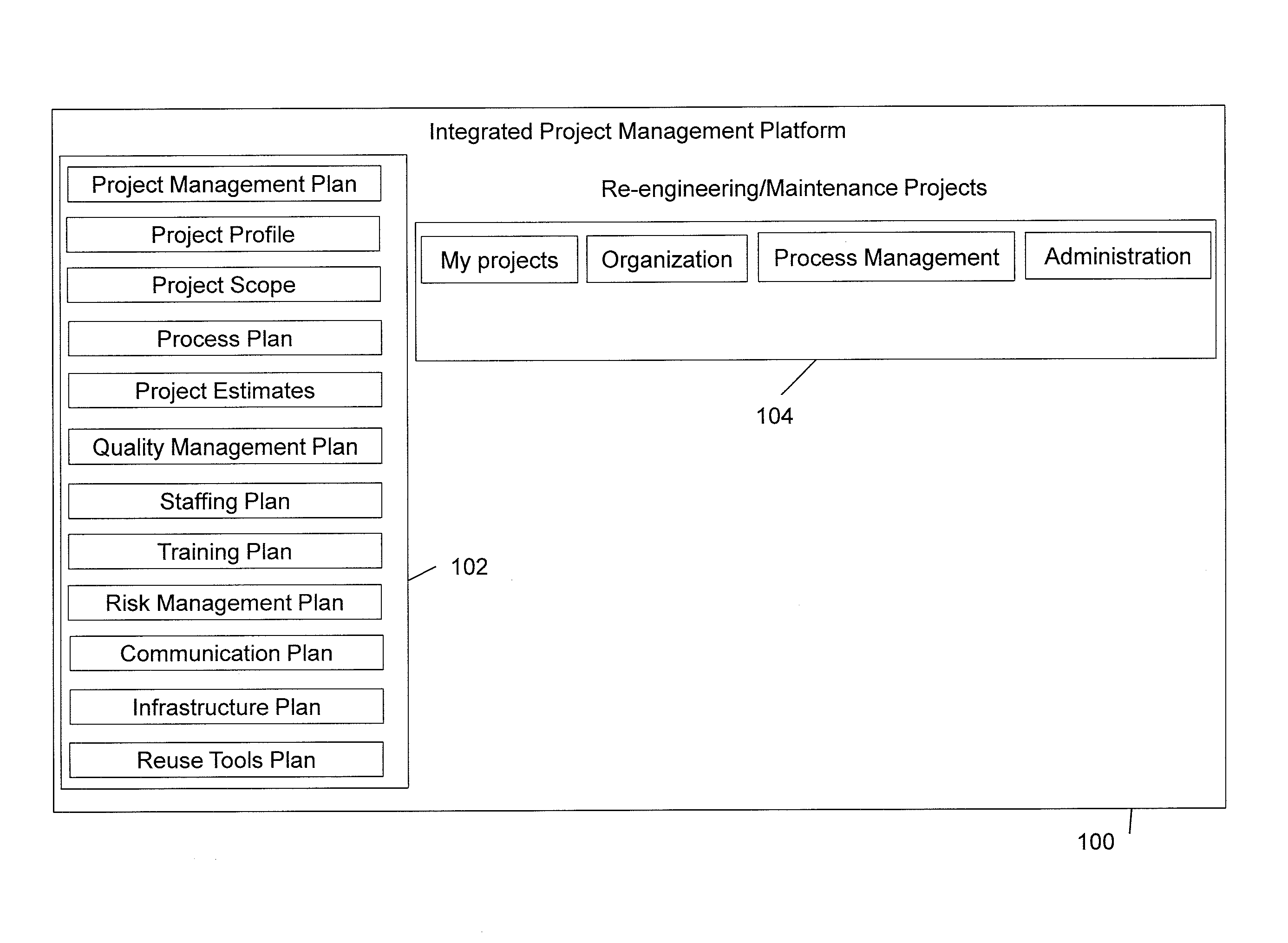

InactiveUS20070016891A1Software designSpecific program execution arrangementsRational Unified ProcessEngineering tool

Embodiments of the present invention address deficiencies of the art in respect to iterative project management and provide a method, system and computer program product for utilizing real options based iterative development program metrics. In an embodiment of the invention, a data processing system configured for software project management can include a computer aided software engineering tool enabled to use a methods architecture configured to manage iterative development, said as Rational Unified Process (TM) (RUP) methodware. The data processing system also can include a data store of unified process data produced by the computer aided software engineering tool. Finally, the data processing system can include real options-based computational logic.

Owner:IBM CORP

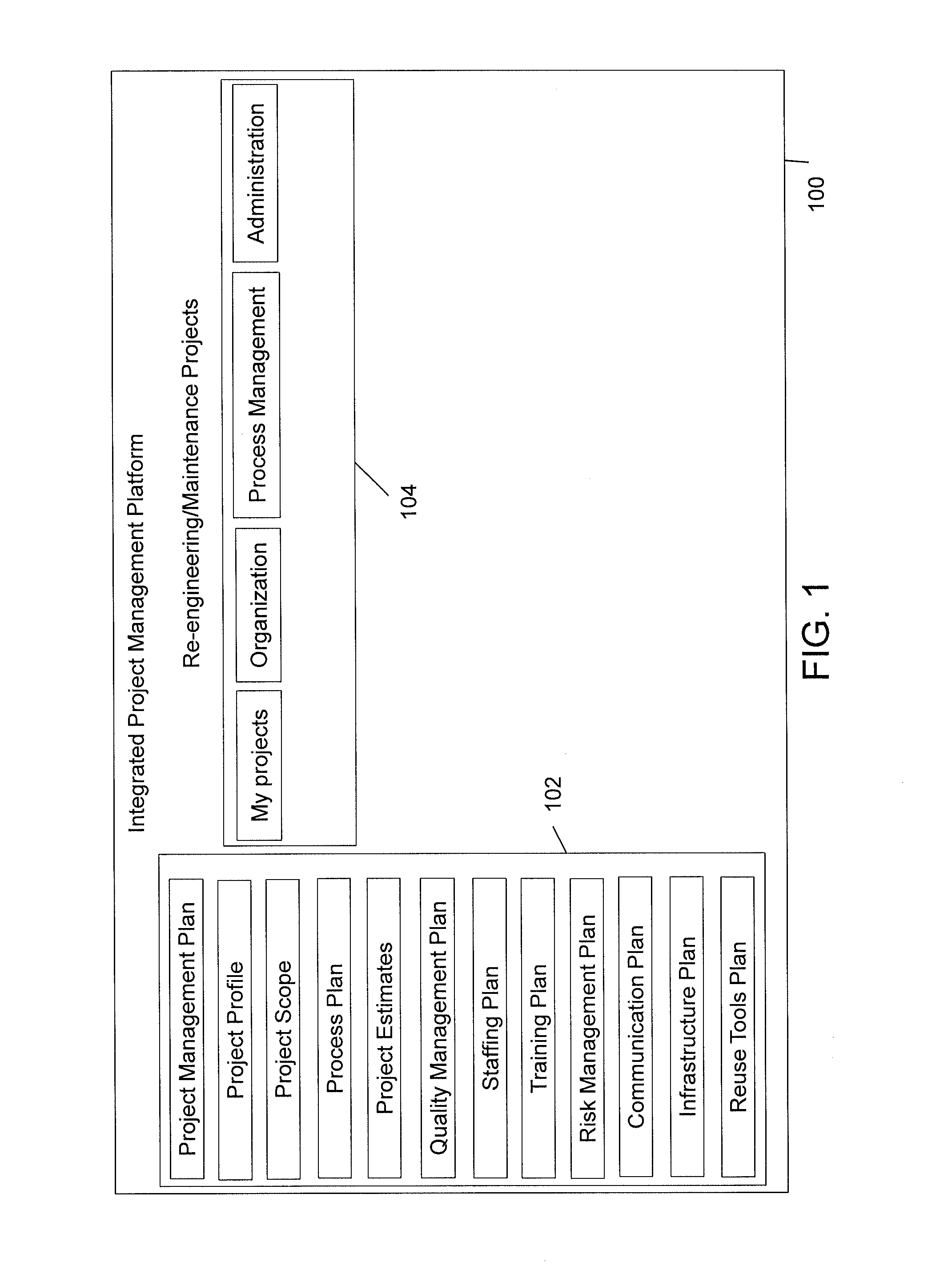

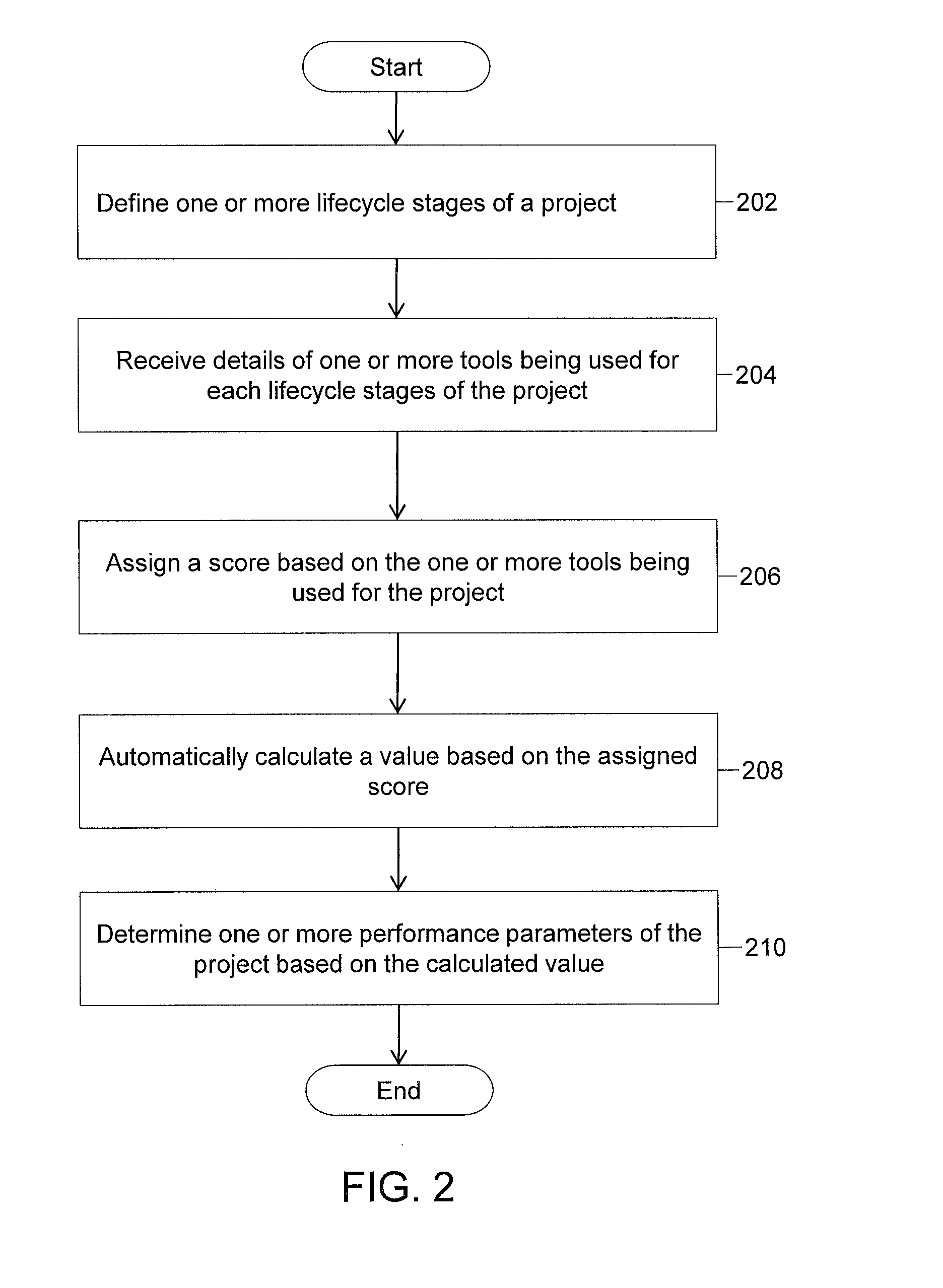

Method and system for determining performance parameters of software project based on software-engineering tools usage

A method and system have been disclosed for determining one or more performance parameters of a project. Various examples of the performance parameters of the project may include productivity, efficiency, and quality. The method described above includes defining one or more lifecycle stages of the project. Examples of the lifecycle stages of the project may include requirement analysis, high-level design, detailed design, build, integration test, system test, documentation, acceptance, installation, and post implementation. Further, the method includes receiving details of one or more tools being used for each lifecycle stages of the project. The method further includes assigning a score based on the one or more tools being used for the project. Further, the method also includes automatically calculating a value based on the assigned score. Thereafter, the performance parameters of the project are determined based on the calculated value.

Owner:INFOSYS LTD

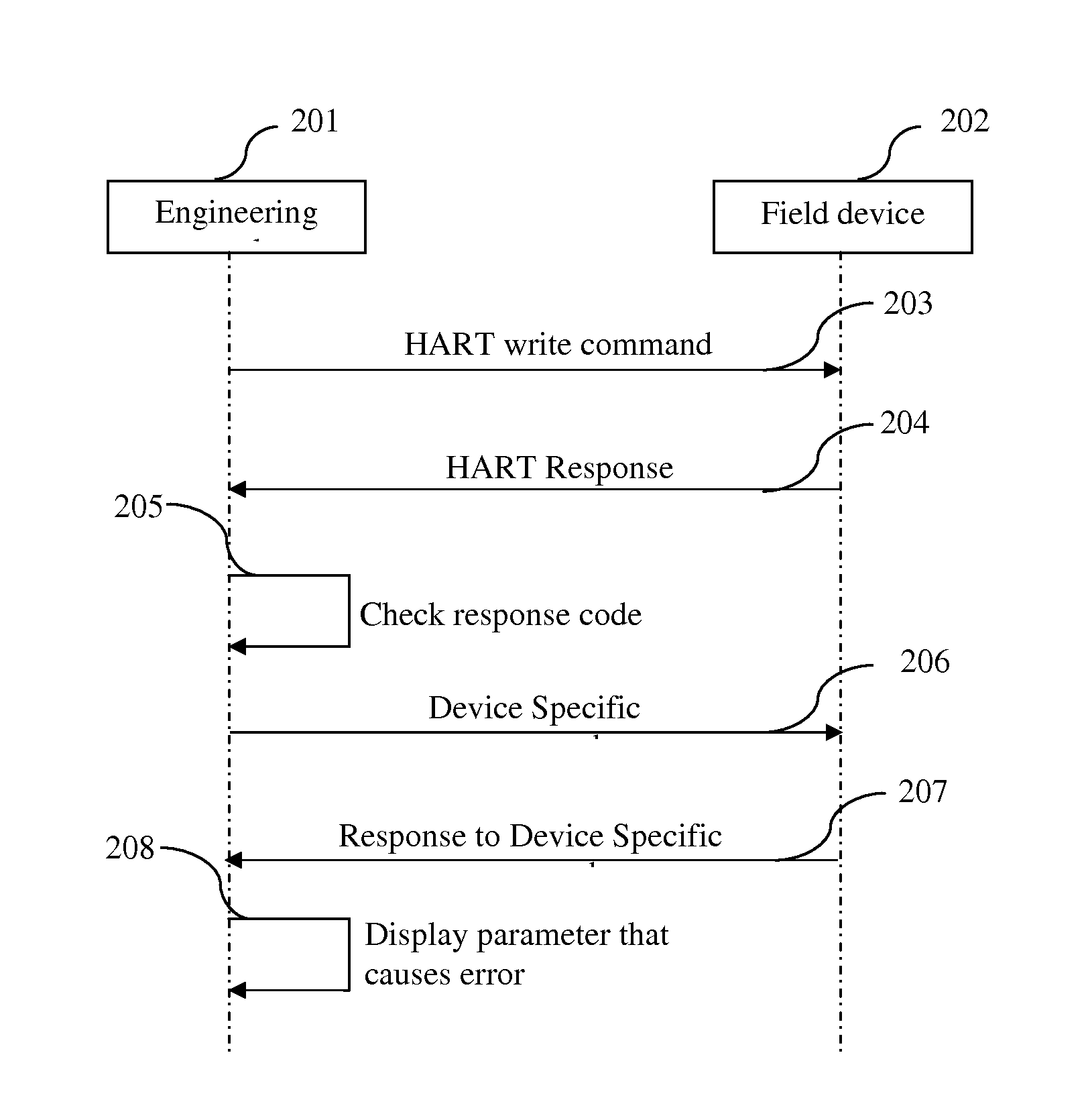

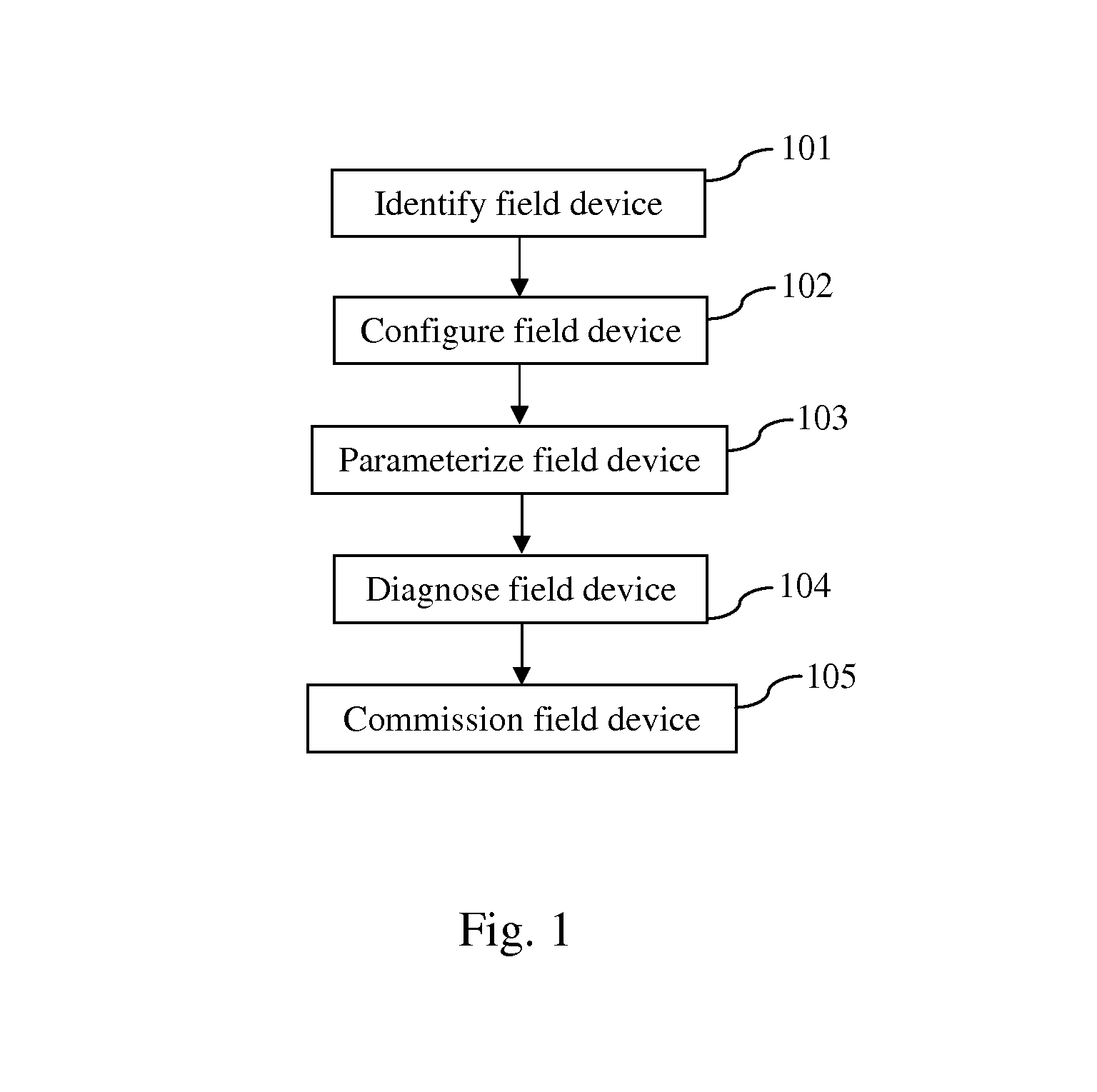

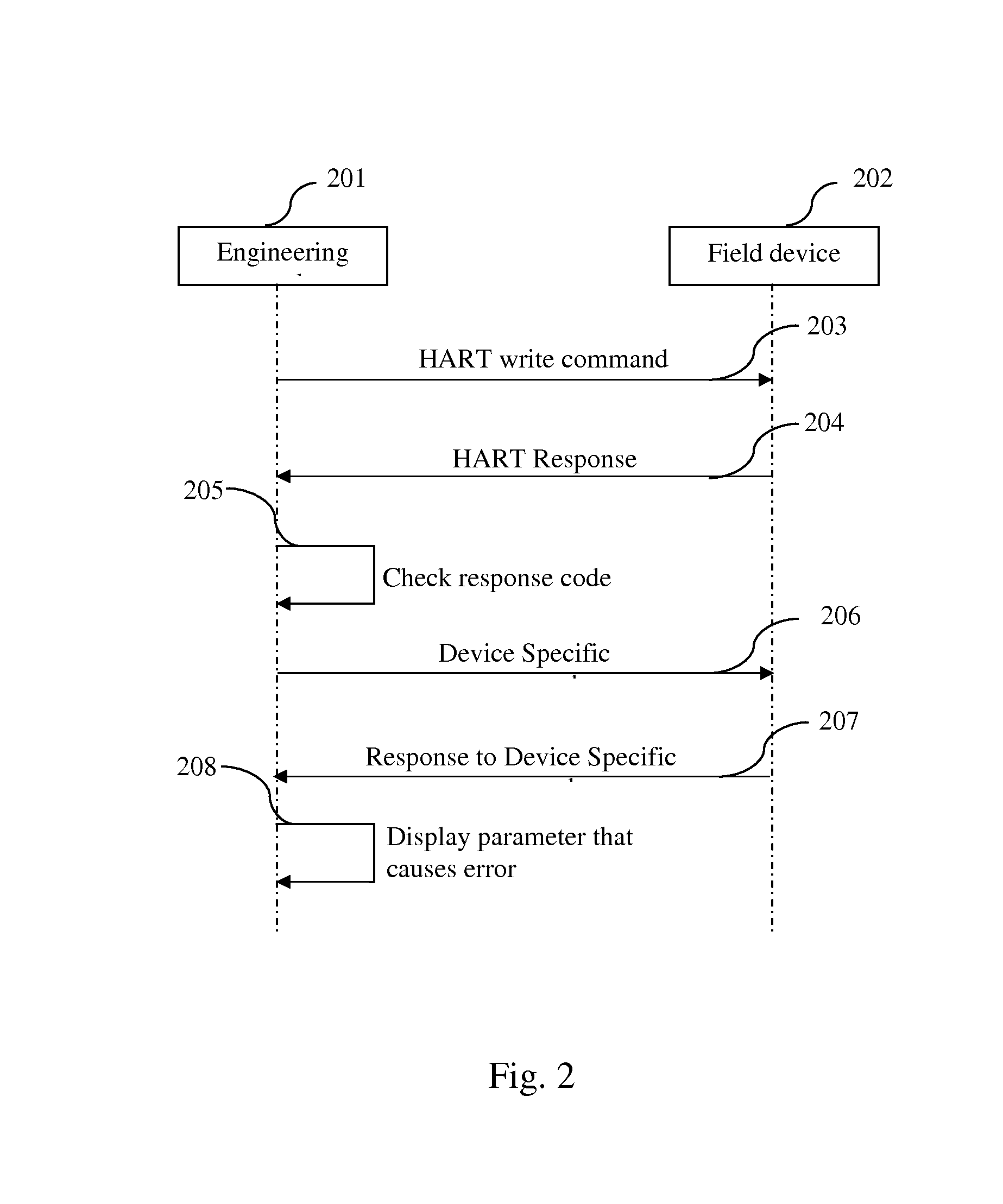

Method of engineering and diagnosing a field device and a system thereof

A method is disclosed for engineering a field device by an engineering tool, which method can include identifying the field device, and configuring, parameterizing, diagnosing and commissioning the field device. Diagnosing the field device can include identifying one or more parameters that cause an error. Diagnosing the field device by an engineering tool can include identifying the parameter that causes an error through a device specific command.

Owner:ABB RES LTD

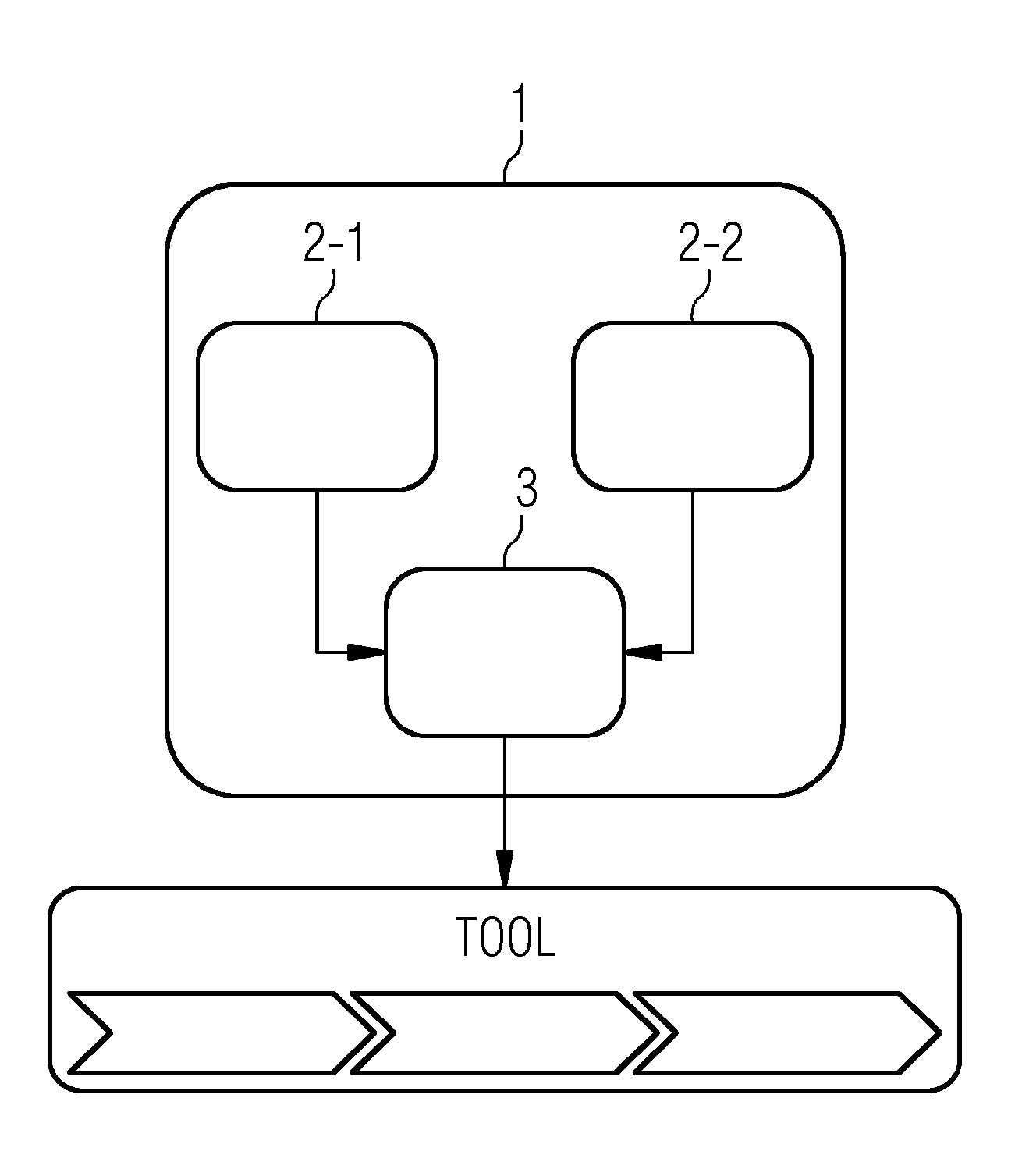

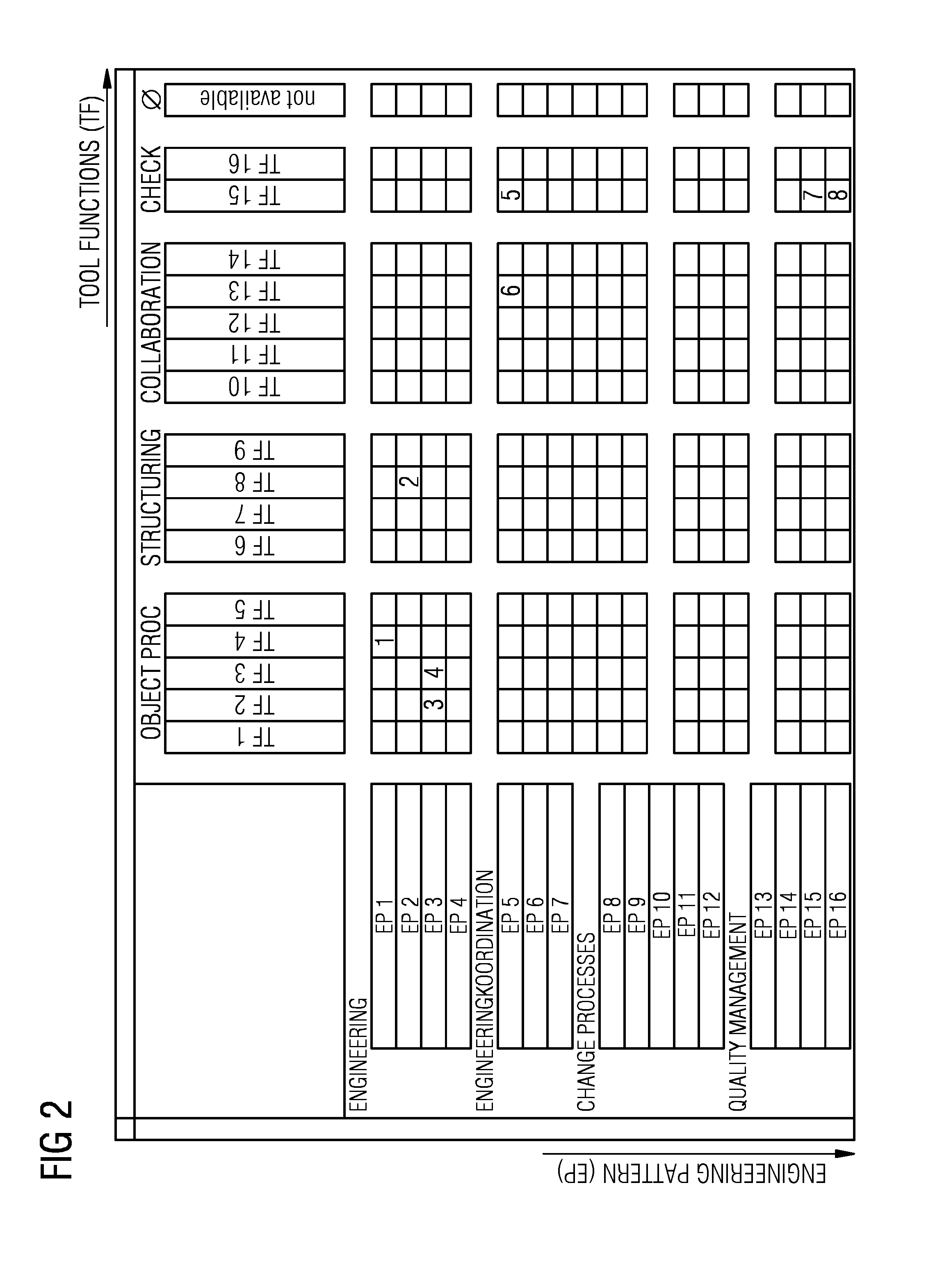

Method And Apparatus For Generating An Engineering Workflow

Computer system configured to generate an engineering workflow, said system comprising a first database which stores a library of engineering patterns and a second database which stores a library of engineering tool functions of an engineering tool, wherein a sequence of automatically concatenated workflow steps forming said engineering workflow is generated by mapping for each workflow step a selected engineering pattern to a selected tool function of said engineering tool.

Owner:SIEMENS AG

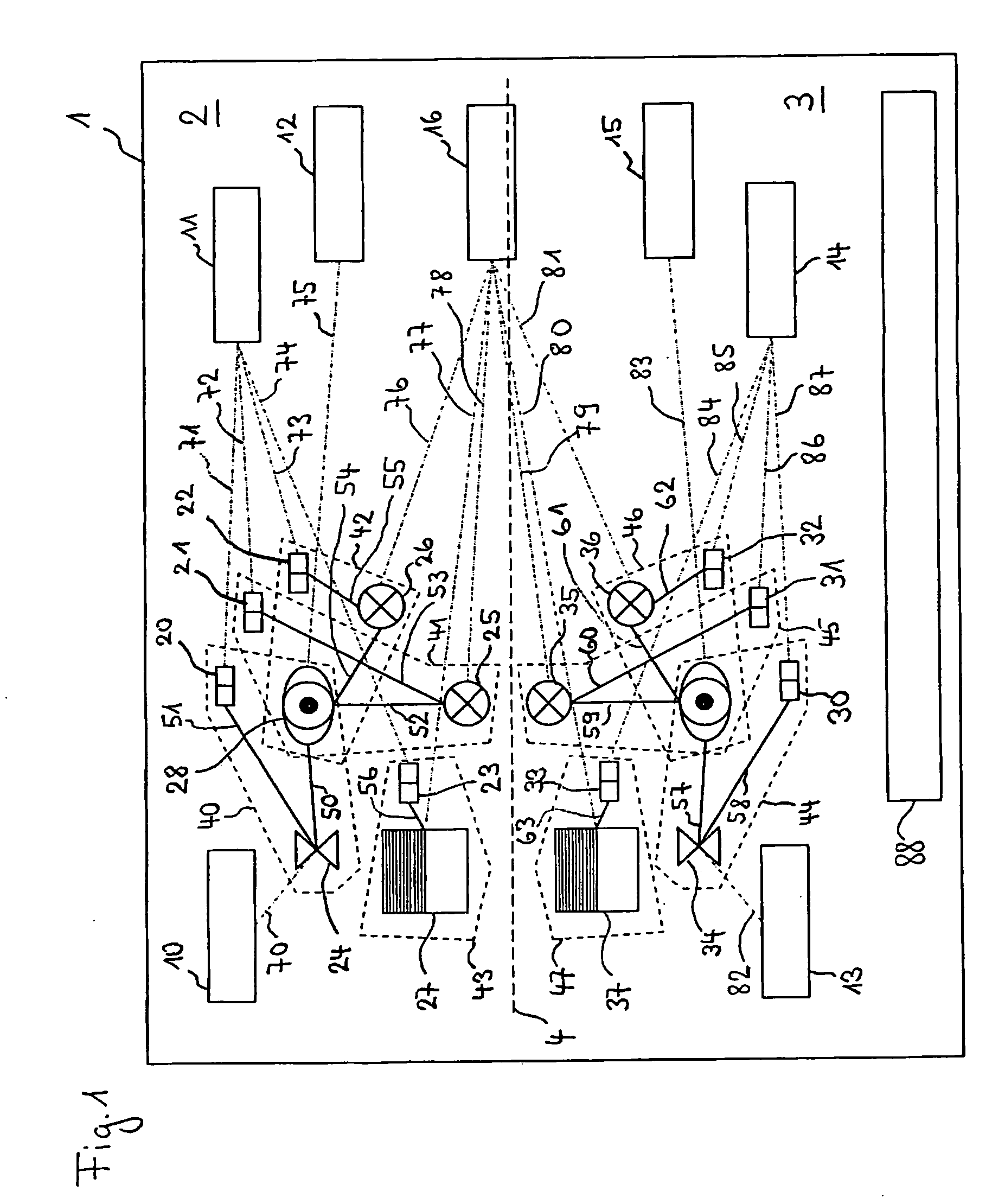

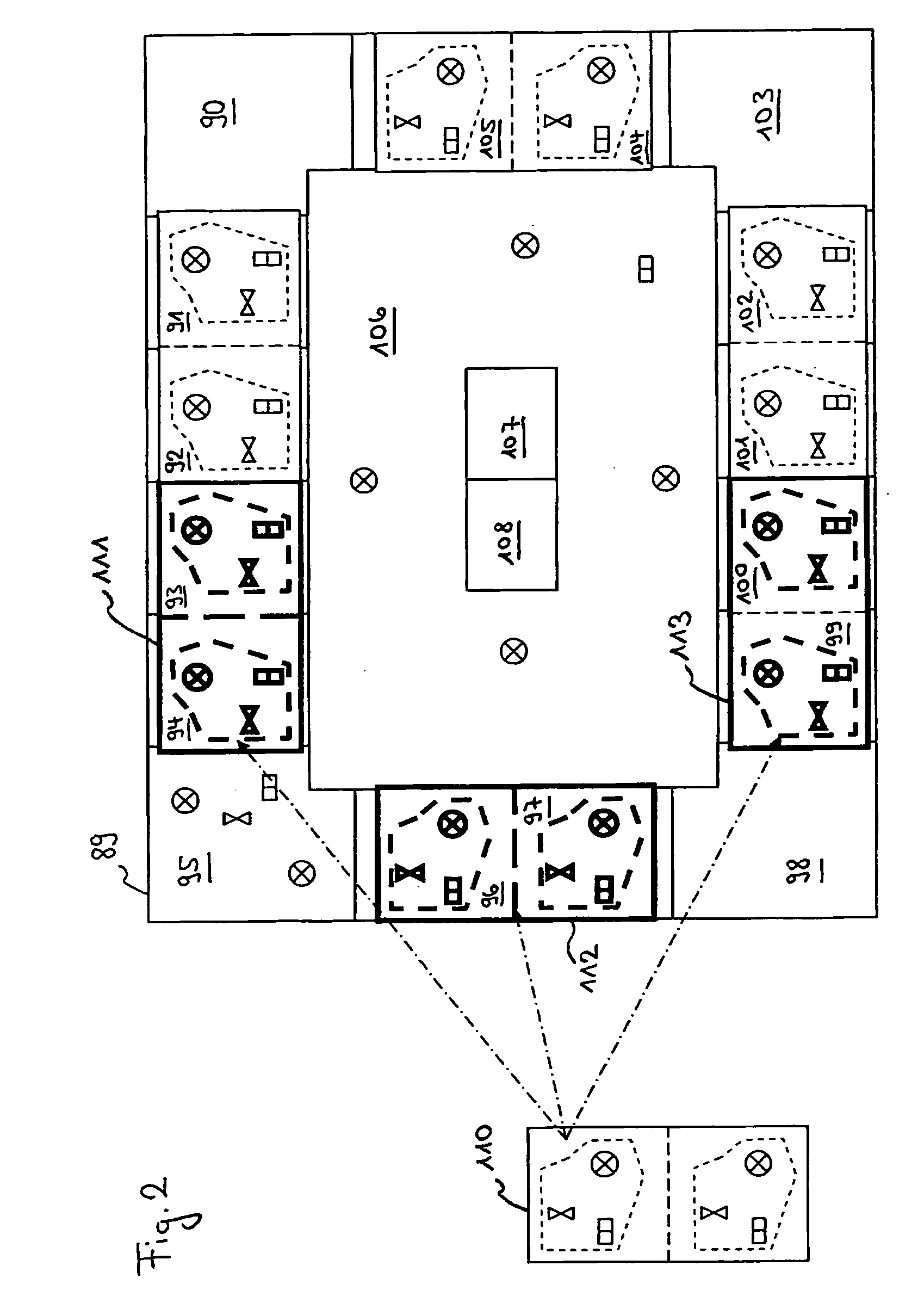

Method and system for generating combination of applications for building automation system

InactiveUS20070016331A1Programme controlSampled-variable control systemsData connectionEngineering tool

Function groups are generated, each having at least two technical functions, interconnected by a data connection and which in their entirety include the technical functions of a combination of applications. A technical function is assigned to a device which belongs to the combination of applications and by which the technical function can be carried out. The combination of applications is assigned to a room template and a template of the combination of applications is generated. An engineering tool may be used to simplify preparation, installation and commissioning of networks with distributed regulator and control applications in a building.

Owner:SIEMENS SWITZERLAND +1

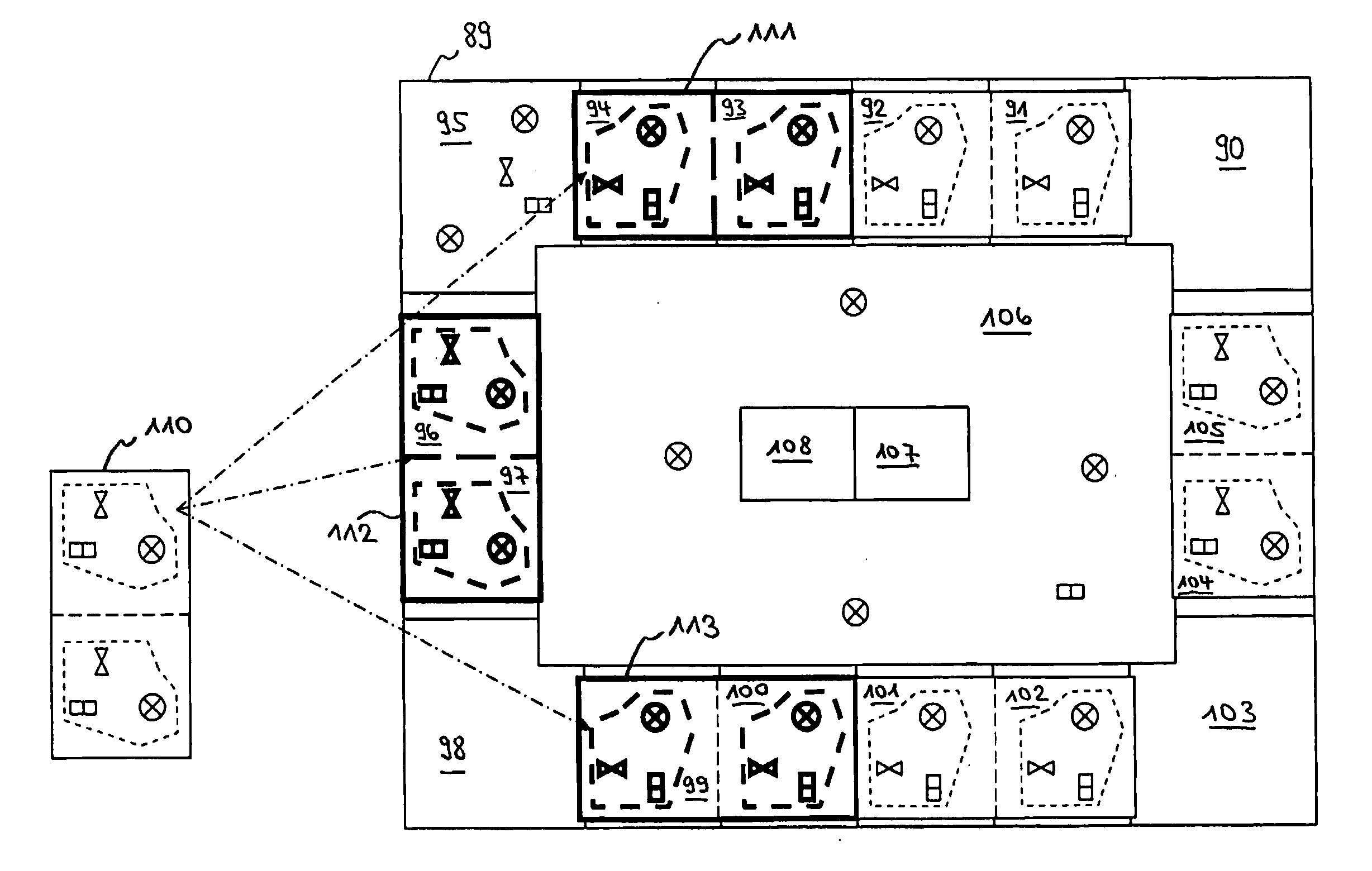

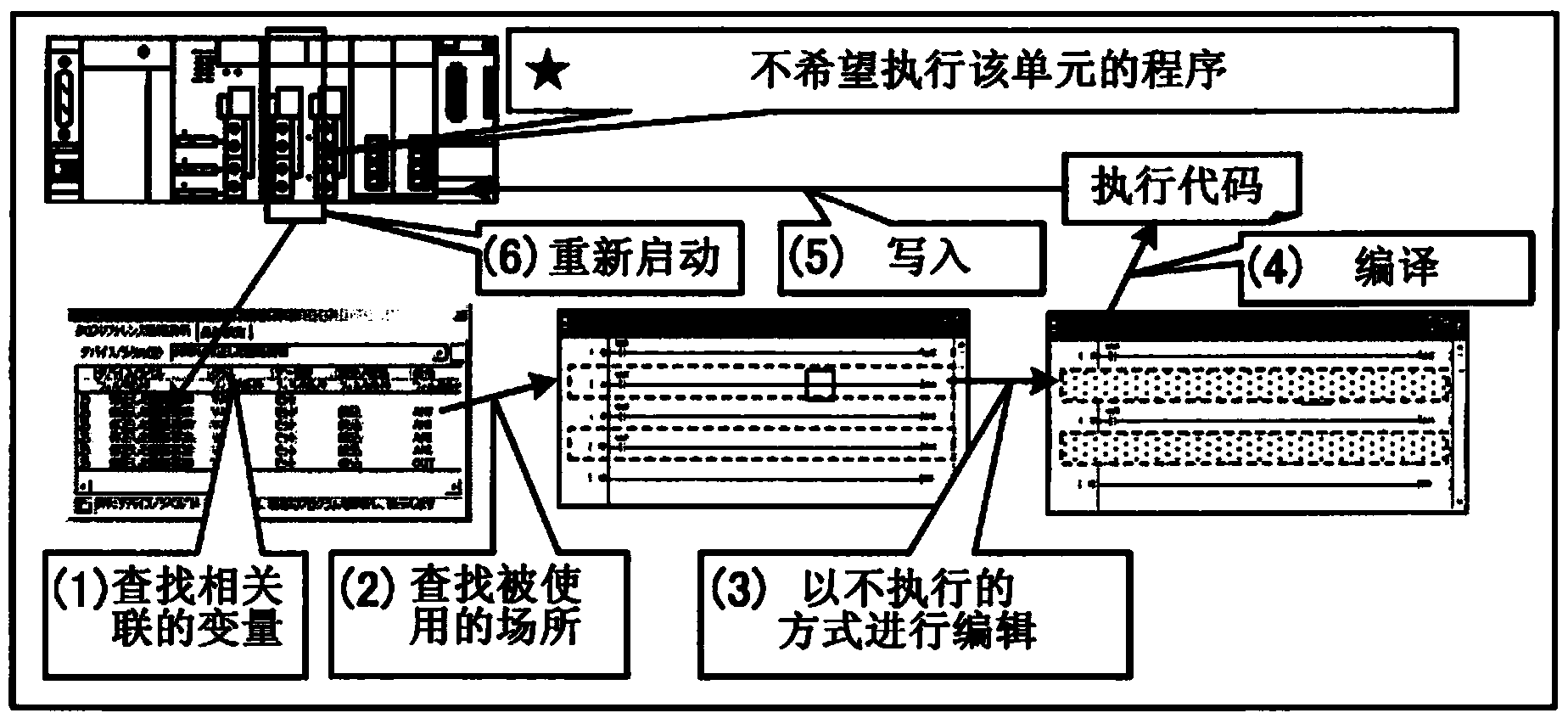

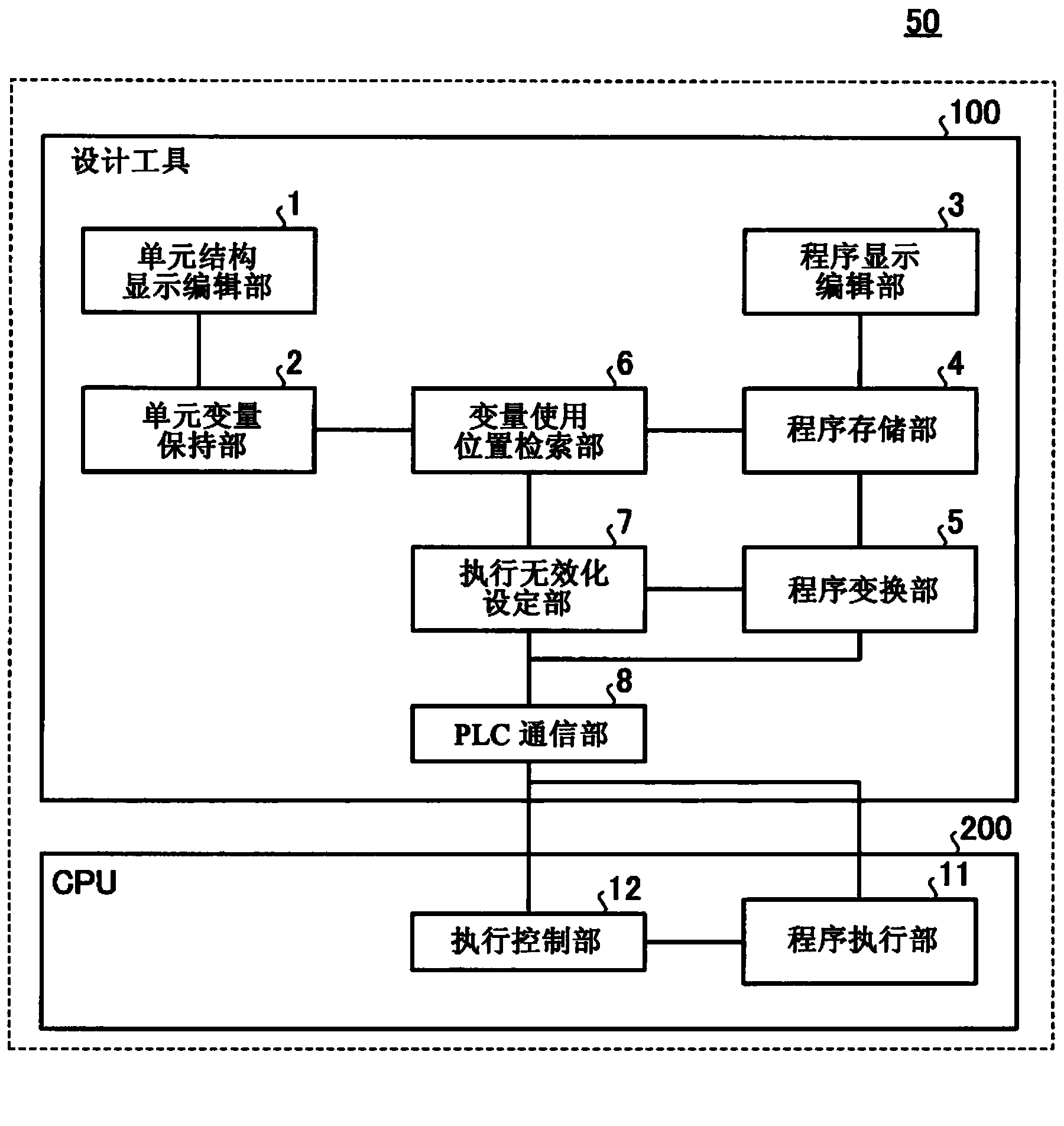

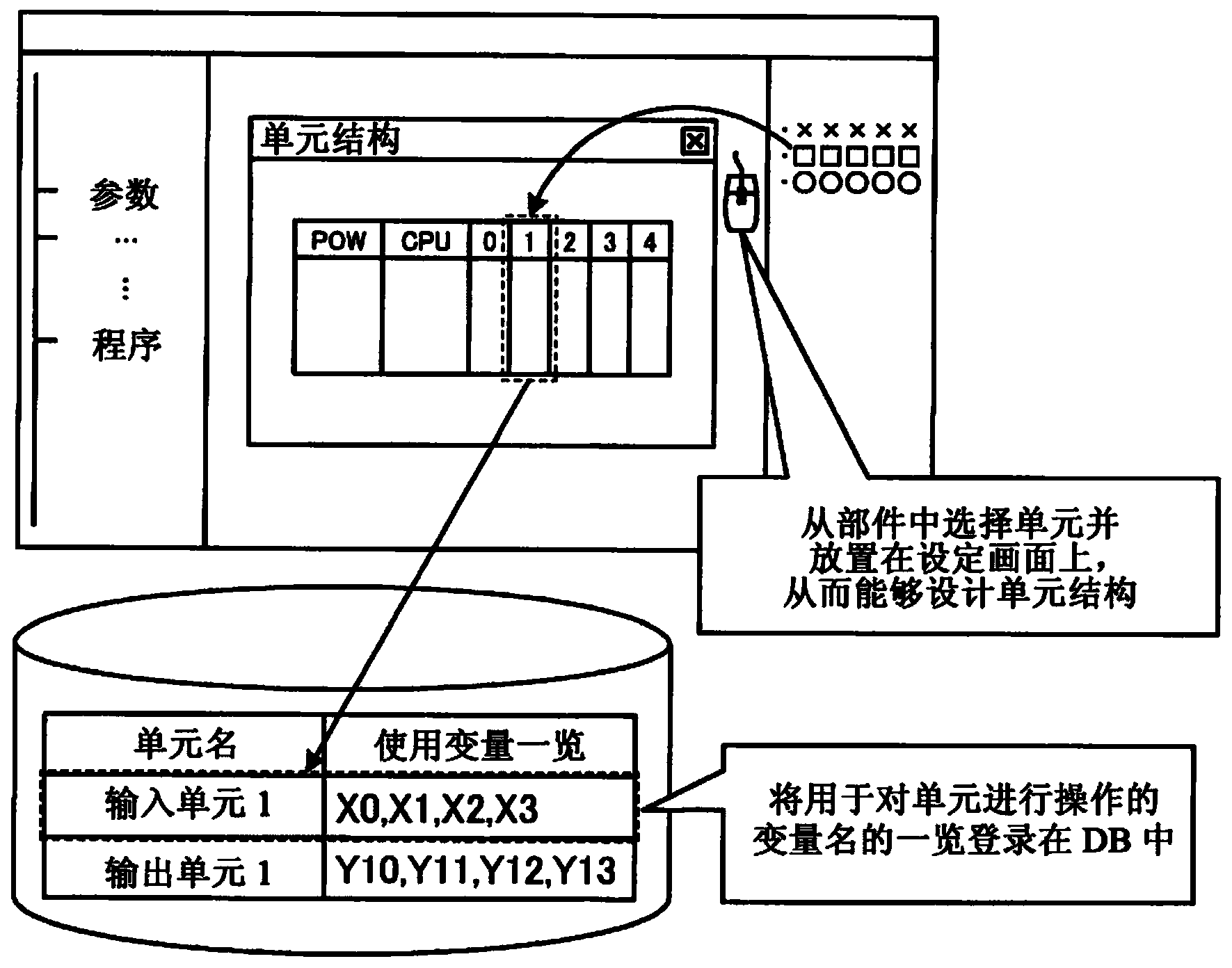

Sequence-program debugging assistance apparatus

InactiveCN104204975AError detection/correctionProgramme control in sequence/logic controllersProgramming languageProgrammable logic controller

A sequence-program debugging assistance apparatus (50) according to an embodiment includes an engineering tool (100) and an execution control section (12). The engineering tool (100) includes a configuration editing section (1) that receives information indicating a unit to be disabled selected from a programmable logic controller by a user, a variable holding section (2) that holds variables to be used by units in a sequence program, a program editing section (3) that can edit the sequence program, a storage section (4) that stores the sequence program, a conversion section (5) that converts the sequence program to execution code executable by an executing section (11), a search section (6) that acquires a variable to be used by the unit to be disabled from the variable holding section and searches the sequence program for a location where the acquired variable is used, and a disabling setting section (7) that writes a region corresponding to the location in the execution code into a disabled-region setting file as a disabled region where execution is disabled. The execution control section (12) controls, on the basis of the disabled-region setting file, the executing section so as not to execute the disabled region.

Owner:MITSUBISHI ELECTRIC CORP

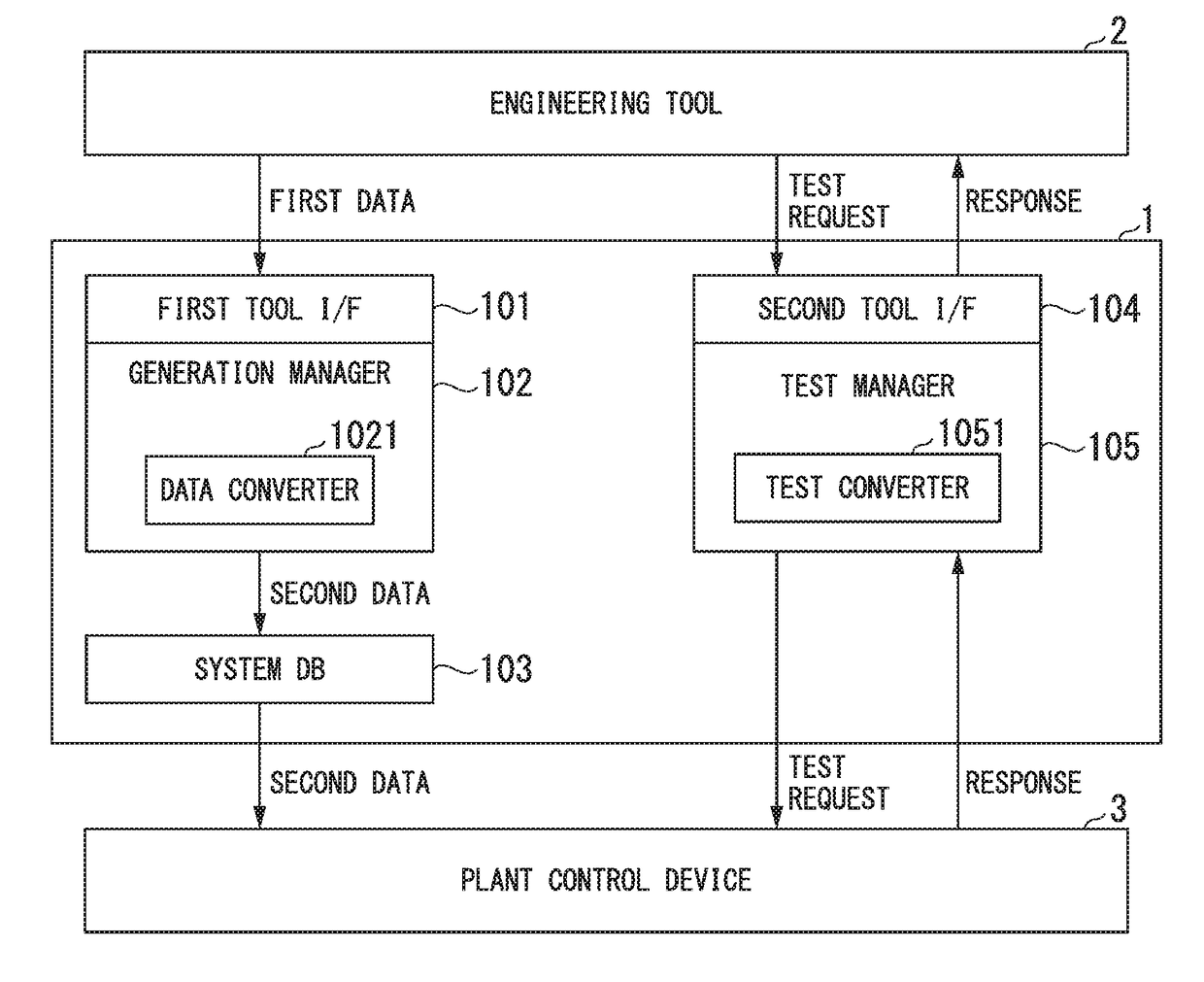

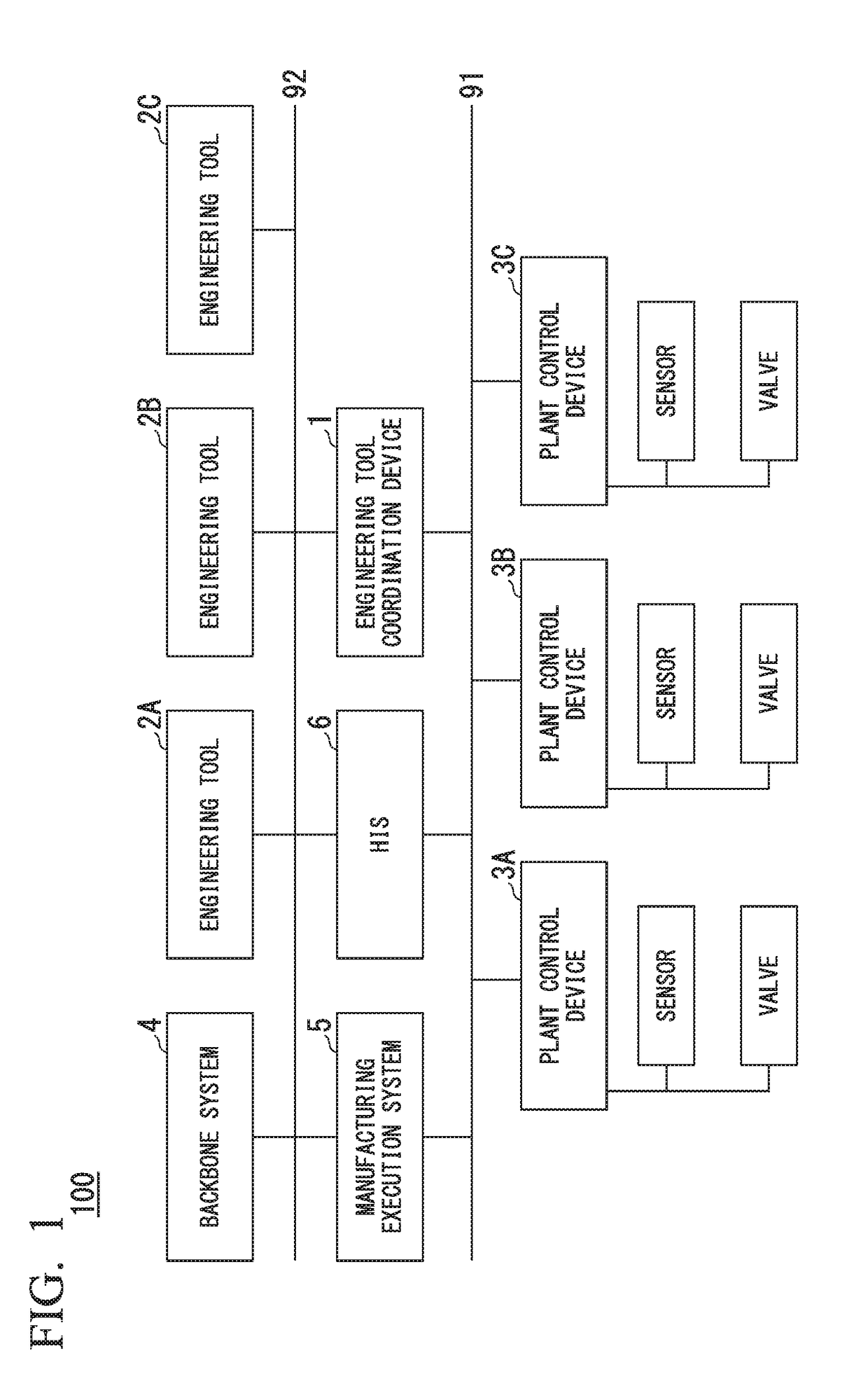

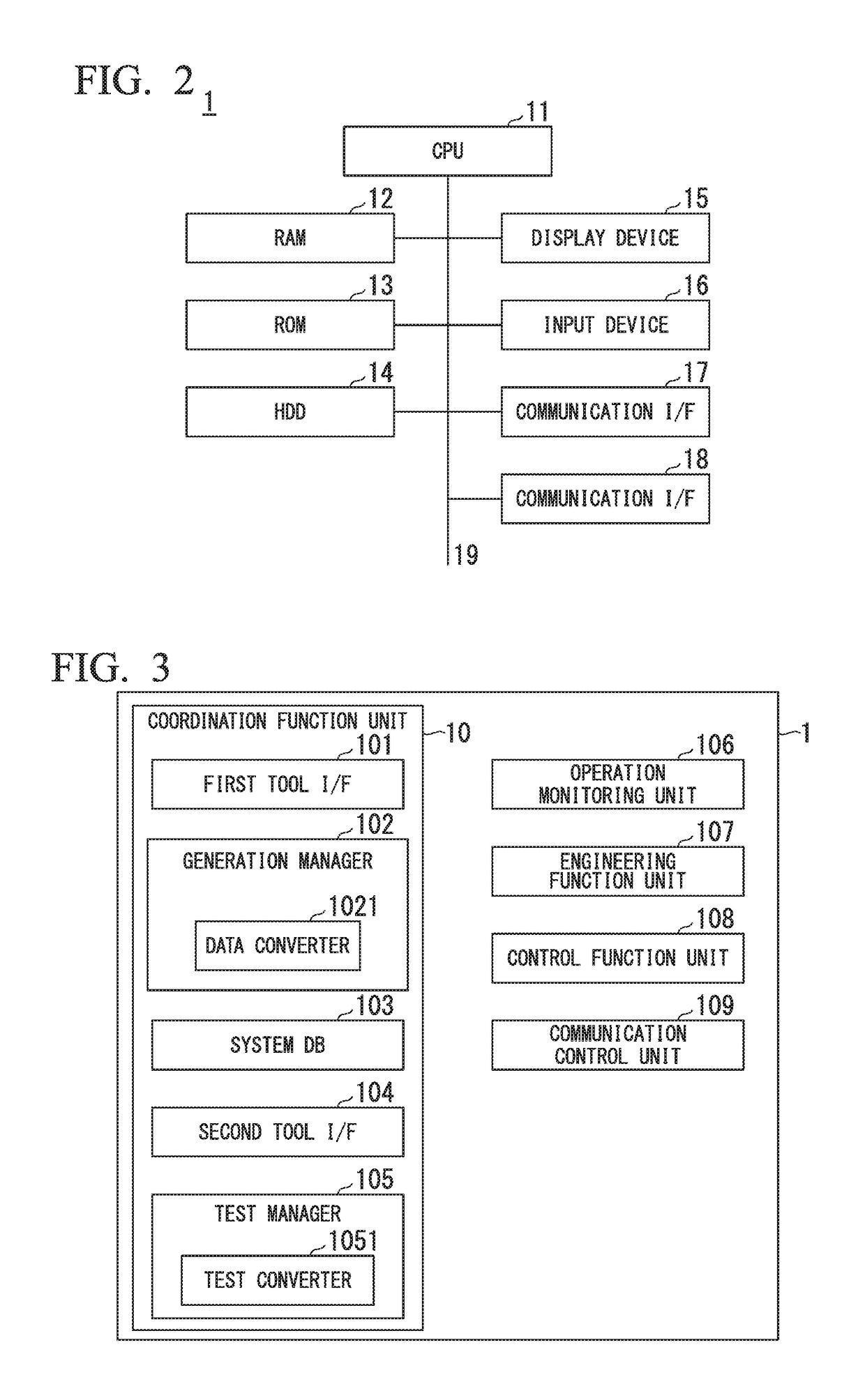

Engineering tool coordination device, engineering tool coordination method, and non-transitory computer readable storage medium

An engineering tool coordination device includes a first tool interface configured to acquire first data having a first data format usable to an engineering tool, a data converter configured to convert the first data into second data usable to the control program, the second data having a second data format, a program provider configured to provide the second data to the control program, a second tool interface configured to acquire a first test request having a first test request format from the engineering tool, a test converter configured to convert the first test request into a second test request executable in the control program, the second test request having a second test request format, and a test manager configured to cause to execute an operation test program in the control program and to operate an operation test using the second data on a basis of the second test request.

Owner:HABCO IND INC +1

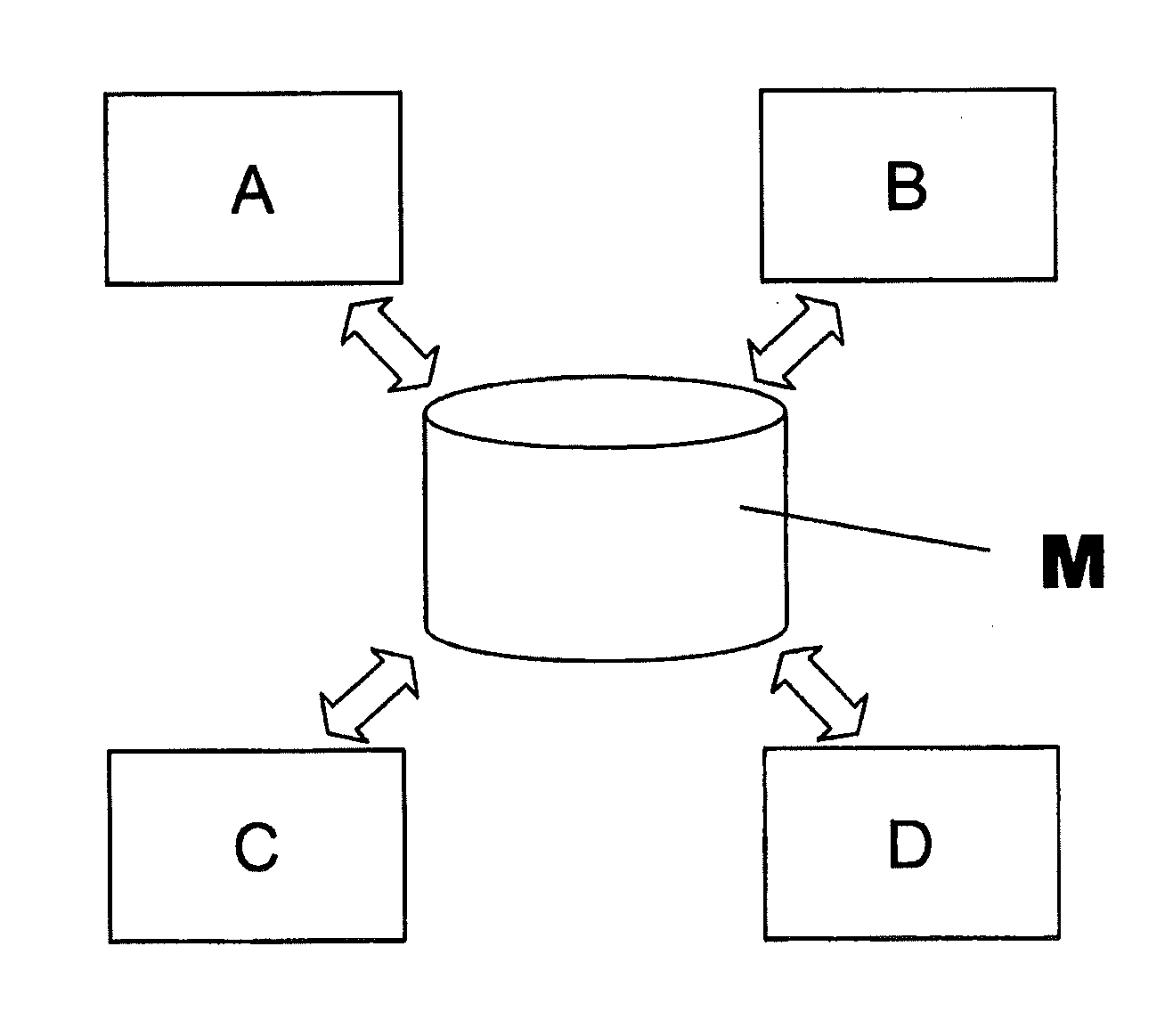

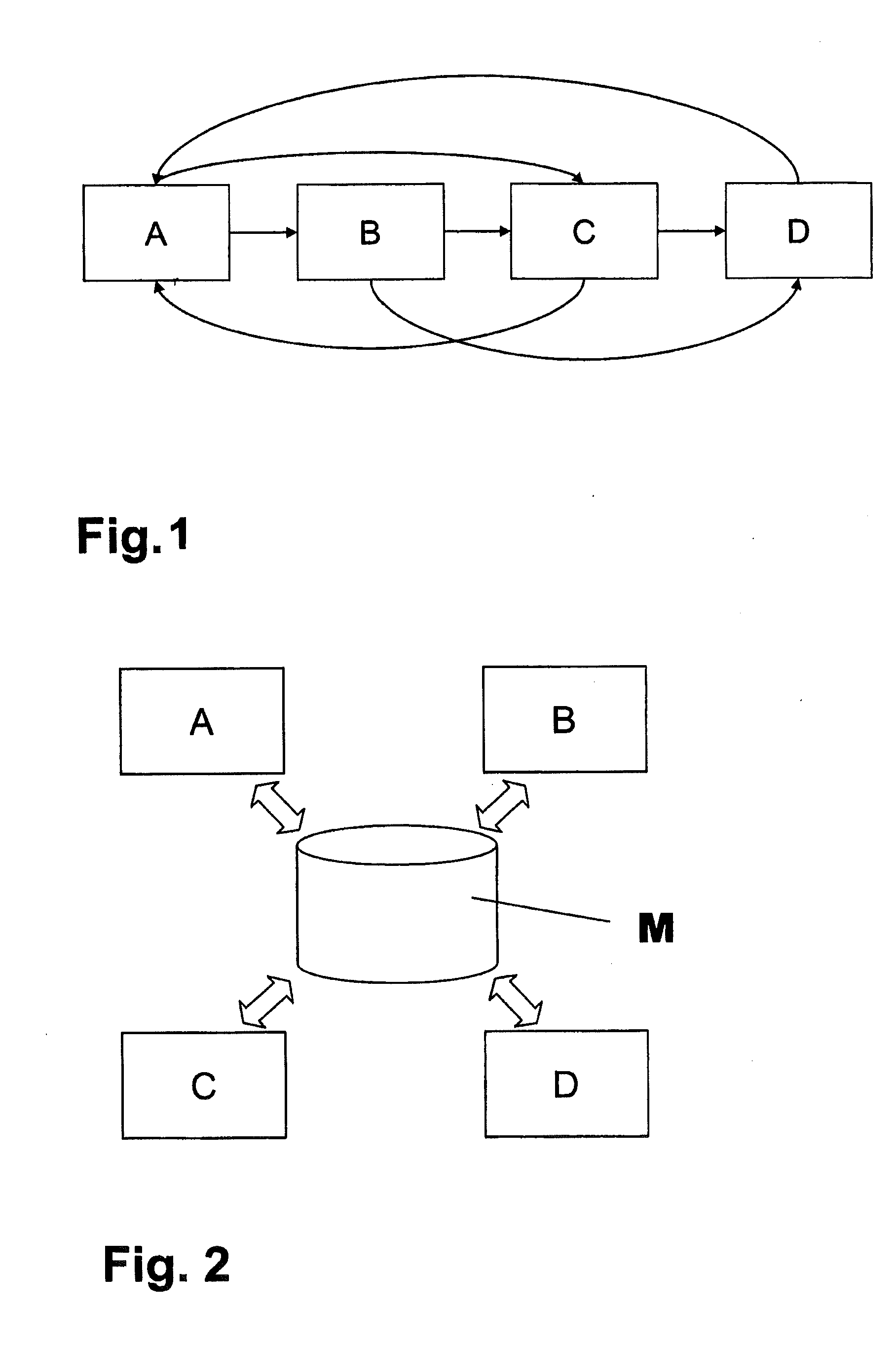

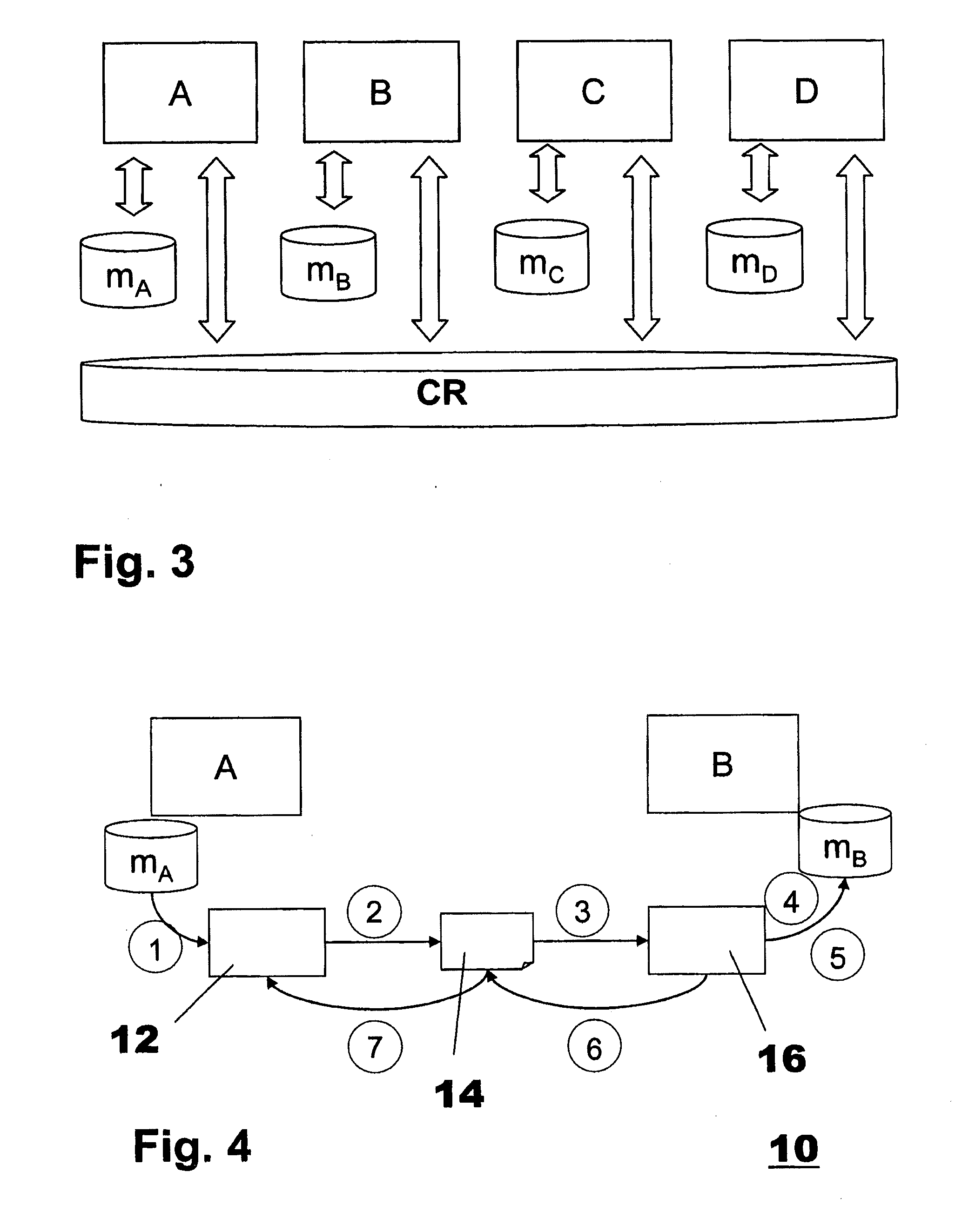

System and method for data integration of engineering tools

InactiveUS20120303586A1Database management systemsDigital data processing detailsOriginal dataEngineering tool

Exemplary embodiments of the present disclosure relates to a system and method for data integration using at least two independent engineering tools including their private database, where all data in the first tool being of interest for the second tool are identified, specified and stored in an electronic data container. Each data item stored in the electronic data container is provided with a link to the original data and with a copy of the stored data items. The electronic data container that includes the data items can be accessed by the target tool or a separate application to obtain a read-only view of the engineering data of the source tool for further use in the target engineering tool and navigation through the data for the engineer as well as for a data import.

Owner:ABB RES LTD

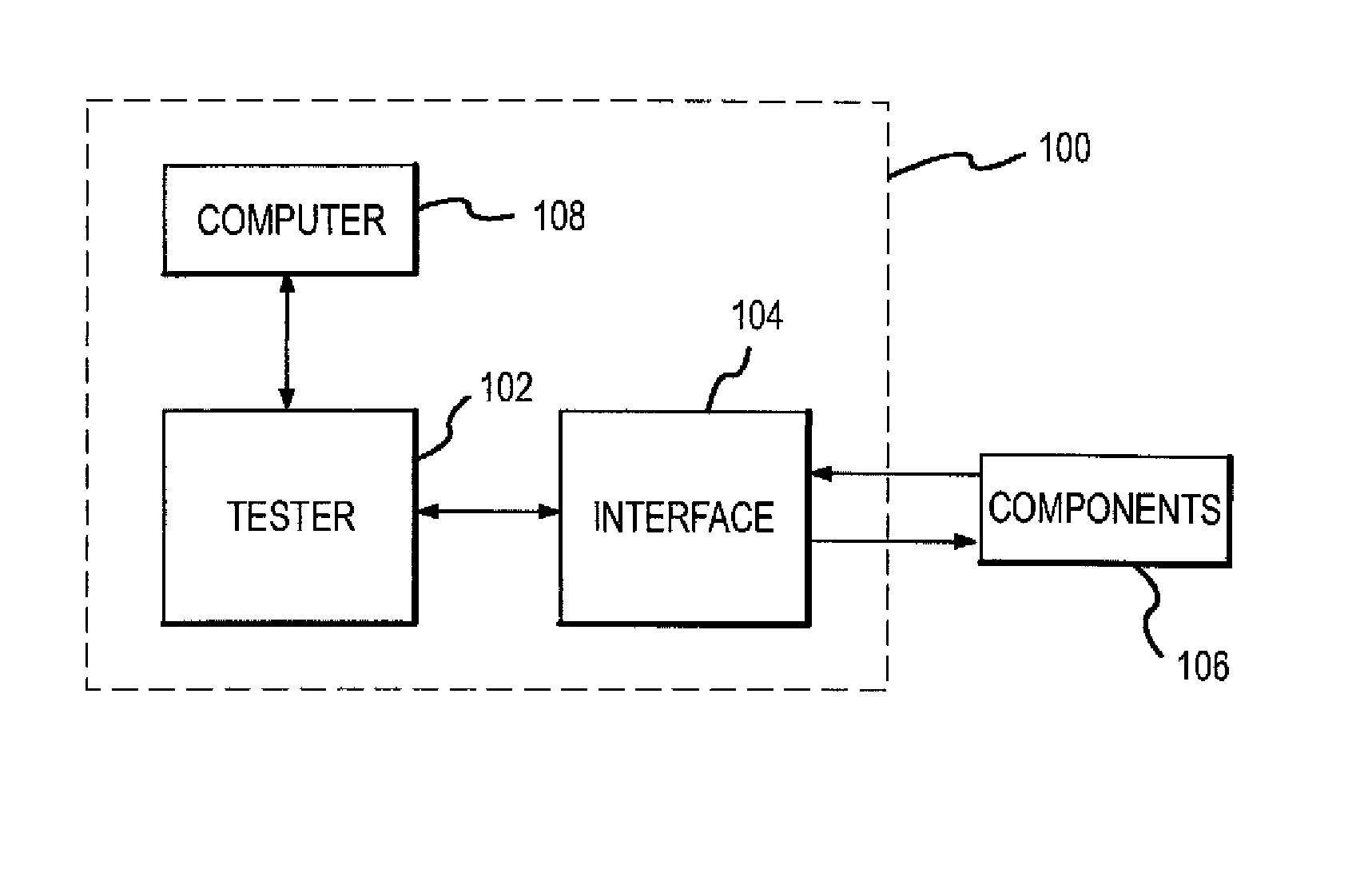

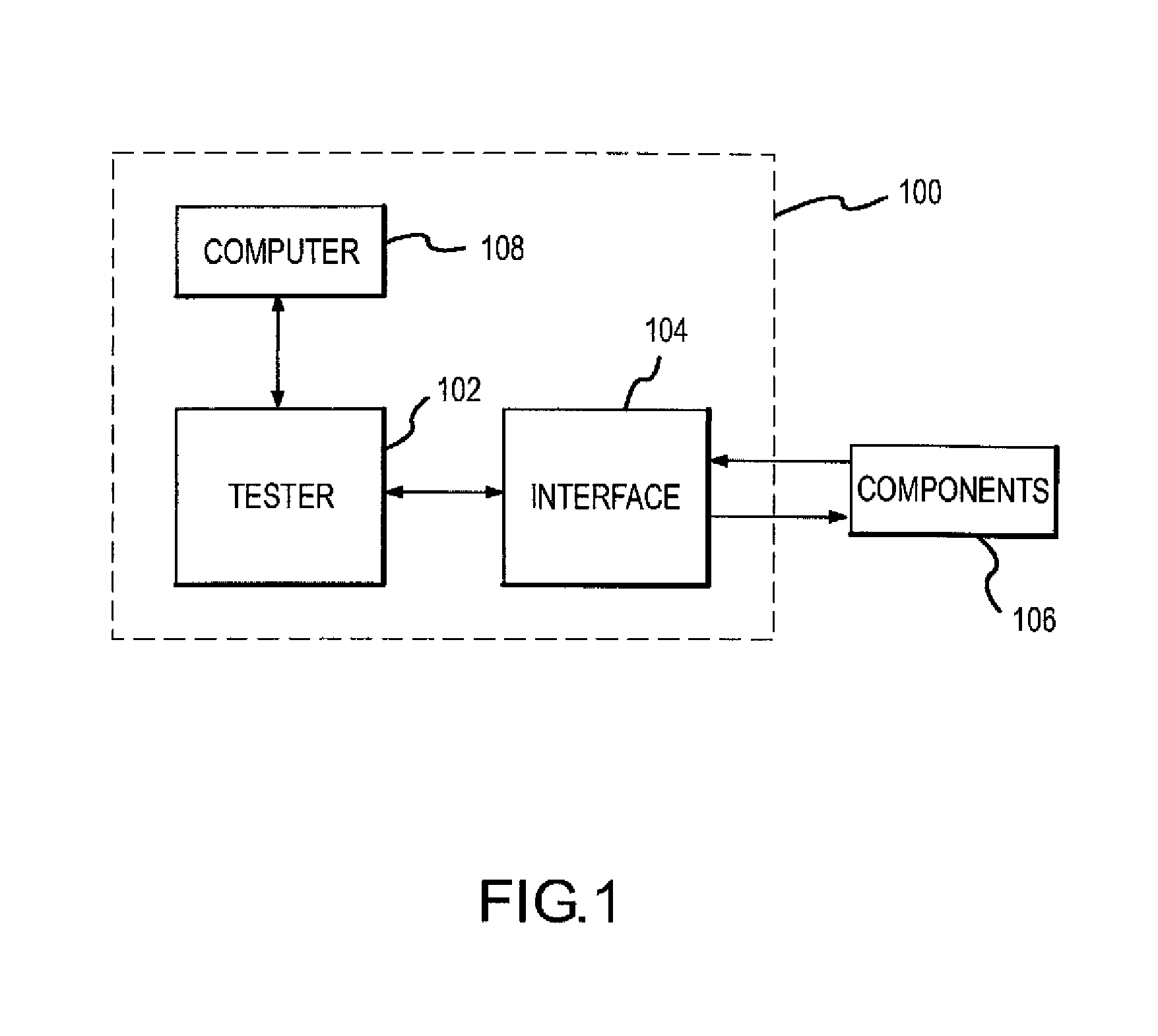

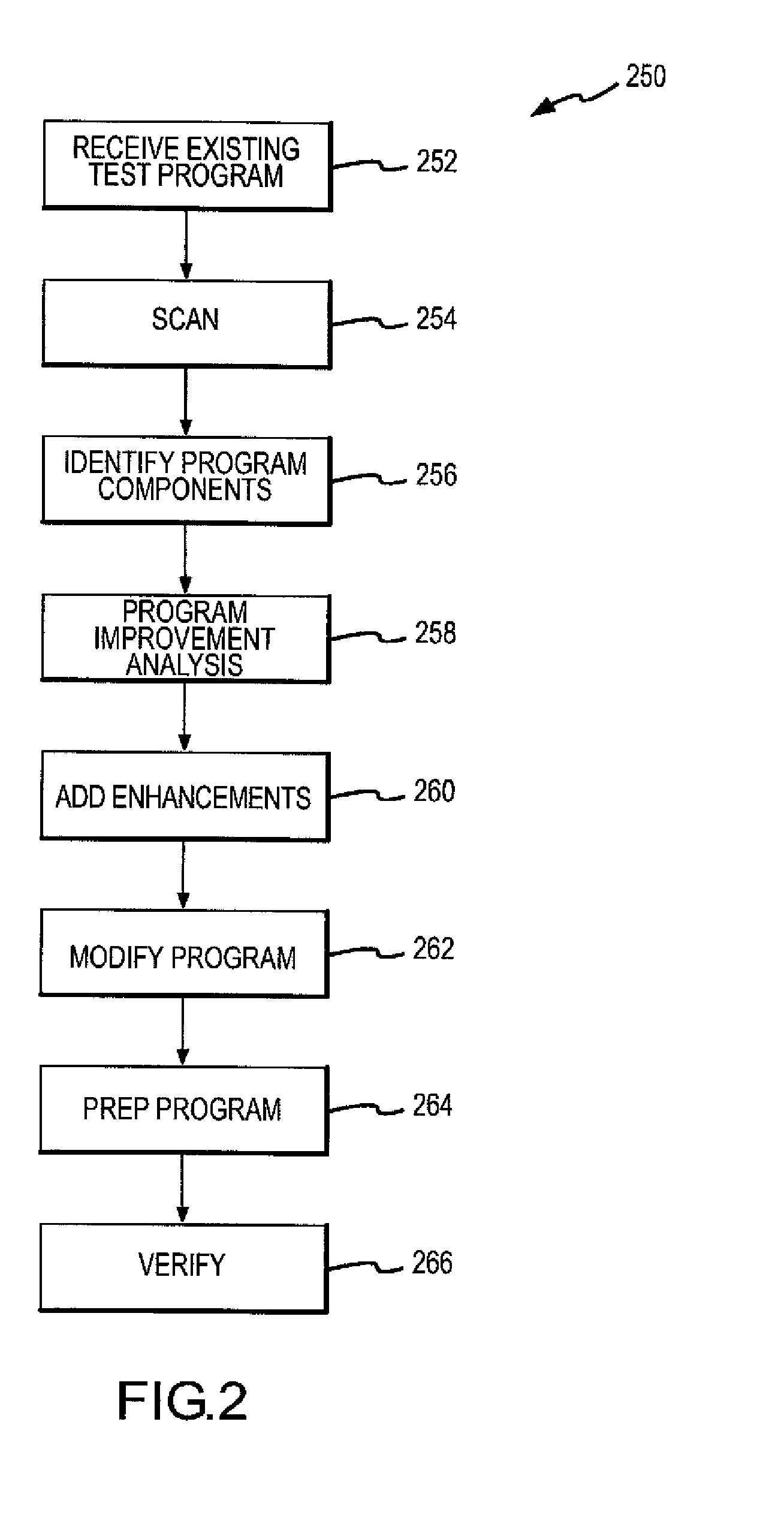

Method and apparatus for automatic test equipment

InactiveUS20080004829A1Improve performanceExtended test timeTesting/monitoring control systemsElectrical measurementsAutomatic test equipmentEngineering tool

Methods and apparatus for automatic test equipment enhance performance of automatic test equipment and provide test engineering tools. Various aspects of the present invention provide improved test times and other performance characteristics for ATE. In addition, a test system according to various aspects of the invention may include test tools to assist personnel in test processes.

Owner:TEST ADVANTAGE

Design engineering tools for visualizing existing utility lines within a land area and validating placement of new utility lines

InactiveUS20200097618A1Geometric CADData processing applicationsComputer graphics (images)Engineering tool

A design engineering tool and associated method are disclosed. The design engineering tool and method allow a user to view a photo of a land area or a map derived from the photo, to overlay the photo or map with existing utility lines and proposed utility lines, and to generate alerts regarding any conflict that is identified between a proposed utility line and an existing utility line. The tool also has an augmented reality mode where it displays visualizations of existing and proposed utility lines over a real-time image obtained from a camera. Optionally, the exact location and condition of existing utility lines can be determined using radar and camera devices that generate data describing the location and physical characteristics of the utility lines. The generated data can be imported into the design engineering tool.

Owner:I D TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com