Sequence-program debugging assistance apparatus

A technology of sequencing programs and auxiliary devices, applied in program control, electrical program control, program control in sequence/logic controllers, etc., can solve problems such as non-execution of programs, and achieve the effect of reducing man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

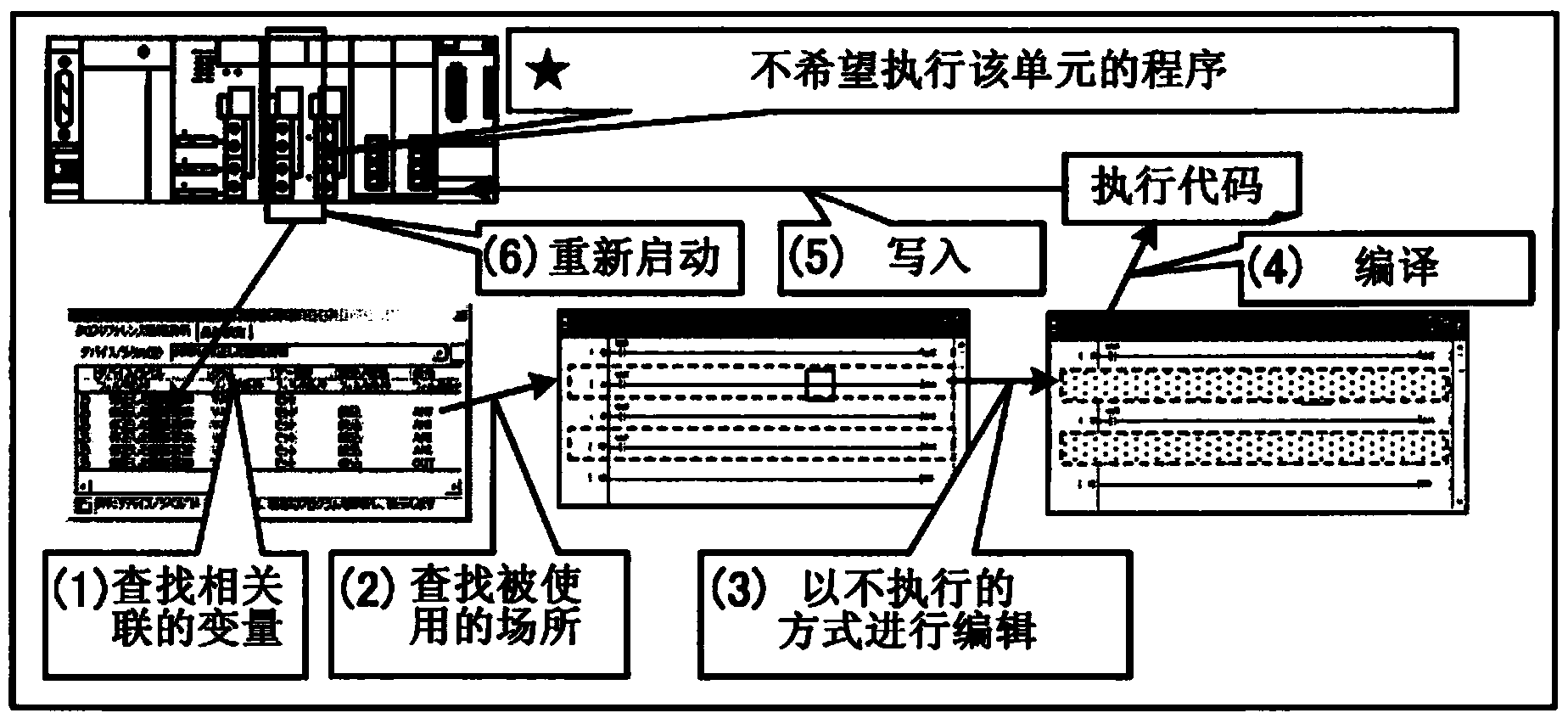

Method used

Image

Examples

Embodiment approach 1

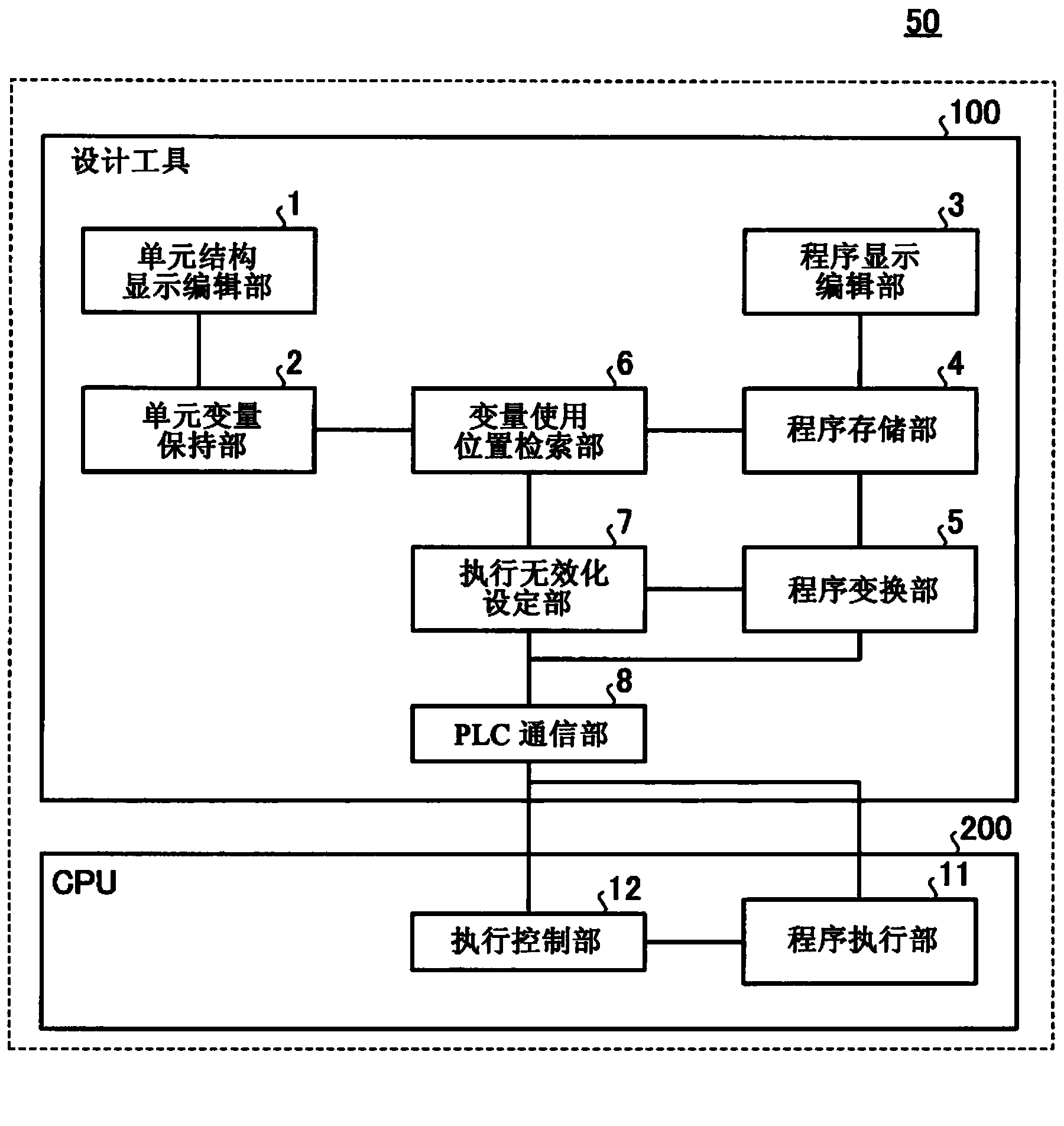

[0029] exist figure 2 The basic configuration of the sequence program debugging support device 50 according to Embodiment 1 of the present invention is shown in . As a basic structure for realizing the sequence program debugging support device 50, it is conceivable to have a computer or the like on which design tool software is installed, that is, a design tool 100, and a CPU 200 (hardware) of a programmable logic controller (PLC) that executes a program created by the design tool 100. ) structure. The CPU 200 is a part of a programmable logic controller (PLC) main body (not shown as a whole).

[0030] The outline of each constituent element will be described below. The design tool 100 is a tool for editing a program operating in the PLC system, and is realized by, for example, a computer on which design tool software is installed. The design tool 100 has each processing unit shown below.

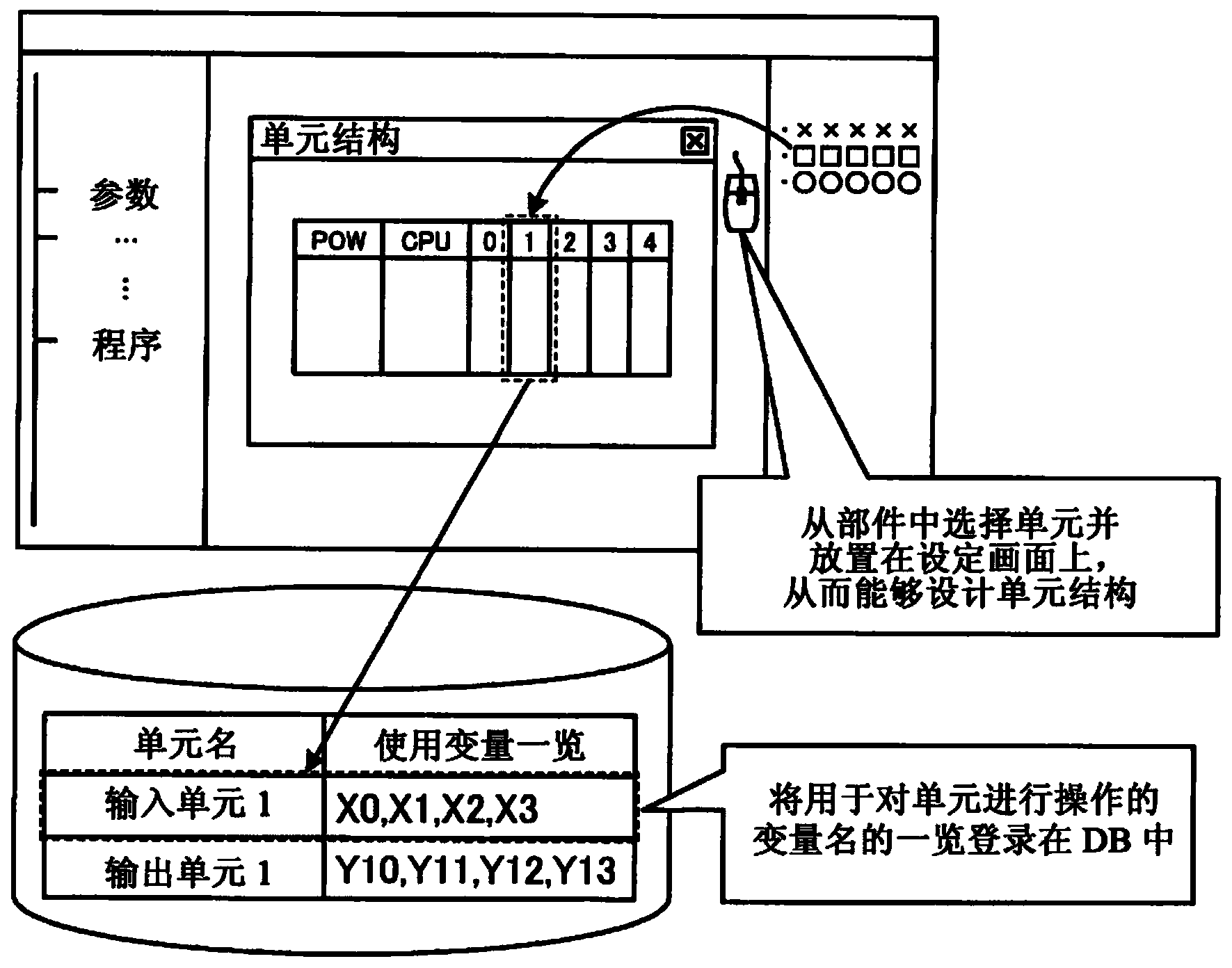

[0031] Cell Structure Display Editorial 1:

[0032] It is an editor that can set ...

Embodiment approach 2

[0088] In addition, in Embodiment 1, it is assumed that the user manually selects the unit to be invalidated on the unit configuration diagram in the (execution invalidation operation of the program using the unit), but in the actual system of the PLC, there are In the case of the unit, this operation can also be omitted.

[0089] In this embodiment, if Figure 13 As shown, the sequence program debugging support device 50 includes an automatic recognition unit 20 having a function of automatically recognizing a unit not mounted on a programmable logic controller (PLC) (unconnected unit). Such as Figure 13 As shown, the automatic recognition unit 20 may be provided only on the CPU 200 (hardware) side to notify the design tool 100 (software) of the recognition result, or it may be shared by the CPU 200 and the design tool 100 . exist Figure 14 The operation flow of this embodiment including the operation of the sequence program debugging support device 50 is shown in .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com