Hydrophilic-underwater oleophobic polymer porous membrane, preparation method and applications thereof

A polymer and porous membrane technology, applied in the field of materials, can solve the problems of inability to separate emulsified oil, poor strength of separation membrane, etc., and achieve the effects of simple and easy preparation process, efficient separation, high separation efficiency and flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The preparation method of the hydrophilic-underwater oleophobic polymer porous membrane of the present invention comprises:

[0027] Dissolving polymer materials in organic solvents to prepare polymer solutions;

[0028] Transferring the polymer solution to the surface of the substrate for spreading or direct spinning;

[0029] A hydrophilic-hydrophobic polymer porous membrane was obtained through phase inversion induced by salts.

[0030] Further, it is obvious that based on the foregoing contents of this specification, those skilled in the art can easily think of preparing Membranes of different strengths, thicknesses and areas to meet the needs of practical applications.

[0031] For example, as a preferred embodiment of the present invention, the concentration of the polymer material in the mixed solution can be 0.05-40% by weight, and the polymer material grafted with hydrophilic functional groups includes polyacrylic acid and its derivatives, poly-N-ethyl ethyl ...

Embodiment 1

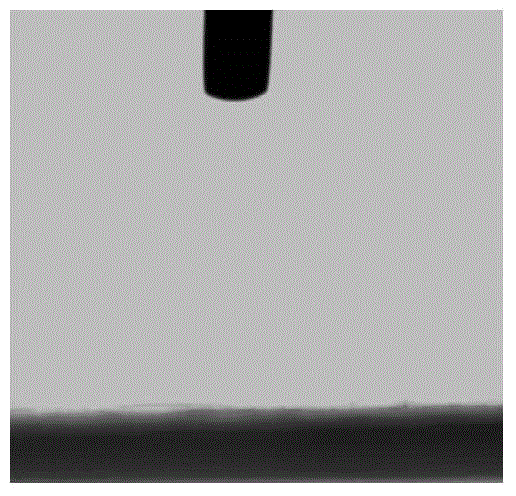

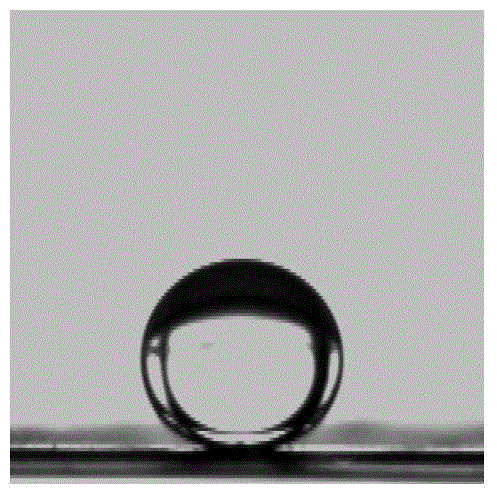

[0041] Weigh polyvinylidene fluoride (PVDF, grafted polyacrylic acid, graft rate 7.1% by weight) and dissolve it in N-methylpyrrolidone (NMP), prepare 10ml of 0.05g / ml solution, and stir until uniform. Accurately weigh sodium acetate and dissolve it in pure water to prepare a 15% by weight coagulation bath. After the obtained polymer solution is scraped on the surface of the pre-cleaned glass substrate, it is transferred to a coagulation bath for phase inversion. Then the membrane is taken out from the coagulation bath and dried at room temperature to obtain a hydrophilic-hydrophobic polymer porous membrane, and its surface structure can be found in Figure 4 , with a contact angle of 0° for water (see figure 2 ), the underwater oil (dichloroethane) contact angle is 150° (see image 3 ).

Embodiment 2

[0043] Weigh polyethersulfone (PES, grafted sodium polysulfonate, grafting rate 8.0% by weight) and dissolve it in dimethylacetamide (DMAc) to prepare 200ml of 0.17g / ml solution, stir evenly and ultrasonically defoam. Accurately weigh potassium nitrate and dissolve it in water to prepare a 10% by weight coagulation bath. The obtained polymer solution is transferred to the reaction kettle of the small hollow fiber spinning machine, and the polymer solution is extruded through the spinneret and directly enters the coagulation bath for phase inversion. Then the membrane was taken out from the water bath, and dried in an oven at 60°C to obtain a hydrophilic-hydrophobic polymer porous membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com