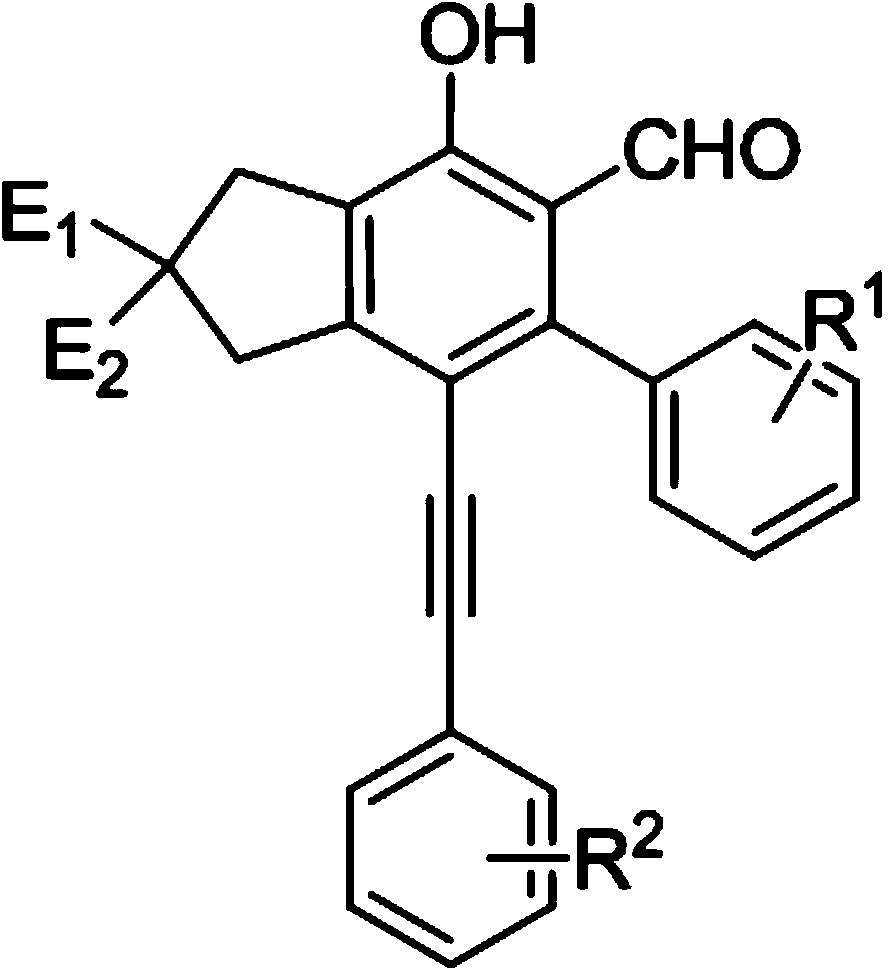

Salicylaldehyde derivatives and preparation method thereof

A derivative, salicylaldehyde technology, applied in the field of salicylaldehyde derivatives and their preparation, can solve the problems of low efficiency, unfriendly environment, high cost, and achieve the effects of complex and diverse structures and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

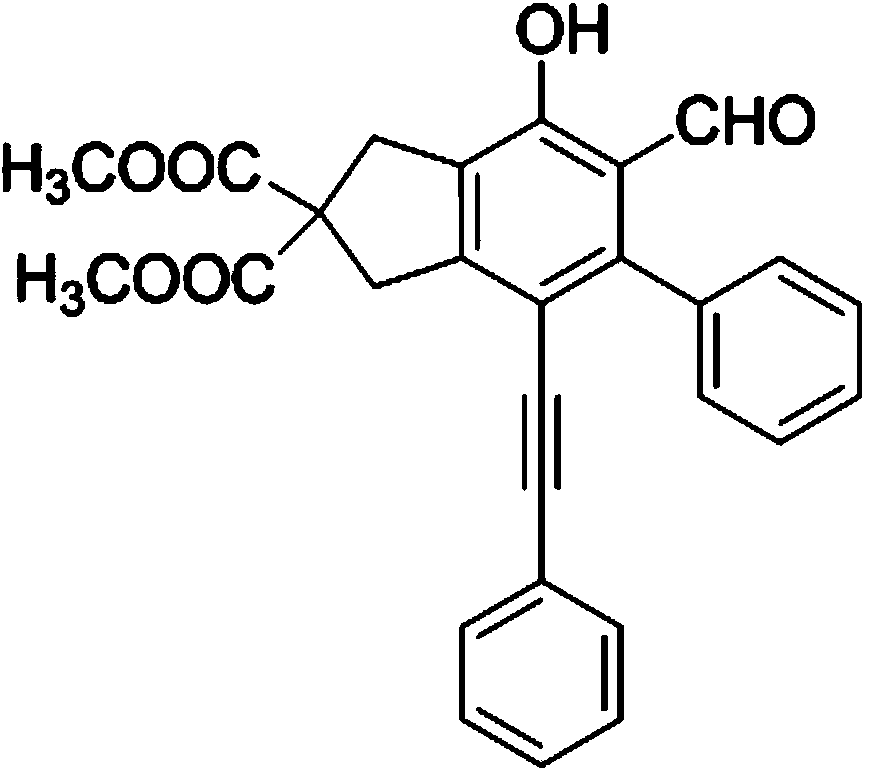

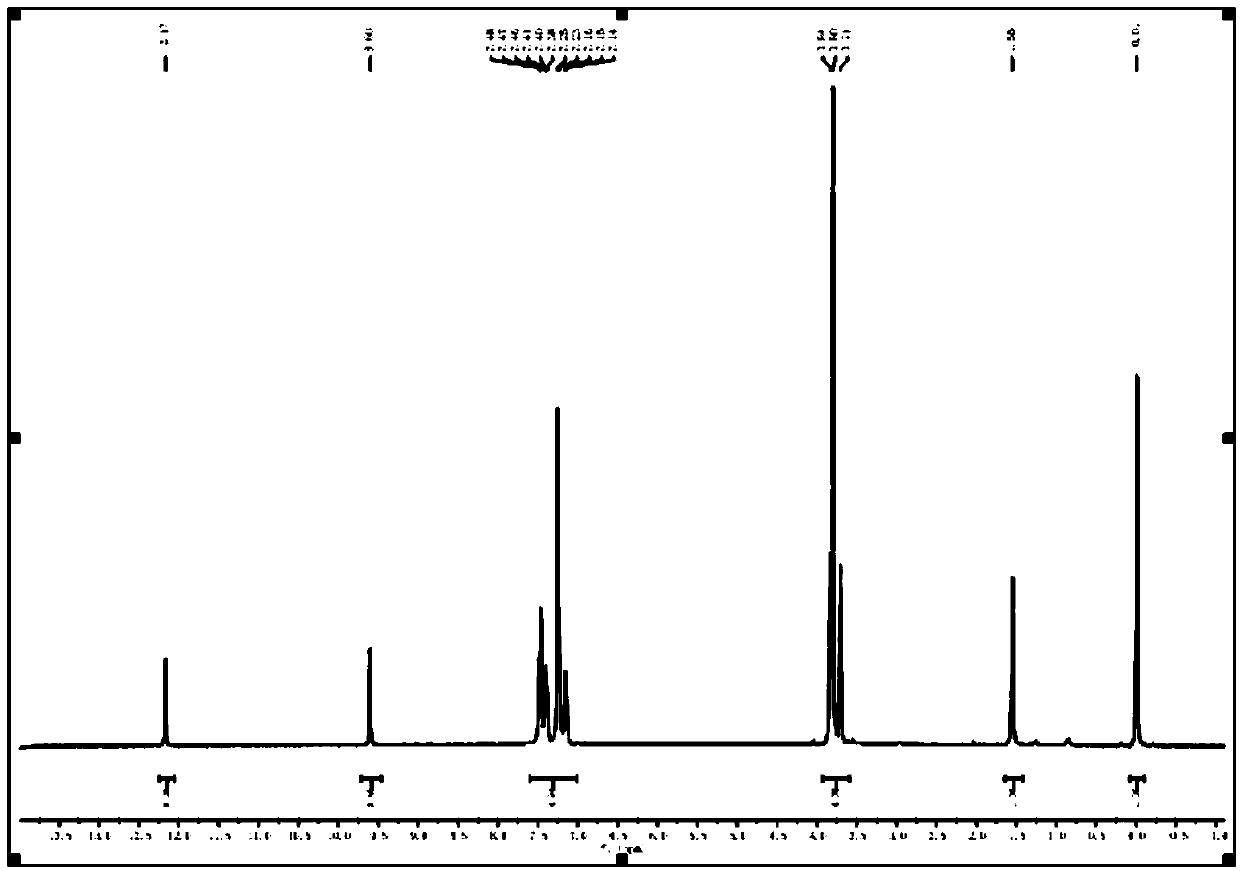

Embodiment 1

[0056] A salicylaldehyde derivative, the structural formula of the salicylaldehyde derivative is:

[0057]

[0058] A kind of preparation method of salicylaldehyde derivative, described preparation method comprises the following steps:

[0059] a. Precursor compound synthesis;

[0060] b. Synthesis of the target product;

[0061] c. Purification.

[0062] Wherein, a, precursor compound is synthesized, comprises the following steps:

[0063] (1) Using sodium hydride as a catalyst, add 200mmol dimethyl malonate and 440mmol propargyl bromide into anhydrous acetonitrile in an ice-water bath, stir and react for 8 hours, wash the product with water, extract with ethyl acetate, spin under reduced pressure Dry, column chromatography (volume ratio ethyl acetate: petroleum ether = 1:100) to obtain a white solid product;

[0064] (2) Mix 80mmol of compound 1 with 240mmol of phenylethynyl bromide in Pd(PPh 3 ) 2 Cl 2 / CuI anhydrous and oxygen-free catalytic system, the molar ratio...

Embodiment 2

[0076] A salicylaldehyde derivative, the structural formula of the salicylaldehyde derivative is:

[0077]

[0078] A kind of preparation method of salicylaldehyde derivative, described preparation method comprises the following steps:

[0079] a. Precursor compound synthesis;

[0080] b. Synthesis of the target product;

[0081] c. Purification.

[0082] Wherein, a, precursor compound is synthesized, comprises the following steps:

[0083] (1) Using sodium hydride as a catalyst, add 200mmol dibenzyl malonate and 600mmol propargyl bromide into anhydrous acetonitrile in an ice-water bath, stir and react for 8 hours, wash the product with water, extract with ethyl acetate, and depressurize Spin dry, column chromatography (volume ratio ethyl acetate:petroleum ether=1:80) to obtain a white solid product;

[0084] (2) Mix 80mmol of compound 1 with 180mmol of phenylethynyl bromide in Pd(PPh 3 ) 2 Cl 2 / CuI anhydrous and oxygen-free catalytic system, the molar ratio Pd(PPh ...

Embodiment 3

[0096] A salicylaldehyde derivative, the structural formula of the salicylaldehyde derivative is:

[0097]

[0098] A kind of preparation method of salicylaldehyde derivative, described preparation method comprises the following steps:

[0099] a. Precursor compound synthesis;

[0100] b. Synthesis of the target product;

[0101] c. Purification.

[0102] Wherein, a, precursor synthesis, comprises the following steps:

[0103] (1) Using sodium hydride as a catalyst, add 200mmol diisopropyl malonate and 460mmol propargyl bromide into anhydrous acetonitrile in an ice-water bath, stir and react for 8 hours, wash the product with water, extract with ethyl acetate, and remove Press and spin dry, column chromatography (volume ratio ethyl acetate: petroleum ether = 1:80) to obtain a white solid product;

[0104] (2) Mix 80mmol of compound 1 with 200mmol of 4-fluorophenylethynyl bromide in Pd(PPh 3 ) 2 Cl 2 / CuI anhydrous and oxygen-free catalytic system, the molar ratio Pd(...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com