Ferro-cerium-based rapid quenching permanent magnet powder and preparation method of ferro-cerium-based rapid quenching permanent magnet powder

A technology of cerium-iron-based permanent magnet powder, which is applied in the field of cerium-iron-based quick-quenching permanent magnet powder and its preparation, to achieve the effects of being suitable for engineering production, saving production time and energy consumption, and reducing melting temperature and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

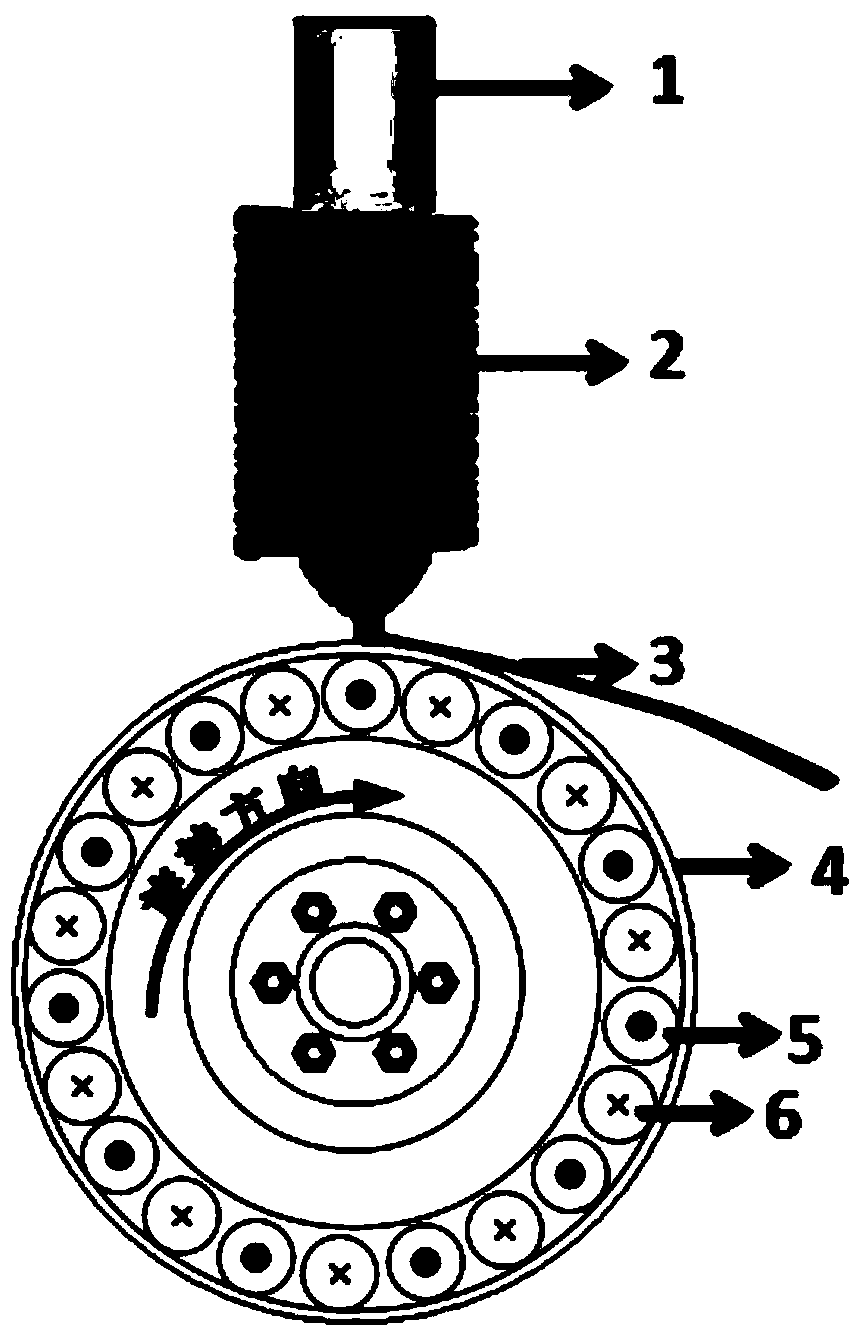

[0042] Using low temperature melting, rapid quenching process to prepare magnetic powder on copper alloy roll or molybdenum roll (such as figure 1 shown), the process steps are as follows:

[0043] Step 1: According to the composition chemical formula of mass percent: [Ce 100-x , Re x ] a Fe 100-a-b-c B b tm c Prepare raw materials (as shown in Table 1), wherein Re is one or more of Nd, Pr, Dy, Tb elements, and TM is one or more of Ga, Co, Cu, Nb, and Al elements.

[0044] Table 1 Alloy composition chemical formula of different embodiments

[0045]

nominal component

Example 1

(Ce 90 Nd 10 ) 30 Fe bal co 4 Ga 0.4 B 0.92

Example 2

(Ce 70 Nd 30 ) 30 Fe bal co 3.9 Ga 0.4 Cu 0.1 B 0.92

Example 3

(Ce 50 Nd 50 ) 30 Fe bal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com