Forming destructive distillation method for crushed low metamorphic coal powder, asphalt and tar residues

A low-metamorphism pulverized coal and tar residue technology, applied in the field of coal chemical industry, can solve problems affecting low-metamorphism pulverized coal mid-low temperature pyrolysis upgrading, product quality and performance, and coke product cracking, etc., to alleviate coal resources The effects of shortage, enhanced mechanical strength, and improved oil yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

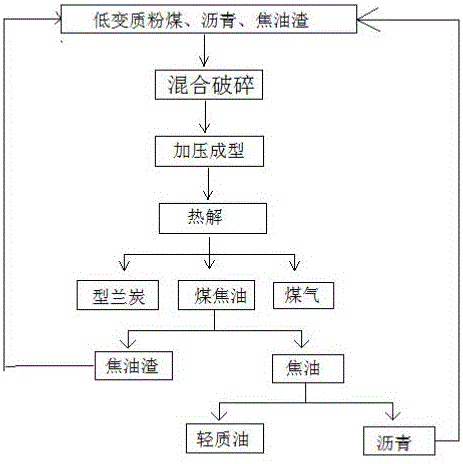

[0032] Such as figure 1 As shown, a method for preparing semi-coke with low metamorphic pulverized coal, asphalt, and tar residue as raw materials, specifically in the following order:

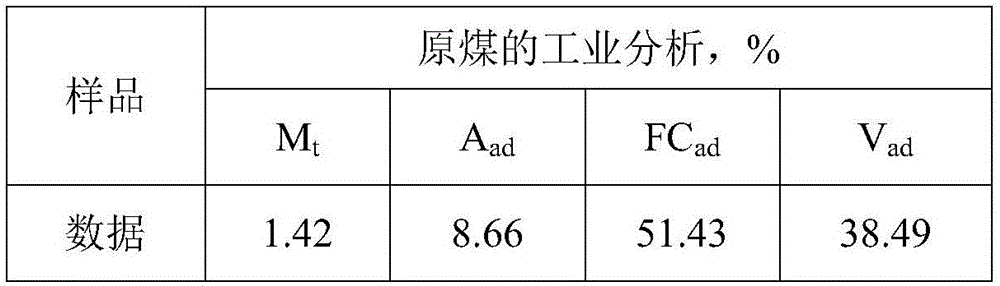

[0033] (1) According to the mass ratio of 85% of low metamorphic pulverized coal, 10% of asphalt, and 5% of tar residue, mixed and crushed to obtain raw material powder with particle size controlled at 0.1mm, wherein the low metamorphic pulverized coal is long-flame coal; The tar residue is the high oil-containing solid waste deposited in the tar pool after pyrolysis of low-modified coal; the pitch is the solid residue coal tar pitch or coal tar pitch coke obtained after distillation or delayed coking of medium and low temperature heavy coal tar;

[0034] (2) press molding the raw material powder of step (1) gained under the condition of 10MPa in the molding die, obtain briquette;

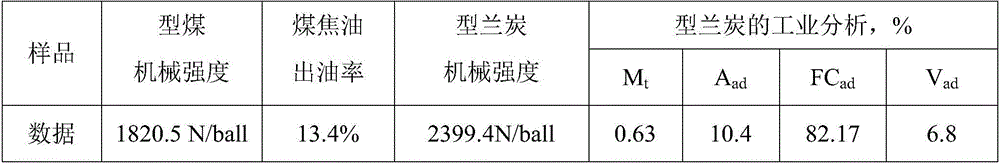

[0035] (3) After naturally drying the briquettes obtained in step (2) for 28 hours, carry out pyrolysis at 750°...

Embodiment 2

[0039] Such as figure 1 As shown, a method for preparing semi-coke with low metamorphic pulverized coal, asphalt, and tar residue as raw materials, specifically in the following order:

[0040] (1) According to the mass ratio of 82% of low metamorphic pulverized coal, 8% of asphalt, and 10% of tar residue, mixed and crushed to obtain raw material powder whose particle size is controlled at 0.1mm; wherein the low metamorphic pulverized coal is long-flame coal and A mixture of weakly caking coal with a mass ratio of 1:2; the tar residue is a high-oil solid waste deposited in a tar pool after pyrolysis of low-modified coal; the pitch is petroleum pitch obtained after petroleum fractionation;

[0041] (2) press molding the raw material powder of step (1) gained under the condition of 5MPa in the forming mold, obtain briquette;

[0042] (3) After naturally drying the briquettes obtained in step (2) for 24 hours, carry out pyrolysis at 650° C. for 4 hours in a retort device to obta...

Embodiment 3

[0046] Such as figure 1 As shown, a method for preparing semi-coke with low metamorphic pulverized coal, asphalt, and tar residue as raw materials, specifically in the following order:

[0047](1) According to the mass ratio of 75% of low metamorphic pulverized coal, 15% of asphalt, and 13% of tar residue, mixed and crushed to obtain raw material powder whose particle size is controlled at 0.1mm; wherein the low metamorphic pulverized coal is long-flame coal, A mixture of weakly caking coal and non-caking coal with a mass ratio of 2:2:1; the tar residue is a high-oil solid waste deposited in the tar pool after pyrolysis of low-modified coal; the pitch is a medium-low temperature heavy coal tar distilled Or the solid residue coal tar pitch or coal tar pitch coke obtained after delayed coking, or the petroleum pitch obtained after petroleum fractionation treatment;

[0048] (2) press molding the raw material powder of step (1) gained under the condition of 5MPa in the forming m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com