Vanadium/copper solid solution transition connection-based welding process for titanium-containing metal layer/pipeline steel layer composite board

A titanium metal layer and welding process technology, applied in metal processing equipment, welding equipment, welding/welding/cutting items, etc., can solve problems such as differences in chemical properties, and achieve high practical value, reliable welding quality, and good barrier effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing, the present invention is described in further detail and embodiment:

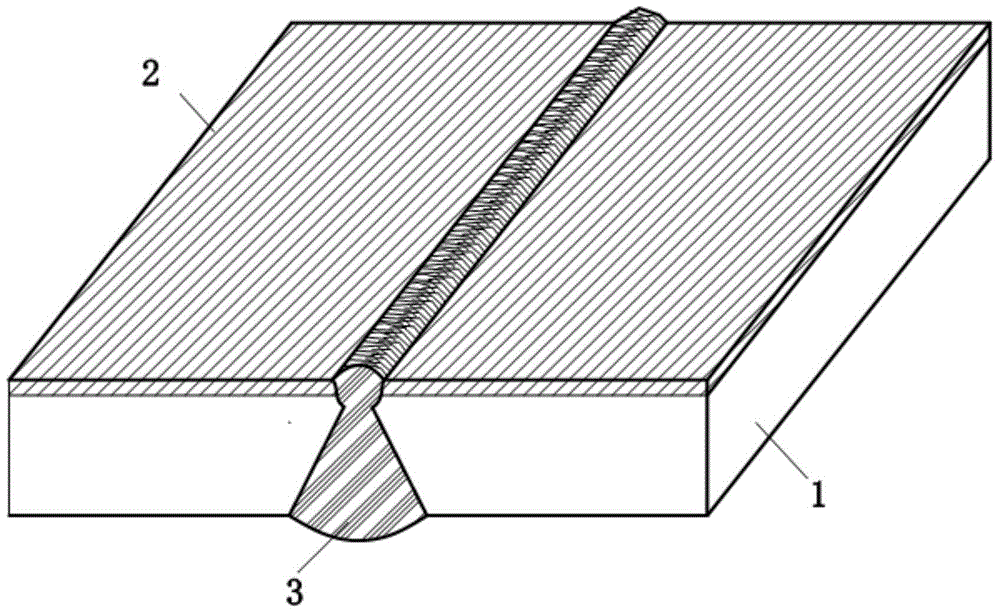

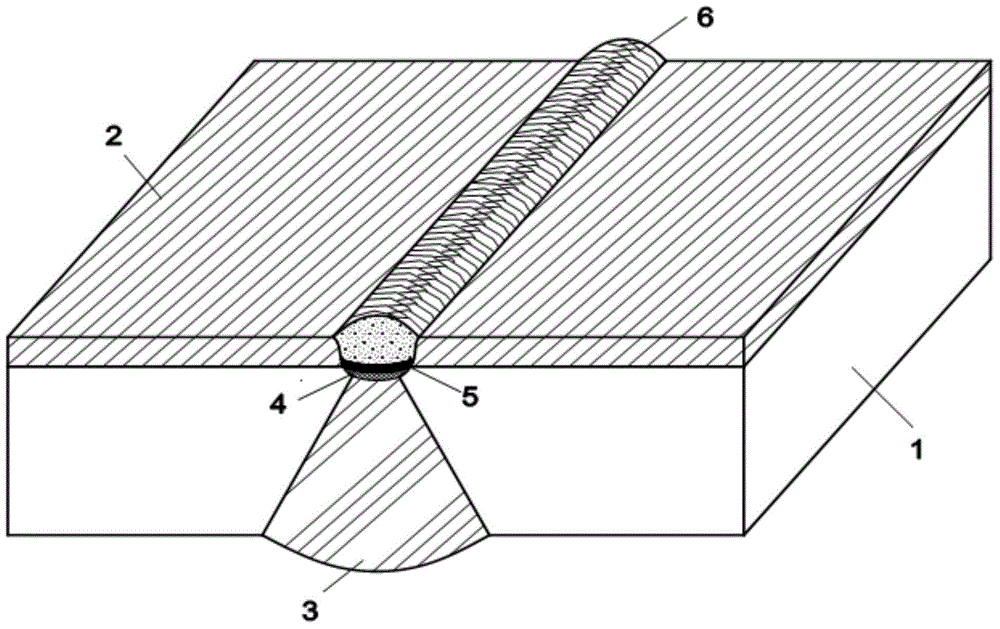

[0027] see figure 1 , 2 , taking explosion + hot rolling TA1 / X65 titanium / pipeline steel clad plate as the welding test plate, in this example, the total thickness of TA1 / X65 titanium / pipeline steel clad plate is 16mm, of which the thickness of one side of X65 steel layer is 14mm, and TA1 pure titanium The thickness of one side of the layer is 2mm.

[0028] "U+V" compound groove is adopted, the depth and width of "U" groove on one side of TA1 pure titanium layer are 4-5mm and 5-6mm respectively, and the bottom of the groove is arc-shaped (such as figure 1 , 2 As shown), the depth and angle of the "V" groove on one side of the X65 steel layer are 11-12mm and 60-70° respectively. After the groove processing is completed, a pair of TA1 / X65 titanium / pipeline steel The composite plate is spot-welded from the side of the X65 steel layer at intervals of 50...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com