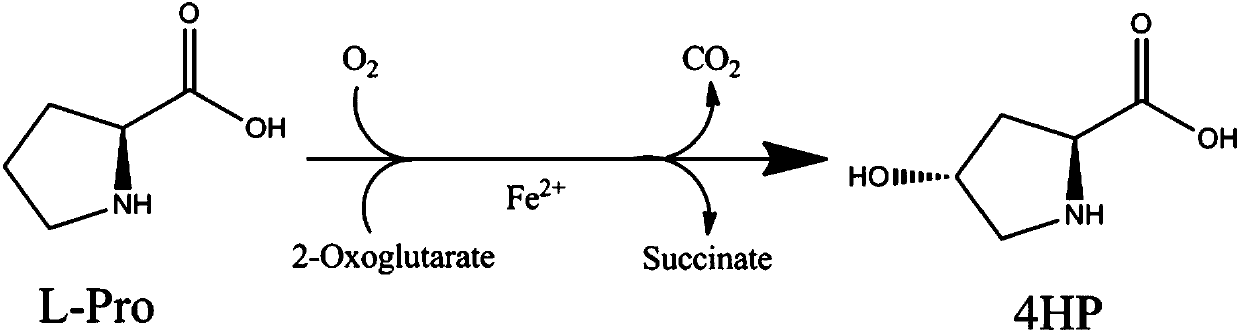

Method for producing trans-4-hydroxy-L-proline

A proline and hydroxyl technology, applied in the field of producing trans-4-hydroxy-L-proline, can solve the problem of poor expression and catalytic performance, and can not better produce trans-4-hydroxy-L- Problems such as poor stability of proline and proline 4-hydroxylase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

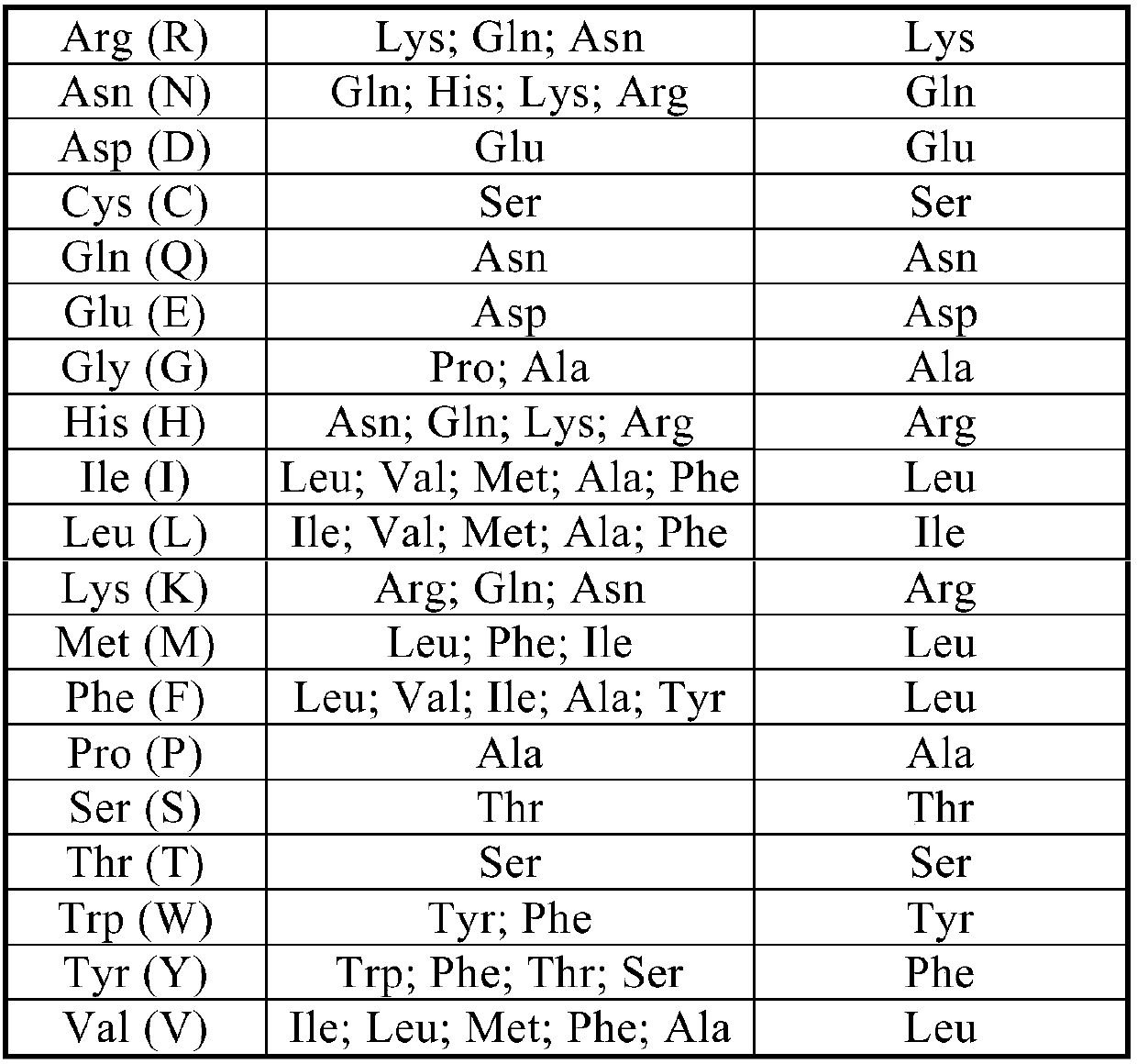

[0117] Embodiment 1. Whole gene synthesis and clone expression of proline 4-hydroxylase

[0118] First, the inventor synthesized the gene whose sequence is shown in SEQ ID NO: 2 through whole gene synthesis. Subsequently, the gene synthesized by the whole gene (sequence shown in SEQ ID NO: 2) was cloned into pET21a plasmid (purchased from Novagen) through NdeI and HindIII restriction sites, and the obtained recombinant plasmid was named pSWXP1, which expressed The protein has 6 his tags at the C-terminus, and then the recombinant plasmid is introduced into the Escherichia coli Rossetta strain (purchased from Beijing Quanshijin Biotechnology Co., Ltd.) to obtain the Escherichia coli Rossetta (pSWXP1) strain. Escherichia coli Rossetta (pSWXP1) is used to induce the expression of the protein shown in SEQ ID NO: 1, using LB medium, inoculated with 1%, adding 50ug / mL ampicillin and 34μg / mL chloramphenicol, and culturing at 220rpm at 37°C for 2-3h , OD grows to 0.6-0.8, add 0.5mM I...

Embodiment 2

[0119] Embodiment 2. The crude enzyme activity assay of proline 4-hydroxylase

[0120]The crude enzyme solution prepared in Example 1, and the crude enzyme solution of Escherichia coli Rossetta (pET21a) empty plasmid control strain were prepared by the same method. The BCA protein quantitative analysis kit (purchased from Bio-Rad, product number: 23227) was used to quantify the total protein of the crude enzyme solution. Enzyme activity assay system: 240mM MES (pH6.5), 6mM FeSO 4 , 24mM α-ketoglutarate, 8mM L-ascorbic acid, 12mM L-proline and an appropriate amount of crude enzyme, react at 35°C for 10min, stop the enzyme activity, and measure the content of trans-4-hydroxy-L-proline. The detection method of trans-4-hydroxy-L-proline refers to the national standard GB / T 9695.23-2008. One unit of enzyme activity U is defined as the amount of 1 nmol of trans-4-hydroxy-L-proline catalyzed per minute. The amount of enzyme required. The specific enzyme activity of the crude enzym...

Embodiment 3

[0123] Example 3. Proline 4-hydroxylase purification and stability assay

[0124] The performance of the enzyme of the present invention was compared with the proline 4-hydroxylase of Dactylocystis sp. RH1. The literature (Liu Hedong, Yuan Chunwei, Zhang Zhenyu. Codon-optimized expression of proline 4-hydroxylase in Escherichia coli and its effect on trans-4-hydroxyproline biosynthesis[J]. Bioprocessing, 2014, 12( 6): 44-51.) The reported codon optimization refers to the Cystomyces RH1 proline 4-hydroxylase (named as P4H-2) gene, which is synthesized by the whole gene through NdeI and HindIII enzyme cleavage sites The gene (sequence is shown in the literature: Liu Hedong. Construction and fermentation optimization of high-yielding trans-4-hydroxyproline recombinant Escherichia coli [D]. Wuxi: Jiangnan University, 2013.) was cloned into pET21a plasmid (purchased from Novagen) , the obtained recombinant plasmid was named as pSWXP2, and the expressed protein had 6 his tags at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com