Super-high diagonal symmetric forced grooving method without grooving well

A cutting well and super-height technology, applied in blasting and other directions, can solve the problems of high cost, low stope height and high safety risk, and achieve the effect of reducing management cost, saving mining cost and improving production intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

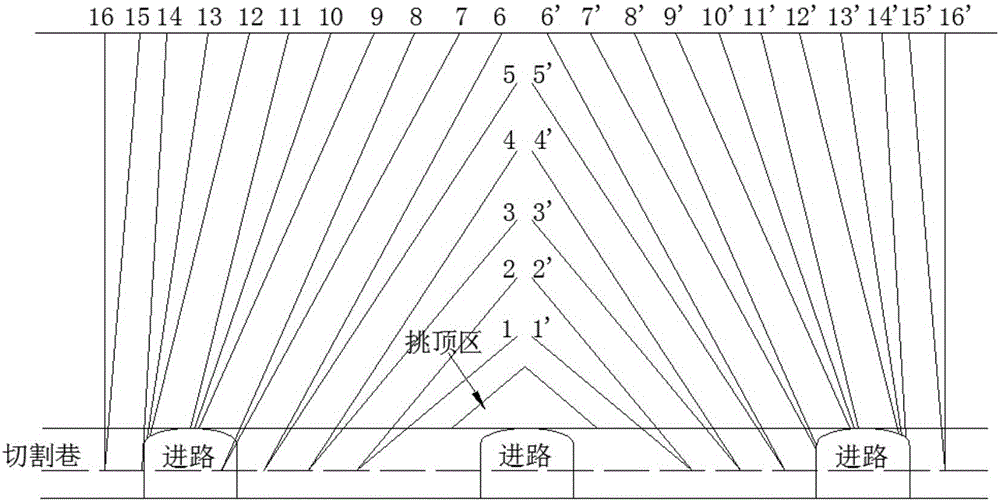

[0050] A method for forced grooving with ultra-high slant line symmetry without cutting wells, the steps are as follows:

[0051] 1) According to stope conditions,

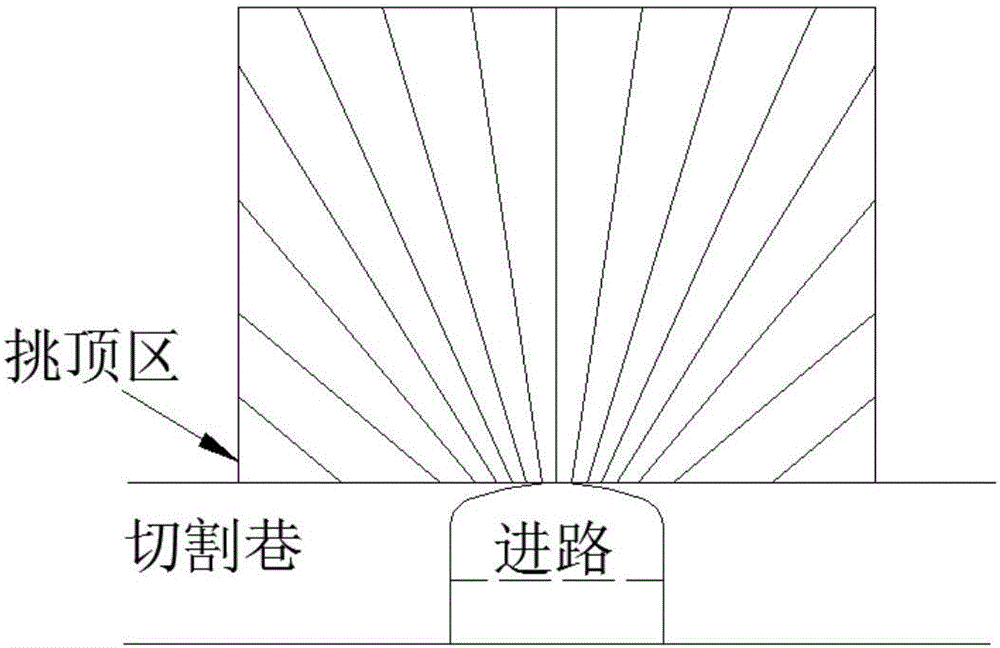

[0052] for construction, such as Figure 5 , complete the construction of ore-out approach road 7, cutting lane 4, joint lane 1, joint lane 2 6, and ore-collecting cutting ditch, forming stope 1 2 and stope 2 3; the height of the top of the top area 1 is 2-2.5 m, so that the drilling rig works on both sides of the top area 1.

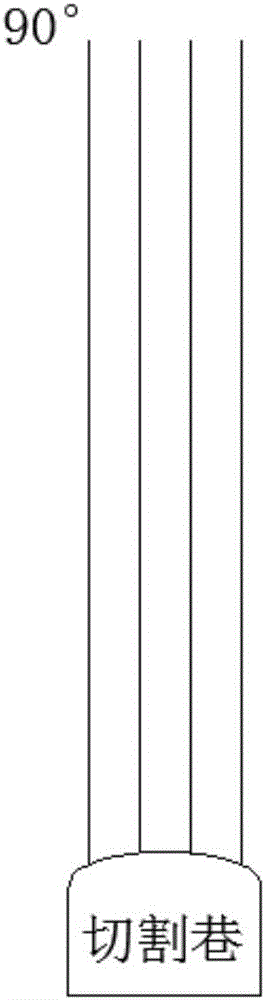

[0053] 2) Construction in the middle of the cutting lane 4 forms a roof area 1, and the roof area 1 is a triangular area;

[0054] 3) Use the drilling trolley to determine the drilling construction point 11 at the left and right symmetrical positions of the roof area 1 of the cutting lane 4. There are 9 to 13 drilling construction points on the left and right sides of the roof area 1. Drill holes with 10 front angles on the hole row surface, and set 2 to 3 blast hole row surfaces 10 for ...

Embodiment 2

[0059] like Figure 5-8 As shown, analyzing the ore characteristics of this mining area, a scheme suitable for the stope height of 33 meters, without the construction of the upper cutting road, the non-cutting shaft forced trough pulling, the design scheme is as follows:

[0060] The required mining height is 33 meters and the panel cutting lane length is 58 meters:

[0061] ①The width of the panel cutting lane is 5.0~6.0m;

[0062] ②The effective rock drilling depth of upward (forward leaning) beam-shaped medium-deep hole drilling jumbo is ≮36.0m;

[0063] ③The effective charge depth of upward-facing medium-deep hole charge device or trolley is ≮36.0m;

[0064] ④Explosive density 0.95~1.25t / m3;

[0065] ⑤Compensation space factor ≮1.25 times;

[0066] ⑥Arrange the forced slotting holes mirror-symmetrically on both wings along the axis of the panel cutting lane;

[0067] ⑦Technical parameters of piercing and blasting technology: the total footage of piercing is 5300m, and...

Embodiment 3

[0102] The actual blasting scheme is as follows:

[0103] The center of the trough is designed as the intersection point of the ore exit approach and the center line of the cutting roadway south of Liandao.

[0104] The small machine cannon is dug at the center line of the groove to ensure the blasting effect of the first sequence.

[0105] There are a total of 22 medium and deep hole rock drilling positions, 11 of which are symmetrically arranged on both sides. If the drilling angle is small and it is difficult to open the hole, use a small machine gun to dig the reverse wedge after setting out to improve the drilling accuracy.

[0106] The blasting adopts symmetrical blasting, and loosens the four sides of the mining area to loosen the ore, and the principle is to expose the eyebrow line.

[0107] The design of the groove is 2 meters, the total footage of the designed groove hole is 5296.4 meters, the volume of the groove is 9048 cubic meters, and the converted ore volume ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Proportion | aaaaa | aaaaa |

| Proportion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com