Genetic engineering bacterium capable of producing uridine at high yield as well as building method and application thereof

A technology of genetically engineered bacteria and uridine, applied in the field of genetic engineering, can solve the problems of low production efficiency, unfavorable product separation and purification, etc., and achieve the effects of high production efficiency, favorable separation and purification, and high production intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Construction of strain E.coli UR11:

[0049] 1 Methods of gene editing

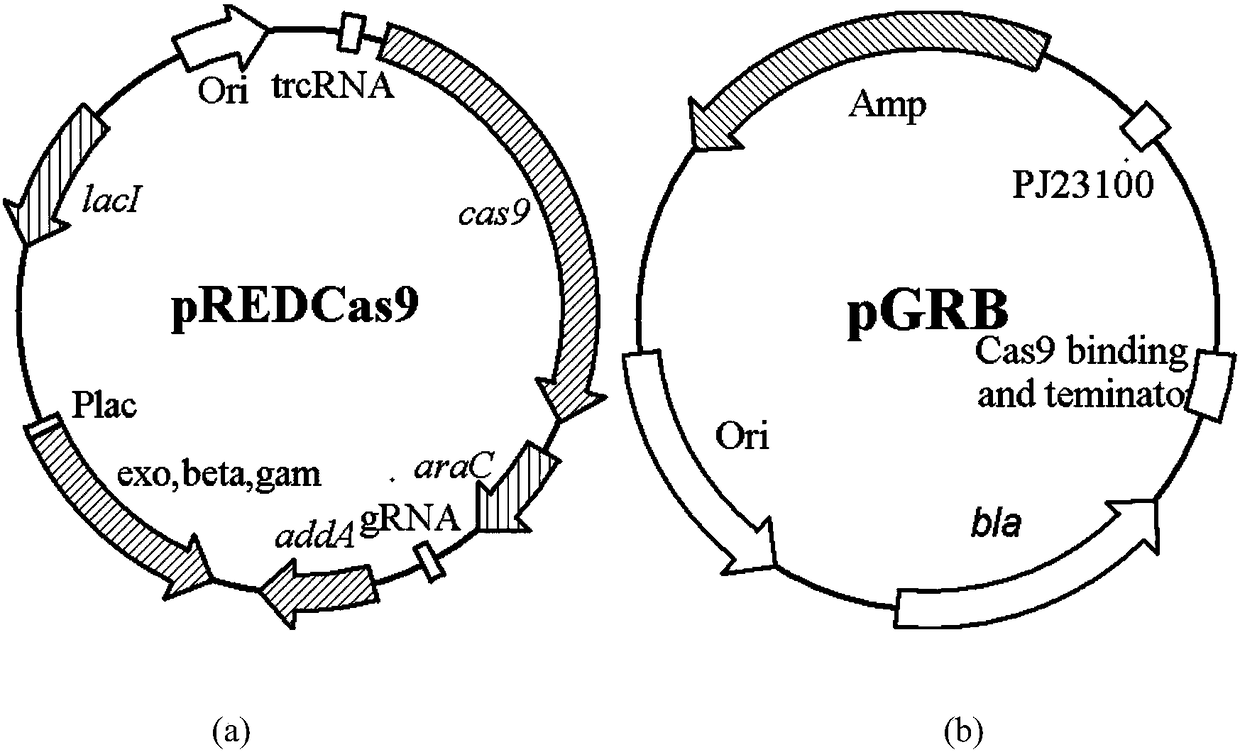

[0050] The gene editing method used in the present invention is carried out with reference to the literature (Li Y, Lin Z, Huang C, et al. Metabolic engineering of Escherichia coli using CRISPR–Cas9 edited genome editing. Metabolic engineering, 2015, 31:13-21.), the method used The two plasmid maps of the attached figure 1 . Among them, pREDCas9 carries gRNA expression plasmid pGRB elimination system, bacteriophage λ Red recombination system and Cas9 protein expression system, spectinomycin resistance (working concentration: 100mg / L), cultured at 32°C; pGRB uses pUC18 as the backbone, including the promoter J23100, gRNA-Cas9 binding region sequence and terminator sequence, ampicillin resistance (working concentration: 100mg / L), cultured at 37°C.

[0051] The concrete steps of this method are as follows:

[0052] 1.1 pGRB plasmid construction

[0053] The purpose of constructing the plasmid pGR...

Embodiment 2

[0125] The method for producing uridine by fermentation of genetically engineered bacteria E.coli UR11 is as follows:

[0126] (1) Shake flask fermentation:

[0127] Slant culture: Streak inoculation of -80°C preserved strains on the activated slant, culture at 37°C for 12 hours, and passage once;

[0128] Shake flask seed culture: Scrape a ring of slant seeds with an inoculation loop and inoculate in a 500mL Erlenmeyer flask containing 30mL of seed medium, seal with nine layers of gauze, and incubate at 37°C and 200rpm for 7-10h;

[0129] Shake flask fermentation culture: Inoculate 10-15% inoculum into a 500mL Erlenmeyer flask with fermentation medium (final volume is 30mL), seal with nine layers of gauze, 37°C, 200r / min shaking culture, during the fermentation process by supplementing Add ammonia water to maintain the pH at 7.0-7.2; add 60% (m / v) glucose solution to maintain the fermentation; the fermentation period is 24-30h;

[0130] The composition of the slant medium i...

Embodiment 3

[0143] Fermentation experiment of strain E.coli UR11 on 5L fermenter:

[0144] Slope activation culture: Scrape a ring of strains from the bacteria preservation tube of the -80°C refrigerator, spread evenly on the activation slope, incubate at 37°C for 12 hours, transfer to an eggplant-shaped bottle and continue to cultivate for 12 hours;

[0145] Seed culture: Take an appropriate amount of sterile water in an eggplant-shaped bottle, insert the bacterial suspension into the seed medium, keep the pH at about 7.0, the temperature at 37°C, and the dissolved oxygen at 25-35%, and cultivate for 6 hours;

[0146] Fermentation culture: add fresh fermentation medium according to 15% inoculation amount, start fermentation, control pH to be stable at about 7.0 during fermentation, maintain temperature at 37°C, and dissolve oxygen between 25-35%; After the glucose is consumed, add 80% (m / v) glucose solution to maintain the glucose concentration in the fermentation medium at 0.1-5g / L; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com