Patents

Literature

30 results about "Homoserine dehydrogenase" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In enzymology, a homoserine dehydrogenase (EC 1.1.1.3) is an enzyme that catalyzes the chemical reaction L-homoserine + NAD(P)⁺ ⇌ L-aspartate 4-semialdehyde + NAD(P)H + H⁺ The 2 substrates of this enzyme are L-homoserine and NAD⁺ (or NADP⁺), whereas its 3 products are L-aspartate 4-semialdehyde, NADH (or NADPH), and H⁺. This enzyme belongs to the family of oxidoreductases, specifically those acting on the CH-OH group of donor with NAD⁺ or NADP⁺ as acceptor.

Mutant of homoserine dehydrogenase from Corynebacterium and DNA encoding thereof

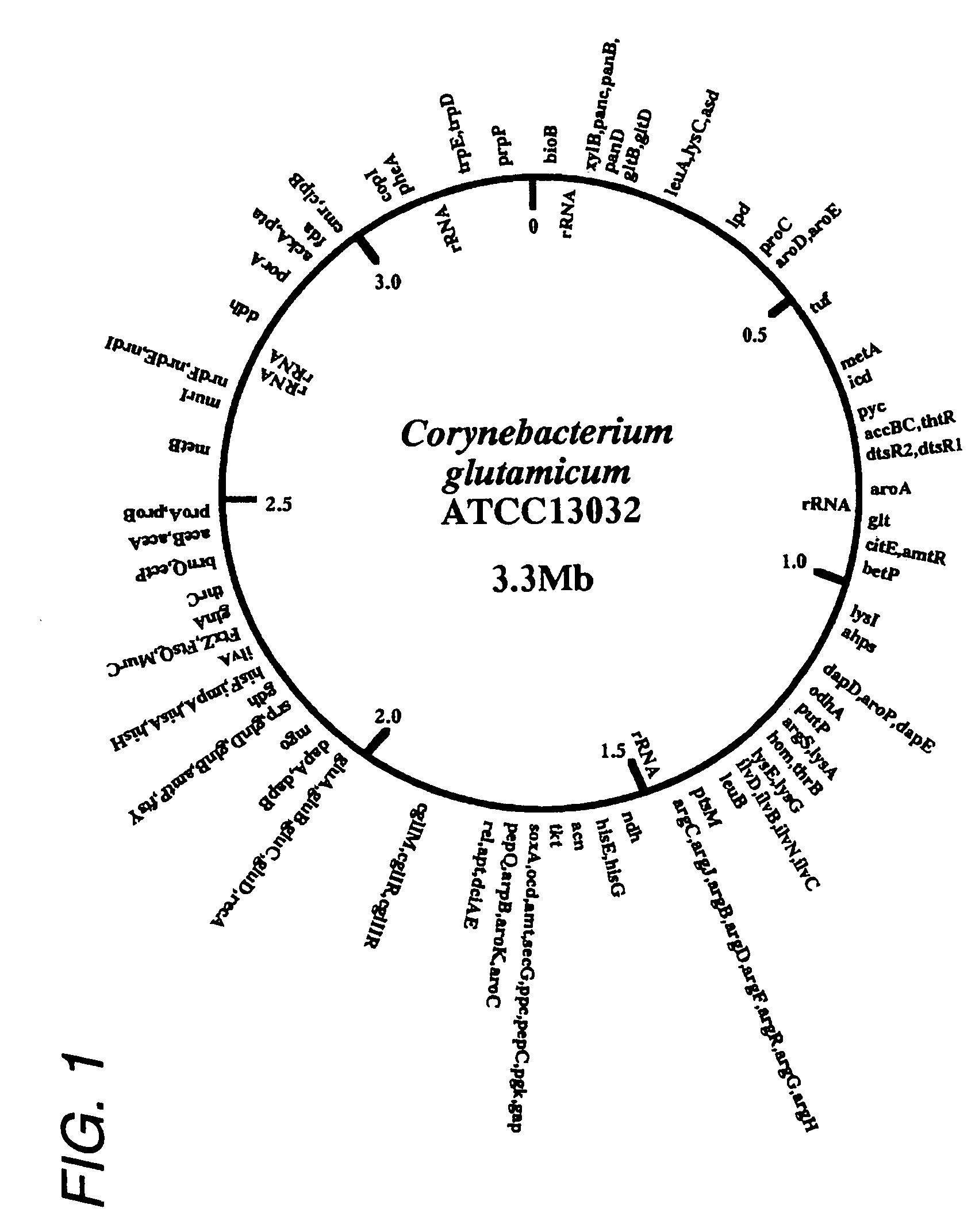

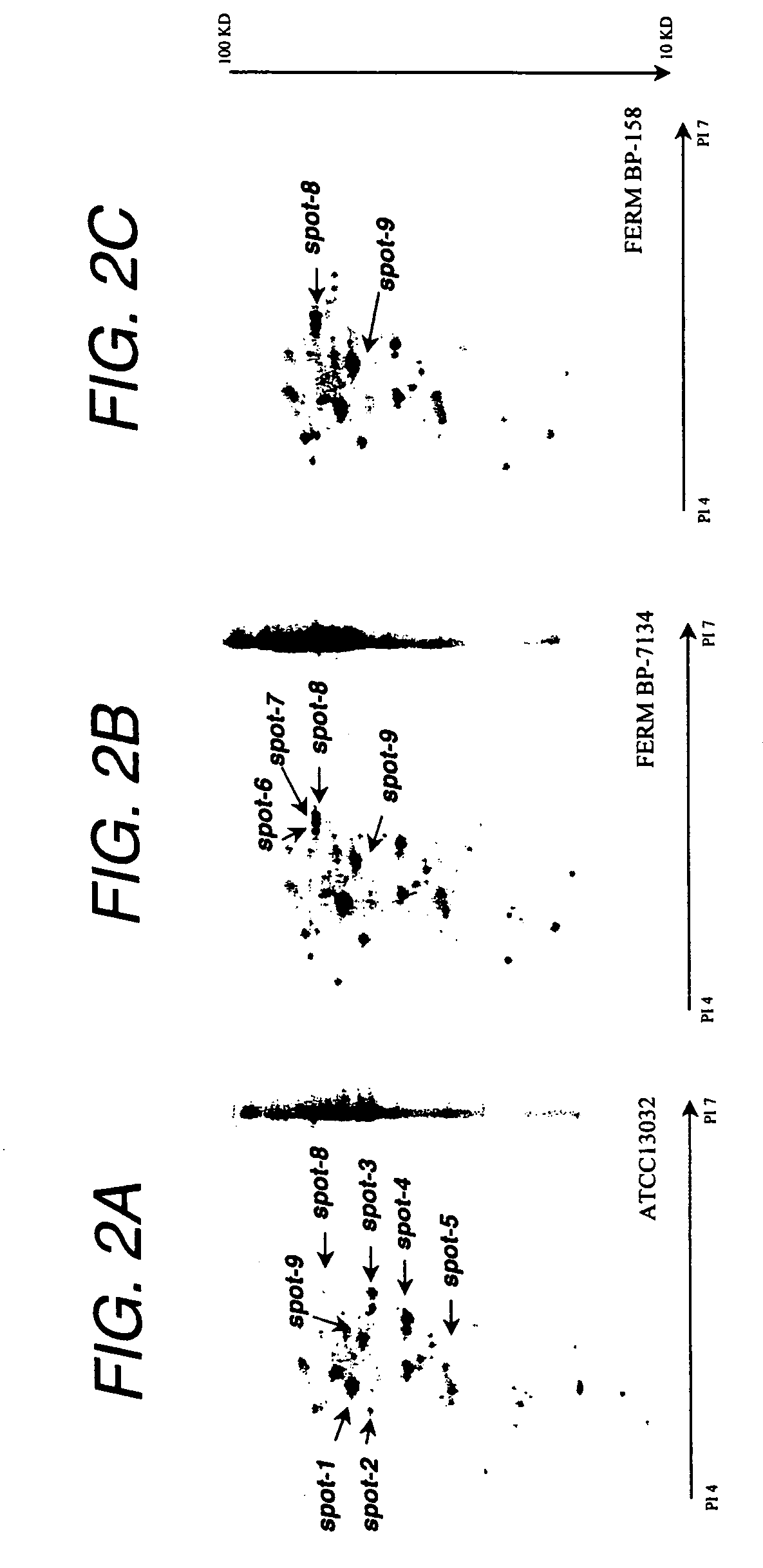

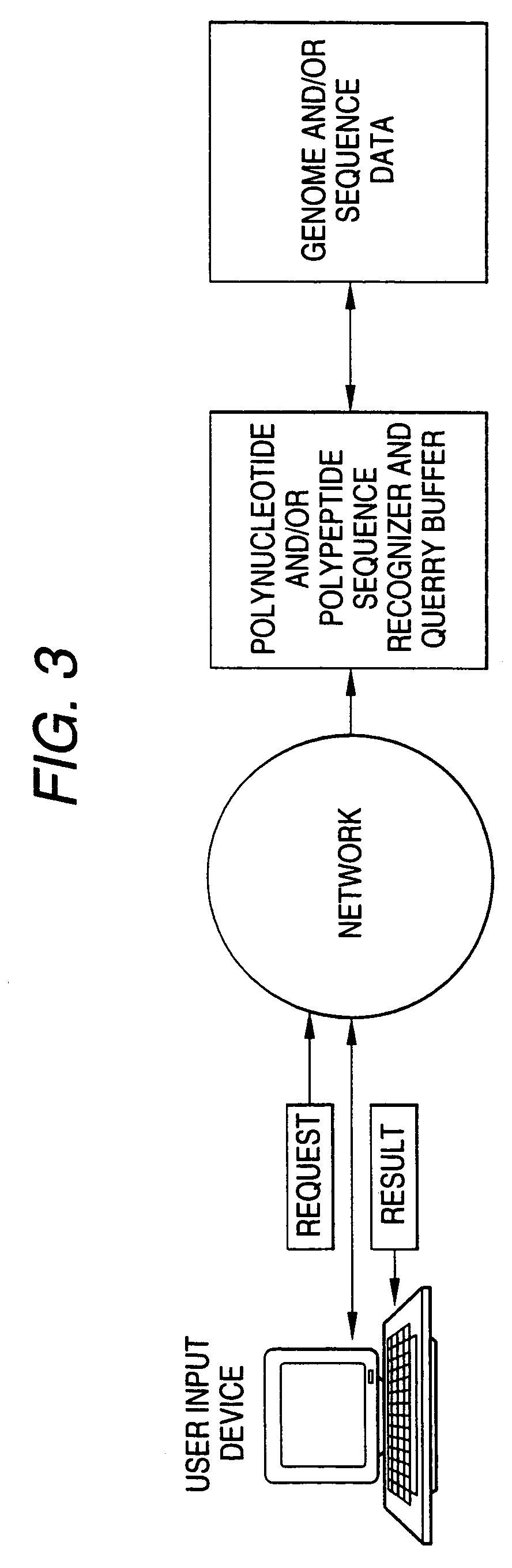

Novel polynucleotides derived from microorganisms belonging to coryneform bacteria and fragments thereof, polypeptides encoded by the polynucleotides and fragments thereof, polynucleotide arrays comprising the polynucleotides and fragments thereof, recording media in which the nucleotide sequences of the polynucleotide and fragments thereof have been recorded which are readable in a computer, and use of them.

Owner:KYOWA HAKKO BIO CO LTD

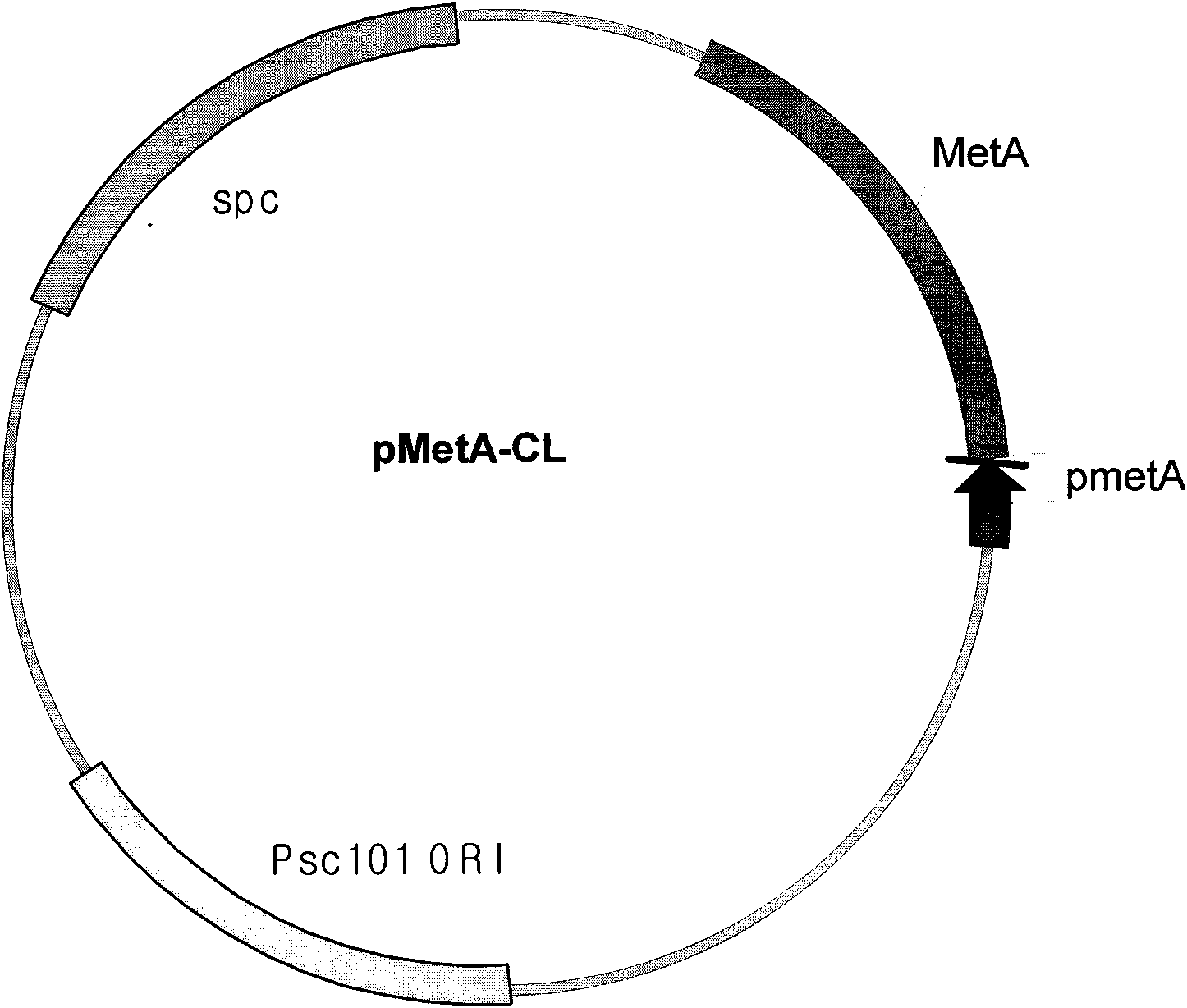

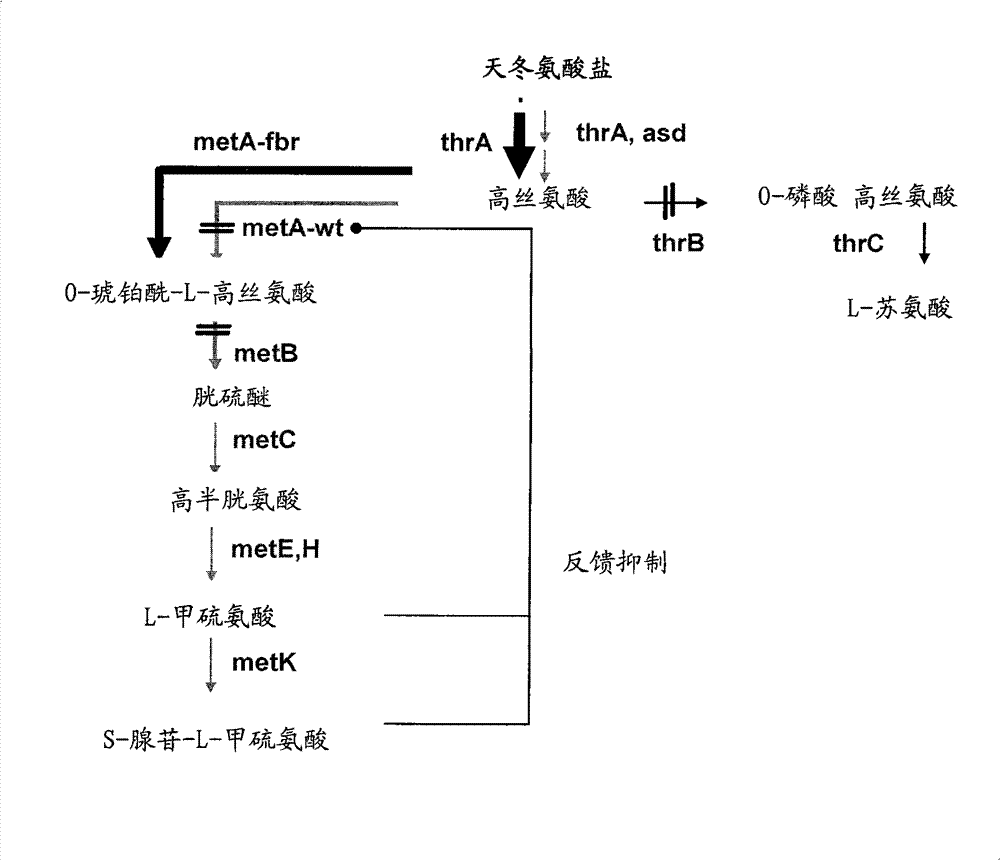

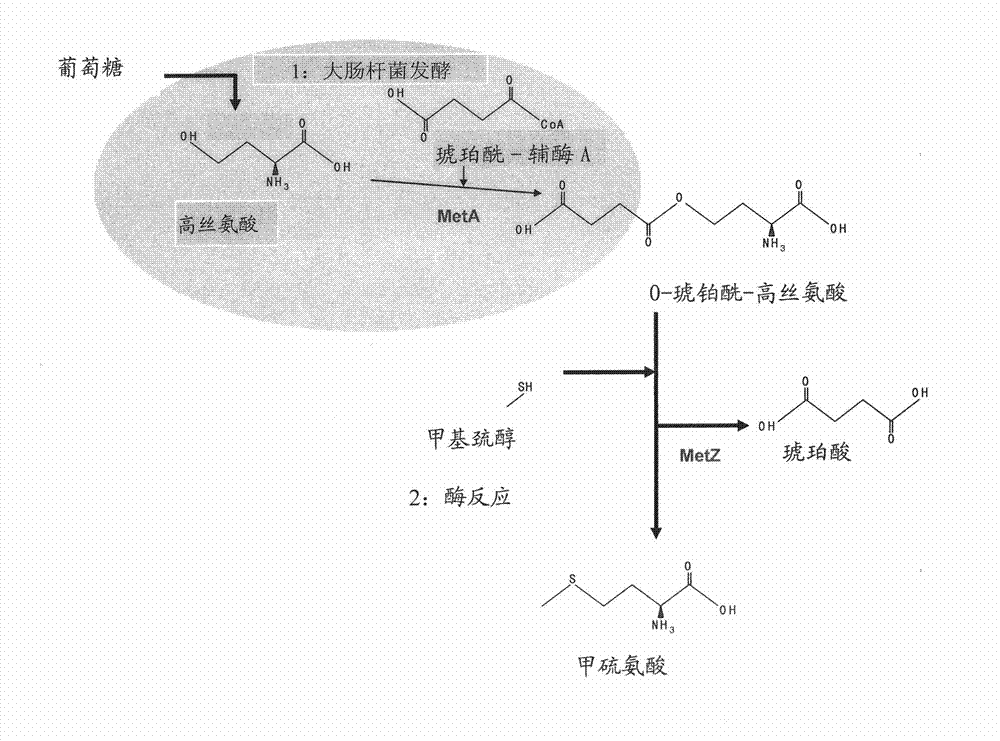

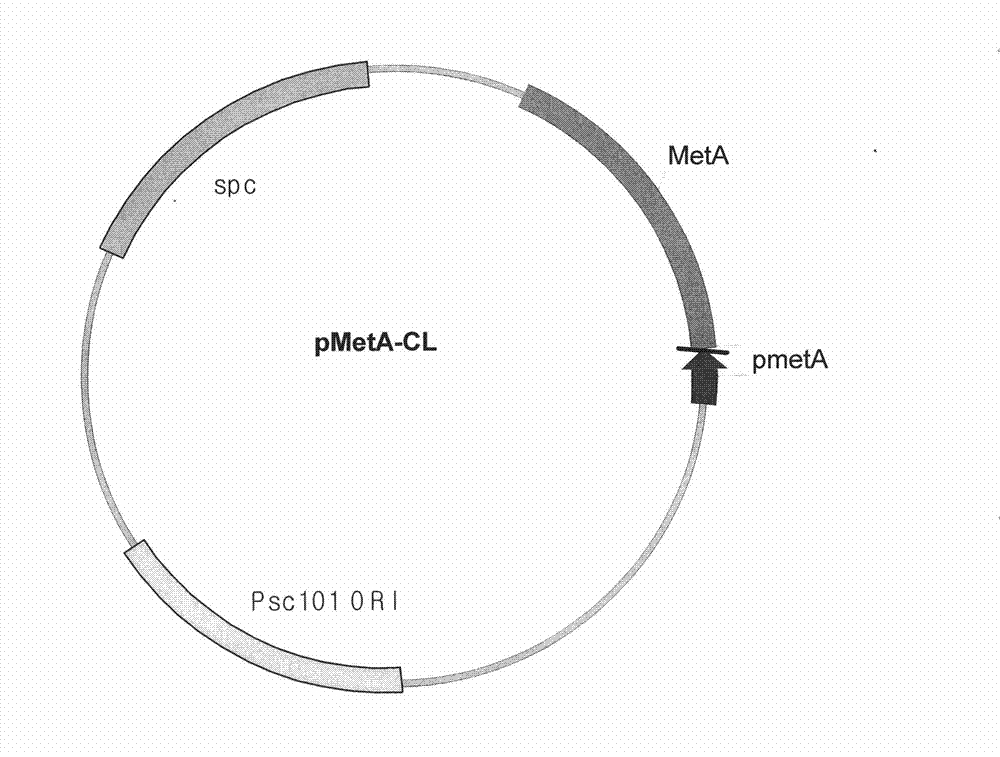

Method for producing L-methionine by fermentation

InactiveUS7611873B1High activityIncrease productivityBacteriaSugar derivativesSerine dehydrogenaseThreonine

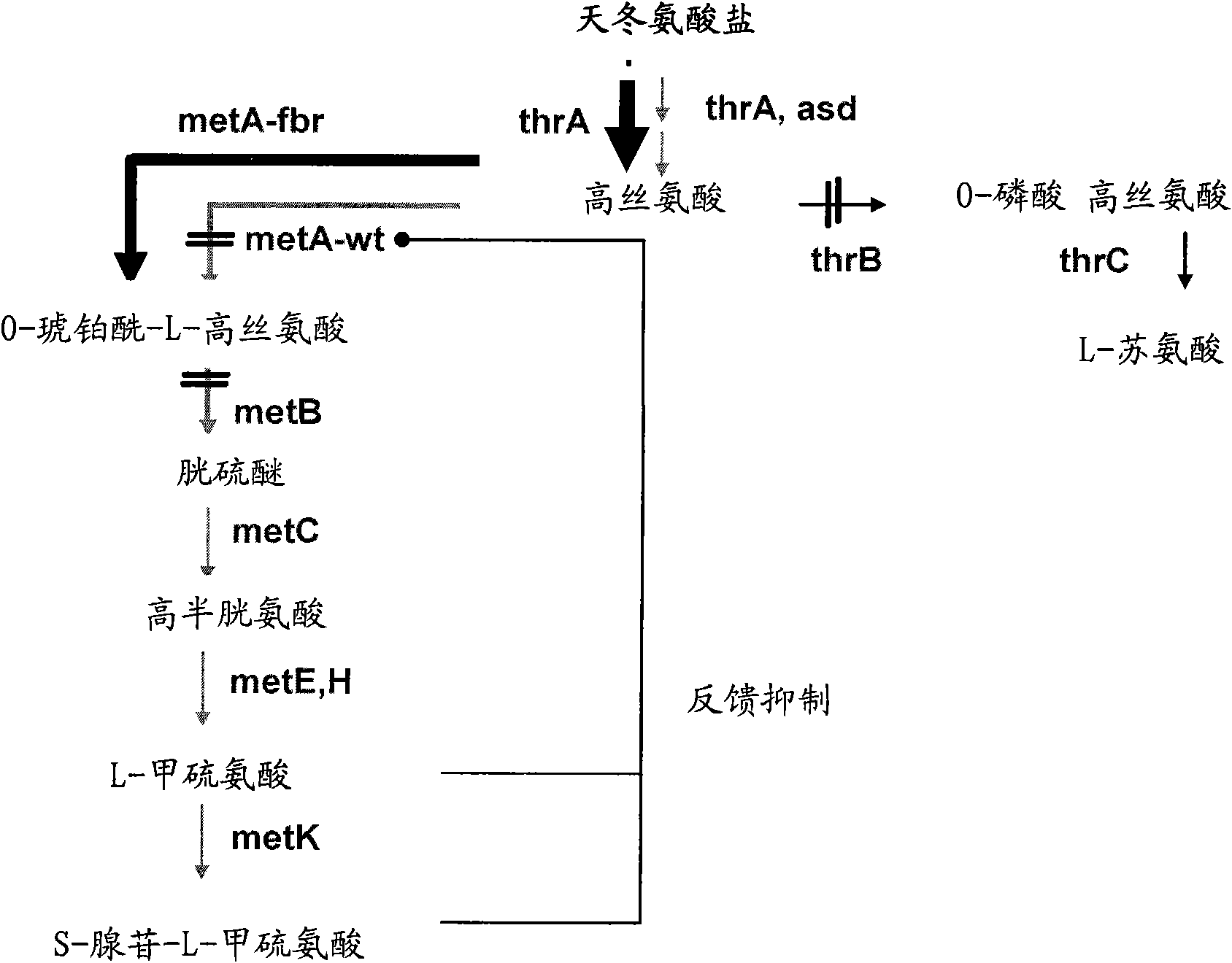

L-Methionine is produced by culturing a microorganism which is deficient in repressor of L-methionine biosynthesis system and / or enhanced intracellular homoserine transsuccinylase activity is cultured in a medium so that L-methionine should be produced and accumulated in the medium, and collecting the L-methionine from the medium. The microorganism preferably further exhibits reduced intracellular S-adenosylmethionine synthetase activity, L-threonine auxotrophy, enhanced intracellular cystathionine γ-synthase activity and enhanced intracellular aspartokinase-homoserine dehydrogenase II activity. The present invention enables breeding of L-methionine-producing bacteria, and L-methionine production by fermentation.

Owner:AJINOMOTO CO INC

Plant methionine synthase gene and methods for increasing the methionine content of the seeds of plants

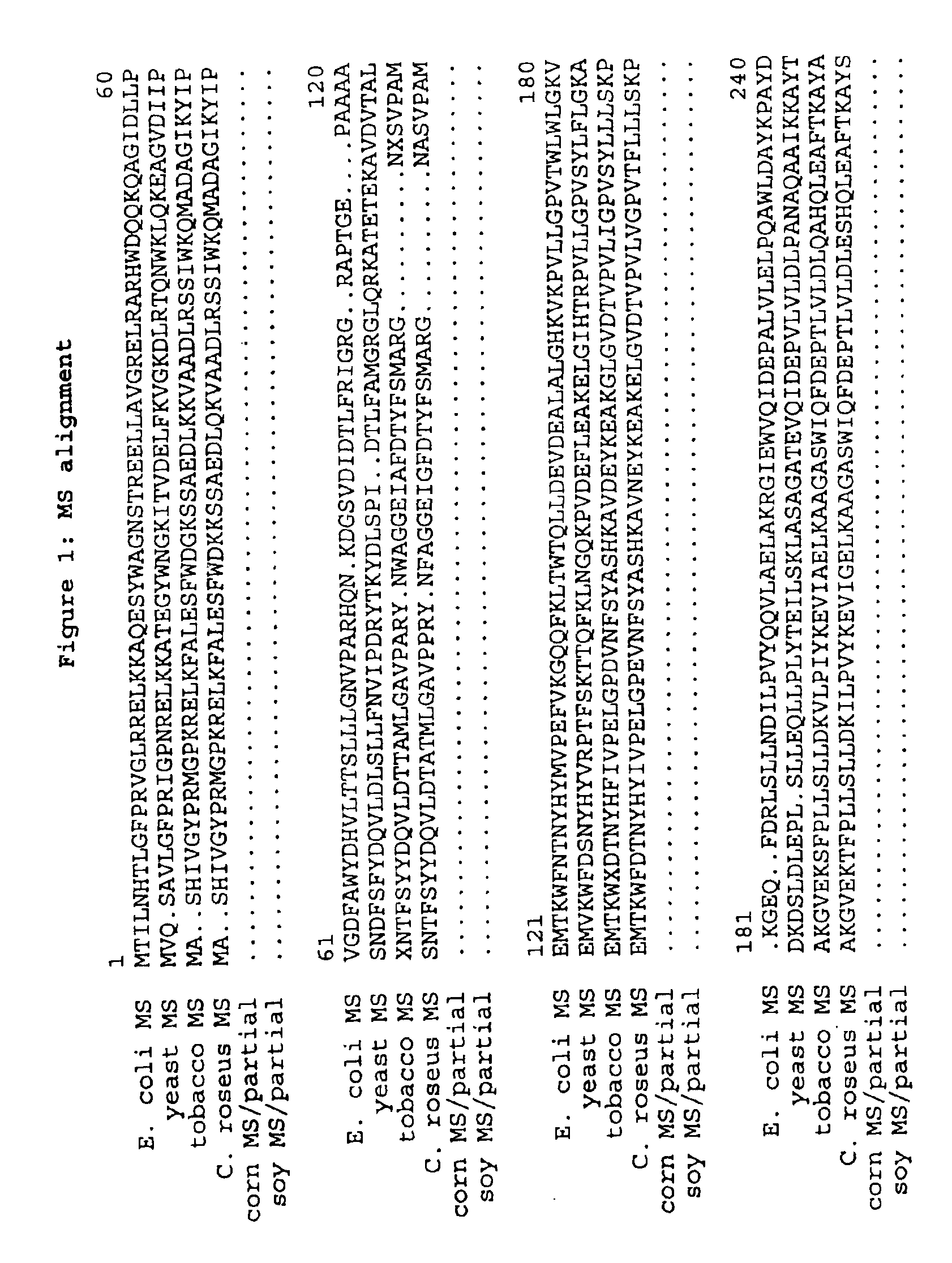

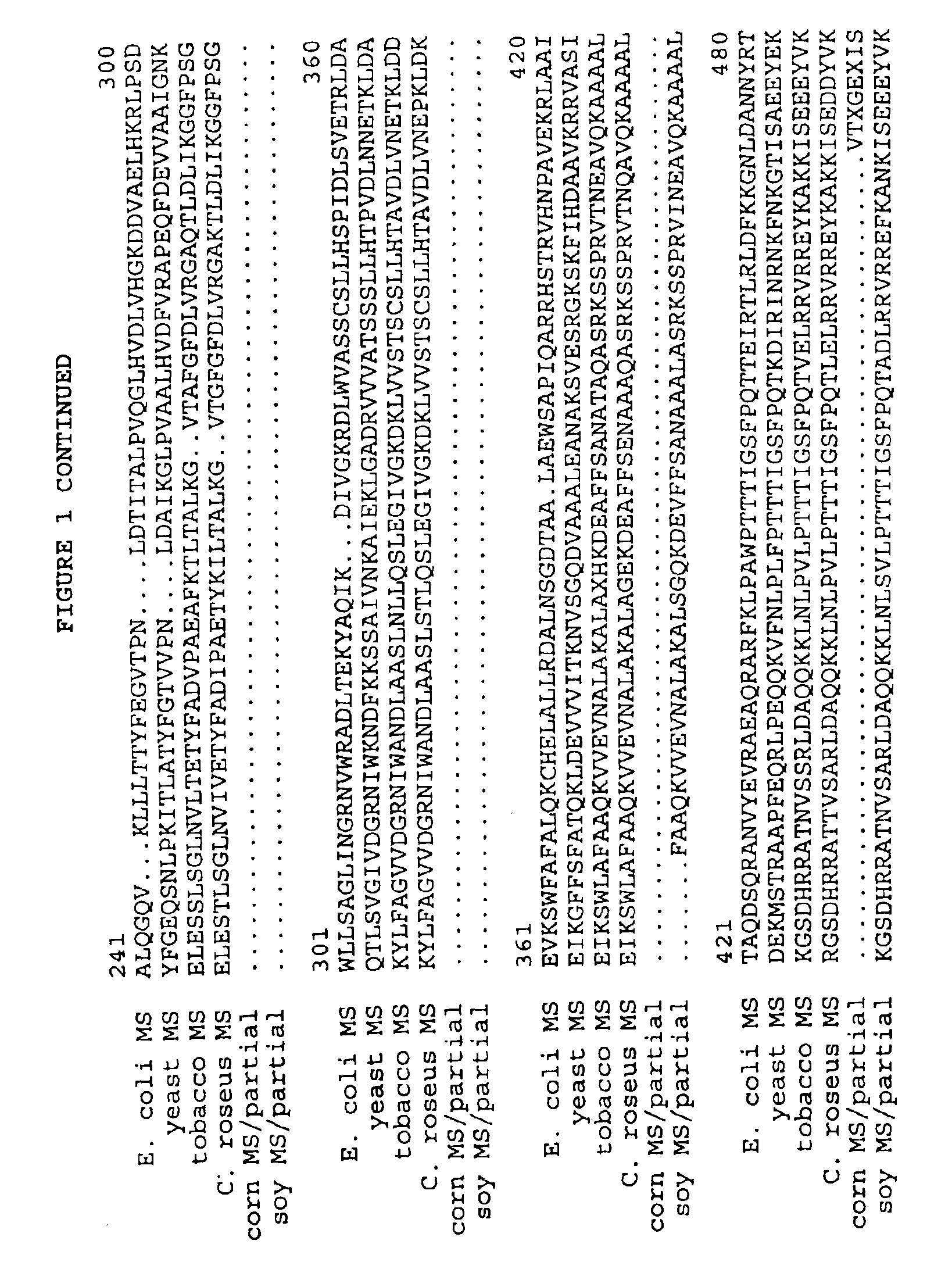

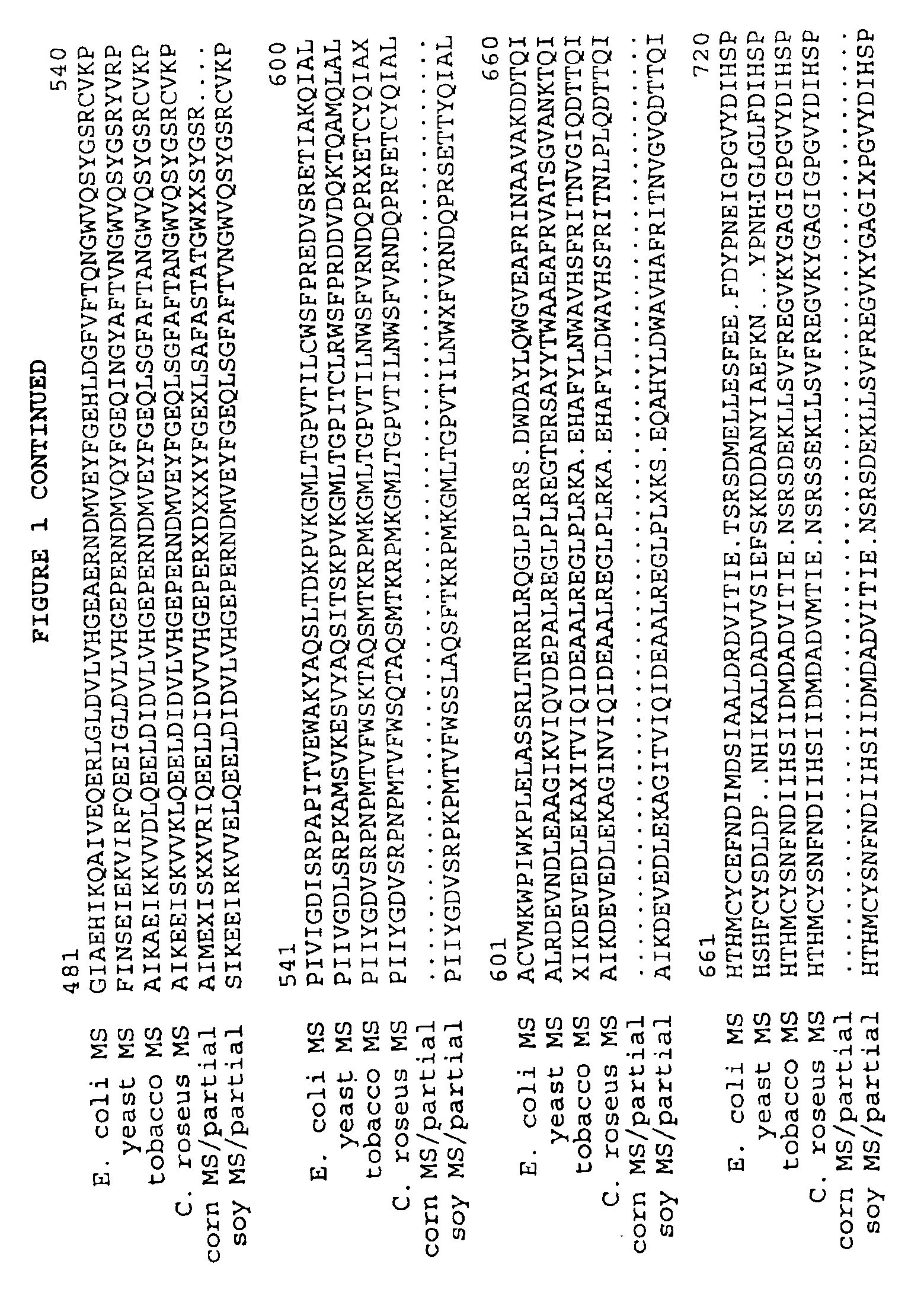

This invention relates to a nucleic acid fragment encoding a plant 5-methyltetra-hydropteroyltriglutamate-homocysteine methyltransferase or methionine synthase. The invention also includes chimeric genes, a first encoding a plant methionine synthase (MS) gene, a second encoding a plant cystathionine γ-synthase (CS) gene, a third encoding feedback-insensitive aspartokinase (AK) or bifunctional feedback-insensitive aspartokinase-homoserine dehydrogenase (AK-HDH), which is operably linked to a plant chloroplast transit sequence, and a fourth encoding a methionine-rich protein, all operably linked to plant seed-specific regulatory sequences. Methods for their use to produce increased levels of methionine in the seeds of transformed plants are provided.

Owner:EI DU PONT DE NEMOURS & CO

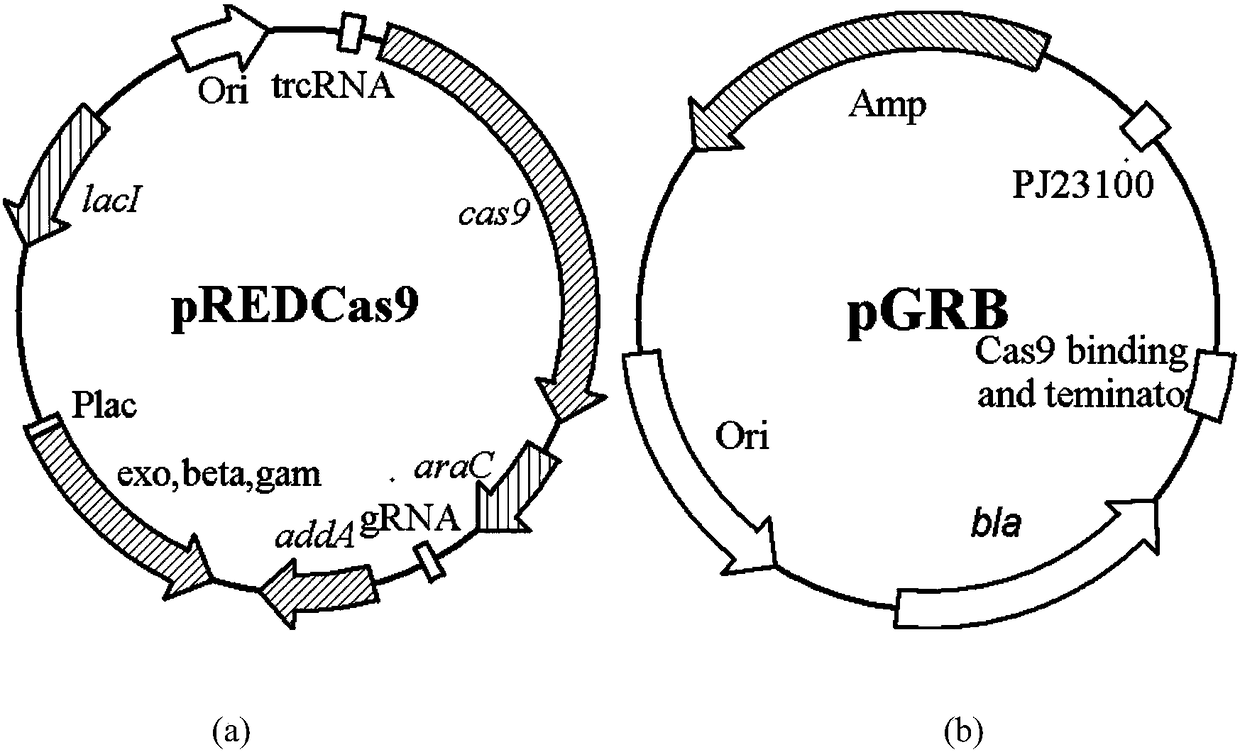

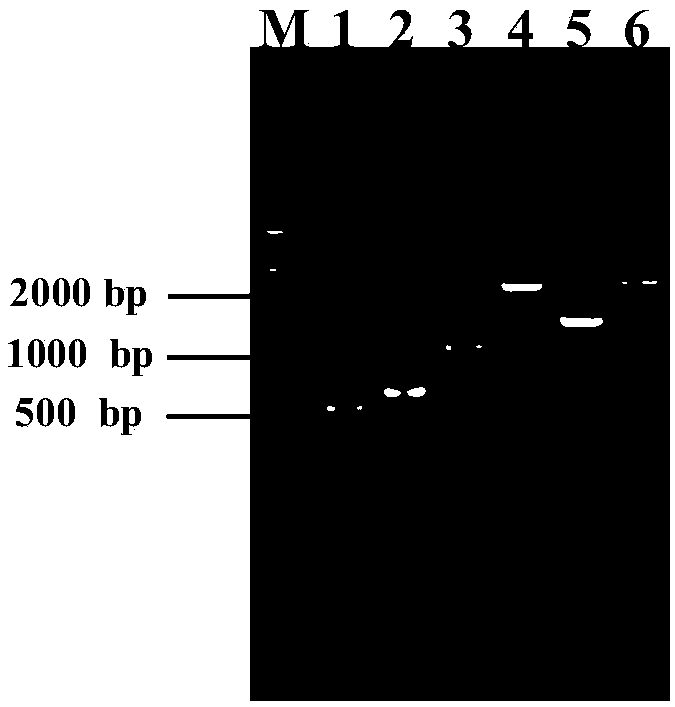

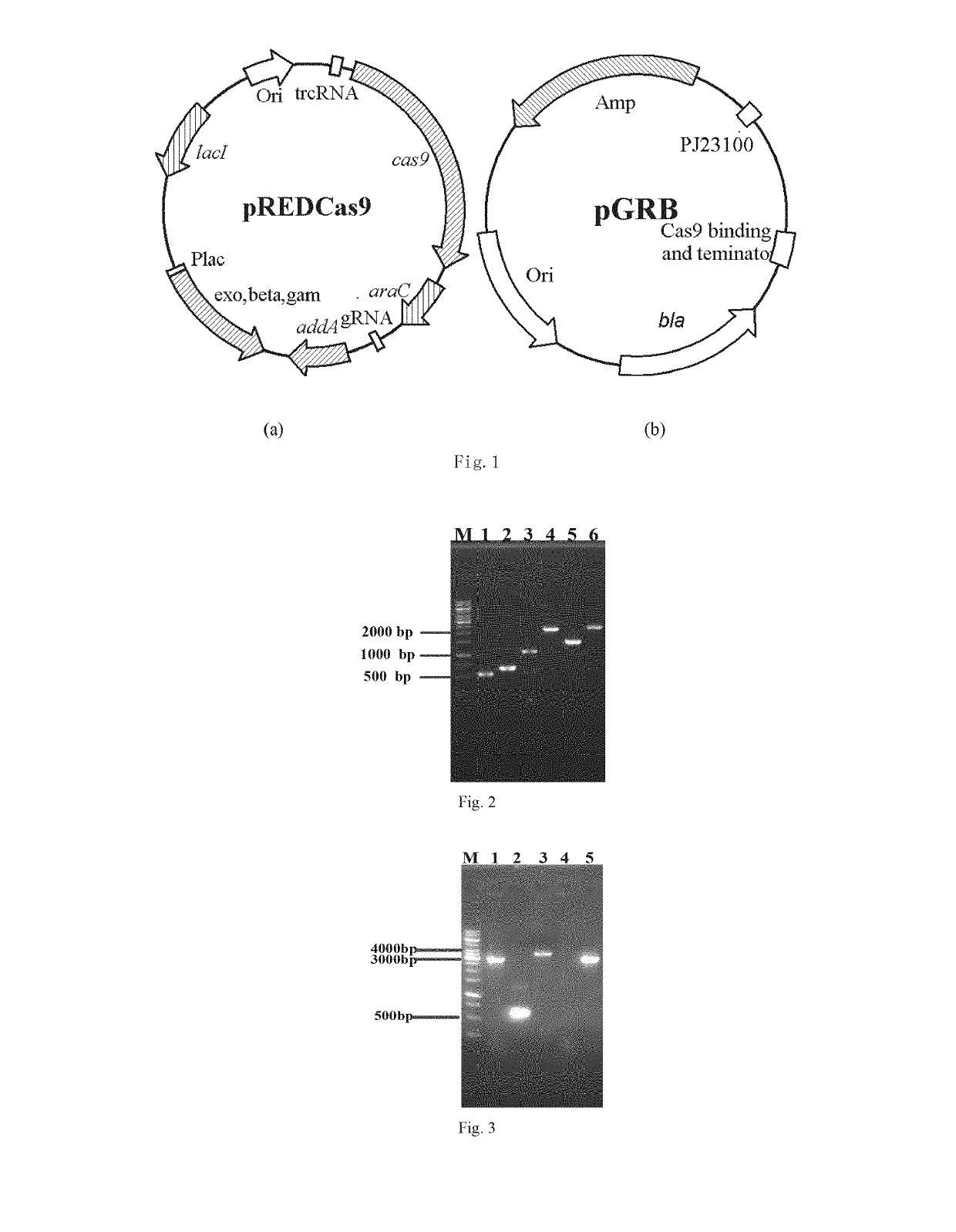

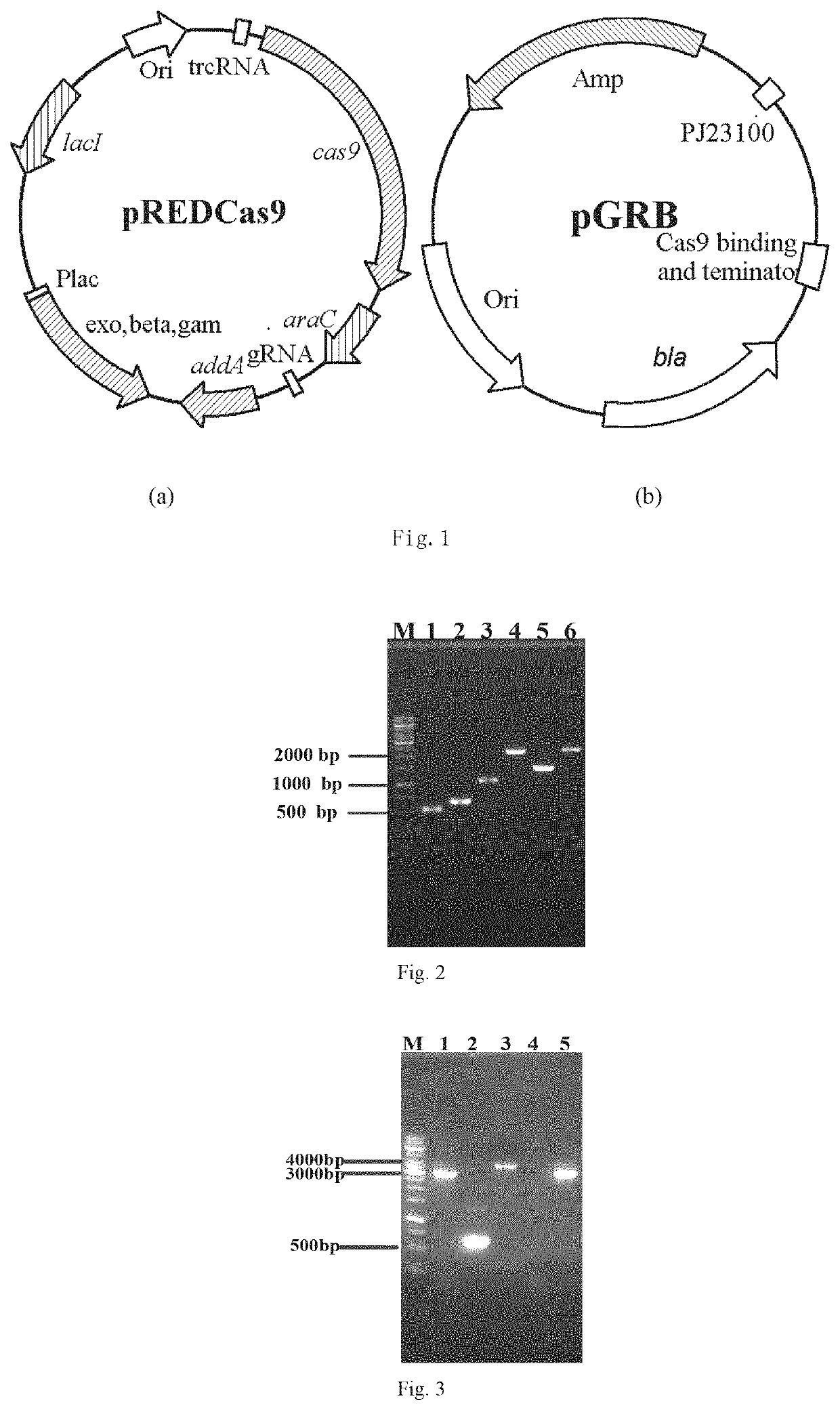

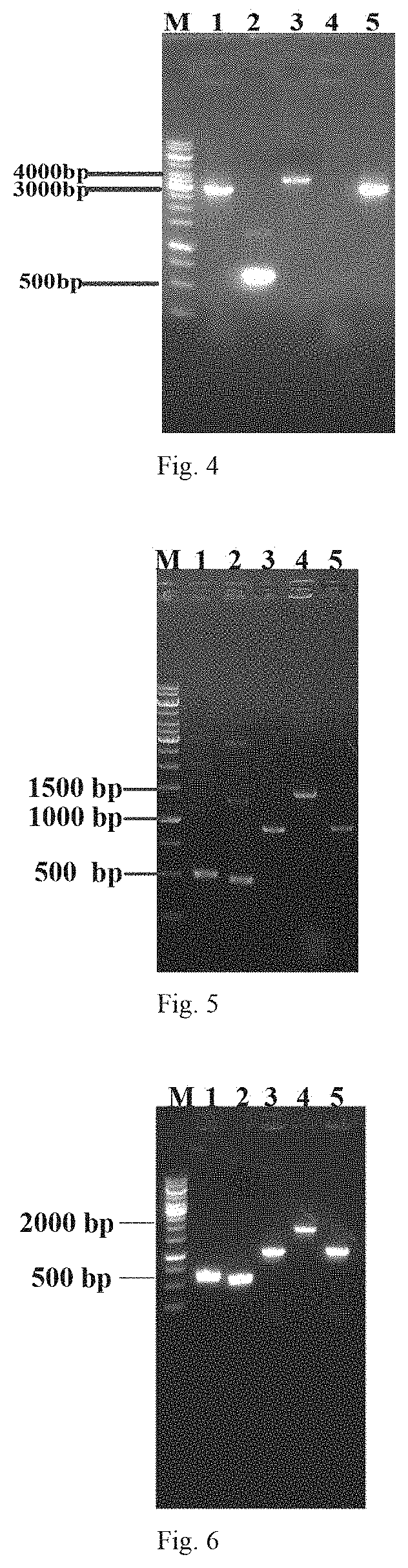

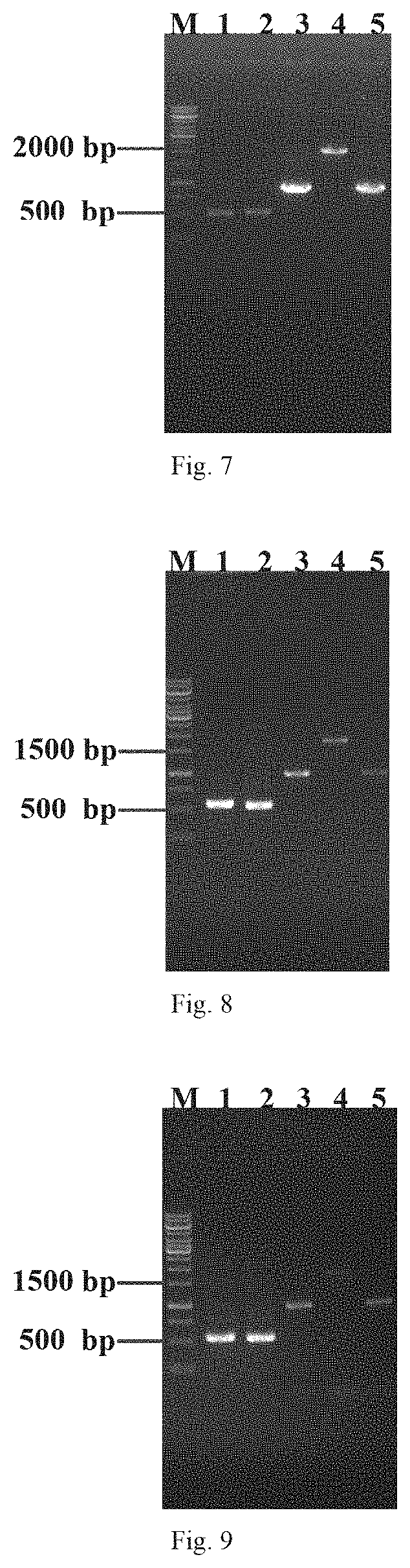

Genetic engineering bacterium capable of producing uridine at high yield as well as building method and application thereof

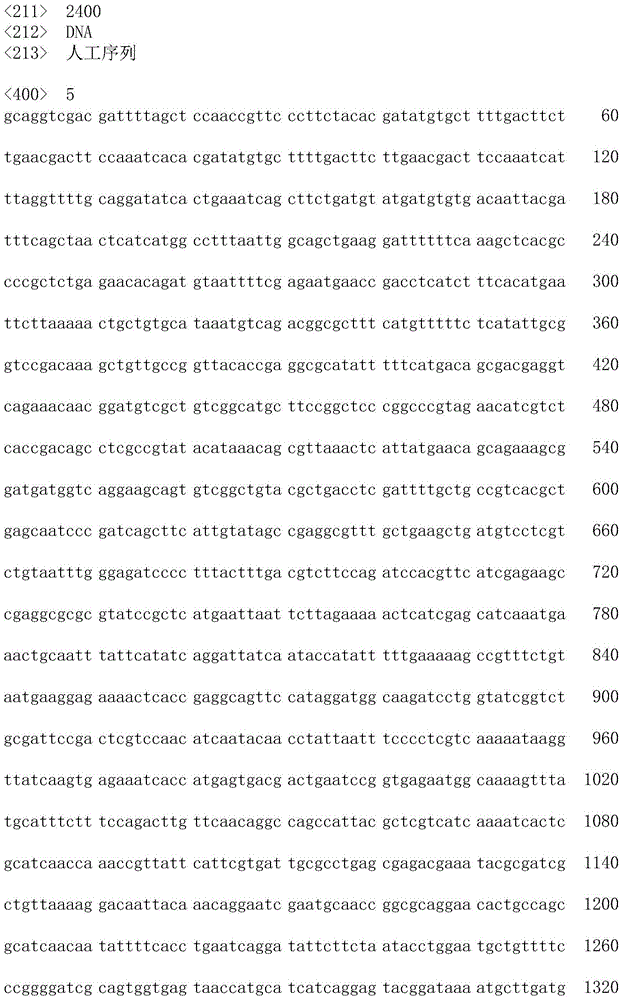

ActiveCN108130306AImprove growth traitsIncrease productivityBacteriaEnzymesEscherichia coliNucleotide

The invention provides a genetic engineering bacterium capable of producing uridine at high yield as well as a building method and application thereof. The genetic engineering bacterium is characterized in that pyrimidine nucleoside operons pyrBCAKDFE with the nucleotide sequence shown as SEQ ID NO:1 is integrated on a genome of colon bacillus; the starting is realized by a strong promoter P[trc];a uridine synthesis path is reconstituted; the self PRPP synthetase coding gene prsA on the genome is subjected to dual copying, and the starting is realized by the strong promoter P[trc]; meanwhile,the activity of udk, udp, and rihA, rihB and rihC is lacked; the thrA activity is lacked; the argF activity is lacked. The genetic engineering bacterium is applied to fermentation production of uridine; 40 to 67g / L of uridine can be produced after the fermentation is performed for 40 to 70h in a 5L fermentation tank; the maximum production intensity can reach 1.5g / (L*h); the glucoside conversionrate is 15 to 25 percent; the genetic engineering bacterium belongs to the highest level for producing the uridine by the fermentation method reported in the prior art.

Owner:TIANJIN UNIV OF SCI & TECH

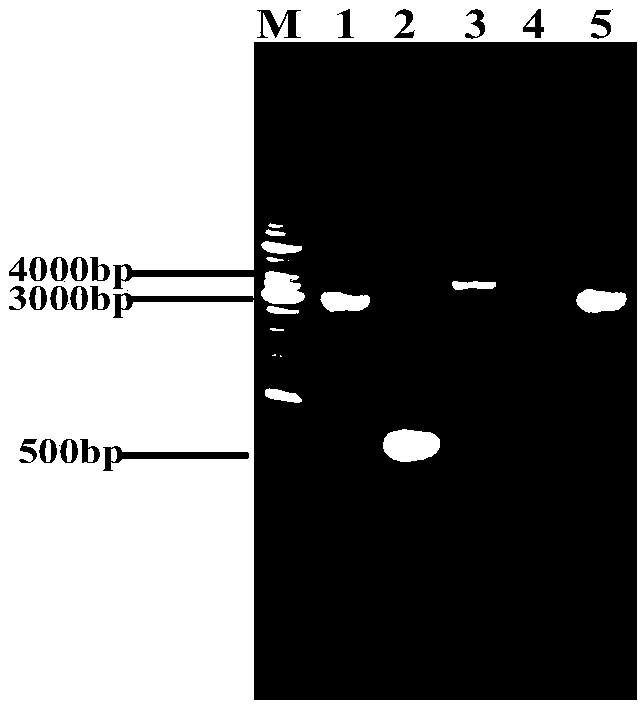

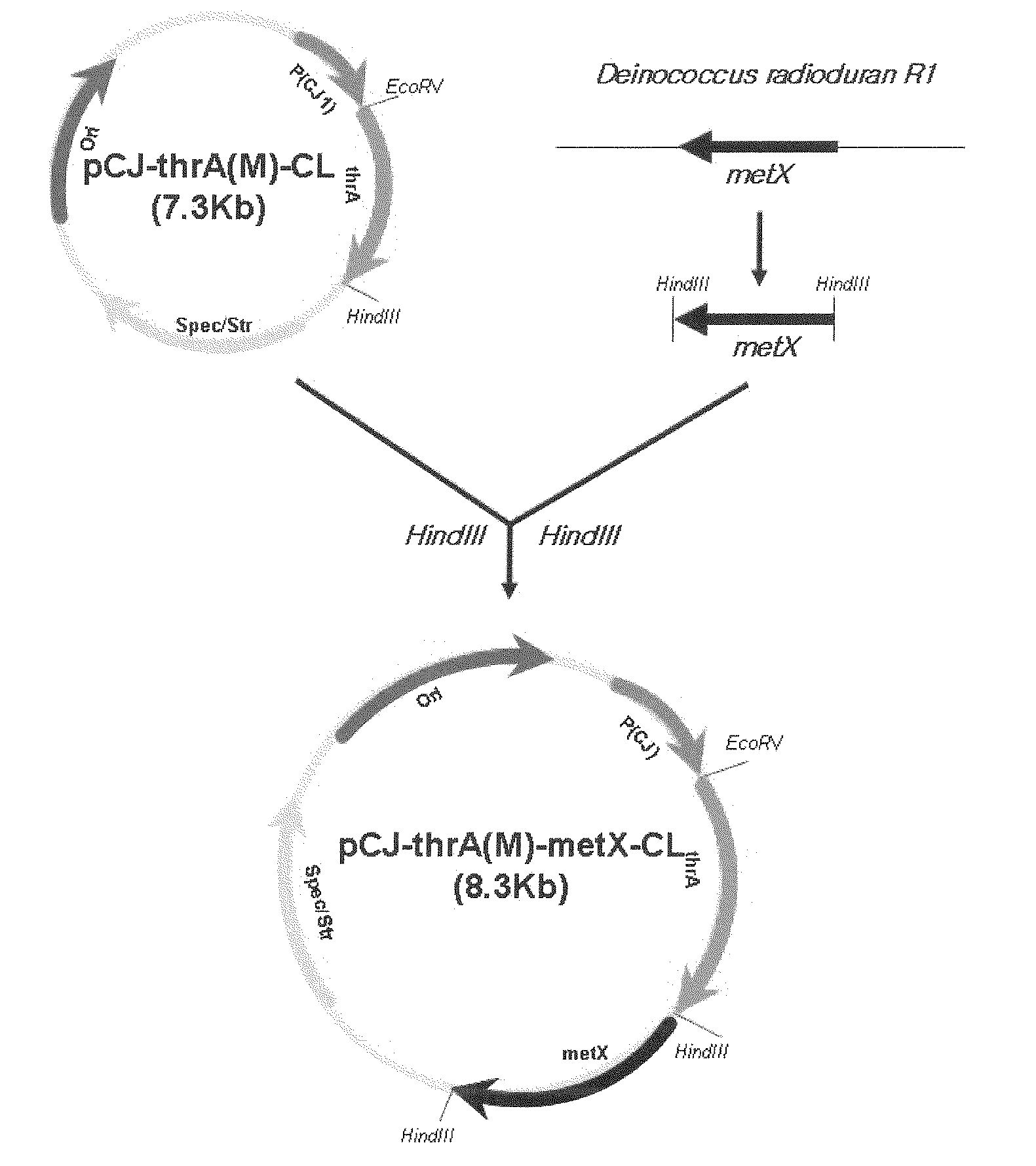

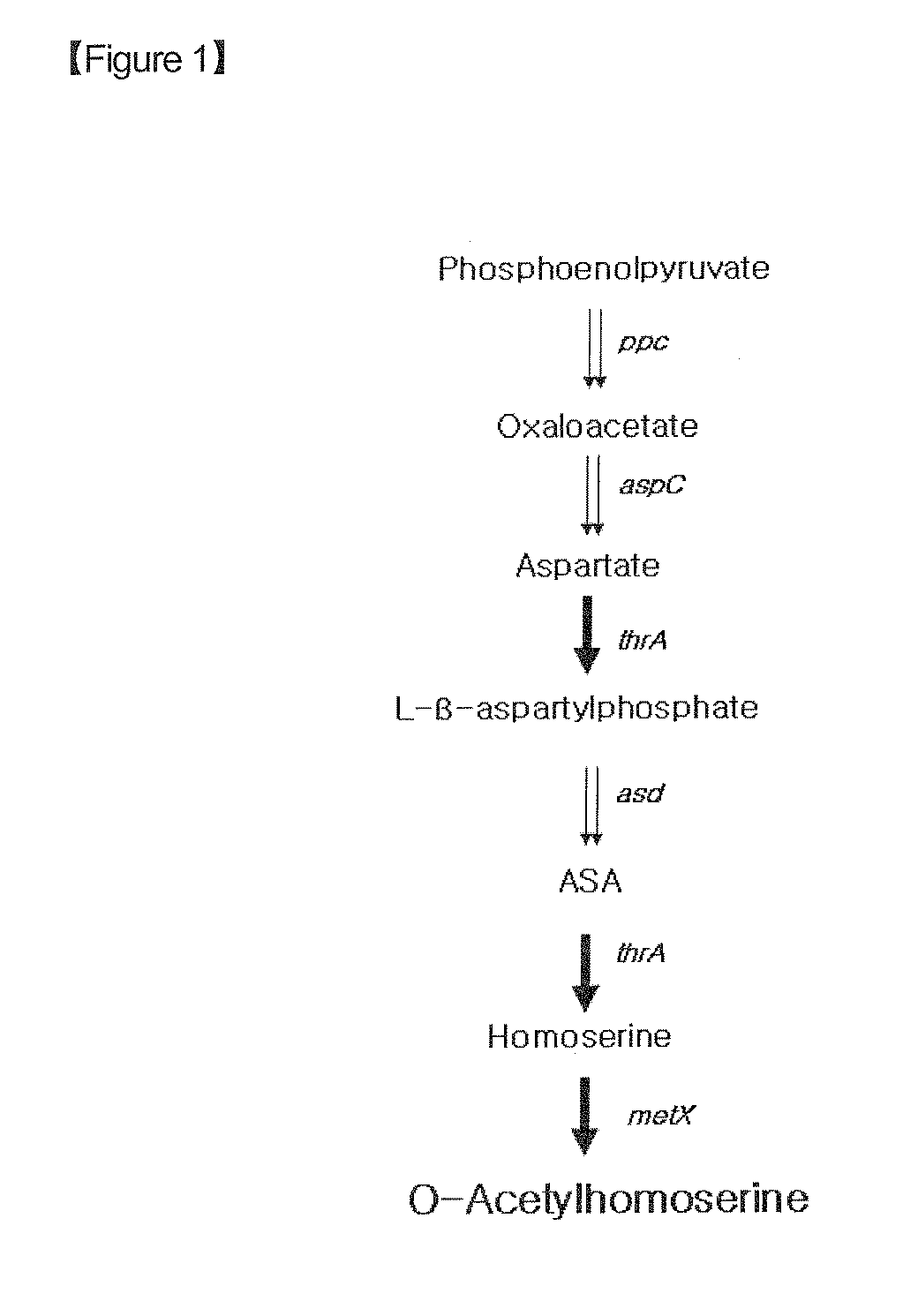

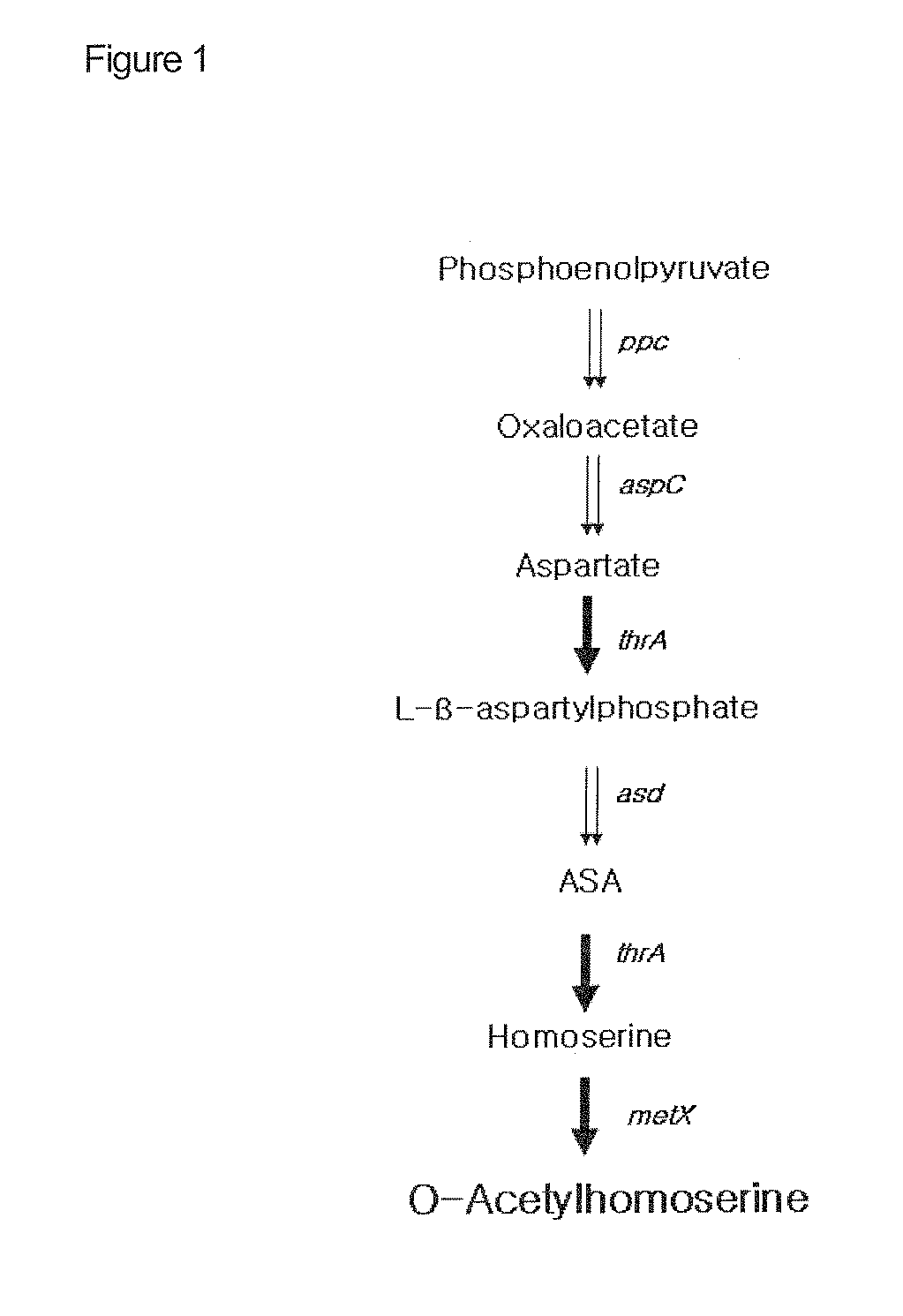

Microorganism producing o-acetyl-homoserine and the method of producing o-acetyl-homoserine using the microorganism

Disclosed is a strain of Escherichia sp., capable of producing O-acetyl homoserine in high yield, with the introduction and enhancement therein of the activity of: homoserine acetyl transferase, aspartokinase and homoserine dehydrogenase; and at least one enzyme selected from a group consisting of phosphoenolpyruvate carboxylase, aspartate aminotransferase and aspartate semi-aldehyde dehydrogenase. Also, a method of producing O-acetyl homoserine using the strain is provided.

Owner:CJ CHEILJEDANG CORP

Genetically engineered bacterium for high-yield production of hydroxytetrahydropyrimidine as well as construction method and application of genetically engineered bacterium

InactiveCN108441460AIncrease productivityImprove growth traitsBacteriaTransferasesBiotechnologyEscherichia coli

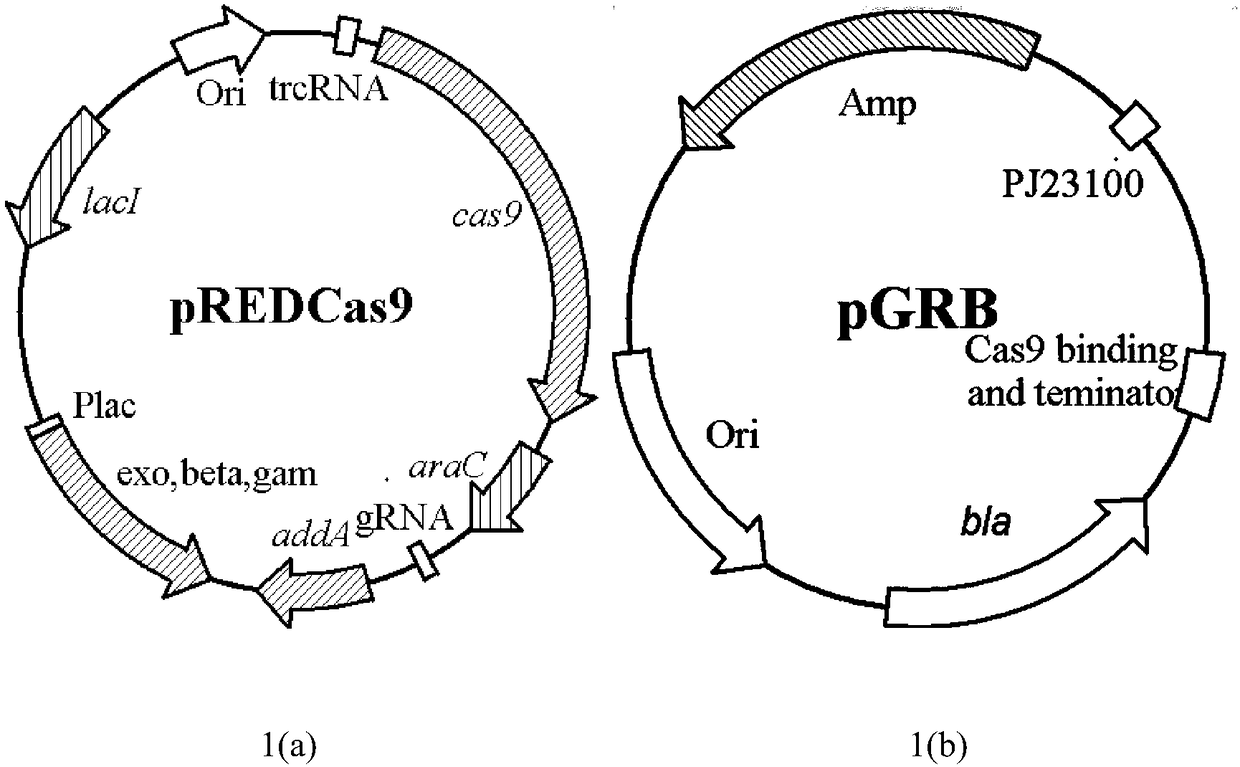

The invention relates to a genetically engineered bacterium for high-yield production of hydroxytetrahydropyrimidine as well as a construction method and application of the genetically engineered bacterium. The strain integrates RNA (Ribonucleic Acid) polymerase which is controlled by a xylose promoter and is derived from T7 bacteriophage; a thrA gene for encoding homoserine dehydrogenase I is knocked out; a lysC gene derived from corynebacterium glutamicum, an ectABC gene cluster derived from halomonas elongate and an ectD gene for encoding tetrahydropyrimidine hydroxylase are integrated andare promoted by a strong promoter PT7; a hydroxytetrahydropyrimidine synthesis way is reconstructed; the ectD gene is integrated at a sucCD site of succinyl coenzyme A synthetase and is started by thestrong promoter PT7; the genetically engineered bacterium has the highest level of producing the hydroxytetrahydropyrimidine by a fermentation method which is reported at present.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Microorganism producing O-acetyl-homoserine and the method of producing O-acetyl-homoserine using the microorganism

Disclosed is a strain of Escherichia sp., capable of producing O-acetyl homoserine in high yield, with the introduction and enhancement therein of the activity of: homoserine acetyl transferase, aspartokinase and homoserine dehydrogenase; and at least one enzyme selected from a group consisting of phosphoenolpyruvate carboxylase, aspartate aminotransferase and aspartate semi-aldehyde dehydrogenase. Also, a method of producing O-acetyl homoserine using the strain is provided.

Owner:CJ CHEILJEDANG CORP

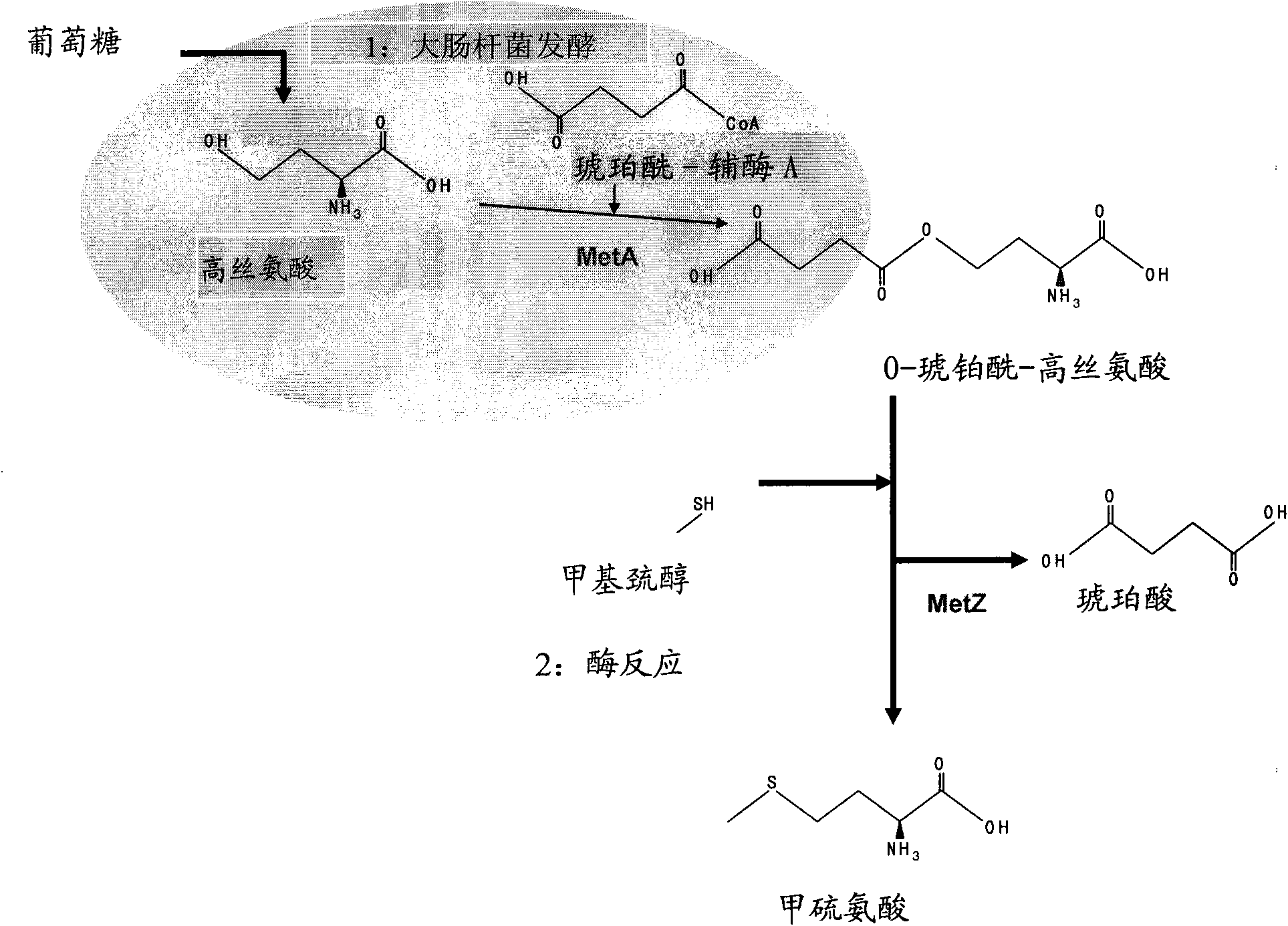

Microorganism producing l-methionine precursor and the method of producing l-methionine precursor using the microorganism

The present invention relates to a microorganism producing L-methionine precursor, O-succinylhomoserine, 1) the homoserine O-succinyltransferase activity (EC2.3.1.46) is introduced and enhanced, wherein the homoserine O-succinyltransferase activity is feed back resistant to methionine; and 2) the aspartokinase or homoserine dehydrogenase activity (EC2.7.2.4 or 1.1.1.3) is enhanced, and a method of producing L-methionine precursor using the microorganism.

Owner:CJ CHEILJEDANG CORP

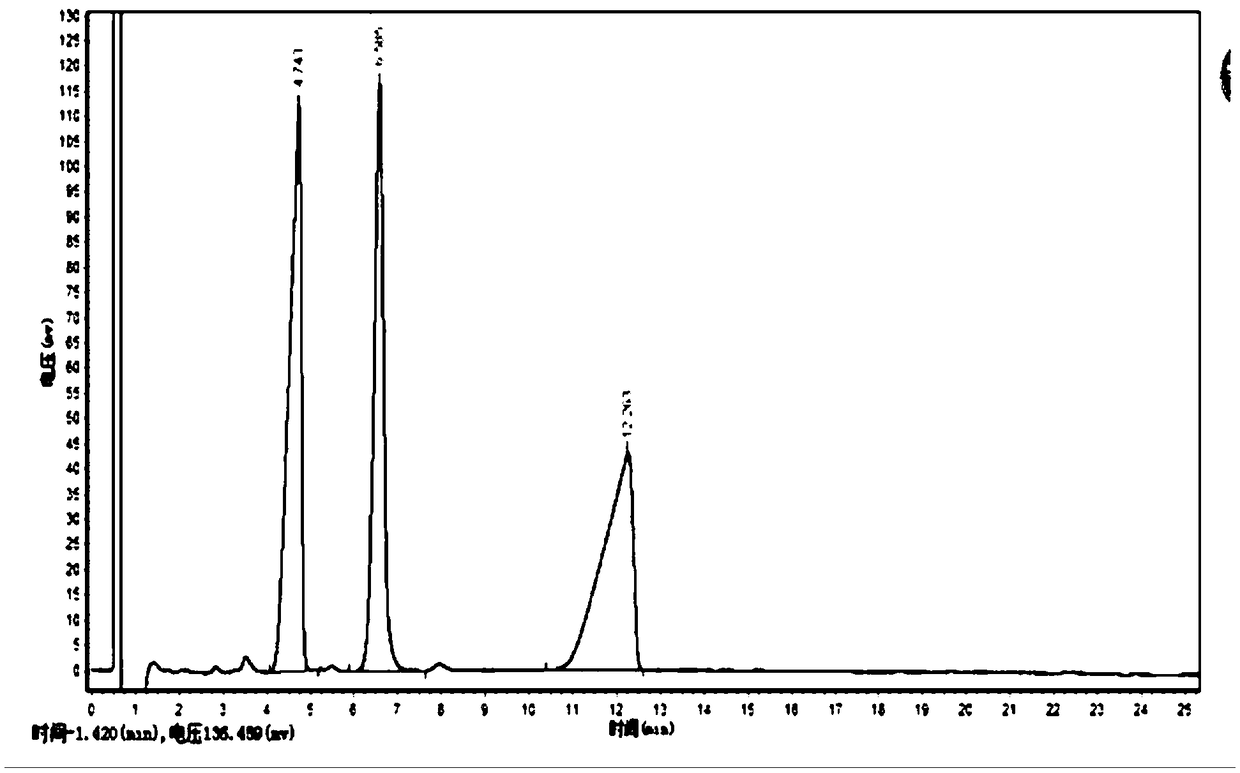

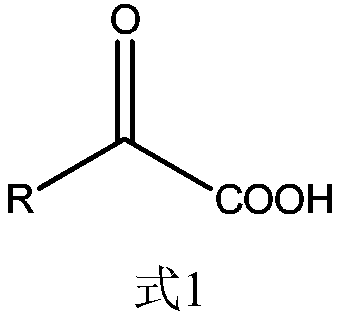

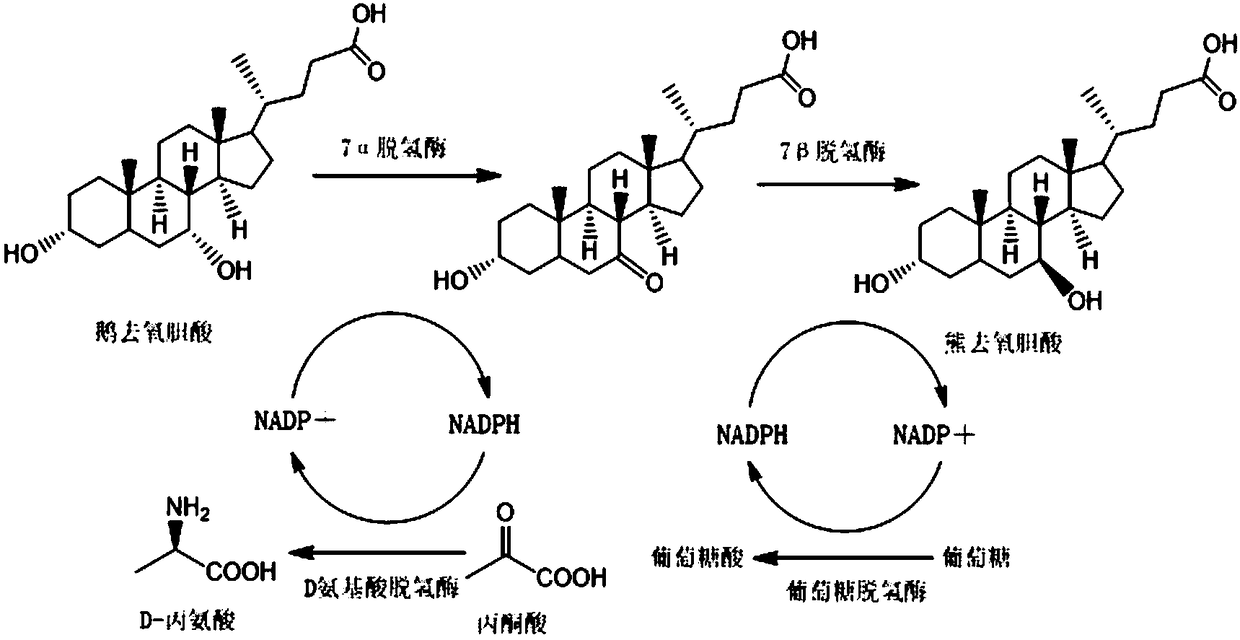

Method for synthesizing ursodeoxycholic acid and high-chiral-purity D-amino acid based on enzyme-method coupling technology

The invention discloses a method for synthesizing ursodeoxycholic acid (UDCA) and high-chiral-purity D-amino acid based on an enzyme-method coupling technology. The method comprises the following steps: putting chenodeoxycholic acid and alpha-ketonic acid into a solution system containing 7alpha-HSDH (Homoserine Dehydrogenase), DAADH and NADP (Nicotinamide Adenine Dinucleotide Phosphate) and carrying out enzyme catalysis reaction; separating a reaction solution by adopting an ultra-filtration membrane to obtain a concentrated mixed enzyme solution; regulating the pH (Potential of Hydrogen) ofa dialysis solution and crystallizing; filtering and separating to obtain 7-KLCA wet powder and filtrate; carrying out chromatographic treatment on the filtrate to obtain the D-amino acid; putting the7-KLCA wet powder into a solution system containing glucose, the NADP, the 7alpha-HSDH and GDH (Glutamate Dehydrogenase) and carrying out enzyme catalysis reaction; separating the reaction solution by adopting the ultra-filtration membrane to obtain the concentrated mixed enzyme solution; crystallizing, filtering and separating the dialysis solution, so as to obtain ursodeoxycholic acid. By adopting the method provided by the invention, UDCA and the high-chiral-purity D-amino acid can be obtained at the same time, the enzyme utilization rate is high, synthesis steps are simple and the cost isreduced; meanwhile, a metal reduction reagent and an organic solvent do not need to be added in a reaction process and conditions are mild; the method is environmentally friendly and is suitable forindustrial production.

Owner:HUNAN BAOLISHI BIOTECH

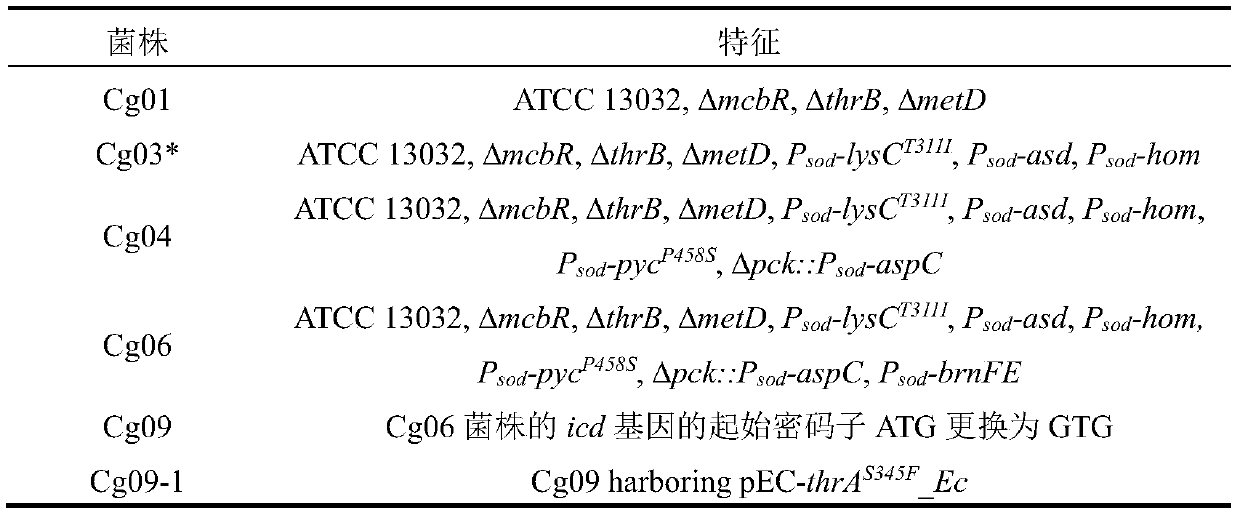

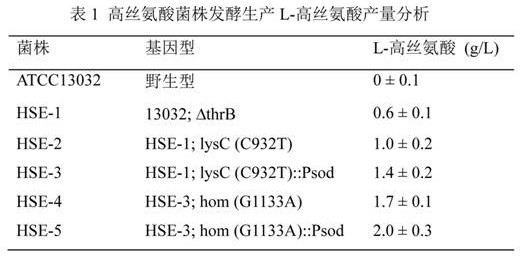

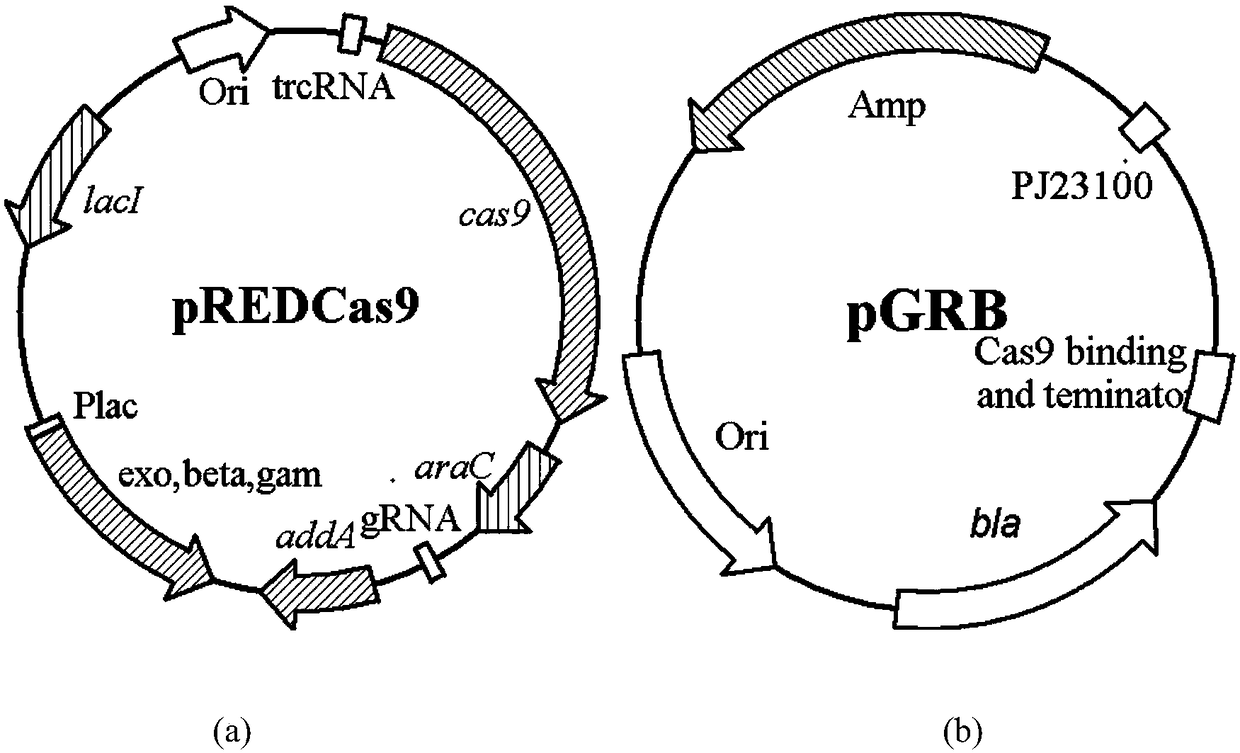

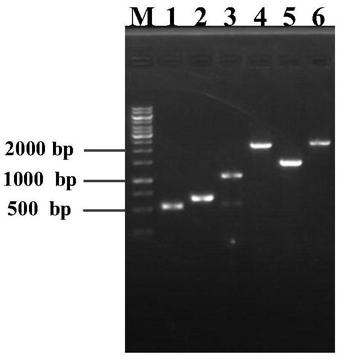

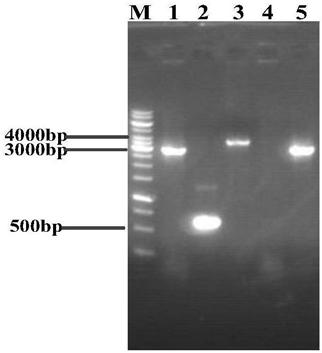

Construction and applications of corynebacterium glutamicum mutant strain for producing L-homoserine

The invention discloses construction and applications of a corynebacterium glutamicum mutant strain for producing L-homoserine, and belongs to the technical field of fermentation engineering. Corynebacterium glutamicum ATCC 13032 is taken as a starting strain to knock out regulatory protein McbR, homoserine kinase, transport protein MetD, phosphoenolpyruvate carboxykinase; the expression of isocitrate dehydrogenase is down regulated; transport protein BrnFE, aspartic semialdehyde dehydrogenase and homoserine dehydrogenase are overexpressed; and the expression of aspartate kinase, pyruvate carboxylase and the aspartate kinase I derived from escherichia coli are enhanced. Shake flask culture can be performed on the mutant strain for 48 h, and the yield of L-homoserine can reach 8.8 g / L.

Owner:JIANGNAN UNIV

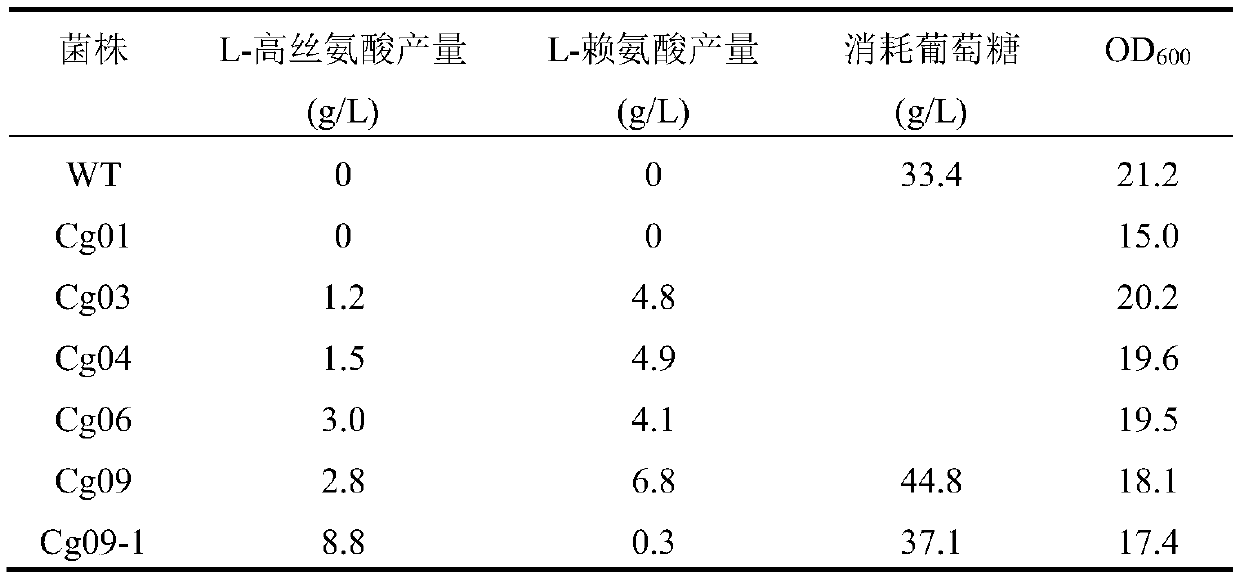

Process for the production of beta-lysine

InactiveCN101400799AFermentationVector-based foreign material introductionPhosphoenolpyruvate carboxylaseTransketolase

Process for the production of -lysine by constructing a recombinant microorganism which has a deregulated lysine 2,3-aminomutase gene and at least one deregulated gene selected from the group (i) which consists of aspartokinase, aspartatesemialdehyde dehydrogenase, dihydrodipicolinate synthase, dihydrodipicolinate reductase, tetrahydrodipicolinate succinylase, succinyl-amino-ketopimelate transaminase, succinyl-diamino-pimelate desuccinylase, diaminopimelate epimerase, diaminopimelate dehydrogenase, arginyl-tRNA synthetase, diaminopimelate decarboxylase, pyruvate carboxylase, phosphoenolpyruvate carboxylase, glucose-6-phosphate dehydrogenase, transketolase, transaldolase, 6-phosphogluconolactonase, fructose 1,6-biphosphatase, homoserine dehydrogenase, phophoenolpyruvate carboxykinase, succinyl-CoA synthetase, methylmalonyl-CoA mutase, provided that if aspartokinase is deregulated as gene (i) at least a second gene (i) other than aspartokinase has to be deregulated, and cultivating said microorganism.

Owner:BASF SE

Process for the production of beta-lysine

InactiveUS20090029425A1FermentationVector-based foreign material introductionPhosphoenolpyruvate carboxylaseTransketolase

Process for the production of -lysine by constructing a recombinant microorganism which has a deregulated lysine 2,3-aminomutase gene and at least one deregulated gene selected from the group (i) which consists of aspartokinase, aspartatesemialdehyde dehydrogenase, dihydrodipicolinate synthase, dihydrodipicolinate reductase, tetrahydrodipicolinate succinylase, succinyl-amino-ketopimelate transaminase, succinyl-diamino-pimelate desuccinylase, diaminopimelate epimerase, diamino-pimelate dehydrogenase, arginyl-tRNA synthetase, diaminopimelate decarboxylase, pyruvate carboxylase, phosphoenolpyruvate carboxylase, glucose-6-phosphate dehydrogenase, transketolase, transaldolase, 6-phosphogluconolactonase, fructose 1,6-biphosphatase, homoserine dehydrogenase, phophoenolpyruvate carboxykinase, succinyl-CoA synthetase, methylmalonyl-CoA mutase, provided that if aspartokinase is deregulated as gene (i) at least a second gene (i) other than aspartokinase has to be deregulated, and cultivating said microorganism.

Owner:BASF AG

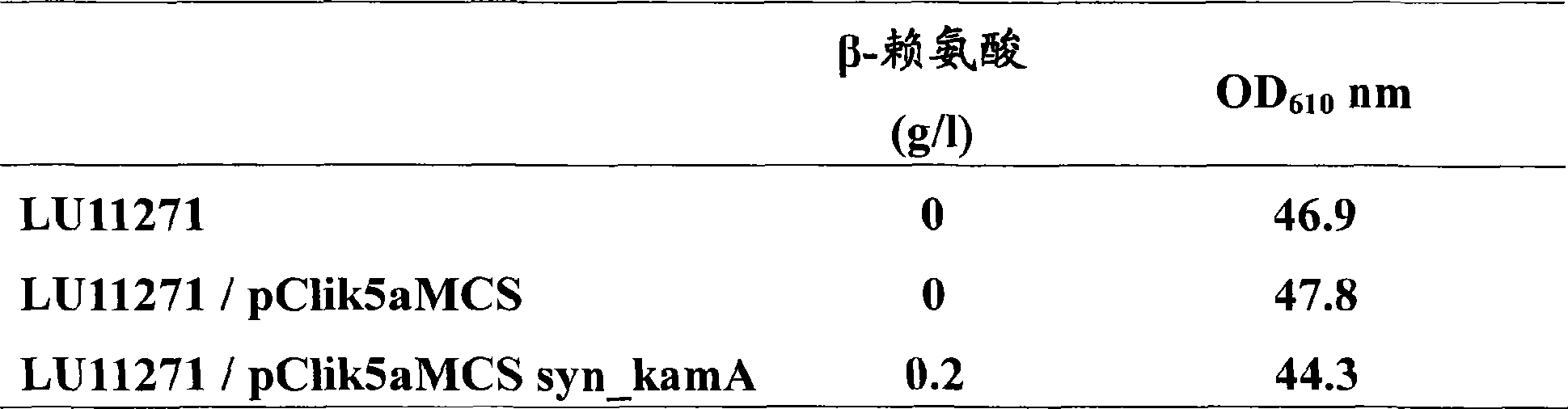

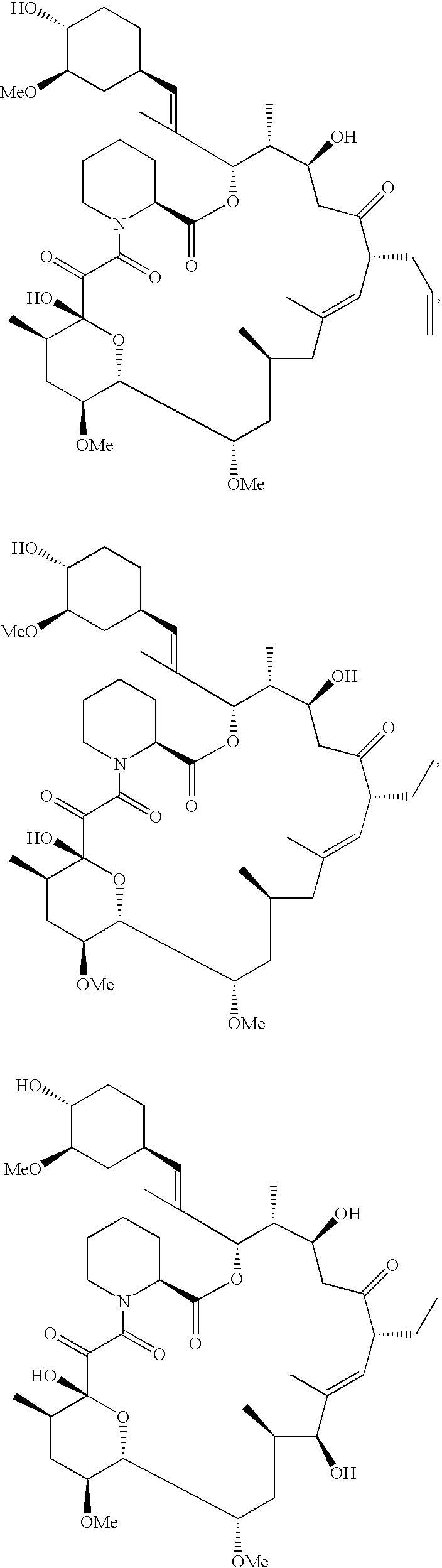

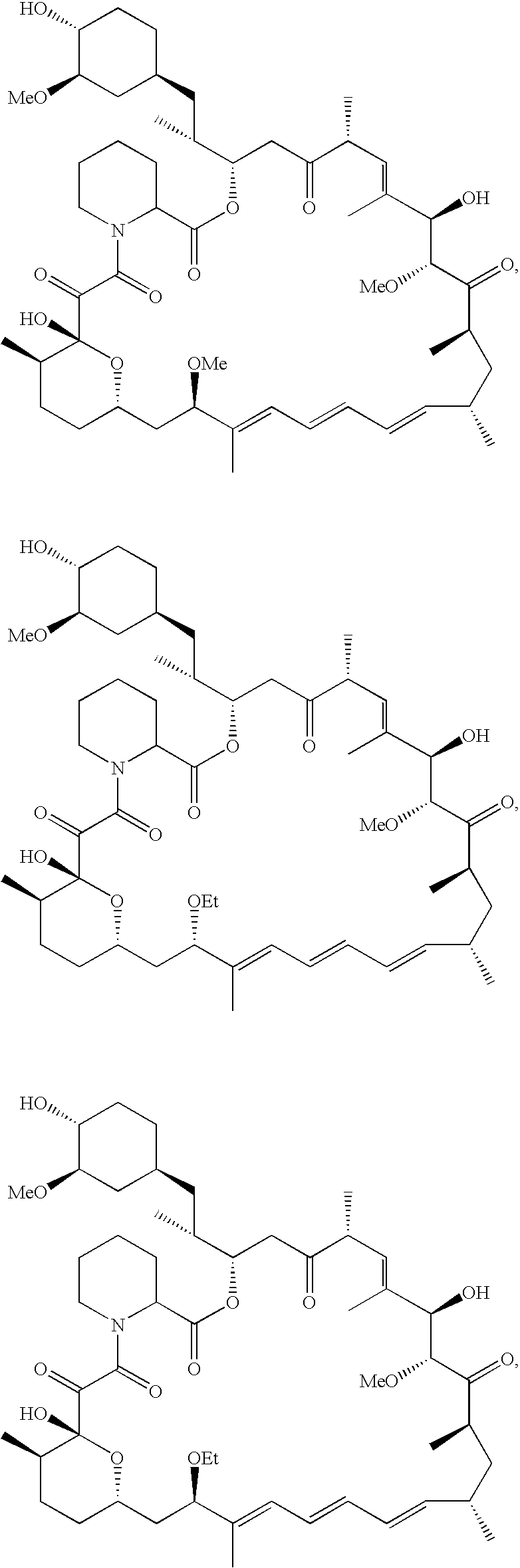

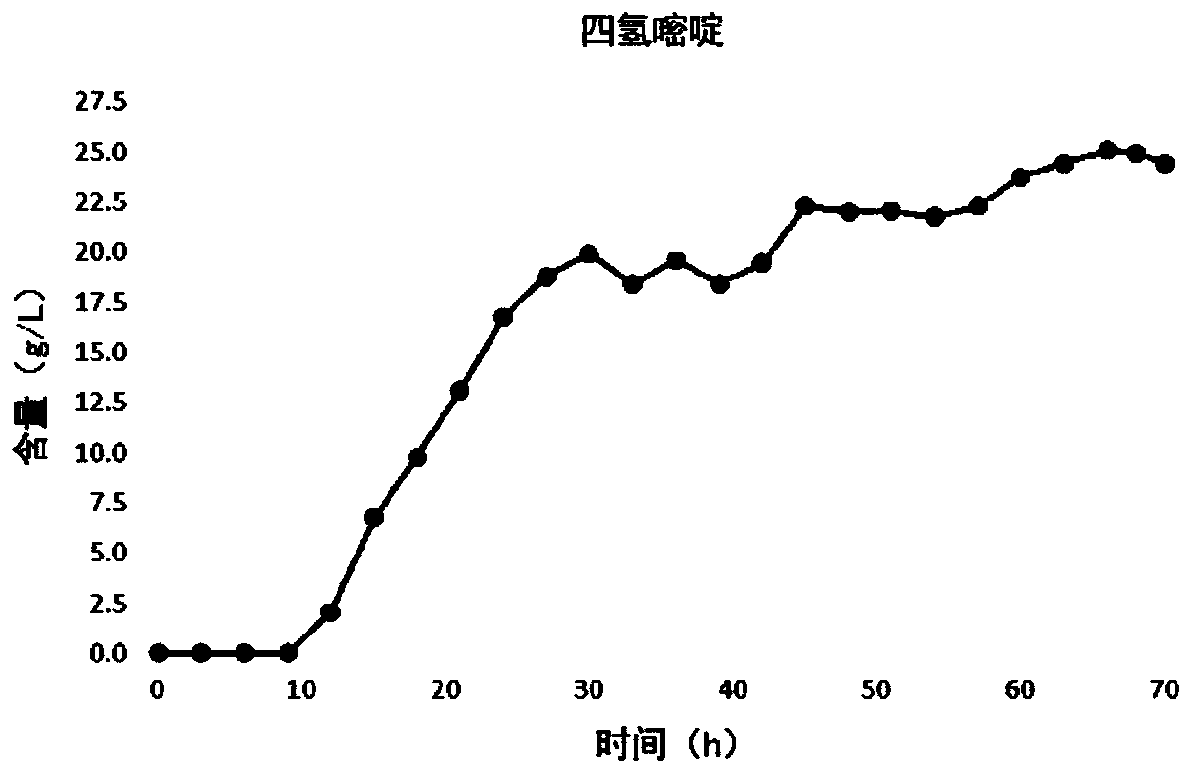

Combination therapies for fungal pathogens

InactiveUS20060189551A1Suppression problemInhibitory activityBiocideCarbohydrate active ingredientsFungal microorganismsSerine dehydrogenase

The present invention relates to methods of treating fungal infections with a drug combination: a first compound that inhibits the activity or expression of the protein FKBP12 and a second compound that inhibits the activity or expression of homoserine dehydrogenase. Evidence indicates that dual inhibitors of proteins FKBP12 and homoserine dehydrogenase are lethal to fungi. Such an approach should be minimally toxic since this combination therapy targets a biosynthetic pathway that is conserved in fungi but not in mammals.

Owner:DUKE UNIV +1

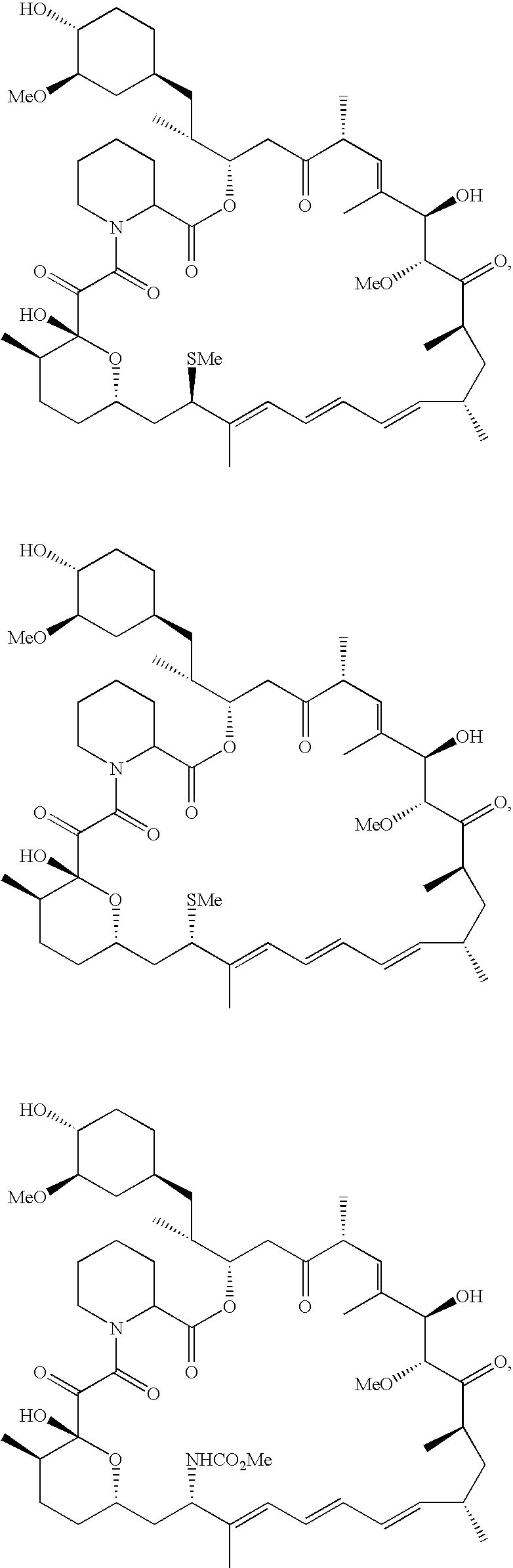

Recombinant corynebacterium glutamicum, construction method thereof and method for producing tetrahydropyrimidine by same

ActiveCN111394288AAvoid Biosecurity ConcernsReduce cumbersome stepsBacteriaMicroorganism based processesPhosphoenolpyruvate carboxylaseSerine dehydrogenase

The invention relates to recombinant corynebacterium glutamicum, a method for constructing the recombinant corynebacterium glutamicum and a method for producing tetrahydropyrimidine by using the recombinant corynebacterium glutamicum. Compared with wild corynebacterium glutamicum, the recombinant corynebacterium glutamicum has phosphoenolpyruvate carboxylase, homoserine dehydrogenase and dihydropyrimidinedicarboxylate synthetase with reduced expression level, and also has a gene expression cassette for expressing phosphoenolpyruvate carboxylase and a gene expression cassette for expressing ectA enzyme, ectB enzyme and ectC enzyme, so that tetrahydropyrimidine can be efficiently produced. The tetrahydropyrimidine produced by using the recombinant corynebacterium glutamicum has high yield, the safety of tetrahydropyrimidine products is improved, the production cost is greatly reduced, and the recombinant corynebacterium glutamicum has good market application prospect.

Owner:BEIJING BIOINNO BIOTECHNOLOGY CO LTD

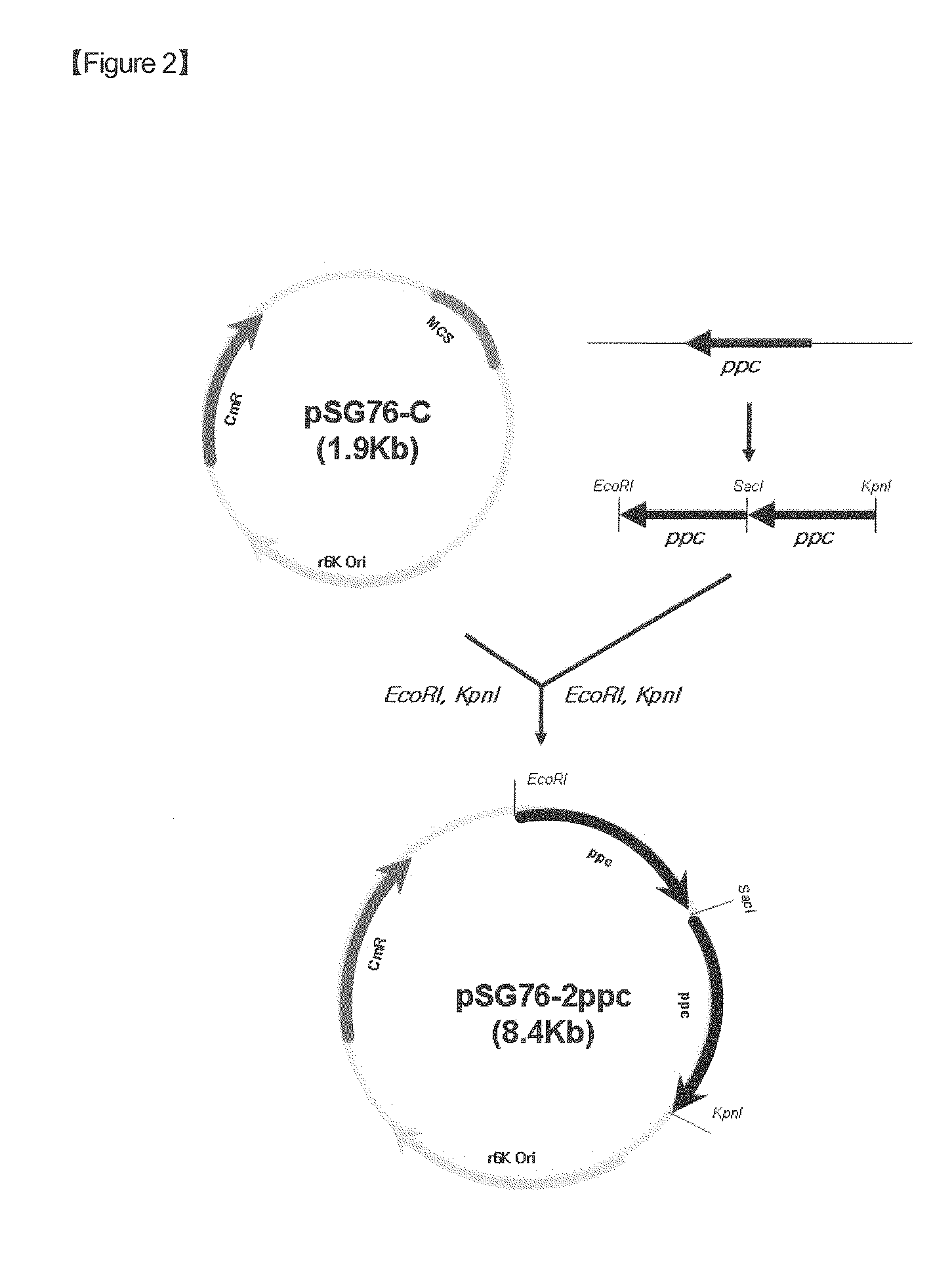

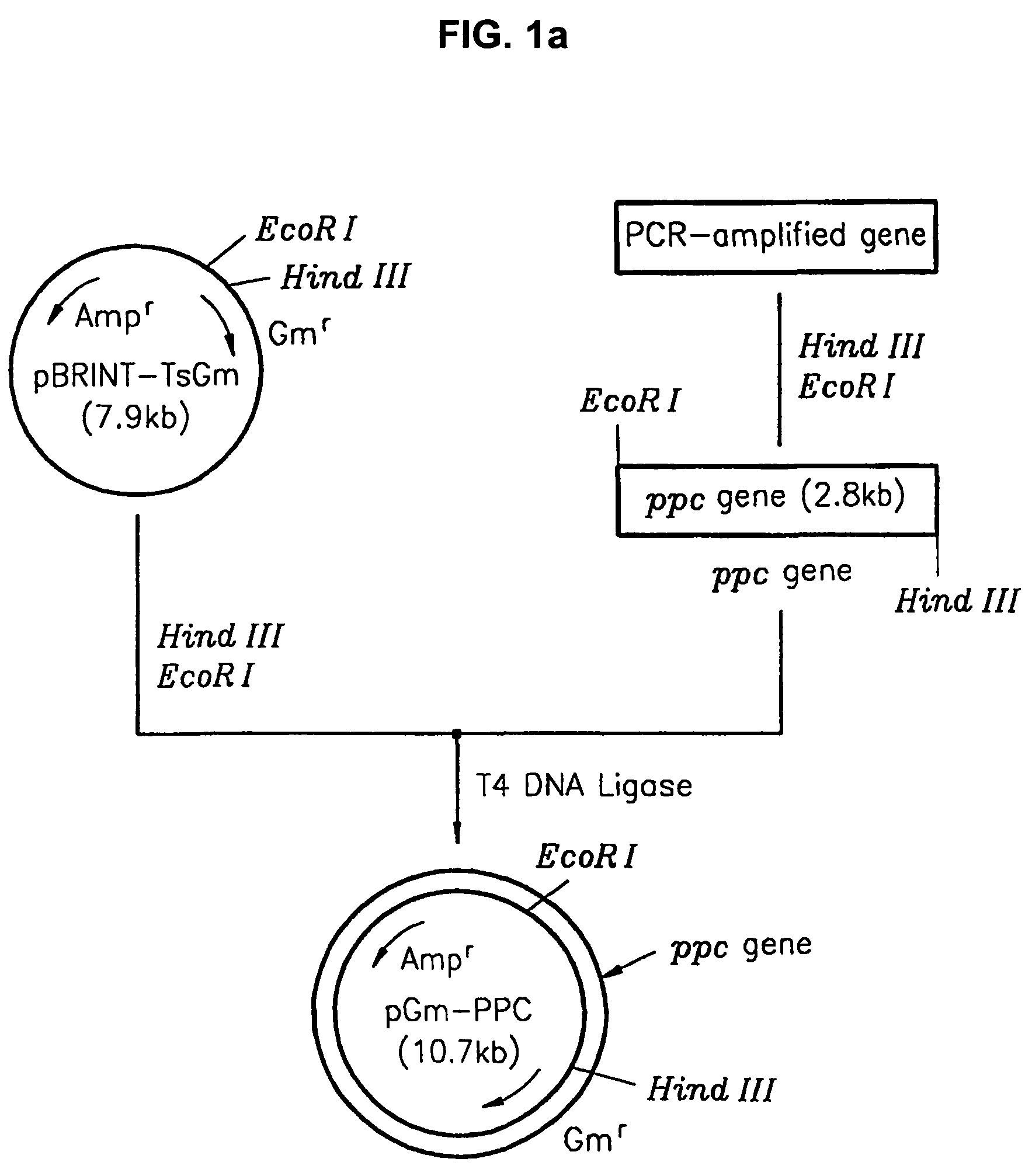

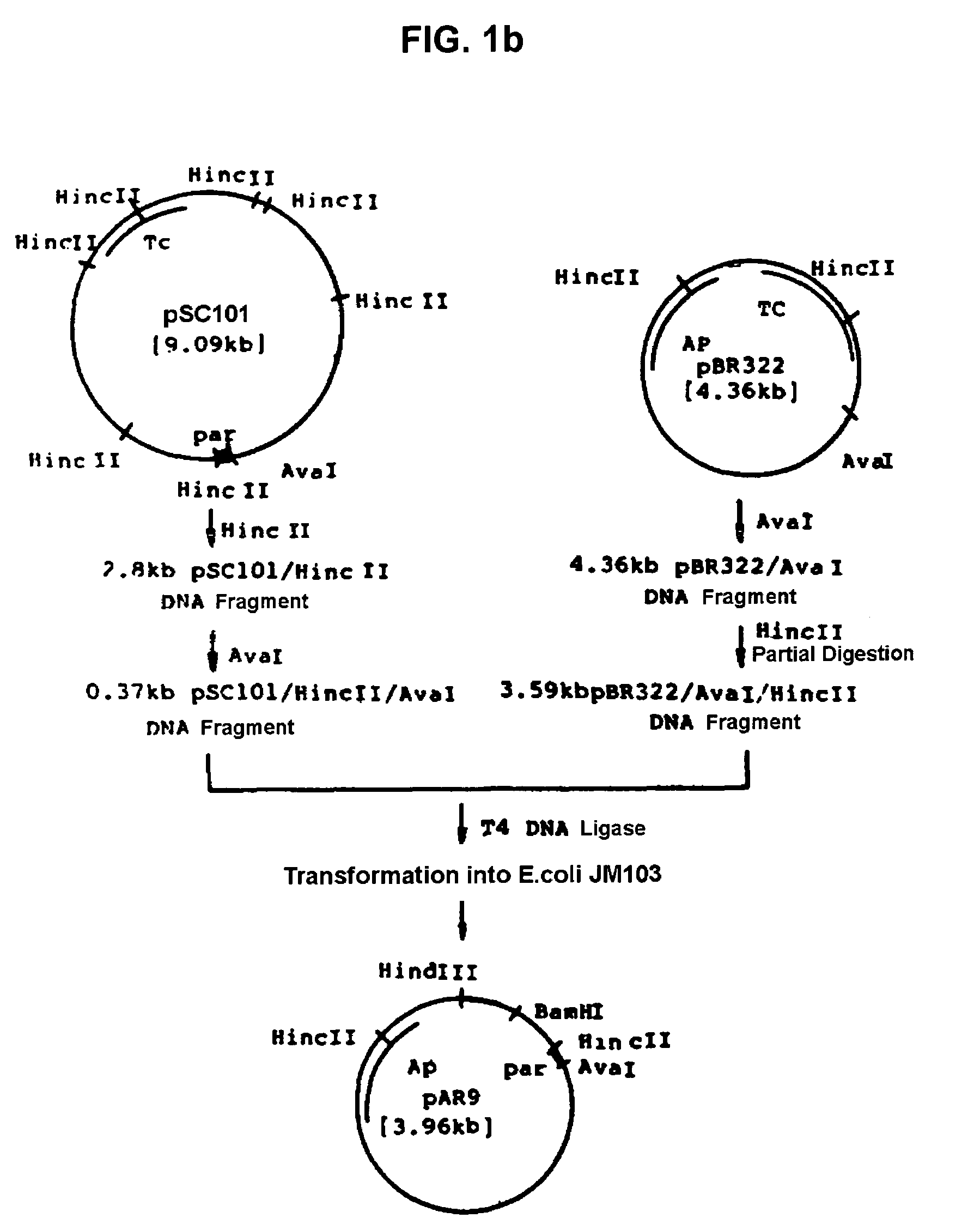

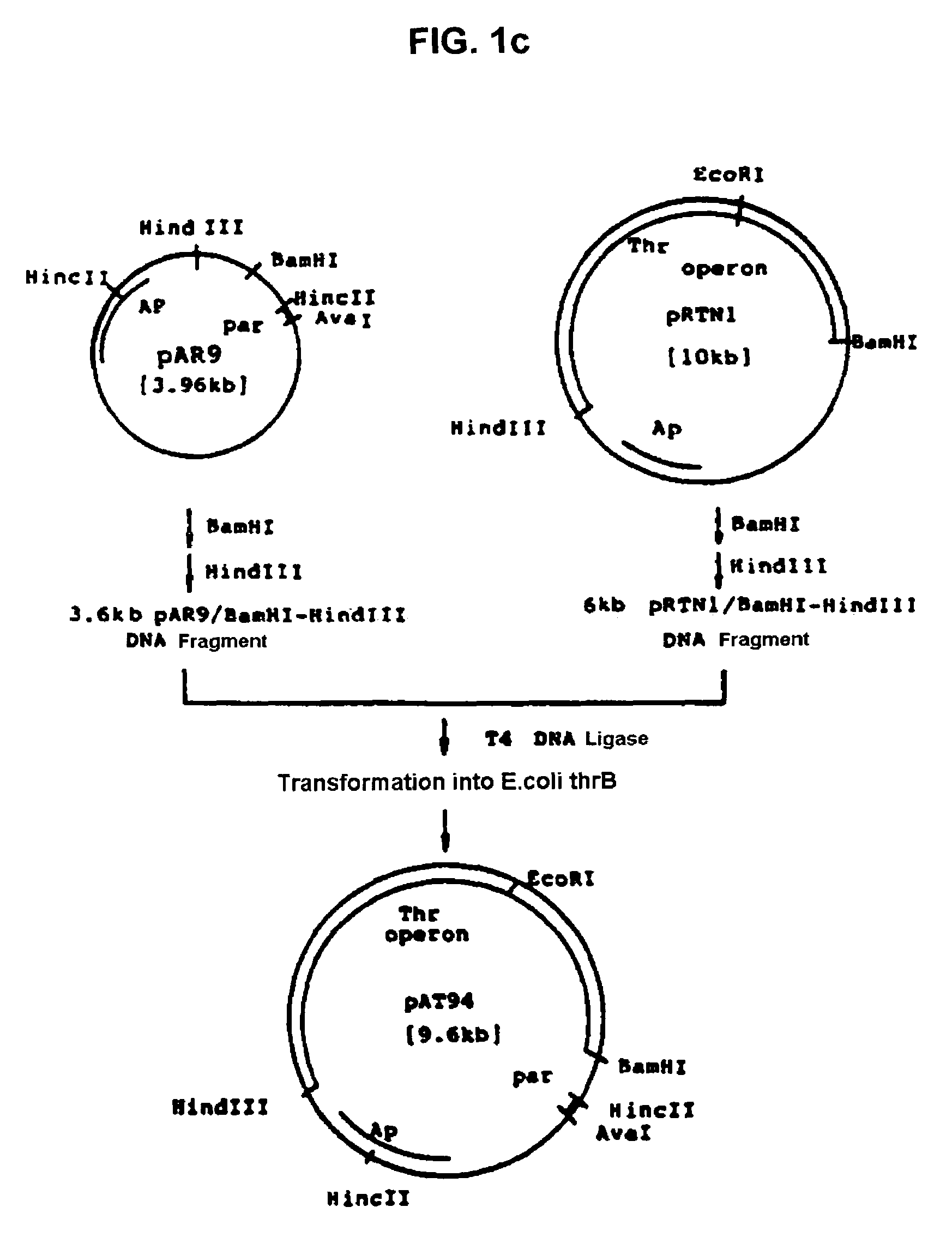

Method for L-threonine production

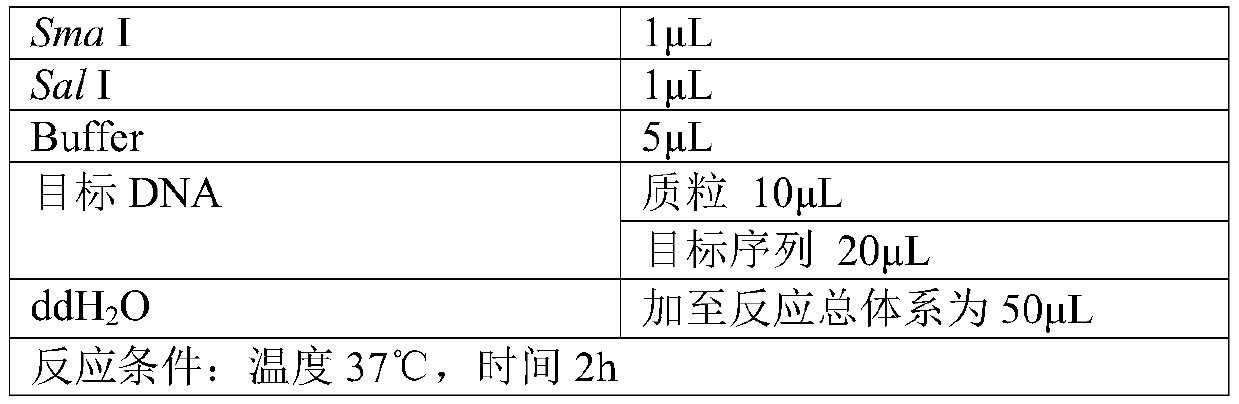

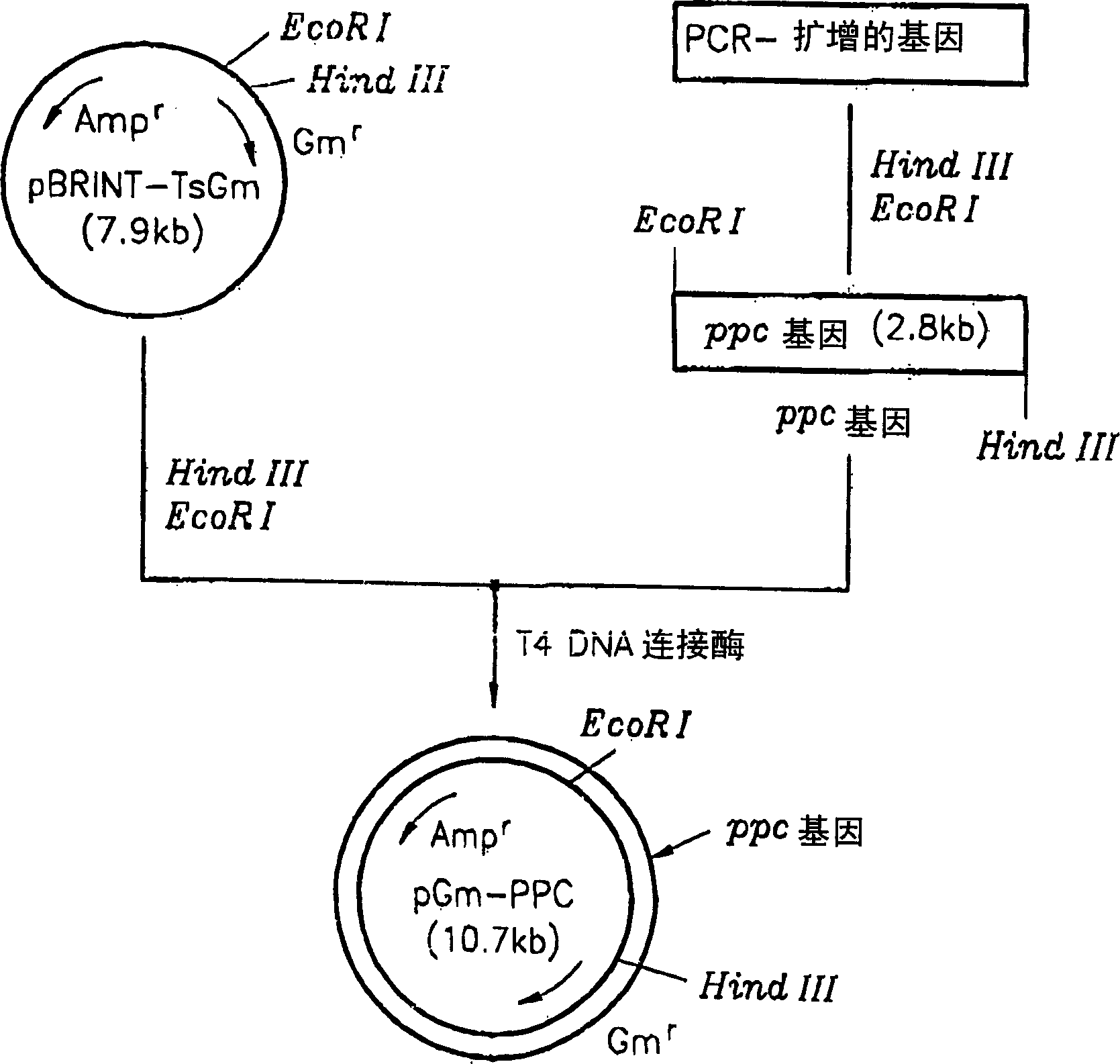

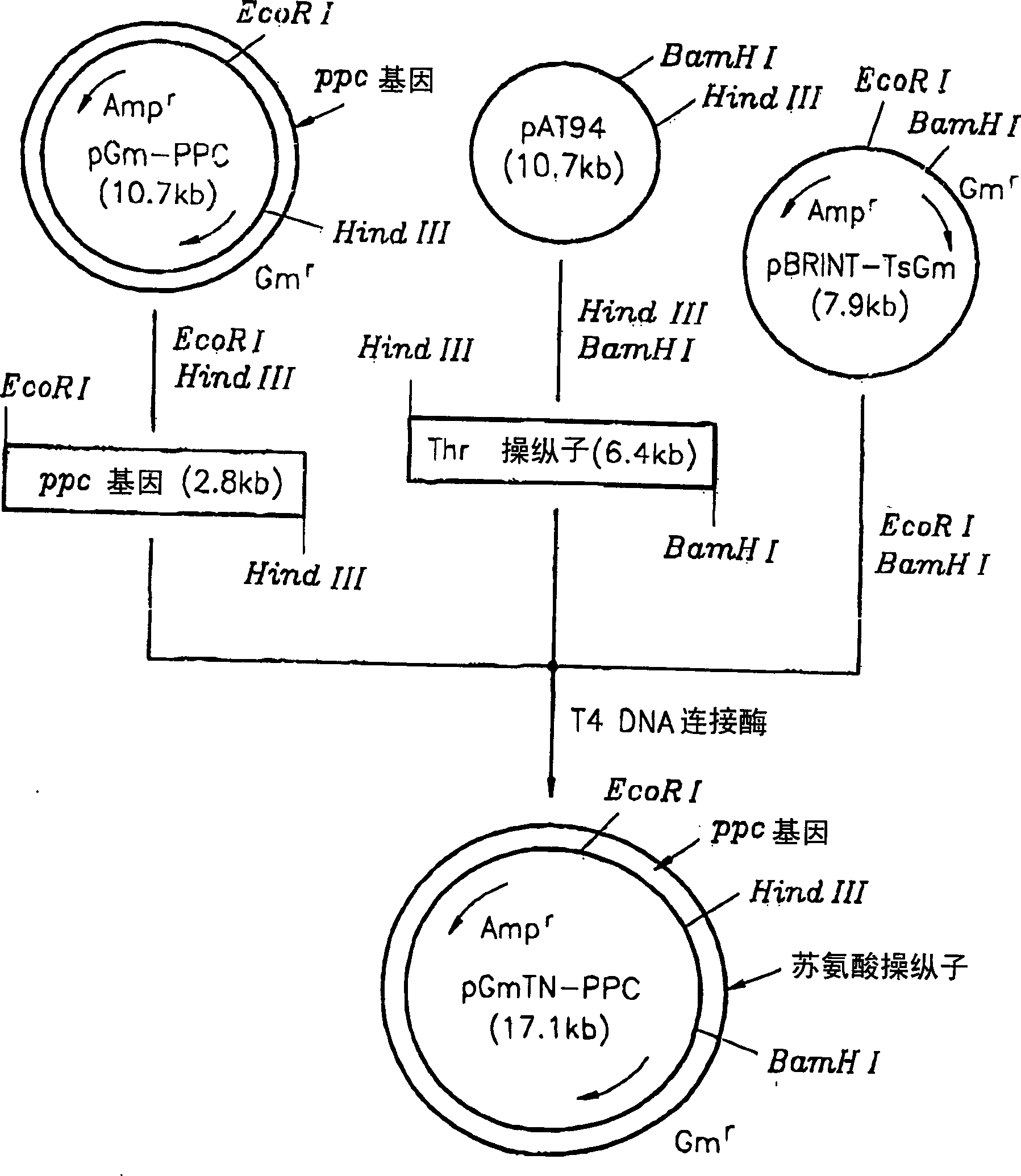

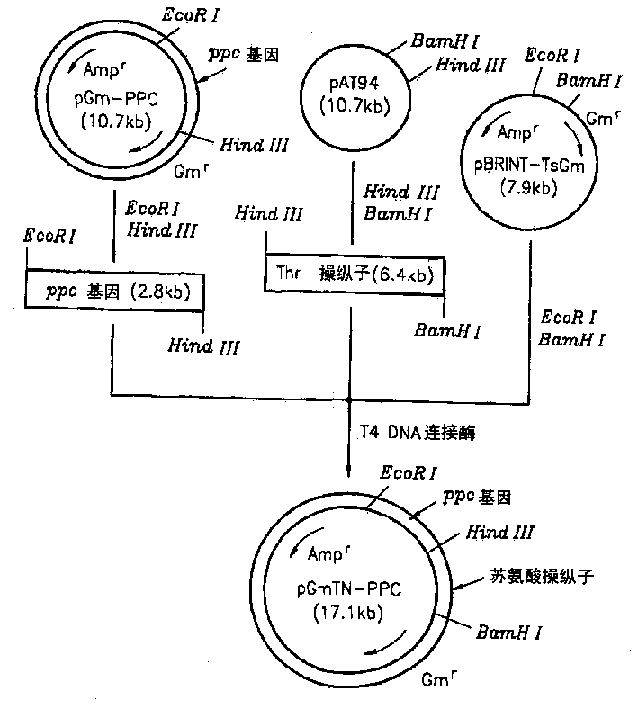

InactiveCN1457365AHigh expressionImprove genesBacteriaMicroorganism based processesPhosphoenolpyruvate carboxylaseOperon

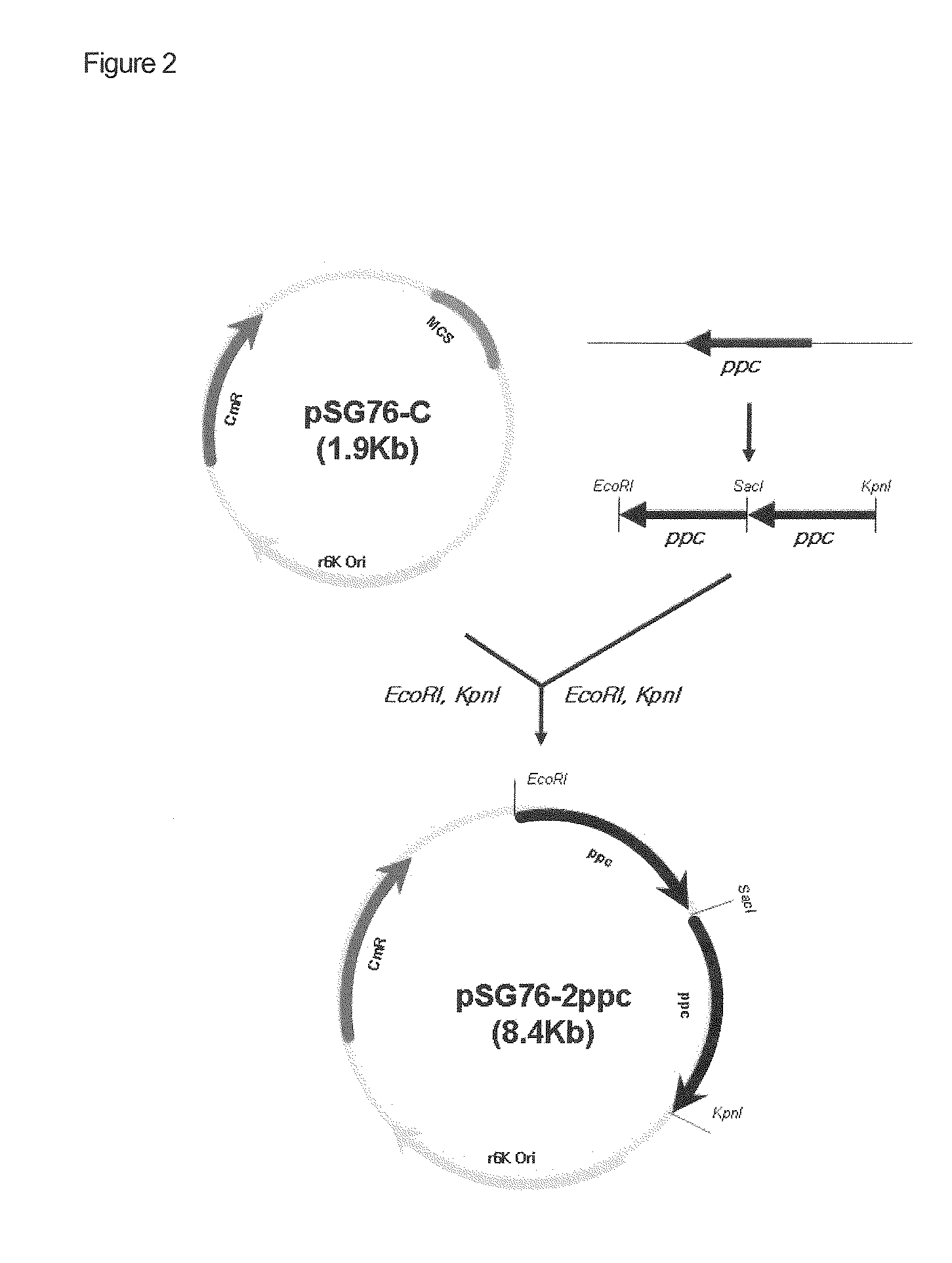

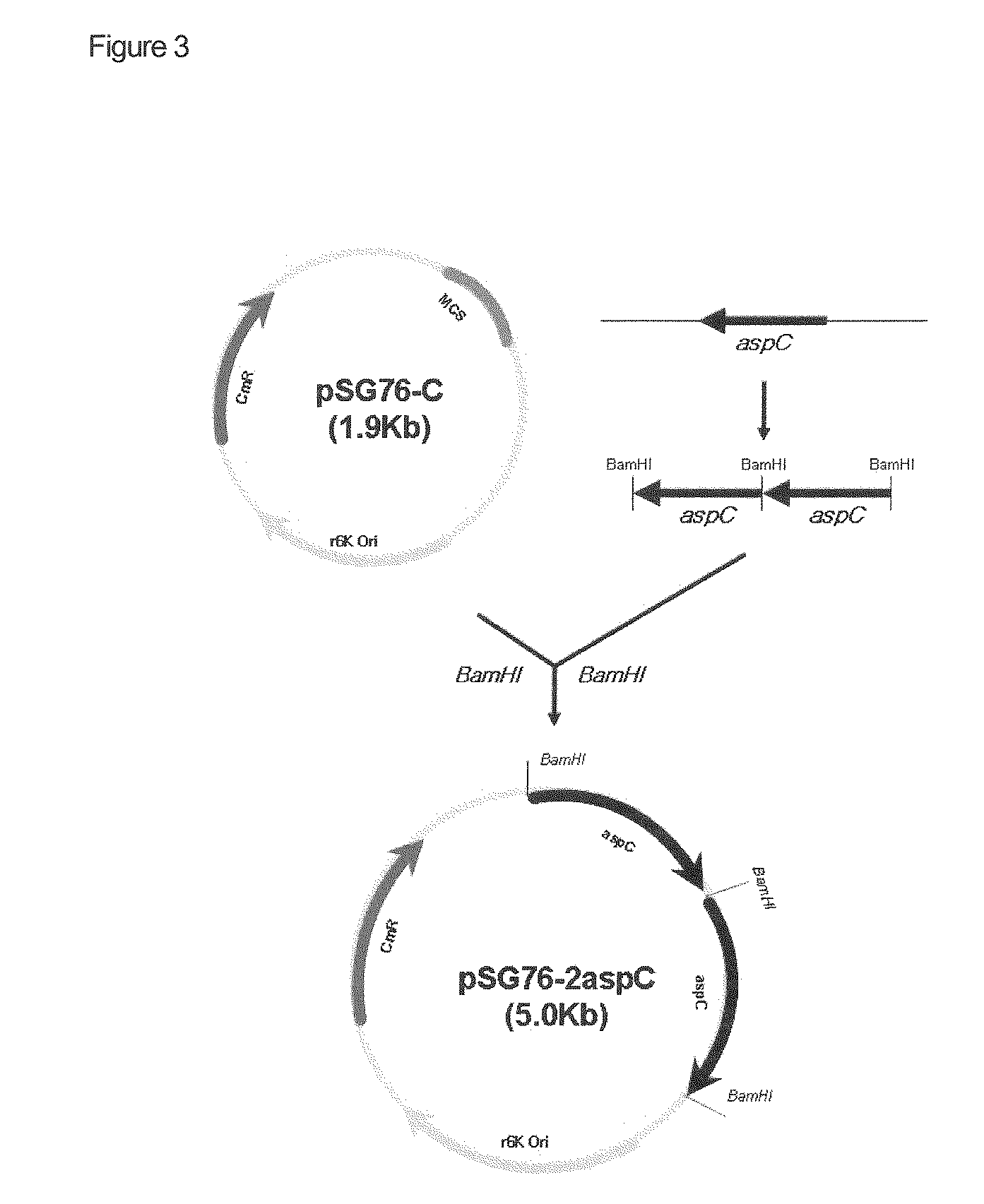

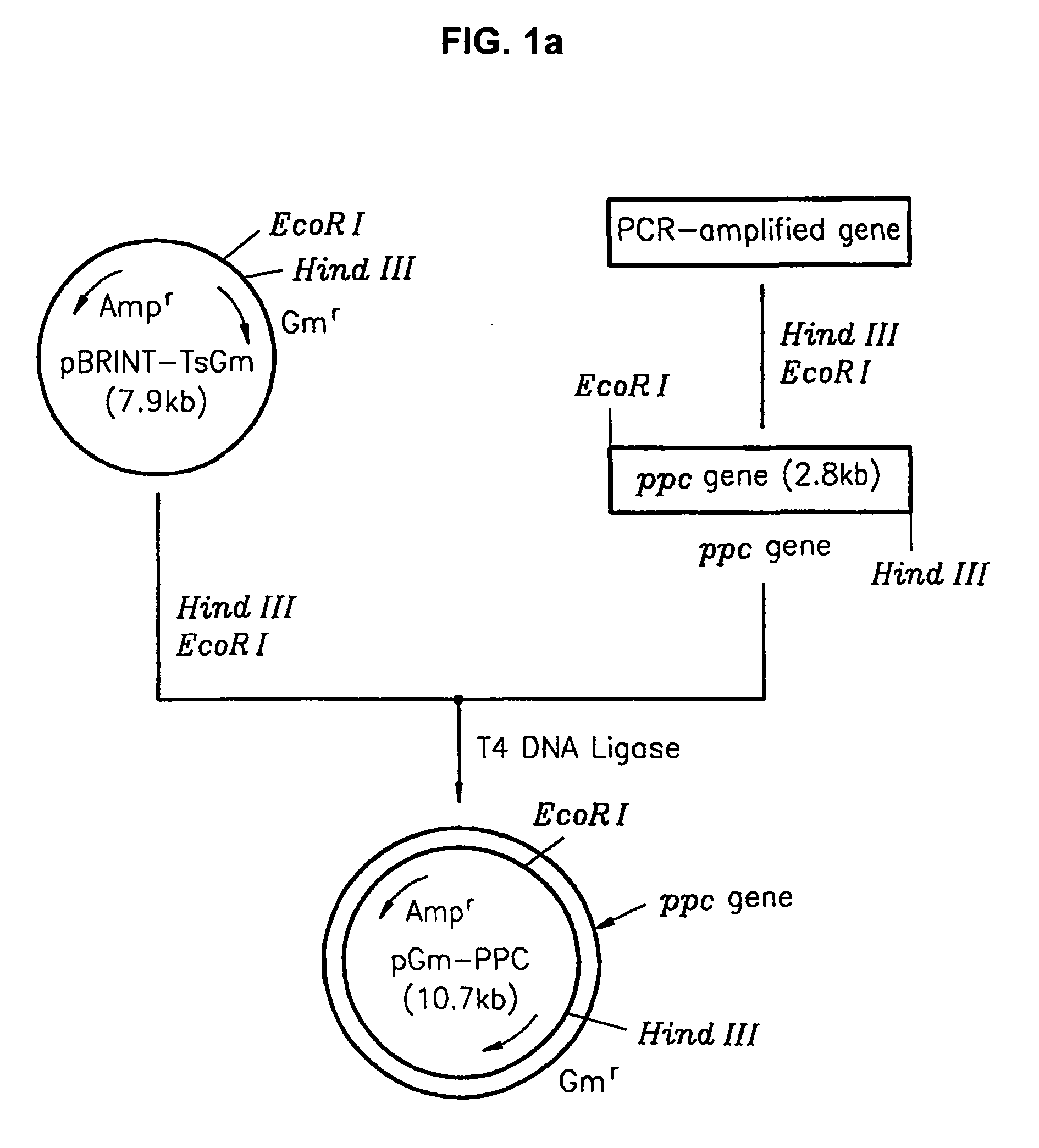

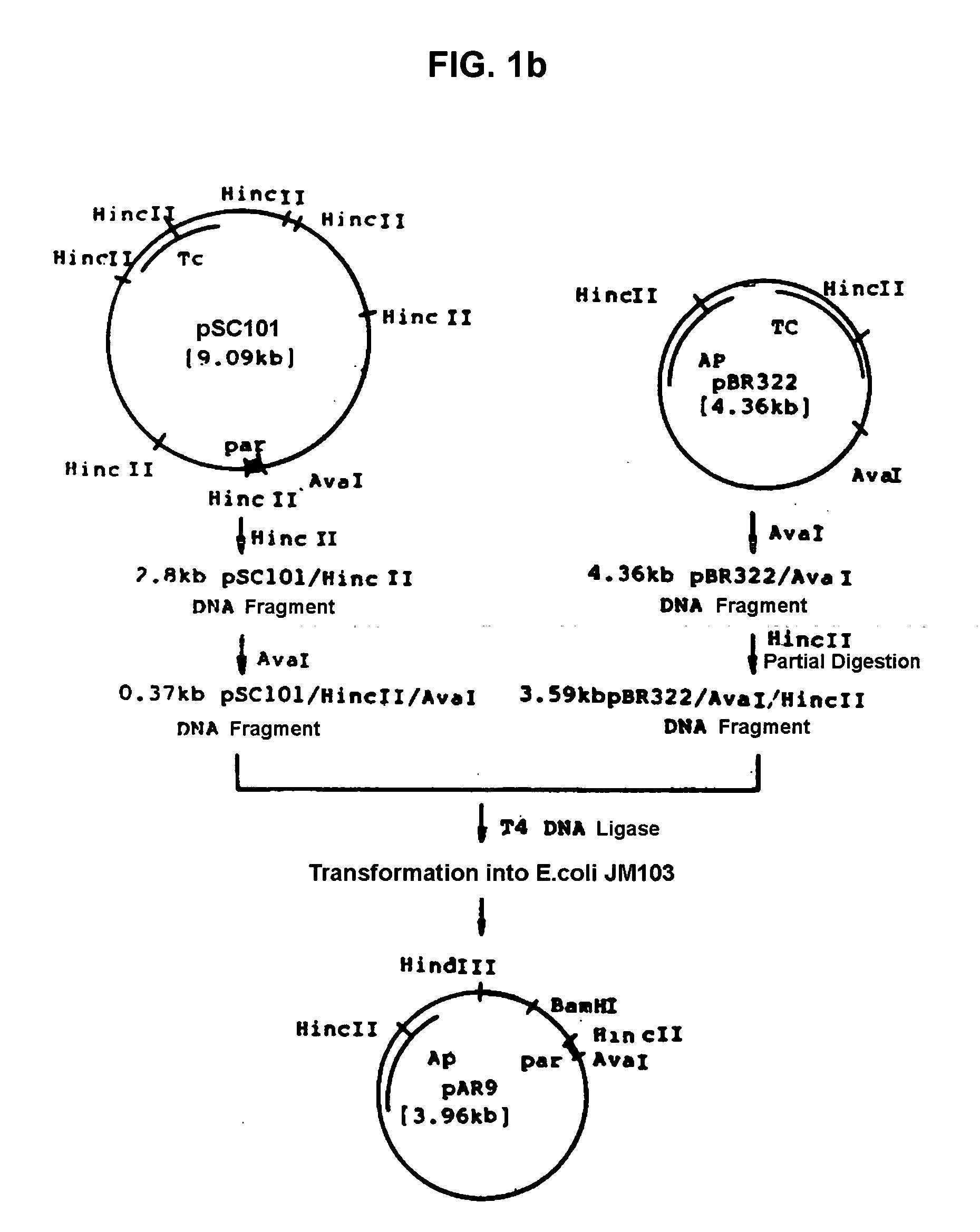

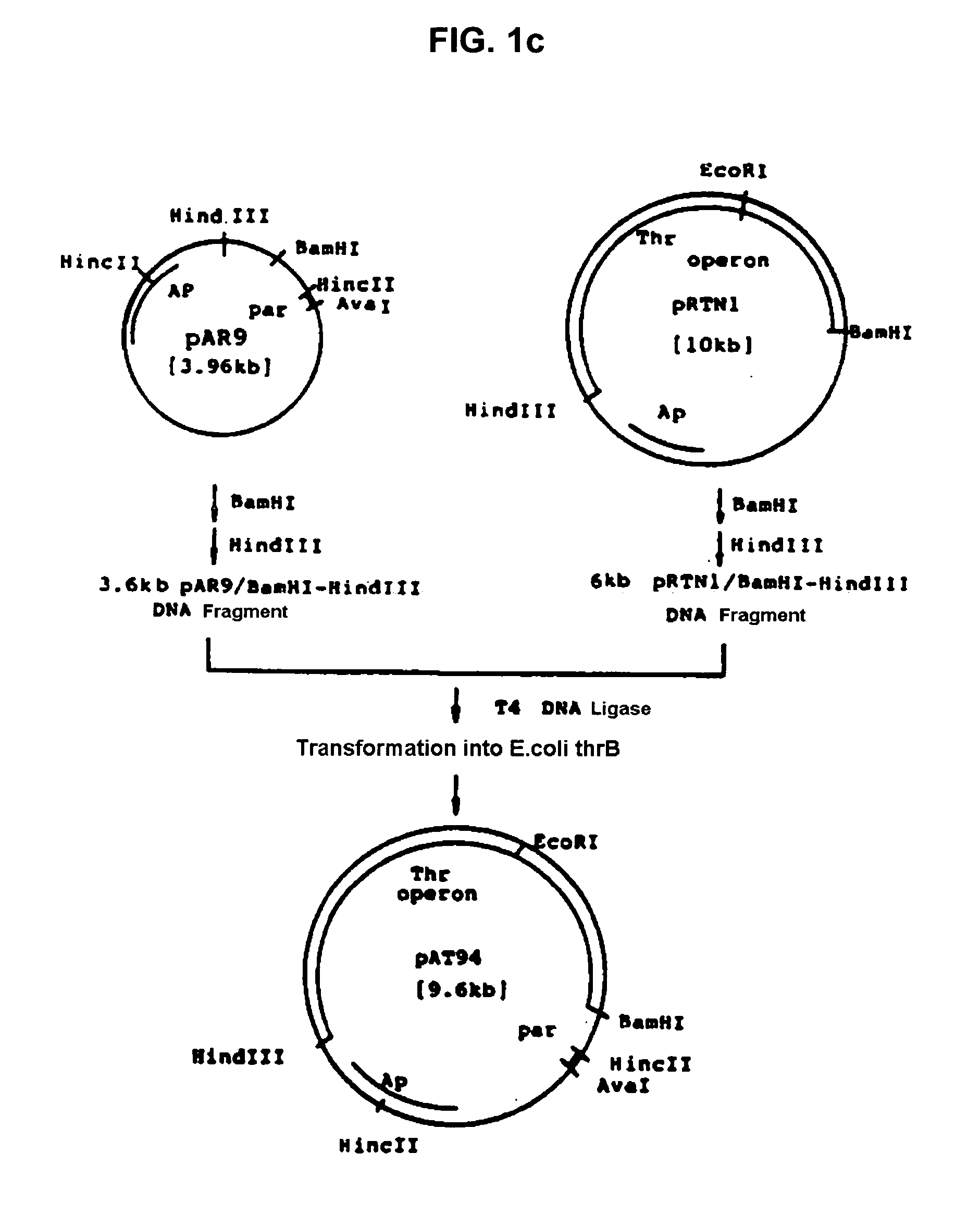

A method for producing L-threonine using a microorganism is provided. In the method, additional one or more copies of each of the phosphoenolpyruvate carboxylase (ppc) gene and the threonine operon are integrated into a particular site of the chromosomal DNA of a microorganism, while its inherent ppc gene and threonine operon remain. Accordingly, two or more ppc genes and threonine operons are included in the chromosomal DNA of the microorganism to thereby enhance the expression of the ppc gene encoding an enzyme to convert phosphoenolpyruvate to a threonine biosynthesis precursor, oxaloacetete, and the genes encoding enzymes involved in the synthetic pathway of threonine from oxaloacetate, including thrA (aspartokinasel-homoserine dehydrogenase), thrB (homoserine kinase), and thrC (threonine synthase), thereby markedly increasing L-threonine productivity.

Owner:CJ CHEILJEDANG CORP

Method for L-threonine production

InactiveUS20050136518A1Eliminate the problemHigh expressionBacteriaSugar derivativesAspartate kinaseHomoserine dehydrogenase

A method for producing L-threonine using a microorganism is provided. In the method, additional one or more copies of each of the phosphoenolpyruvate carboxylase (ppc) gene and the threonine operon are integrated into a particular site of the chromosomal DNA of a microorganism, while its inherent ppc gene and threonine operon remain. Accordingly, two or more ppc genes and threonine operons are included in the chromosomal DNA of the microorganism to thereby enhance the expression of the ppc gene encoding an enzyme to convert phosphoenolpyruvate to a threonine biosynthesis precursor, oxaloacetete, and the genes encoding enzymes involved in the synthetic pathway of threonine from oxaloacetate, including thrA (aspartokinasel-homoserine dehydrogenase), thrB (homoserine kinase), and thrC (threonine synthase), thereby markedly increasing L-threonine productivity.

Owner:CJ CHEILJEDANG CORP

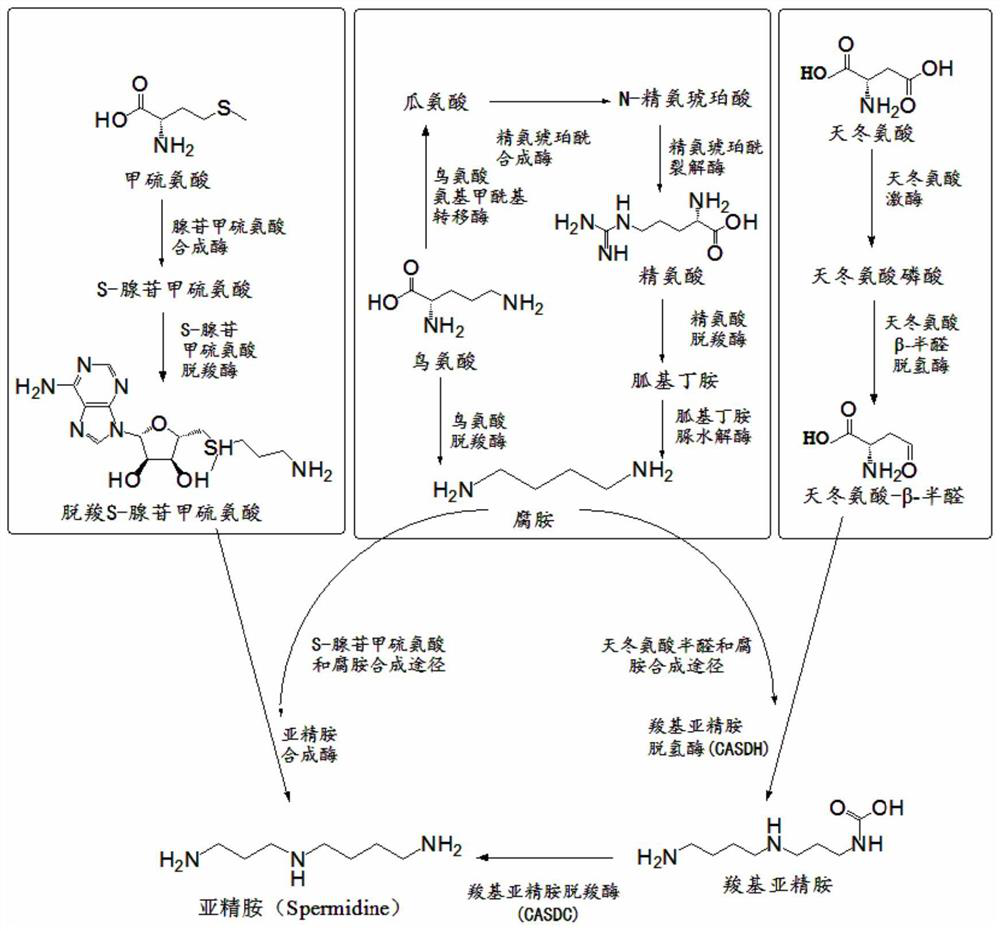

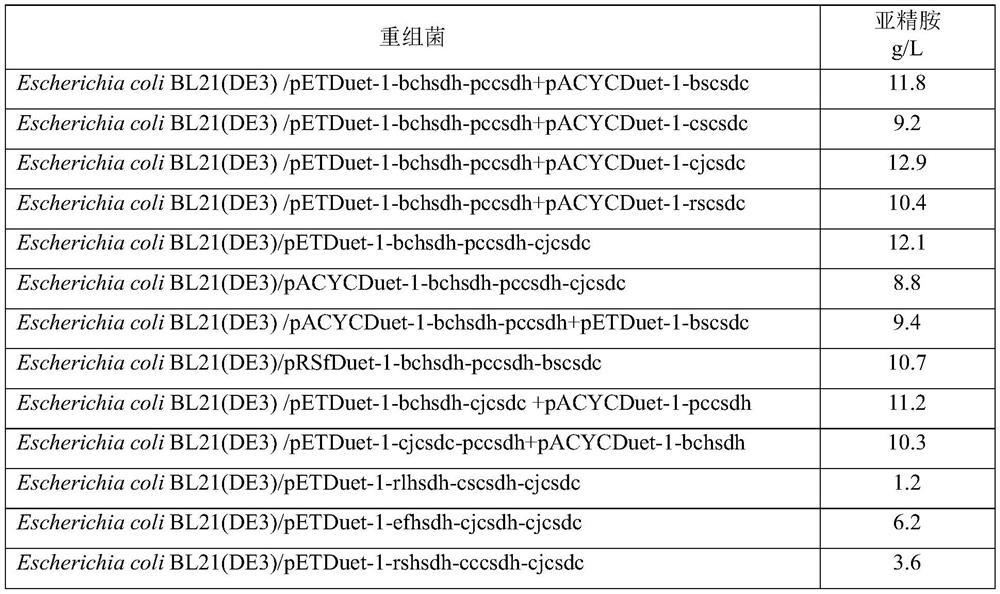

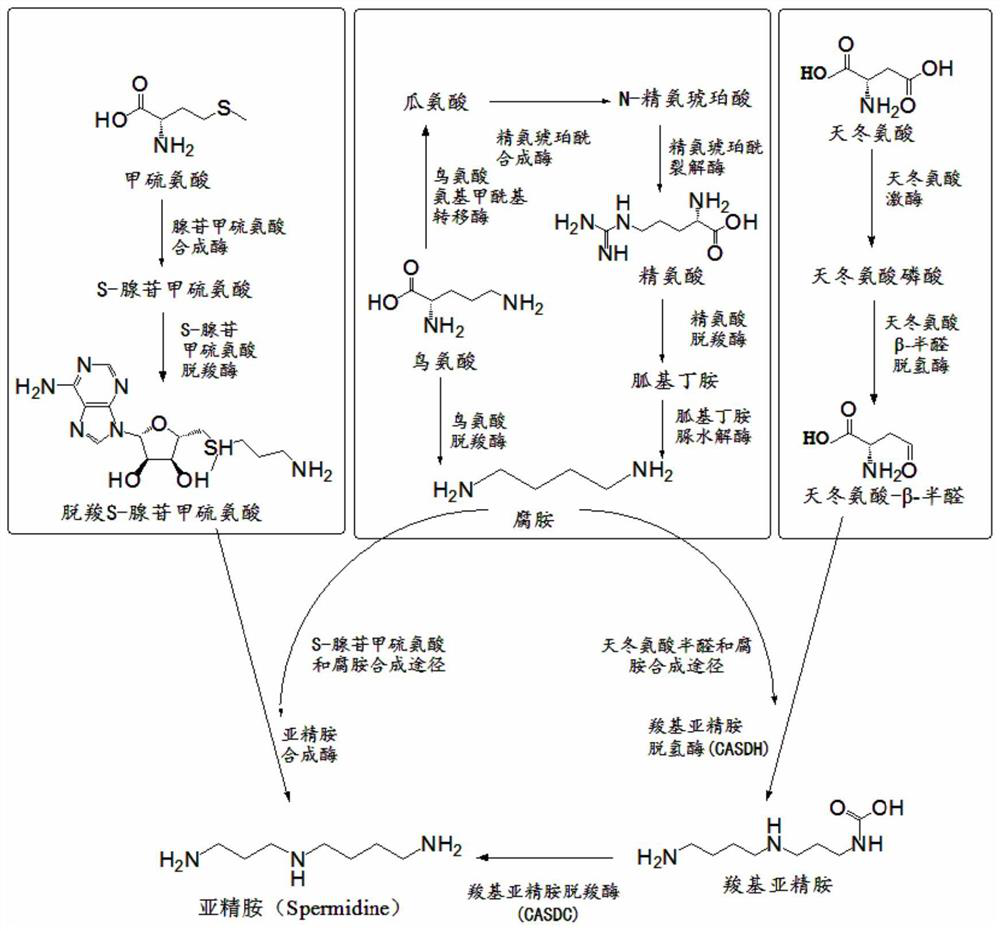

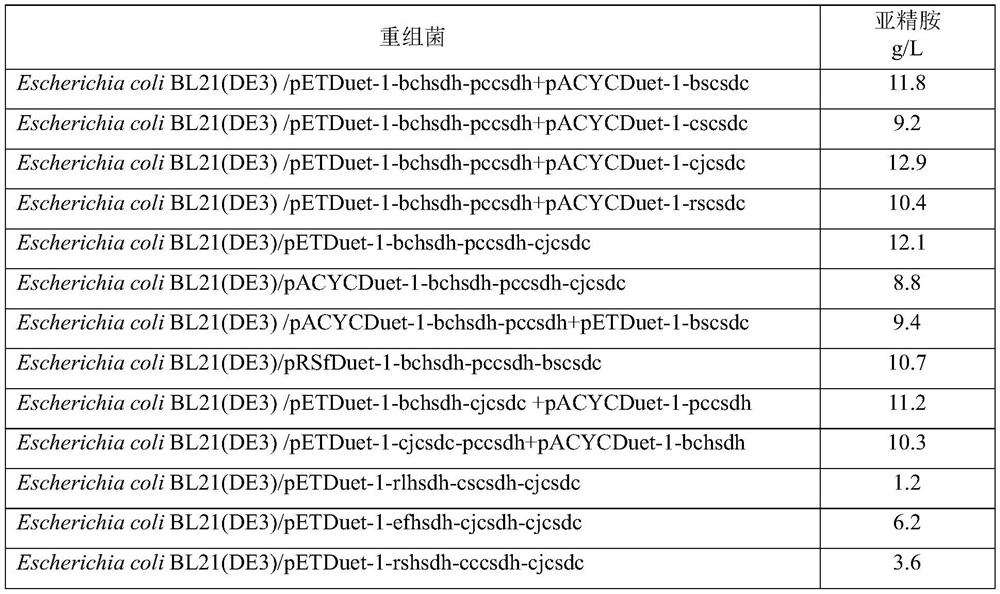

Method for synthesizing spermidine by biological way

ActiveCN111996220AEasy to produceRaw materials are easy to getBacteriaMicroorganism based processesCarboxyl radicalSerine dehydrogenase

The invention discloses a method for synthesizing spermidine through a biological way, and belongs to the technical field of bioengineering. According to the invention, genetically engineered bacteriaare constructed, and homoserine and putrescine (butanediamine) can be used as substrates to synthesize the spermidine. Specifically, homoserine dehydrogenase is used for dehydrogenating homoserine togenerate aspartate semialdehyde and NADH, carboxyl spermidine dehydrogenase synthesizes the aspartate semialdehyde and the putrescine into carboxyl spermidine with NADH as a coenzyme, coenzyme regeneration is achieved to generate NAD, and finally the carboxyl spermidine decarboxylase decarboxylates the carboxyl spermidine to generate the spermidine. The method for biosynthesizing the spermidine provided by the invention is simple in production process, easily available in raw materials and low in cost, and has a good industrial application prospect.

Owner:卓虹超源生物科技(郑州)有限公司

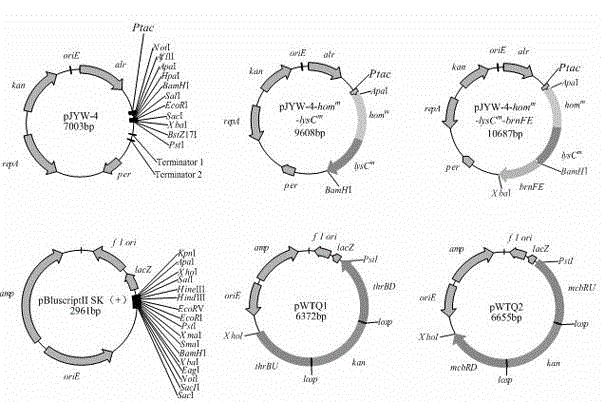

Construction and application of C.glutamicum subspecies lactofermentum with high L-methionine yield

Belonging to the field of bioengineering, the invention relates to construction and application of C.glutamicum subspecies lactofermentum with high L-methionine yield. The methionine high-yielding recombinant strain C.glutamicum subspecies lactofermentum QW102 / pJYW-4-hom<m>-lysC<m>-brnFE provided by the invention is preserved in China Center for Type Culture Collection with a preservation number of CCTCC M2014232. The recombinant strain has the genetic characteristics of: expression of transport protein BrnFE, expression of aspartokinase fragment lysC and homoserine dehydrogenase fragment hom, and deletion of thrB and mcbR genes on a genome at the same time. According to the invention, by a genetic engineering method, a recombinant strain with high methionine yield is obtained. The invention also provides a method for high yield of L-methionine by the recombinant strain.

Owner:JIANGNAN UNIV

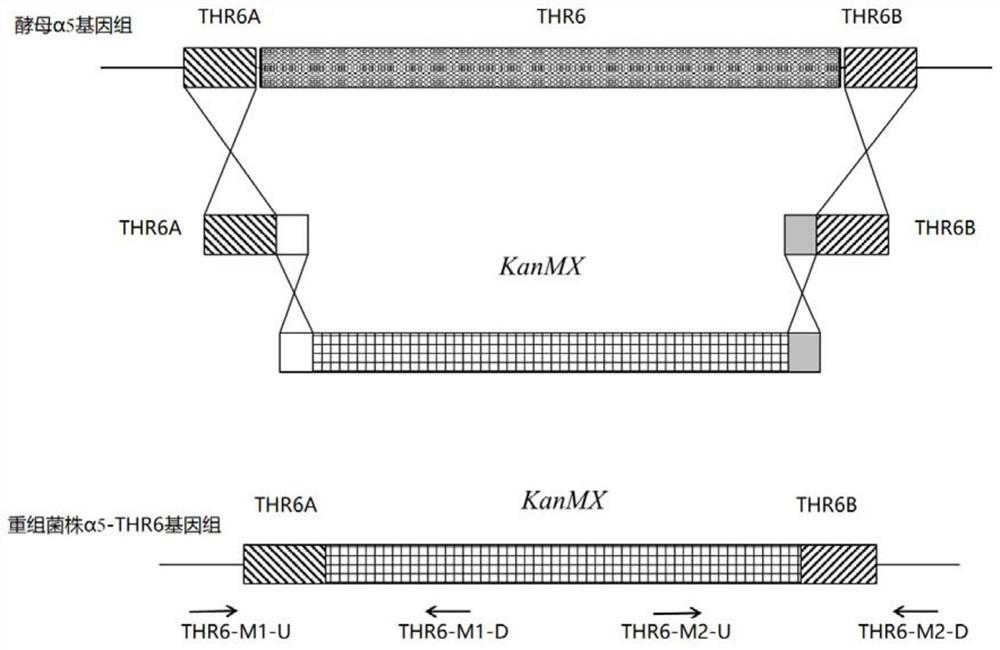

Genetically engineered bacterium with low n-propanol yield and application thereof

The invention provides a genetically engineered bacterium with low n-propanol yield. The genetically engineered bacterium is obtained by completely deleting a homoserine dehydrogenase gene THR6 from saccharomyces cerevisiae, wherein the homoserine dehydrogenase encoded by the THR6 gene can catalyze dimer enzyme in a third step of a threonine biosynthetic pathway, and the dimer enzyme plays a key role in the synthetic pathway of saccharomyces cerevisiae threonine. Threonine can be converted into 2-ketobutyric acid. 2-ketobutyric acid is a necessary precursor substance for synthesizing n-propanol by saccharomyces cerevisiae, and directly influences the yield of n-propanol. The genetically engineered bacterium disclosed by the invention is applied to production of white spirit by a liquid fermentation method.

Owner:TIANJIN UNIV OF SCI & TECH

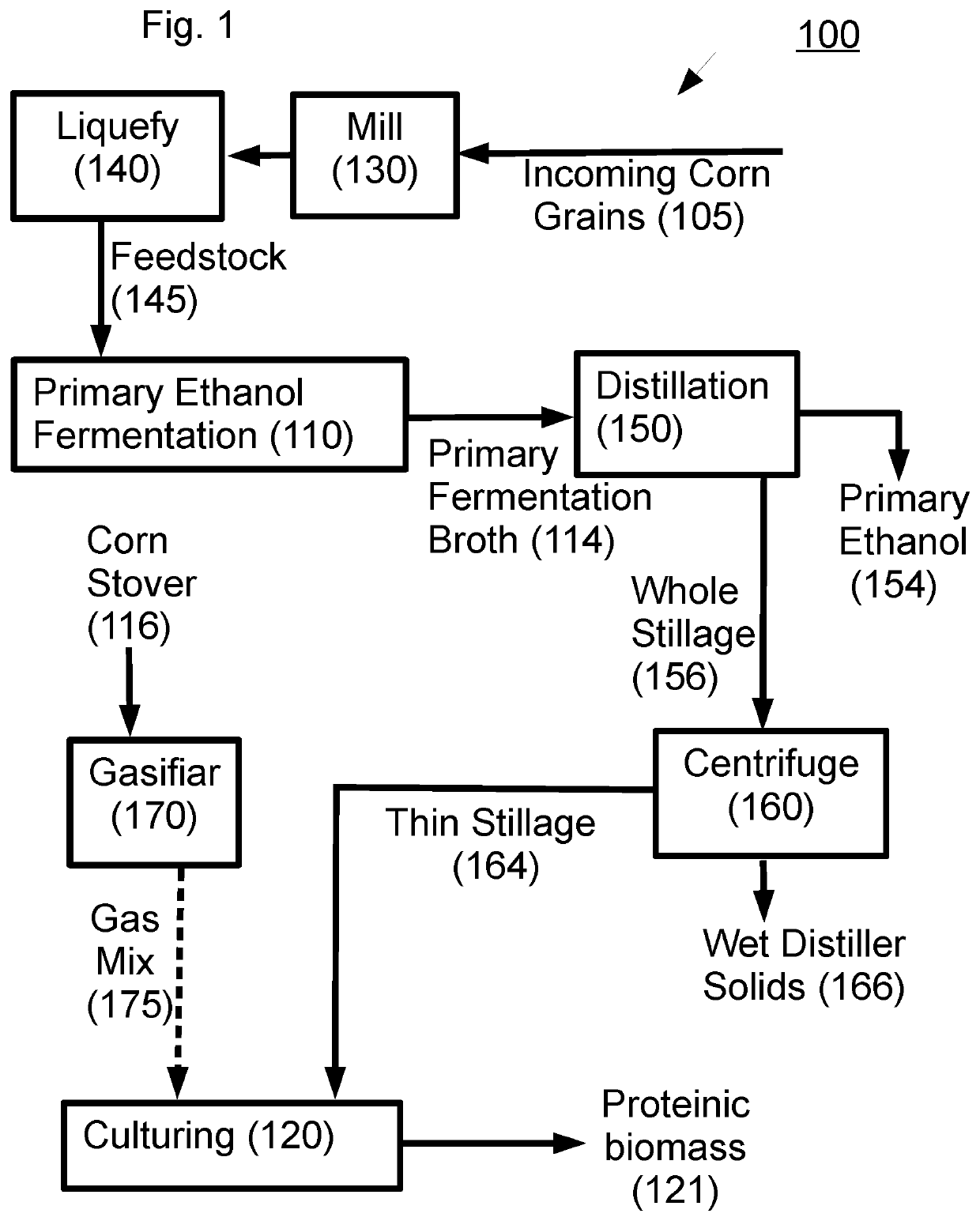

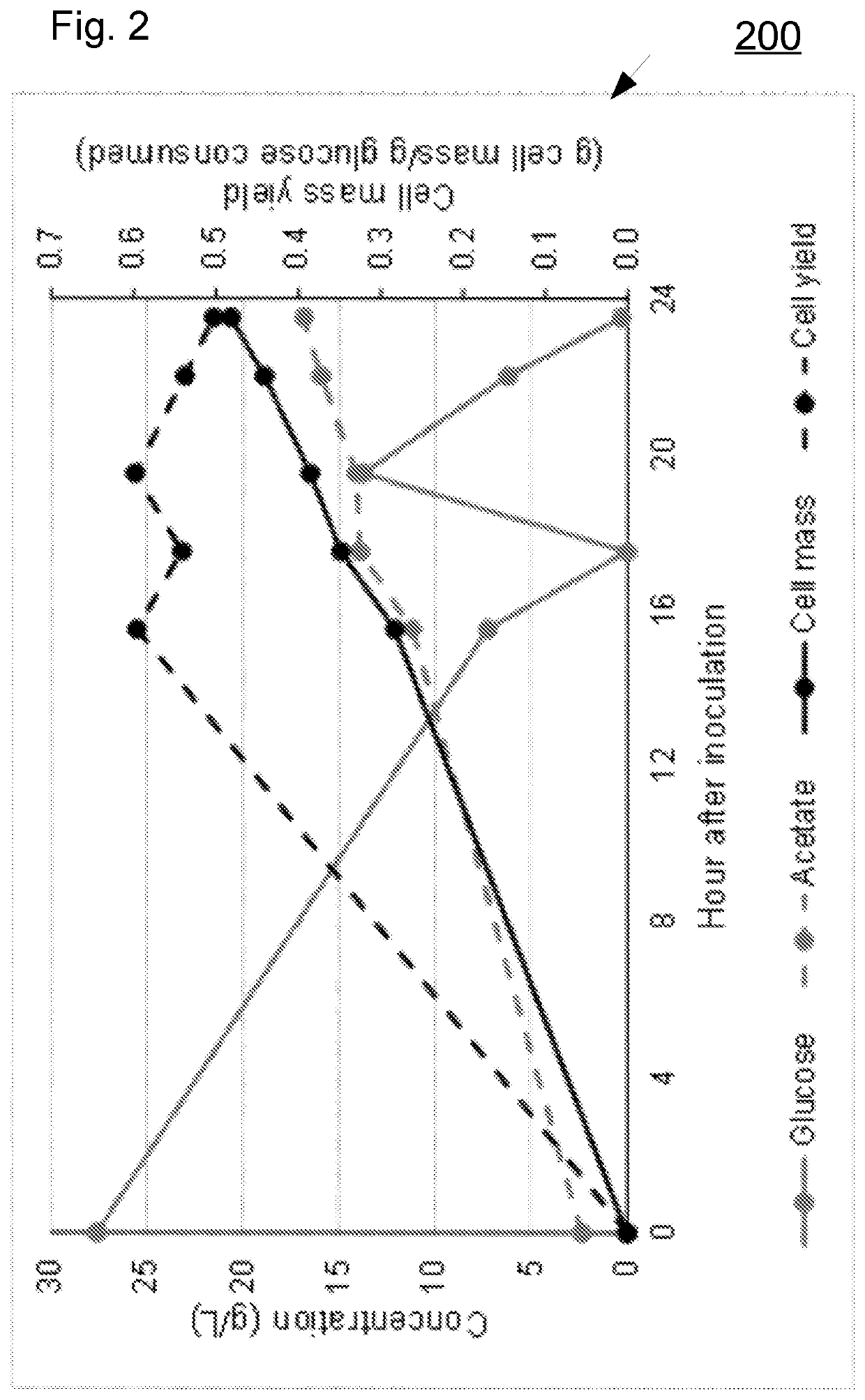

Proteinic biomass preparation comprising a non-native organism of the clostridia class

A proteinic biomass preparation comprising a non-native organism of the Clostridia class, which organism expresses (i) a modified aspartate kinase; (ii) a modified homoserine dehydrogenase; (iii) a modified homoserine kinase; (iv) a modified anthranilate synthase; (v) a functional lycopene pathway and the genes crtY, crtW, and crtZ; and / or (vi) a functional oleic acid pathway and the four gene operon (pfaABCD). Methods of producing proteinic biomass preparations are also described.

Owner:SUPERBREWED FOOD INC

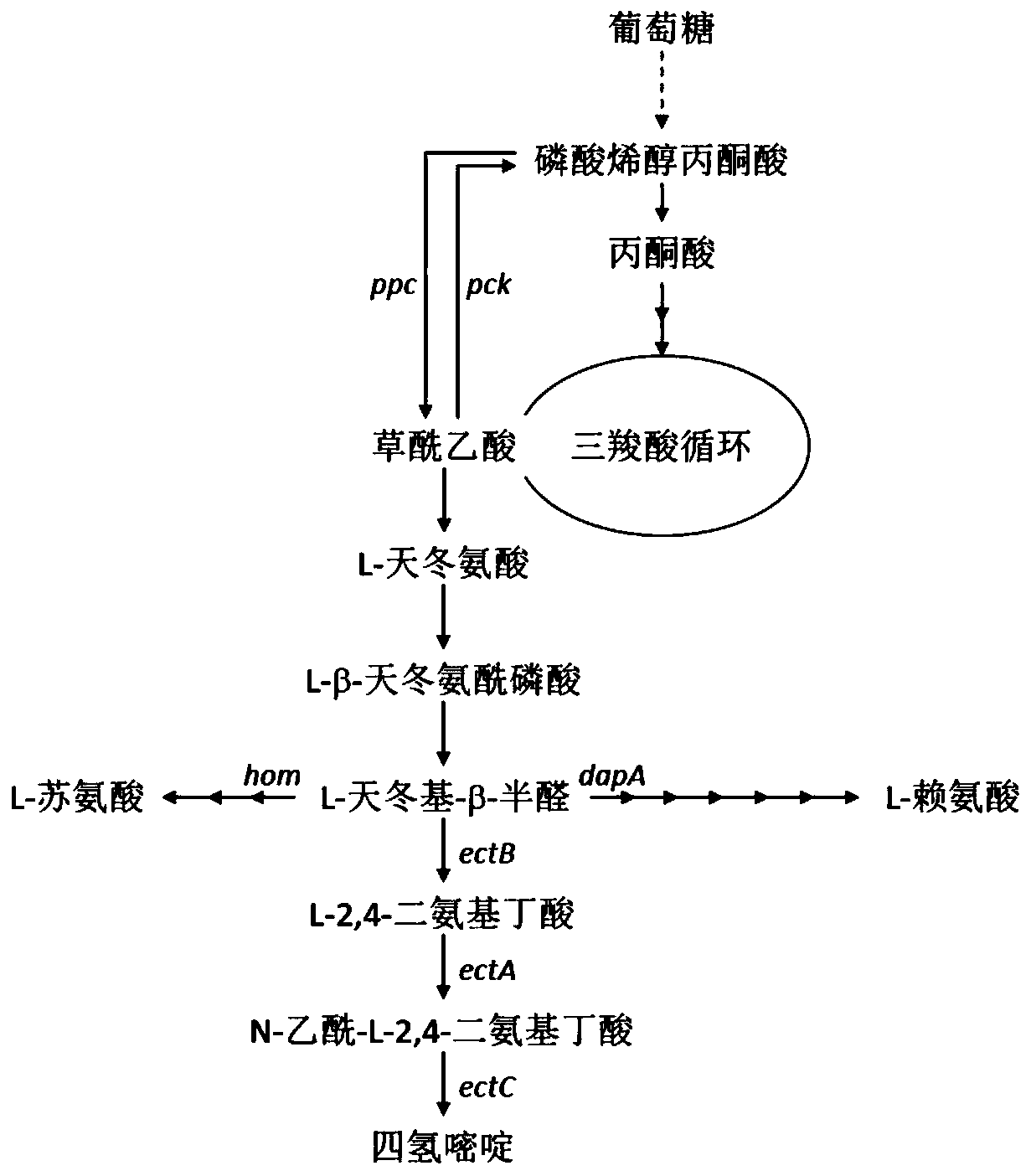

Genetically engineered bacteria used for producing uridine with high-yield and its construction method and use

ActiveUS20190264185A1Reduce usageImprove growth characteristicsBacteriaOxidoreductasesPyrimidineHomoserine dehydrogenase

The present disclosure relates to a genetically engineered strain with high production of uridine and its construction method and application. The strain was constructed as follows: heterologously expressing pyrimidine nucleoside operon sequence pyrBCAKDFE (SEQ ID NO:1) on the genome of E coli prompted by strong promoter Ptrc to reconstruct the pathway of uridine synthesis; overexpressing the autologous prsA gene coding PRPP synthase by integration of another copy of prsA gene promoted by strong promoter Ptrc on the genome; deficiency of uridine kinase, uridine phosphorylase, ribonucleoside hydrolase, homoserine dehydrogenase I and ornithine carbamoyltransferase. When the bacteria was used for producing uridine, 40-67 g / L uridine could be obtained in a 5 L fermentator after fermentation for 40-70 h using the technical scheme provided by the discloure with the maximum productivity of 0.15-0.25 g uridine / g glucose and 1.5 g / L / h respectively which is the highest level of fermentative producing uridine reported at present.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

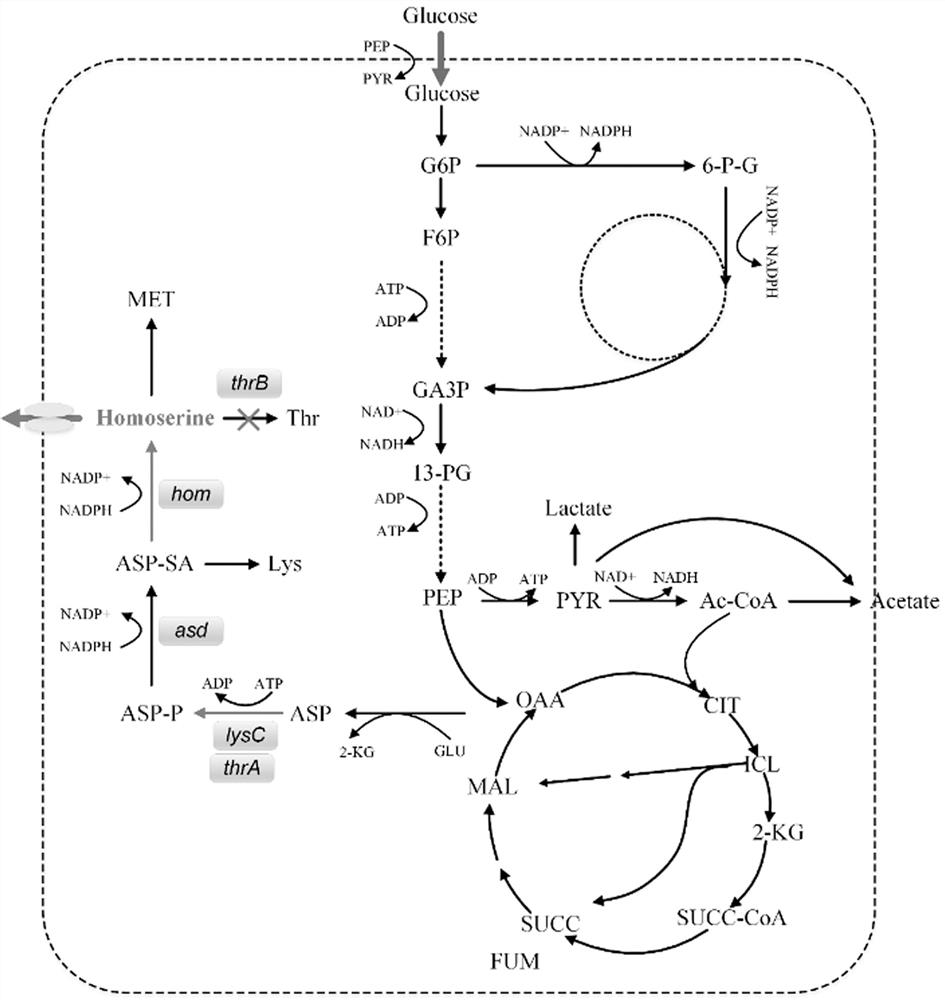

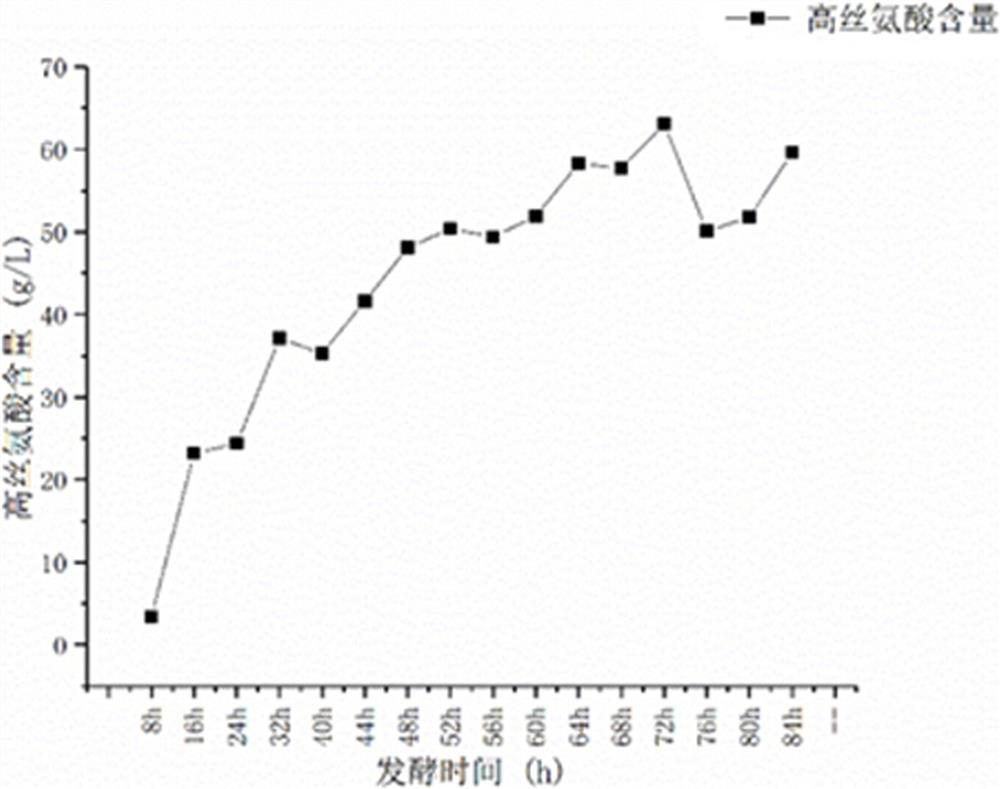

Genetically engineered bacterium for producing L-homoserine and application of genetically engineered bacterium

The invention relates to a genetically engineered bacterium for high production of L-homoserine. The expression of an L-homoserine kinase encoding gene thrB in the bacterium is weakened or eliminated.An aspartate kinase feedback inhibition mutant gene lysC, a homoserine dehydrogenase feedback inhibition mutant gene hom, an overexpression aspartate kinase feedback inhibition mutant gene thrA and atransporter gene are further intensively expressed. The L-homoserine high-producing strain constructed by the invention can produce L-homoserine with a relatively high level, and in the optimal embodiment, after the genetically engineered bacterium disclosed by the invention is fermented for 72 hours, the content of the L-homoserine can reach 63.2 + / -5.4 g / L.

Owner:TIANJIN INST OF IND BIOTECH CHINESE ACADEMY OF SCI

Genetically engineered bacteria with high uridine production and its construction method and application

ActiveCN108130306BImprove growth traitsIncrease productivityBacteriaEnzymesEscherichia coliNucleotide

The invention provides a genetic engineering bacterium capable of producing uridine at high yield as well as a building method and application thereof. The genetic engineering bacterium is characterized in that pyrimidine nucleoside operons pyrBCAKDFE with the nucleotide sequence shown as SEQ ID NO:1 is integrated on a genome of colon bacillus; the starting is realized by a strong promoter P[trc];a uridine synthesis path is reconstituted; the self PRPP synthetase coding gene prsA on the genome is subjected to dual copying, and the starting is realized by the strong promoter P[trc]; meanwhile,the activity of udk, udp, and rihA, rihB and rihC is lacked; the thrA activity is lacked; the argF activity is lacked. The genetic engineering bacterium is applied to fermentation production of uridine; 40 to 67g / L of uridine can be produced after the fermentation is performed for 40 to 70h in a 5L fermentation tank; the maximum production intensity can reach 1.5g / (L*h); the glucoside conversionrate is 15 to 25 percent; the genetic engineering bacterium belongs to the highest level for producing the uridine by the fermentation method reported in the prior art.

Owner:TIANJIN UNIV OF SCI & TECH

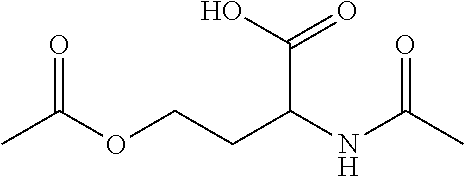

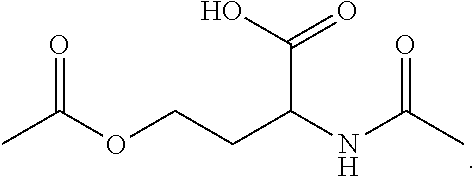

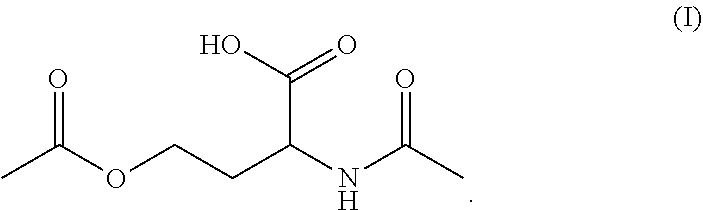

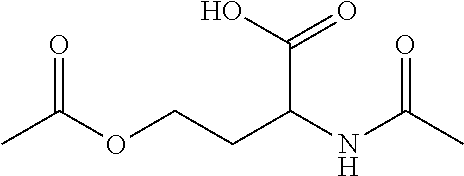

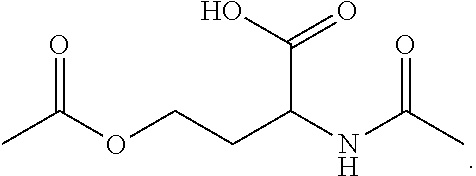

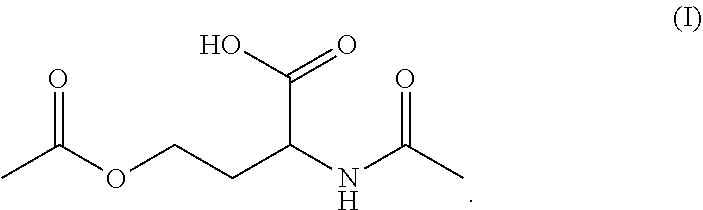

N-acetyl homoserine

The present invention relates to a compound of general formula IThe present invention also relates to a method of producing N-acetyl homoserine and / or derivatives thereof, the method comprisingcontacting at least one recombinant cell in an aqueous medium with acetate wherein the recombinant cell comprises an increased activity relative to a wild type cell of(a) an enzyme E1, a homoserine dehydrogenase (EC1.1.1.3) and / or an enzyme E5, an aspartokinase (EC2.7.2.4); and(b) an enzyme E2, a homoserine O-acetyl transferase (EC2.3.1.31)and the acetate is maintained at a concentration of at least about 0.001 g / L in the aqueous medium.

Owner:EVONIK OPERATIONS GMBH

N-acetyl homoserine

The present invention relates to a compound of general formula IThe present invention also relates to a method of producing N-acetyl homoserine and / or derivatives thereof, the method comprisingcontacting at least one recombinant cell in an aqueous medium with acetate wherein the recombinant cell comprises an increased activity relative to a wild type cell of(a) an enzyme E1, a homoserine dehydrogenase (EC1.1.1.3) and / or an enzyme E5, an aspartokinase (EC2.7.2.4); and(b) an enzyme E2, a homoserine O-acetyl transferase (EC2.3.1.31)and the acetate is maintained at a concentration of at least about 0.001 g / L in the aqueous medium.

Owner:EVONIK OPERATIONS GMBH

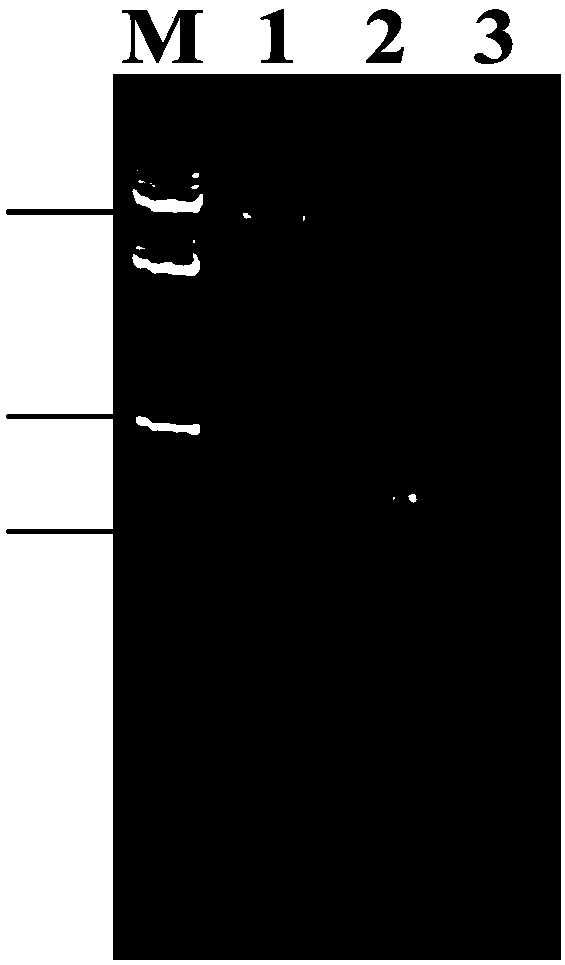

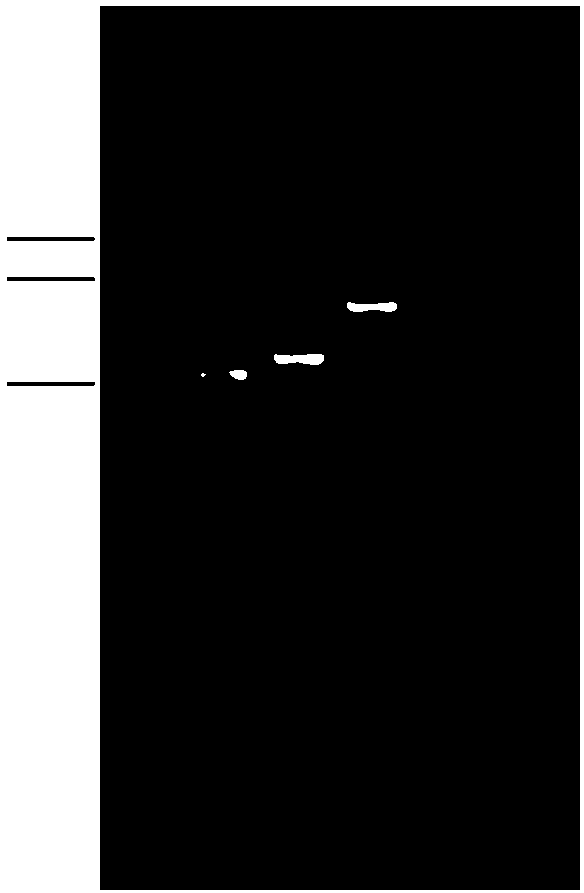

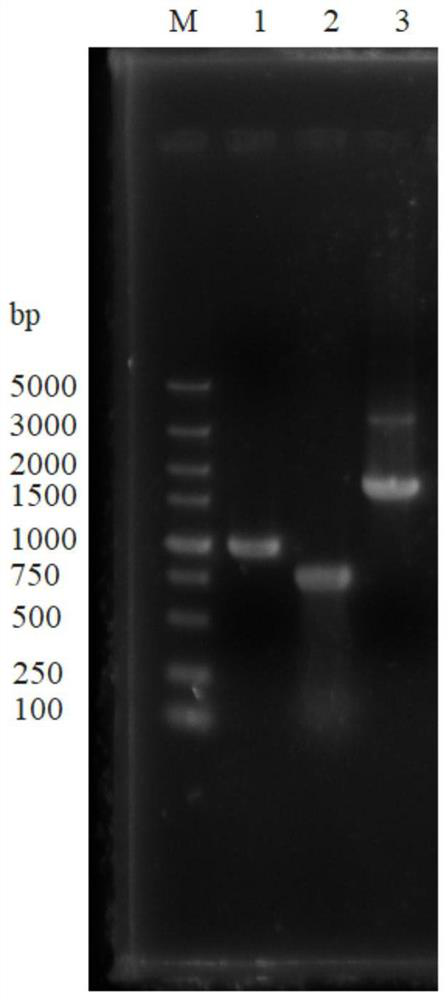

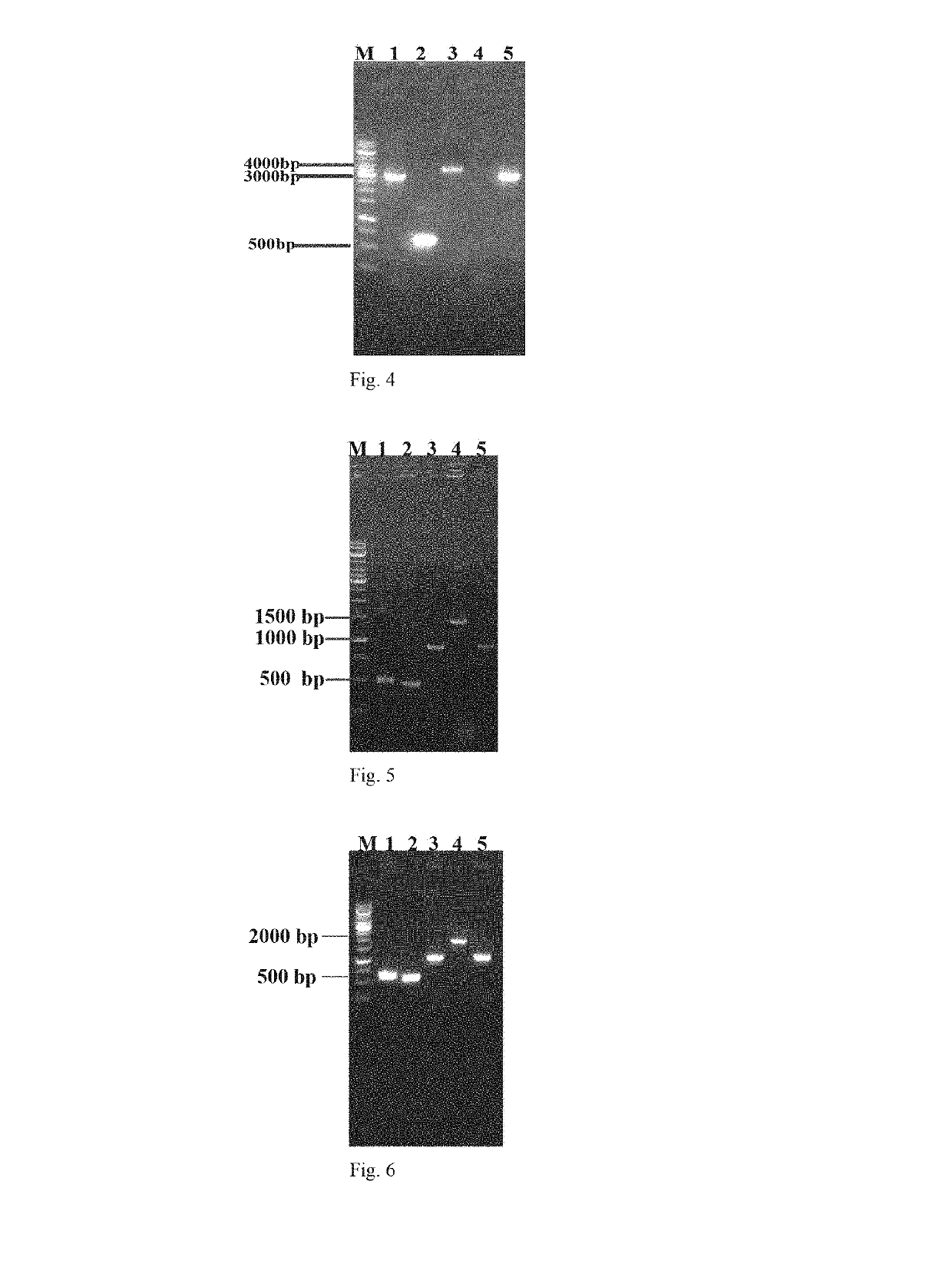

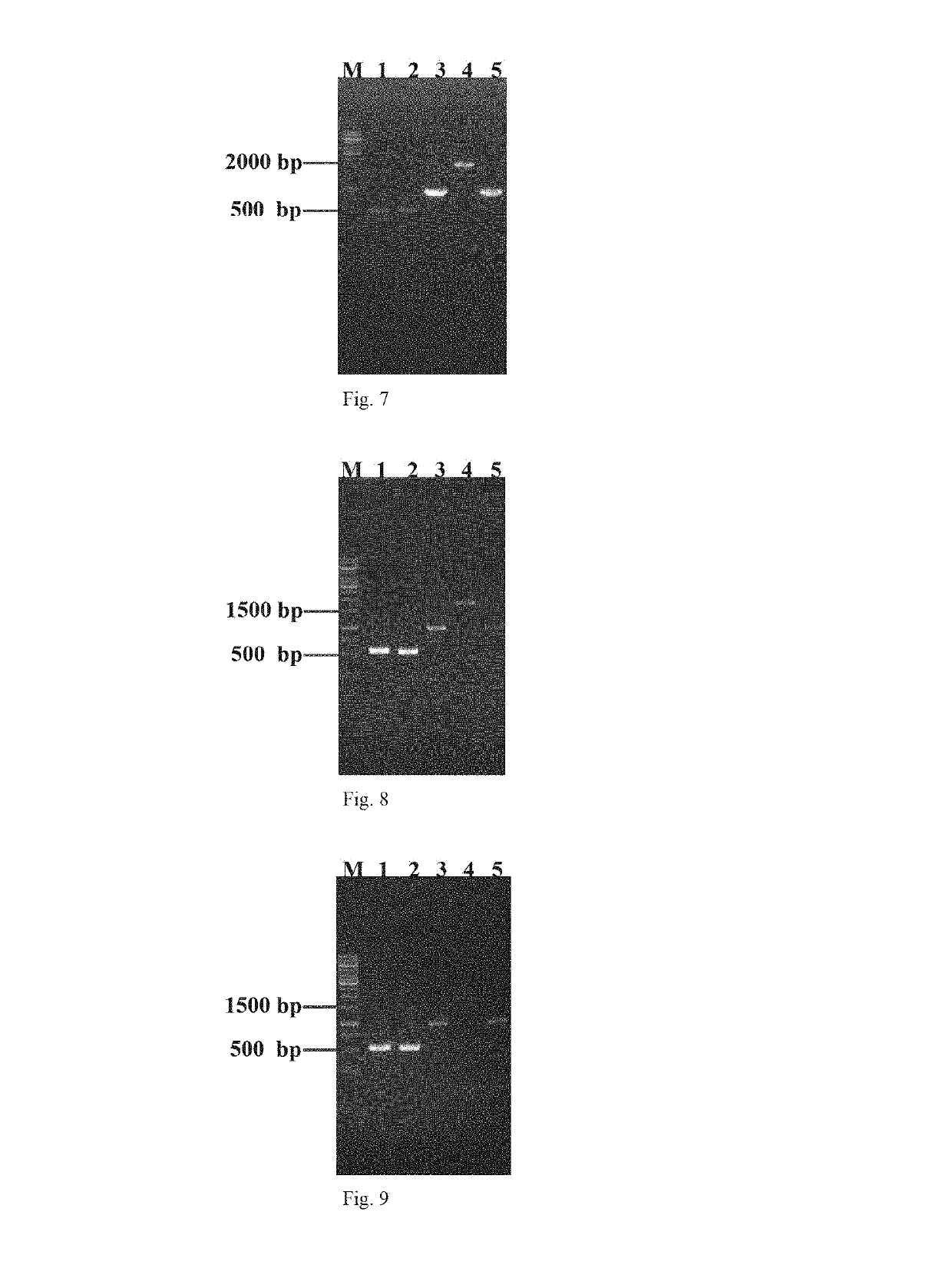

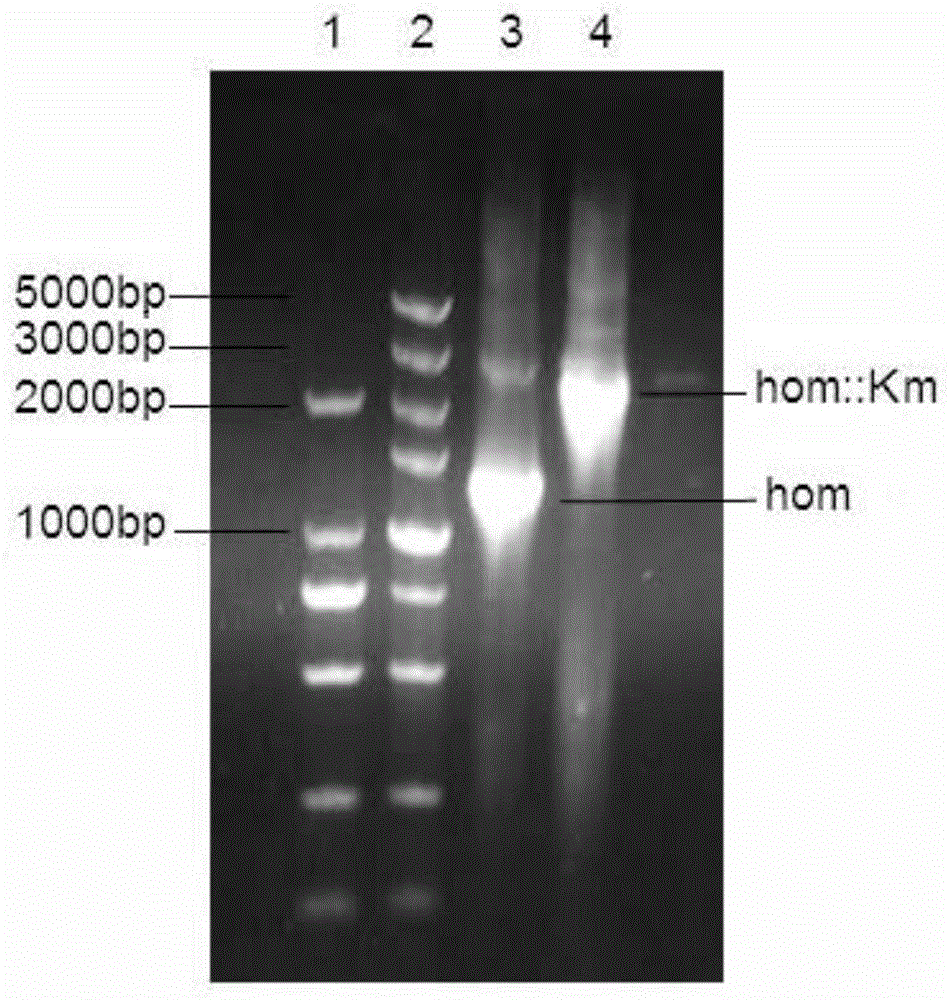

Homoserine dehydrogenase gene inactivation method of Bacillus subtilis

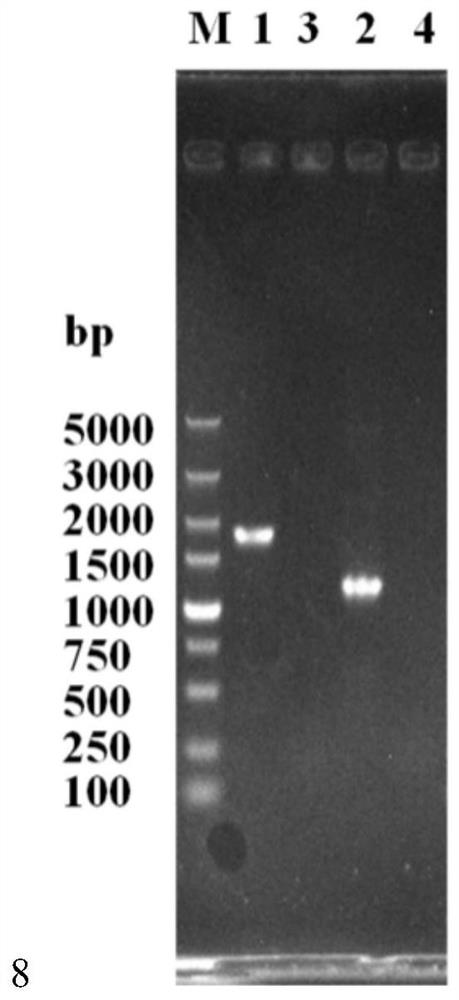

InactiveCN104630253AHigh in lysineAmplified full-length geneBacteriaVector-based foreign material introductionCompetent cellDNA fragmentation

The invention relates to a homoserine dehydrogenase gene inactivation method of Bacillus subtilis, which comprises the following steps: establishing a PCR (polymerase chain reaction) product plasmid for homologous recombination, wherein the recombinant plasmid is composed of a pMD18-T vector, a kanamycin resistance gene and a homoserine dehydrogenase gene, and the homologous recombinant DNA (deoxyribonucleic acid) segment contains a homoserine dehydrogenase gene for substituting knock-out gene and a kanamycin resistance gene inserted in the middle of the homoserine dehydrogenase gene; and carrying out PCR amplification on the homoserine dehydrogenase gene and kanamycin resistance gene inserted in the middle of the homoserine dehydrogenase gene from the recombinant plasmid so as to obtain the single-chain PCR product, electrically transforming the single-chain PCR product into a Bacillus subtilis competent cell to obtain a transformant, and screening the positive transformant to obtain the homoserine dehydrogenase gene inactivated mutant strain. Compared with the existing technique for transforming the homoserine dehydrogenase recombinant plasmid into the Bacillus subtilis competent cell, the method is more simple and time-saving.

Owner:INST OF SUBTROPICAL AGRI CHINESE ACAD OF SCI

A kind of method for synthesizing spermidine by biological method

ActiveCN111996220BEfficient expressionEasy to produceBacteriaMicroorganism based processesCarboxyl radicalSerine dehydrogenase

The invention discloses a biological method for synthesizing spermidine, which belongs to the technical field of biological engineering. The invention constructs genetic engineering bacteria, which can synthesize spermidine using homoserine and putrescine (butanediamine) as substrates. Specifically, homoserine dehydrogenase is used to dehydrogenate homoserine to form aspartic semialdehyde and NADH, and carboxyspermidine dehydrogenase uses NADH as a coenzyme to synthesize aspartic semialdehyde and putrescine into carboxyspermidine, and realize Coenzyme regeneration produces NAD, and finally, carboxyspermidine decarboxylase decarboxylates carboxyspermidine to produce spermidine. The method for biosynthesizing spermidine provided by the invention has the advantages of simple production process, readily available raw materials and low cost, and has good industrial application prospect.

Owner:卓虹超源生物科技(郑州)有限公司

Microorganism producing l-methionine precursor and the method of producing l-methionine precursor using the microorganism

ActiveCN101555464BBacteriaMicroorganism based processesMicroorganismHomoserine dehydrogenase activity

The present invention relates to a microorganism producing L-methionine precursor, O-succinylhomoserine, 1) the homoserine O-succinyltransferase activity (EC2.3.1.46) is introduced and enhanced, wherein the homoserine O-succinyltransferase activity is feed back resistant to methionine; and 2) the aspartokinase or homoserine dehydrogenase activity (EC2.7.2.4 or 1.1.1.3) is enhanced, and a method ofproducing L-methionine precursor using the microorganism.

Owner:CJ CHEILJEDANG CORP

Method for L-threonine production

InactiveUS7368266B2High expressionEliminate the problemSugar derivativesBacteriaPhosphoenolpyruvate carboxylaseMicroorganism

Owner:CJ CHEILJEDANG CORP

Genetically engineered bacterium used for producing uridine with high-yield

The present disclosure relates to a genetically engineered strain with high production of uridine and its construction method and application. The strain was constructed as follows: heterologously expressing pyrimidine nucleoside operon sequence pyrBCAKDFE (SEQ ID NO:1) on the genome of E coli prompted by strong promoter Ptrc to reconstruct the pathway of uridine synthesis; overexpressing the autologous prsA gene coding PRPP synthase by integration of another copy of prsA gene promoted by strong promoter Ptrc on the genome; deficiency of uridine kinase, uridine phosphorylase, ribonucleoside hydrolase, homoserine dehydrogenase I and ornithine carbamoyltransferase. When the bacteria was used for producing uridine, 40-67 g / L uridine could be obtained in a 5 L fermentor after fermentation for 40-70 h using the technical scheme provided by the disclosure with the maximum productivity of 0.15-0.25 g uridine / g glucose and 1.5 g / L / h respectively which is the highest level of fermentative producing uridine reported at present.

Owner:TIANJIN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com