Homoserine dehydrogenase gene inactivation method of Bacillus subtilis

A technology of homoserine dehydrogenase and serine dehydrogenase, which is applied in the field of genetic engineering, can solve the problems of competition for imported products, many steps, and small production scale, and achieve simple, fast and effective results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

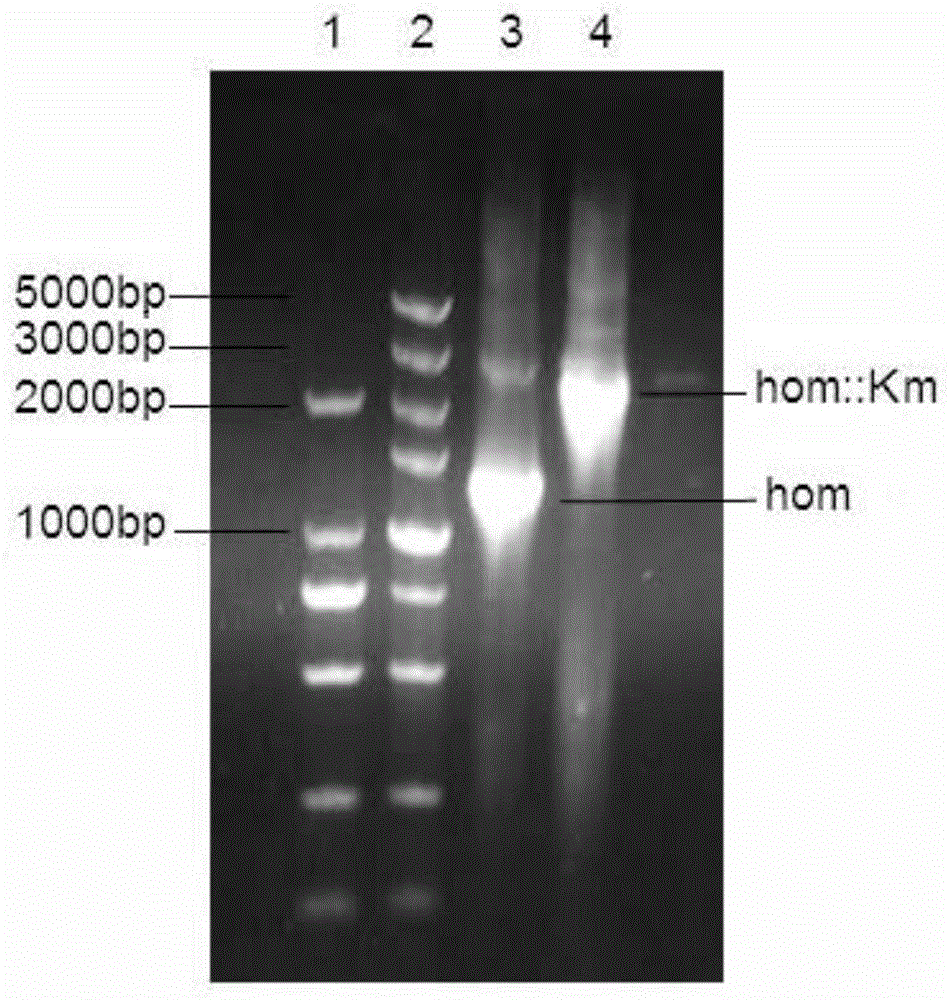

[0013] Embodiment 1 Bacillus subtilis PA105 homoserine dehydrogenase gene inactivation

[0014] Bacillus subtilis PA105 was provided by the experimental center of the applicant, and the deposit number is CCTCC: M2011328.

[0015] 1. Competent preparation medium for Bacillus subtilis:

[0016] GMI medium: 1 mL of 10×Spizizen salts, 0.1 mL of 10% yeast powder, 0.25 mL of 20% glucose, 0.2 mL of 1% hydrolyzed casein, 0.2 mL of 0.25% required amino acids, supplemented with sterilized distilled water to a total volume of 10 mL.

[0017] GMII medium: 1mL 10×Spizizensalts, 0.05mL 10% yeast powder, 0.25mL 20% glucose, 0.04mL 1% hydrolyzed casein, 0.2mL 0.25% required amino acids, 0.05mL 0.1mol / LCaCl2, 1mL 25mmol / LMgCl2, supplemented with sterilization Distill water to a total volume of 10 mL.

[0018] 10 x Spizizen salts stock solution: 15% K 2 HPO 4 ·3H 2 O, 6% KH 2 PO 4 , 2% (NH 4 ) 2 SO 4 , 0.2% MgSO 4 and 1% sodium citrate dissolved in 75.8% distilled water, 6.6×10 4 Au...

Embodiment 2

[0038] The preparation of embodiment 2 mutant strain fermented liquid

[0039] The preparation of shake flask fermentation seed liquid: get the mutant strain 2ml that embodiment 1 obtains (concentration of viable bacteria is 10 8 -10 10 CFU / ml), inoculated in 100ml LB liquid medium for shake flask fermentation culture, the fermentation temperature is 37°C, the pH value is 7.2, the rotation speed is 200r / min, and the fermentation time is 24h. Among them, the composition of LB liquid medium is: tryptone 10g, yeast extract 5g, sodium chloride 10g, distilled water 1000ml, pH value is 7.2.

[0040] Carry out fermentor pilot test after shake bottle fermentation finishes, get 100ml shake bottle fermentation seed liquid (the concentration of seed liquid is 10 8 CFU / ml) was inoculated into a 10L fermenter with a liquid volume of 5L, the fermentation temperature was 37°C, the pH value was 7.2, the stirring speed was 300r / min, the fermentation was 24h, and the aeration ratio was 1:1. ...

Embodiment 3

[0041] Lysine yield analysis in embodiment 3 mutant strain fermented liquid

[0042] Take 5ml of the fermented liquid obtained in Example 2, centrifuge at 12000r / min for 10min, take 1ml of supernatant, add 2.5ml of 7.5% (mass ratio) trichloroacetic acid per ml, mix well, centrifuge at 18000r / min at 4°C for 15min, draw 1ml of the supernatant was transferred to an amino acid analysis vial, and the contents of arginine and other amino acids were determined with a Hitachi L-8800 automatic amino acid analyzer. The results showed that the lysine content in the fermentation broth was 63g / L.

[0043] Adopt the method of Example 2 to prepare Bacillus subtilis PA105 (preservation number is CCTCC: M2011328) fermented liquid, and analyze the yield of lysine in the fermented liquid according to the method of Example 3, the result shows that the lysine in its fermented liquid The content is 3.03g / L.

[0044]

[0045]

[0046]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com