Recombinant corynebacterium glutamicum, construction method thereof and method for producing tetrahydropyrimidine by same

A technology of Corynebacterium glutamicum and recombinant bacteria, which is applied in the field of genetic engineering and biological fermentation, can solve the problems of increasing the difficulty of downstream purification processes, ectoine restricting the industrial production and large-scale application of ectoine, and increasing production costs. Achieve the effect of solving biological safety problems, good industrial application prospects, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

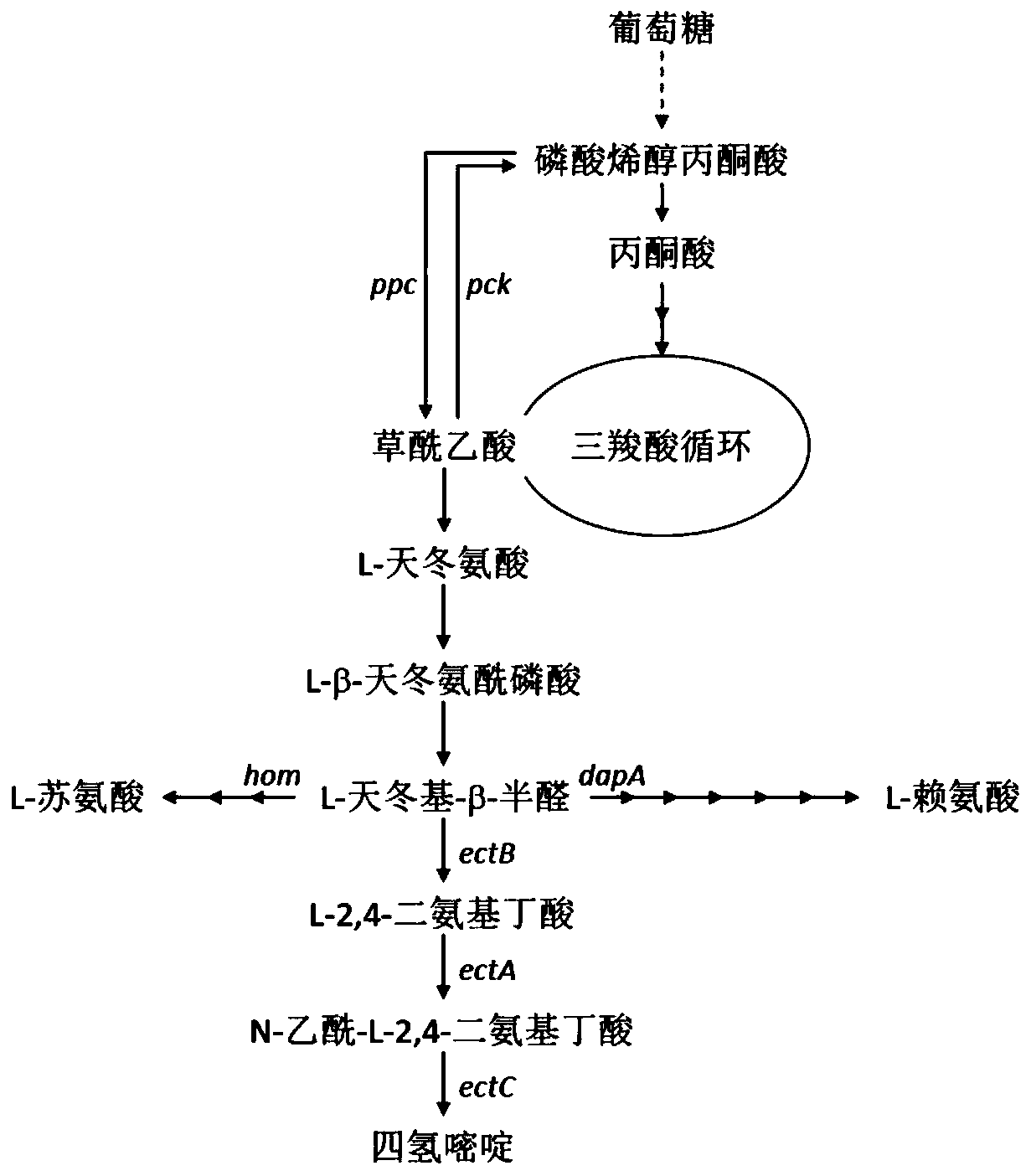

[0046] In the method for preparing recombinant Corynebacterium glutamicum of the present invention, wild-type Corynebacterium glutamicum includes but not limited to: Corynebacterium glutamicum wild-type strain ATCC13032 or Corynebacterium glutamicum wild-type strain S9114. In some embodiments, when the wild-type Corynebacterium glutamicum used contains the ppc gene itself, for example, the strain ATCC13032 is used as the starting strain, then the introduction into the starting strain for expressing phosphoenolpyruvate carboxyl This step is the expression cassette of the enzyme gene. In some embodiments, when the expression level of phosphoenolpyruvate carboxykinase, homoserine dehydrogenase and / or dihydropyrimidinedicarboxylate synthetase of wild-type Corynebacterium glutamicum itself is low , the step of reducing the expression level of the corresponding enzyme can be omitted.

[0047] In some embodiments of the construction method of the present invention, the knockout and / ...

Embodiment 1

[0132] The construction of embodiment 1 recombinant Corynebacterium glutamicum

[0133] (1) Knock out the pck gene and introduce the ppc gene at the same time

[0134] Using Corynebacterium glutamicum wild-type strain S9114 as the starting strain, the pck gene on the genome of the wild-type Corynebacterium glutamicum is replaced with the ppc gene, so as to realize the knockout of the pck gene and the introduction of the ppc gene. Artificially synthesize the polynucleotide sequence shown in SEQID NO.:6 for replacing the pck gene with the ppc gene. SEQ ID NO.: 6 consists of 1001 bp upstream of the pck gene, SEQ ID NO.: 2 (ppc gene) and 999 bp downstream of the pck gene.

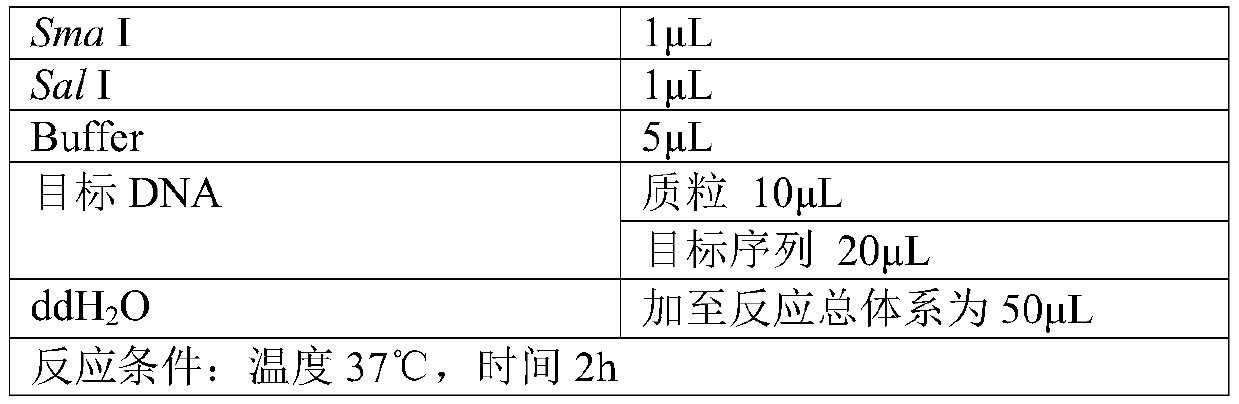

[0135] The Corynebacterium glutamicum suicide plasmid pK18mobsacB and the above polynucleotide sequence were double digested with Sma I / Sal I restriction endonuclease according to the enzyme digestion reaction system and reaction conditions in Table 2. Recover the digested fragments respectively, and then use...

Embodiment 2

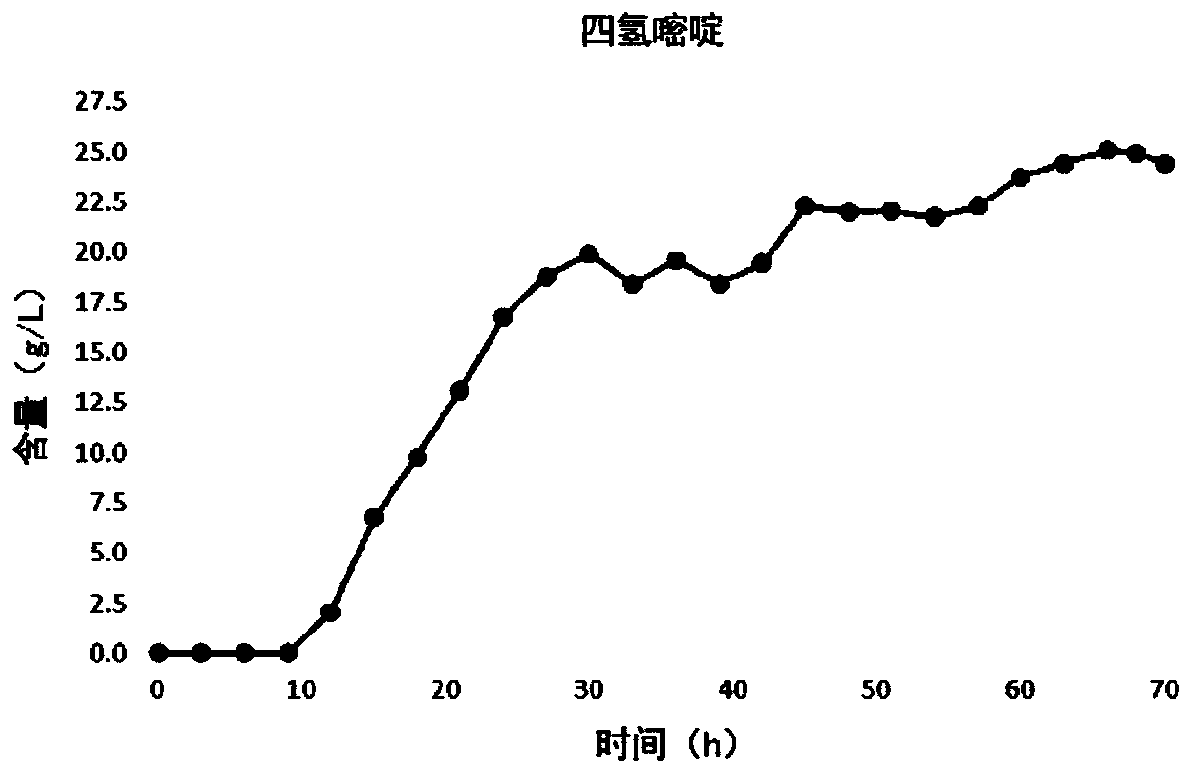

[0149] Example 2 uses CG.ECT-2 to ferment and produce ectoine

[0150] The recombinant Corynebacterium glutamicum CG.ECT-2 obtained in Example 1 was cultured overnight at 30° C. on an LB plate. The next day, a single colony was picked from the plate and inoculated into a 250 mL shaker flask with baffles containing 30 mL of seed medium (containing 15 mg / L kanamycin), and cultivated at 32° C. and 200 rpm for 12 hours to obtain a seed liquid.

[0151] Inoculate the seed solution into a 2L fermentation medium (containing 15mg / L kanamycin) with an inoculation amount of 10v / v%, use a 5L fermenter for fermentation, control the temperature at 32°C, the ventilation rate is 1vvm, and the initial rotation speed is 350 -500rpm, adjust the rotation speed during the fermentation process to keep the dissolved oxygen level above 10%, and control the pH value to be stable at about 7.0 by feeding 13% ammonia water. 1 mM IPTG was added at 3 h of fermentation. Samples were taken at different fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com