Calcinating shaft kiln comprehensively utilizing heat energy unit temperature field

A technology of temperature field and roasting, which is applied in the field of shaft kiln, can solve the problems of large capacity of a single machine, low product quality, and small roasting area, and achieve the effect of large capacity of a single machine, uniform air distribution, and small roasting area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

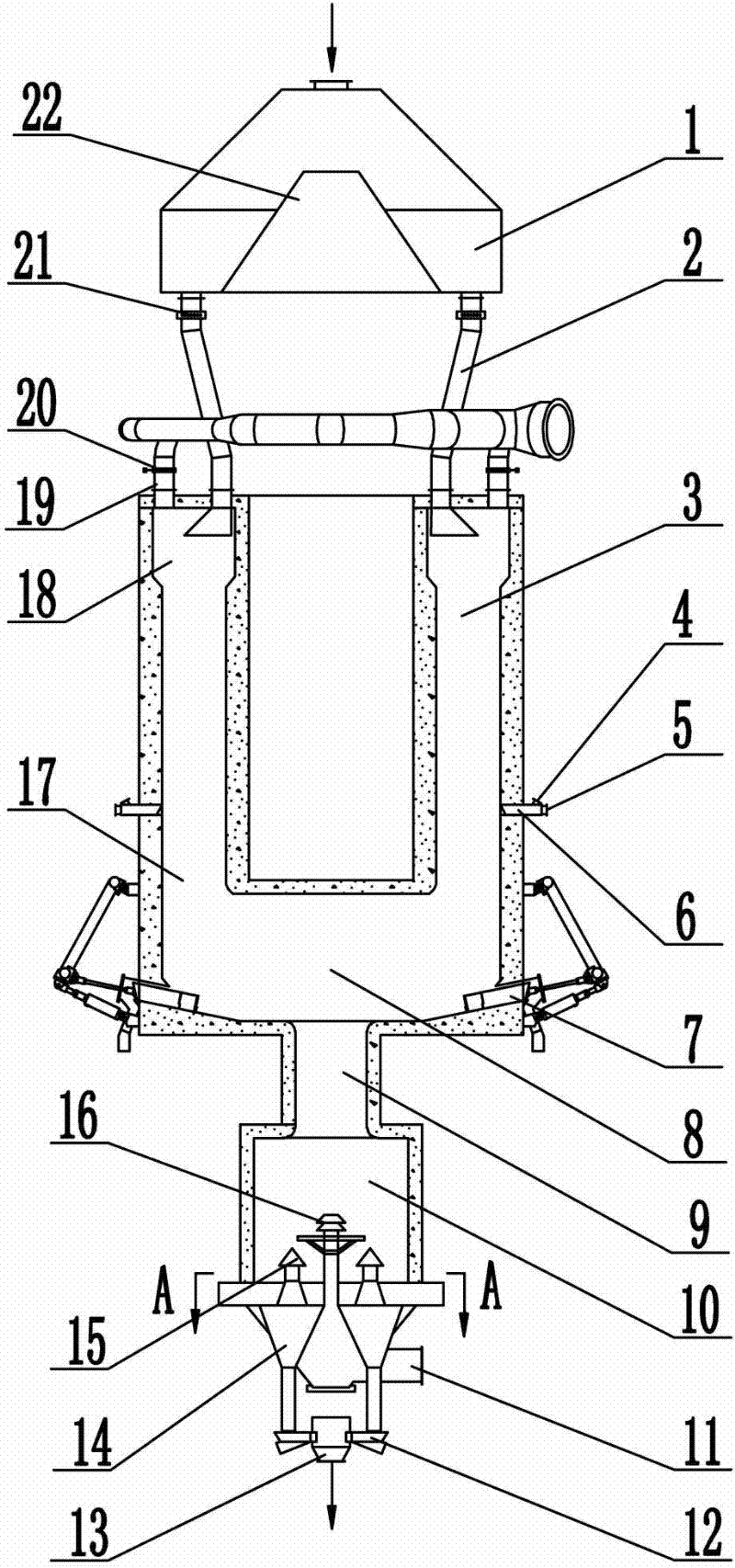

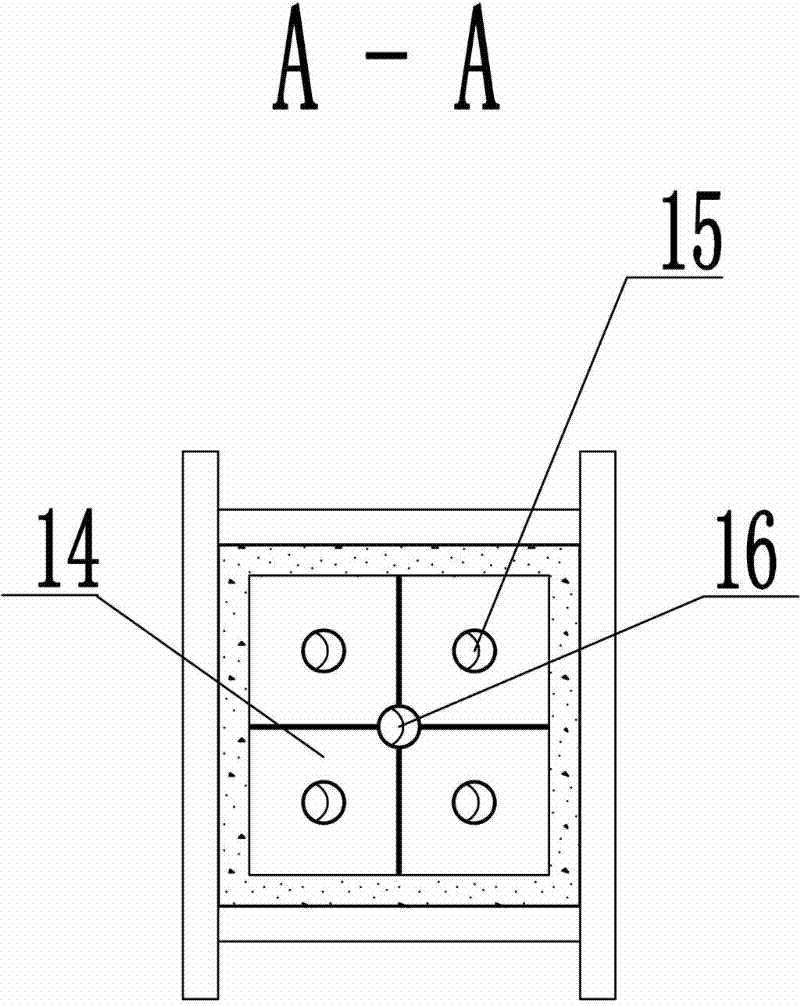

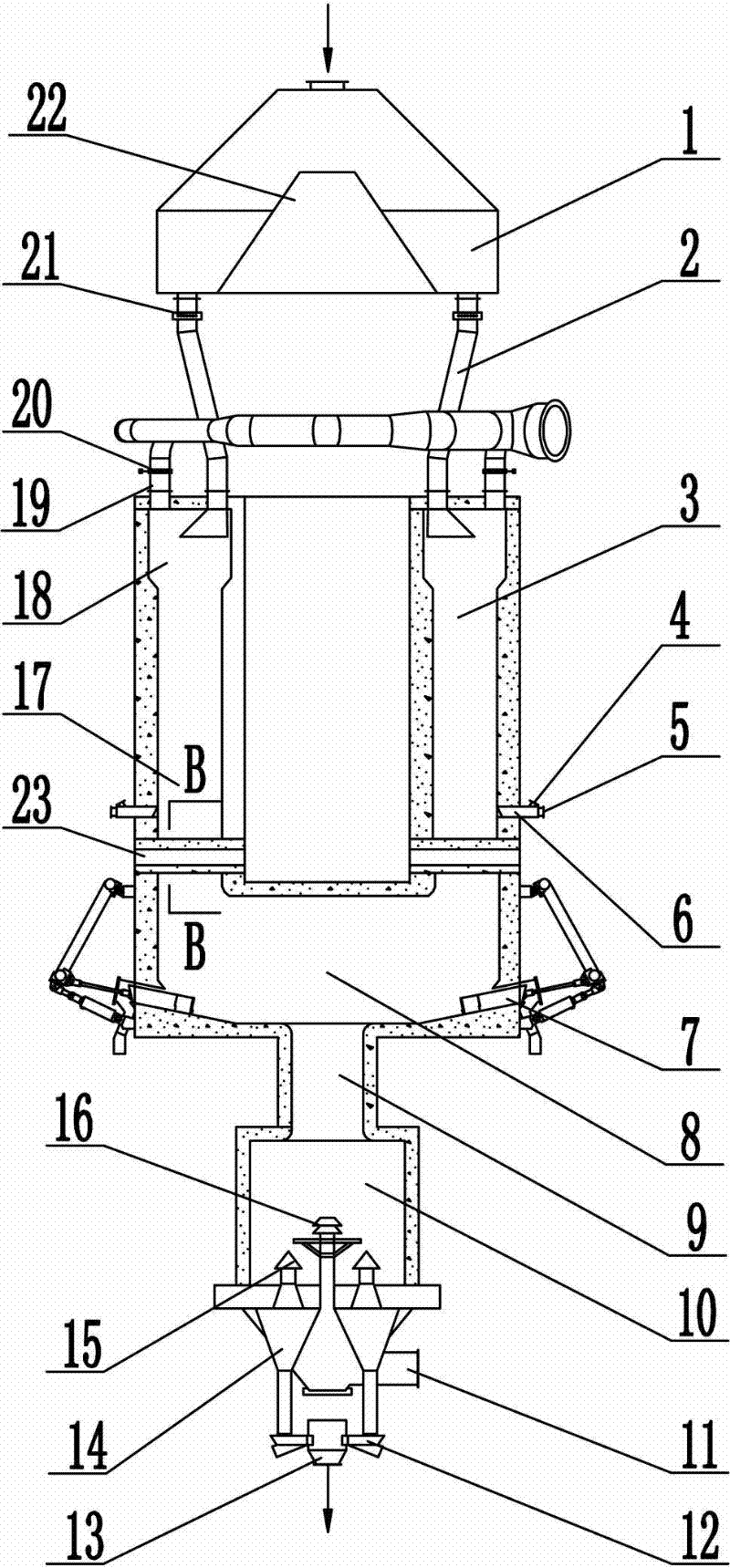

[0044] Combine below Figure 1~4 Specific embodiments of the present invention will be described in detail. The temperature field roasting shaft kiln for comprehensive utilization of thermal energy includes a feeding bin, a feeding pipe, a roasting chamber and a cooling chamber, wherein the specification and shape of the ring channel diverting feeding bin 1 arranged on the top of the shaft kiln should be selected according to actual use needs. The feed distribution cone 22 is set in the feed bin 1 of the ring channel diversion, so that the material in the feed bin is evenly distributed in the loop between the feed bin wall and the feed feed cone 22 through the feed distribution cone 22, and is respectively connected with each feeding lock air pipe 2 The discharge ports are symmetrically and evenly distributed along the ring road at the bottom of the silo. Using the peripheral unloading method, the materials in the silo are evenly distributed directly above the feeding lock ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com