Automated donut production apparatus

A technology for producing equipment and doughnuts, applied in dough forming and cutting equipment, dough forming machinery or equipment, baking, etc., can solve the problems of unstable product quality, inability to continuous production, low work efficiency, etc., and achieve savings The effect of manpower, lower production cost and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The idea, specific structure and technical effects of the present invention will be further described below in conjunction with the accompanying drawings, so as to fully understand the purpose, features and effects of the present invention.

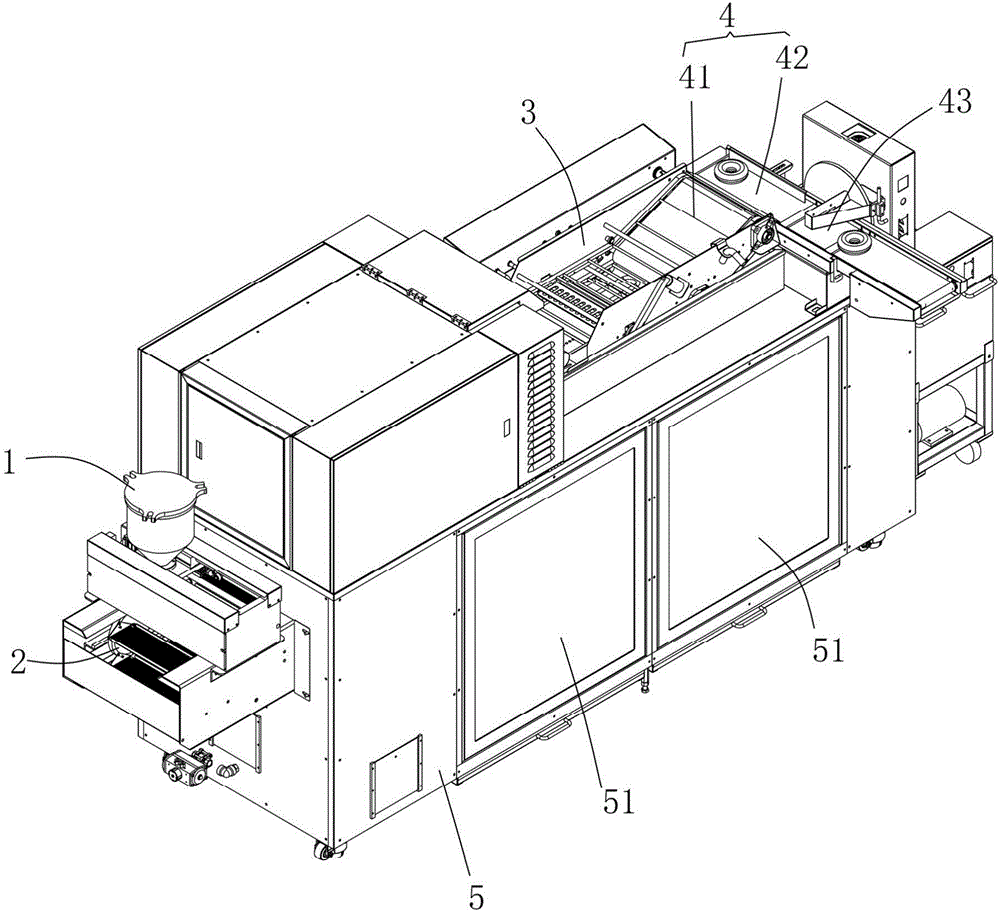

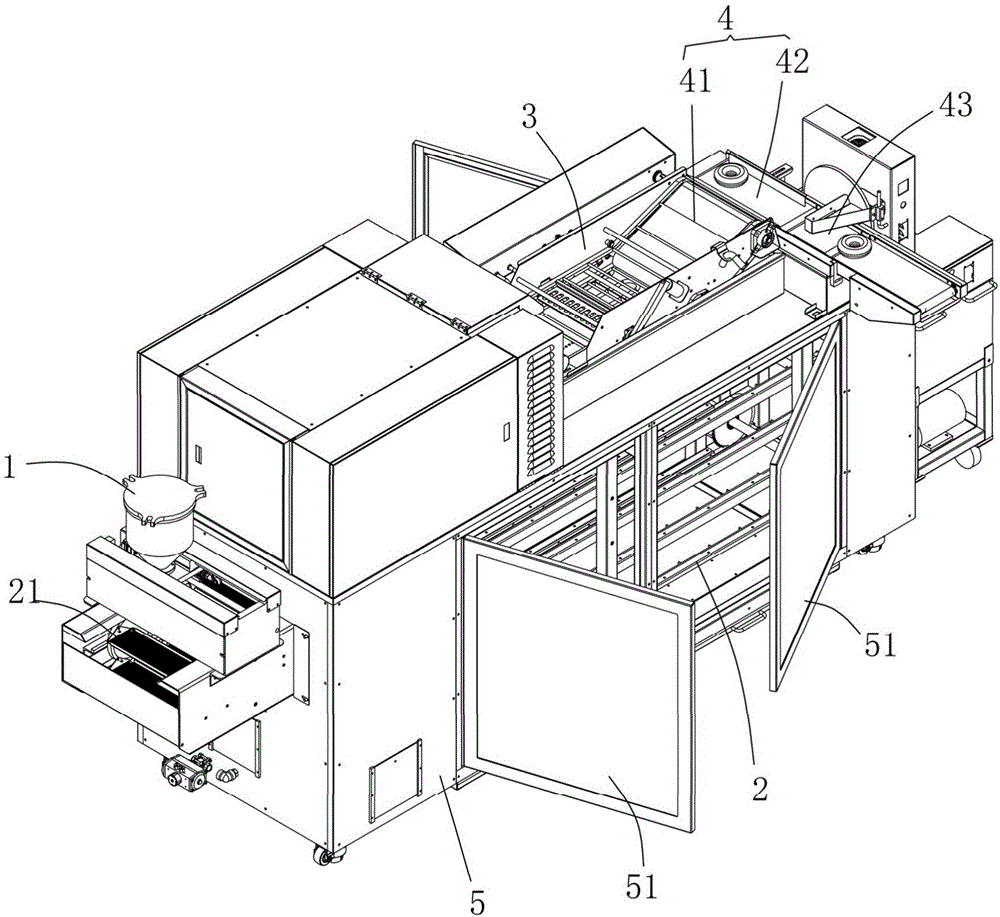

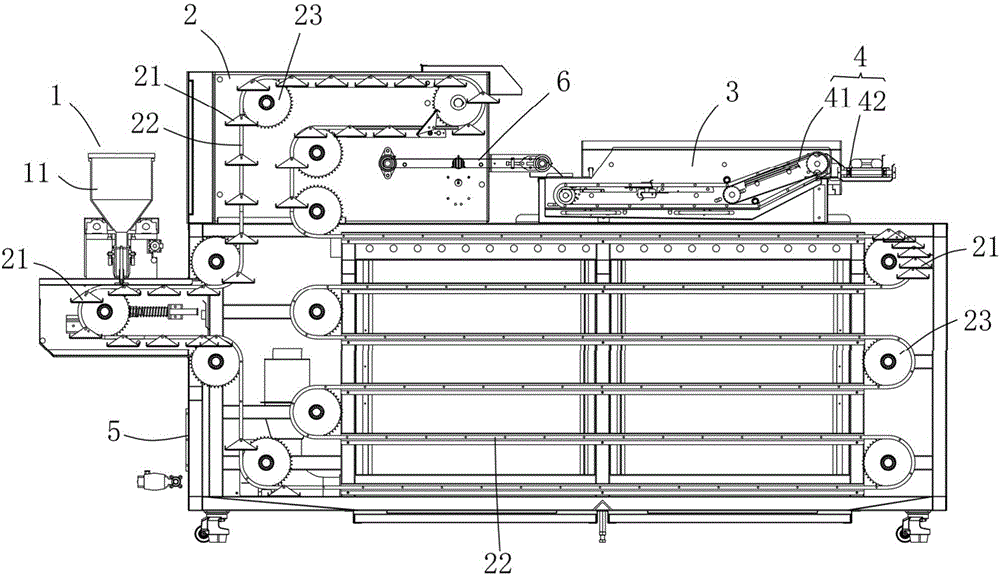

[0027] refer to figure 1 , 2 , 3, 4, 5, and 6, the present invention relates to an automatic donut production equipment, which has an extrusion molding unit 1, a fermentation unit 2, a frying unit 3, an output unit 4 and a machine rack 5. The extrusion molding unit 1, the fermentation unit 2, the frying unit 3 and the output unit 4 are integrated together through the frame 5. The extrusion molding unit 1 realizes the extrusion molding of the fabric into a doughnut body; the fermentation unit 2 receives the extrusion Forming unit 1 extrudes the donut embryo body formed, and provides fermentation environment and time to ferment the donut embryo body; frying unit 3 receives the donut embryo body that has been fermented from the outp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com