Fire coal blending method of thermal power plants

A thermal power plant, coal-fired technology, applied in instruments, data processing applications, calculations, etc., can solve problems such as poor practical applicability, no introduction of boiler combustion parameters, etc., to enhance reliability, improve coal consumption economy, reduce The effect of unit energy consumption price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The preferred embodiments will be described in detail below in conjunction with the accompanying drawings. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

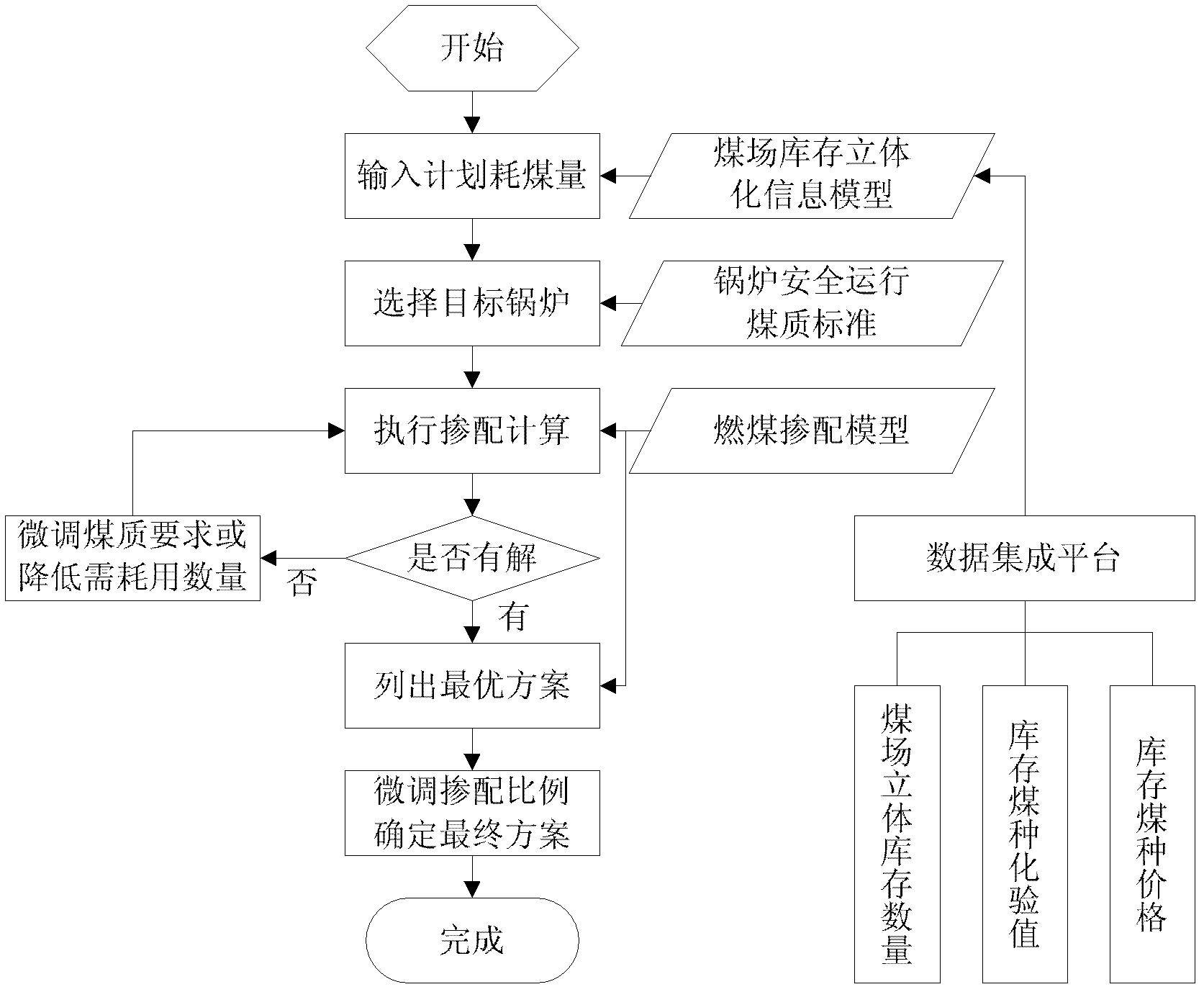

[0064] Technical scheme and process of the present invention are as follows:

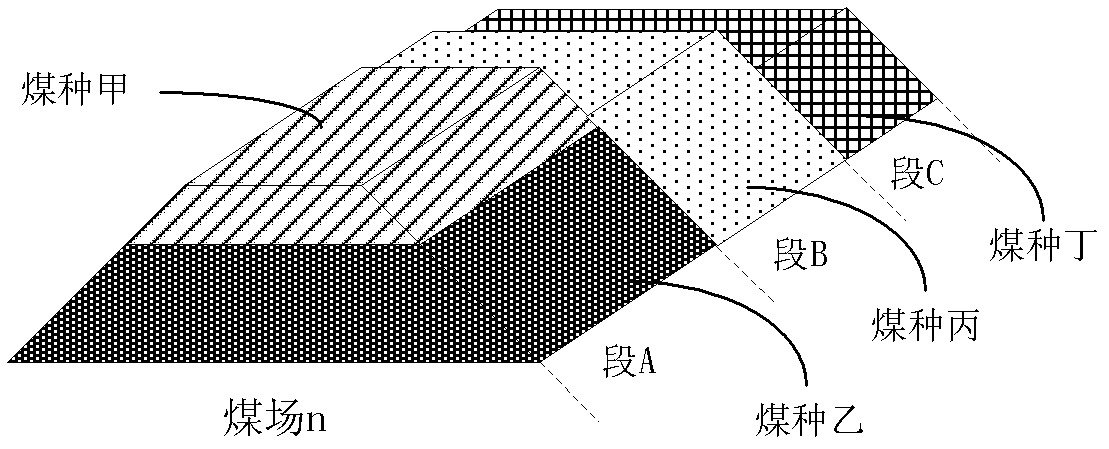

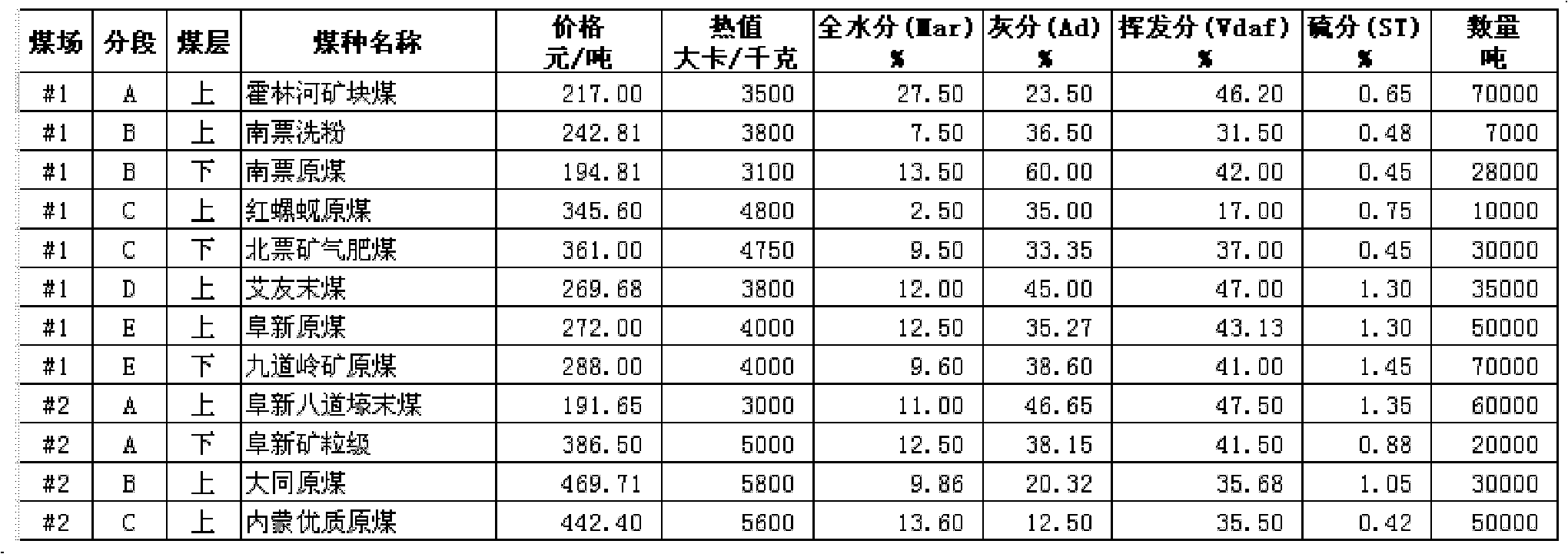

[0065] 1. First establish a three-dimensional information model database of coal yard inventory, and use the data integration platform (which can be understood as an interface platform that supports data transfer between different systems) to obtain the quantity information of coal inventory from the coal yard inventory management system, which can be replaced by X, Quantity information should be subdivided into coal yard, segment number, level, etc., each with X n Instead; obtain the coal quality information of each coal type from the furnace coal quality inspection system, which includes calorific value Q, volatile content V, total moistu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com