Chemical industry device emptying tail gas process heat-recovering system

A waste heat recovery system and tail gas treatment technology, which is applied in the chemical industry, incinerators, climate sustainability, etc., can solve problems such as energy waste, safety hazards, and low operating efficiency, and achieve environmental pollution reduction, full combustion, and safe combustion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

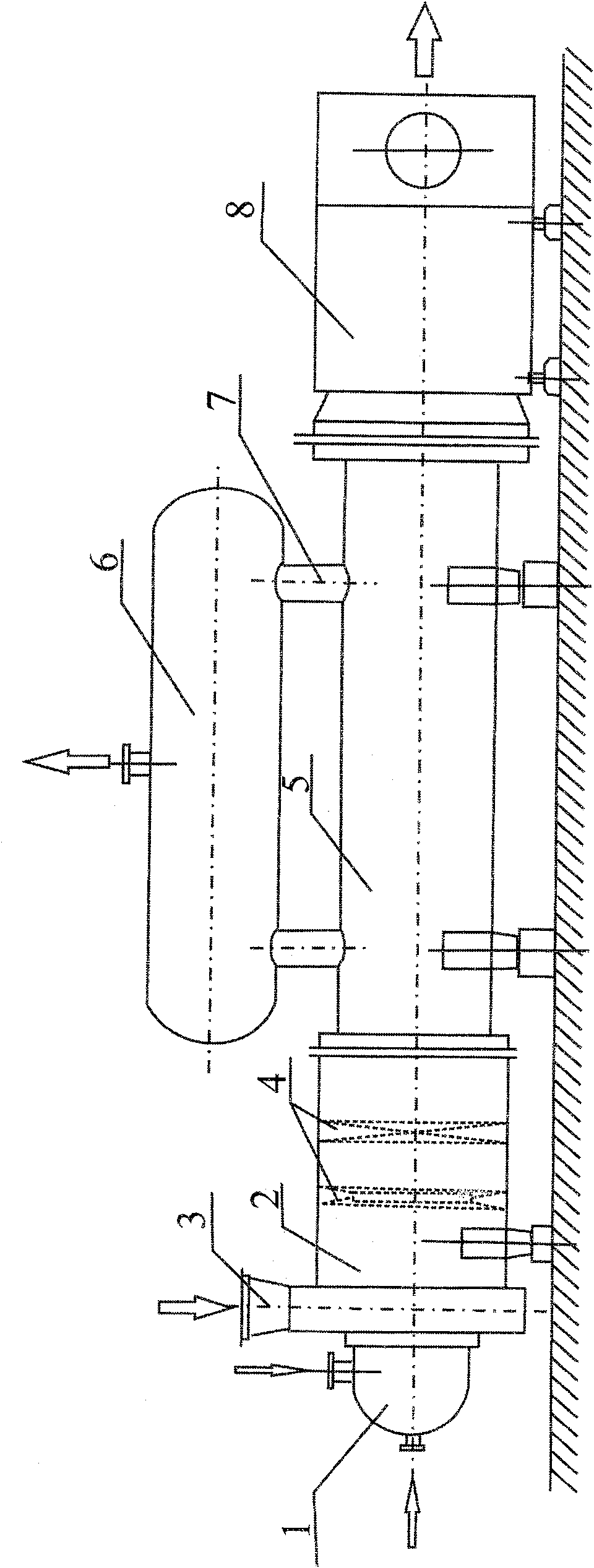

[0009] The present invention will be further described below in conjunction with the accompanying drawings.

[0010] Such as figure 1 As shown, the system includes a combustion chamber 1, a burning chamber 2, an annular chamber 3, a steam generator 6, and a water preheater 9 connected in series to form a serial system, wherein the combustion chamber 1 is connected with an air blower, and the combustion The chamber 1 and the burning chamber 2 are connected by the ring cavity 3, which is connected to the exhaust gas discharge pipe of the chemical plant, and the gas jet device is installed inside the ring cavity 3, so that multiple jets of the tail gas can enter the combustion chamber 1 and the burning chamber 3. It is fully mixed with air and burnt. A temperature uniform distribution device is installed in the burning chamber 2, which can accelerate the full combustion between air and exhaust gas and improve the mixing effect. The steam generator 5 is connected in series with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com