Method for preparing fiber with thermal insulation function based on microfluidic technology

A technology of microfluidic technology and a microfluidic device, which is applied in the field of preparing fibers with heat preservation function based on microfluidic technology, can solve the problems of single fiber function, complicated silk forming process, and single function, and achieve high-efficiency heat transfer, The effect of good biocompatibility and simple operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1: Preparation of phase change fibers whose inner phase is liquid phase change material liquid paraffin

[0035] Refer to attached figure 2 , using the method of the present invention to prepare suspended micro-droplets, the specific steps are as follows:

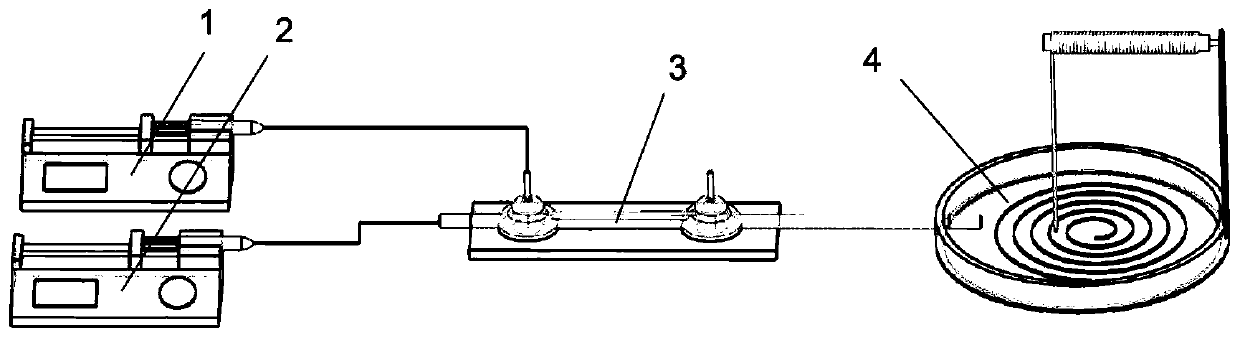

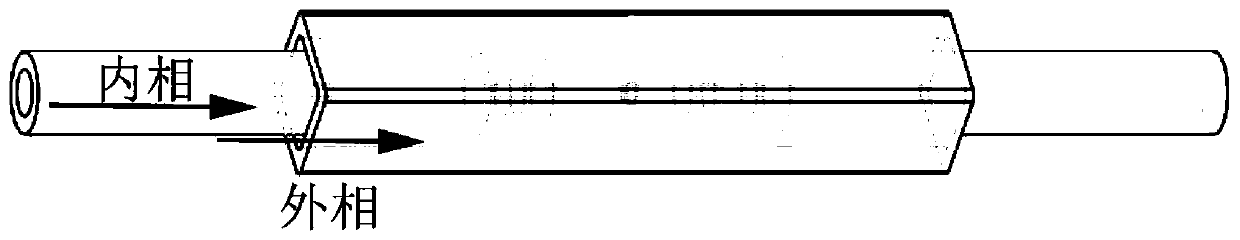

[0036] (1) Fabrication of the microfluidic device: clean the capillary glass tube and dry it; then use an extensometer to pull out one end of the glass capillary tube into a tapered shape; use sandpaper to grind the capillary glass tube to a suitable diameter; The glass capillary and the glass square tube are fixed on the glass slide; finally, the needle is sealed and fixed at the entrance of the glass tube with glue. Glass capillary microfluidic device as attached figure 1 As shown, there is an inner phase tube and a glass square tube through the outer phase.

[0037] (2) Preparation of internal phase and external phase: phase change material liquid paraffin is selected for the internal phase; ABC soluti...

Embodiment 2

[0040] Example 2: Preparation of phase change fibers whose internal phase is the solid phase change material myristyl alcohol

[0041] (1) Prepare glass capillary microfluidic devices as mentioned in Example 1, the internal phase solid phase change material myristyl alcohol; select the external phase as ABC solution, that is, sodium alginate with a mass fraction of 2.7%, and a mass fraction of A mixed solution of 4.6% polyethylene glycol 6000 (PEG) and 4.6% polyvinyl alcohol (PVA) in mass fraction.

[0042] (2) Preparation of fibers: inject the internal phase obtained in step (2) into the internal phase inlet of the capillary glass microfluidic device through a syringe pump; inject the external phase obtained in step (2) into the microfluidic device through a syringe pump The external phase inlet; the internal phase flow rate is 0.01ml / h, and the external phase flow rate is 0.2ml / h. At the outlet of the internal phase tube, the internal phase solution obtains fibers with node...

Embodiment 3

[0044] Example 3: Preparation of fibers with nodes with silk protein as one of the outer phase components

[0045] (1) Preparation of silk protein: first select a certain amount of natural silkworm cocoon, cut it into debris about the size of a bean grain, and then configure a mass fraction of 0.5% Na 2 CO 3 solution, heated in a water bath, and placed the shredded cocoon debris in Na 2 CO 3 In the solution, after boiling for about half an hour, replace with new Na 2 CO 3 Solution, repeat about 6 times, you can get cotton-like flocs, remove sericin, because sericin is in Na 2 CO 3 Hydrolysis will occur in the solution, and the floc silk obtained is mixed with lithium bromide / ethanol / water according to the mass ratio of 44:45:11, and the floc obtained after degumming is placed in the mixed solution in a 60°C water bath Heating, and then purifying through repeated operations such as dialysis and filtration, to obtain a silk fibroin solution.

[0046] (2) Preparation of fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com