Monitoring method for solidification process of concrete test blocks on basis of piezoelectric impedance method

A technology of concrete test block and piezoelectric impedance method, which is applied in the direction of material resistance to achieve the effect of accurate quality control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

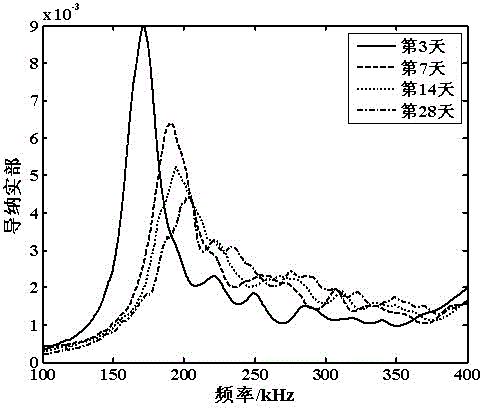

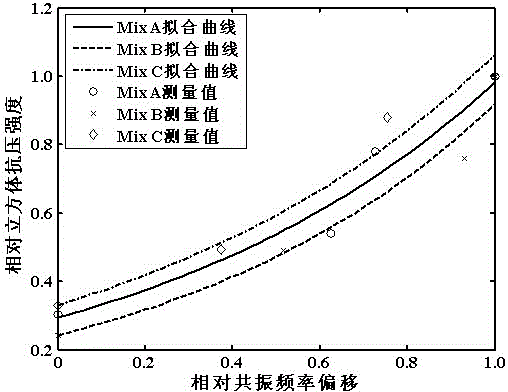

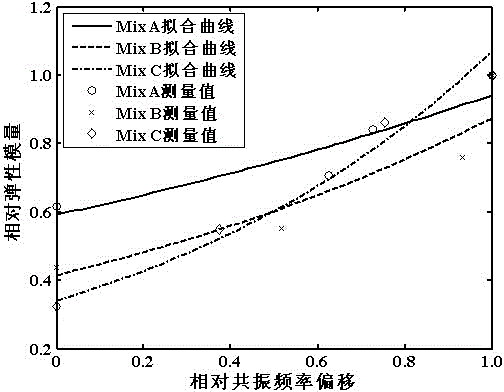

[0022] A method for monitoring the curing process of concrete test blocks based on the piezo-electrical impedance method, extracting the resonance frequency shift index and the root mean square deviation shift index from the piezoelectric admittance signal of the piezoelectric ceramic pasted on the concrete test block to monitor the concrete test block Changes in block compressive strength and modulus of elasticity during curing. Further, it includes the following steps:

[0023] 1) Perform piezoelectric impedance test on the concrete test block and obtain the compressive strength, elastic modulus and piezoelectric admittance signal of the concrete test block;

[0024] 2) Analyze and process the piezoelectric admittance signal to obtain the resonance frequency and the root mean square deviation. The formula for calculating the root mean square deviation is:

[0025]

[0026] In the formula: Y k is the piezoelectric admittance signal, N is the number of sampling points...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com