Middle-toughness high-formability heat-resisting magnesium alloy

A magnesium alloy and formability technology, applied in the field of magnesium alloys, can solve the problems of high price of Nd and the need to improve the formability of the alloy, so as to hinder the high temperature grain boundary slip, improve the high temperature mechanical properties and formability, and have excellent strength and toughness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

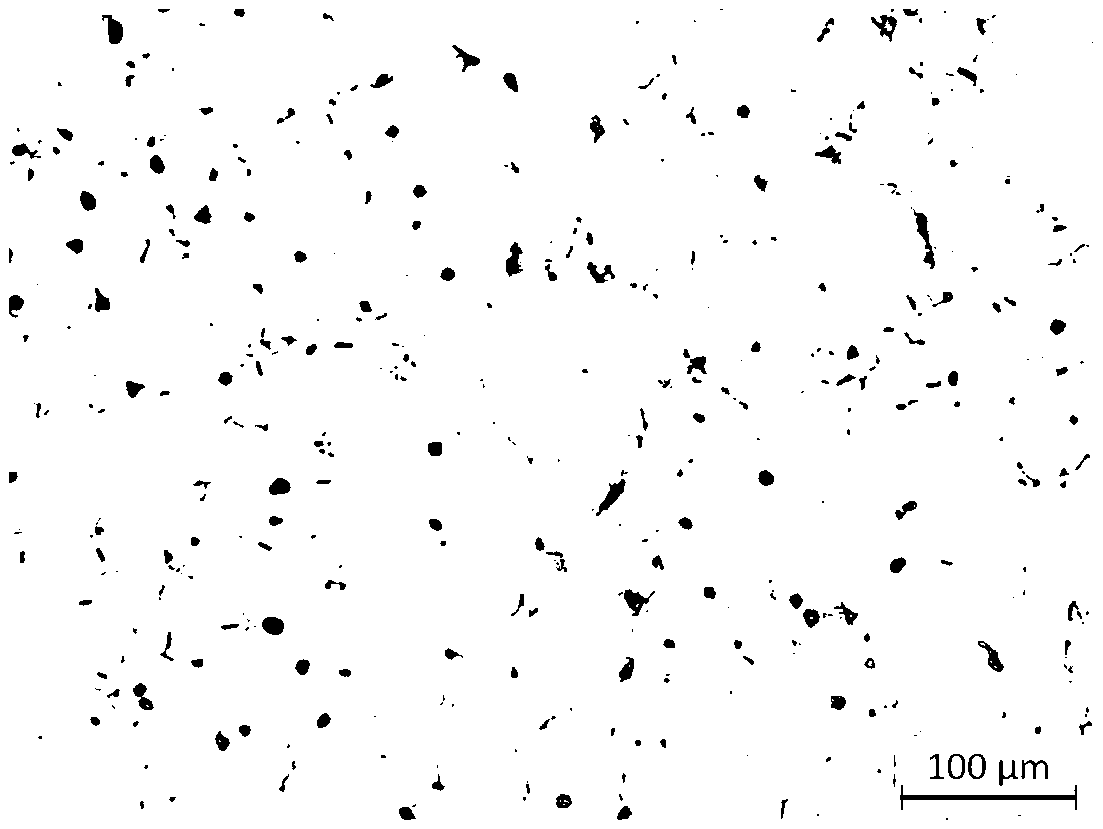

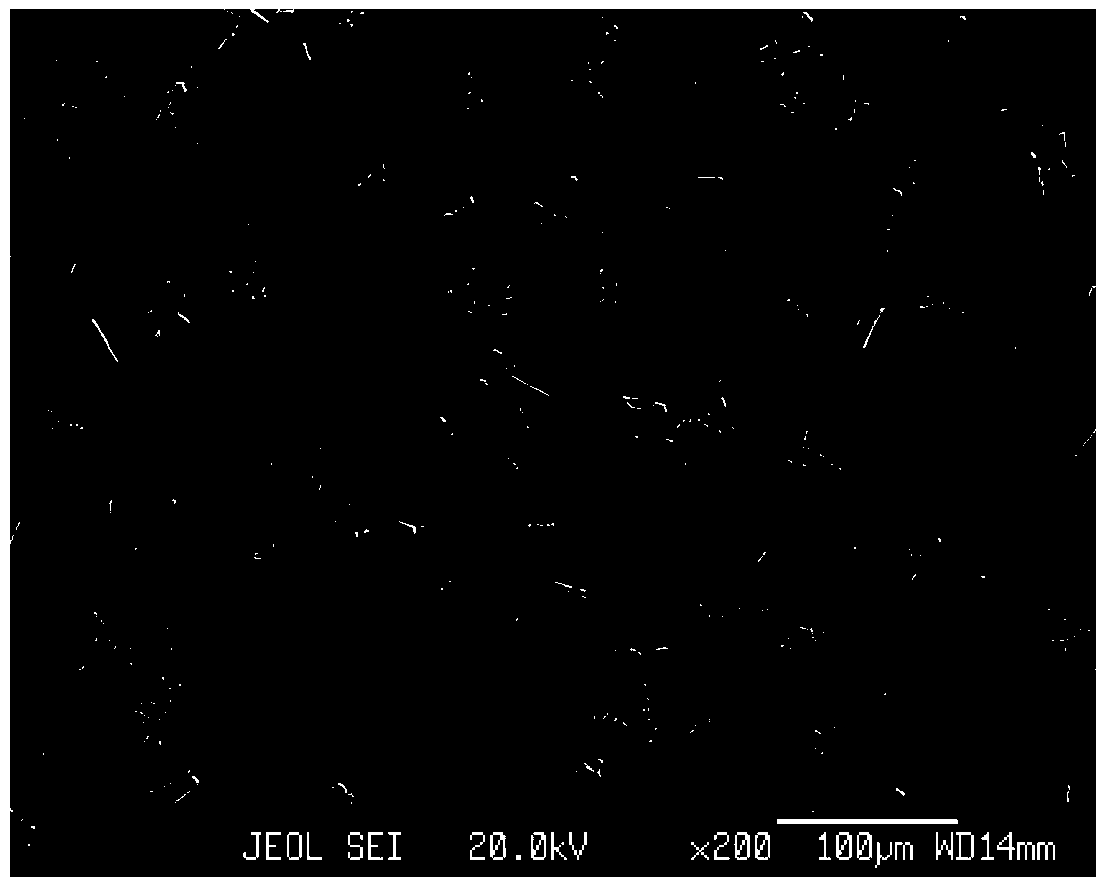

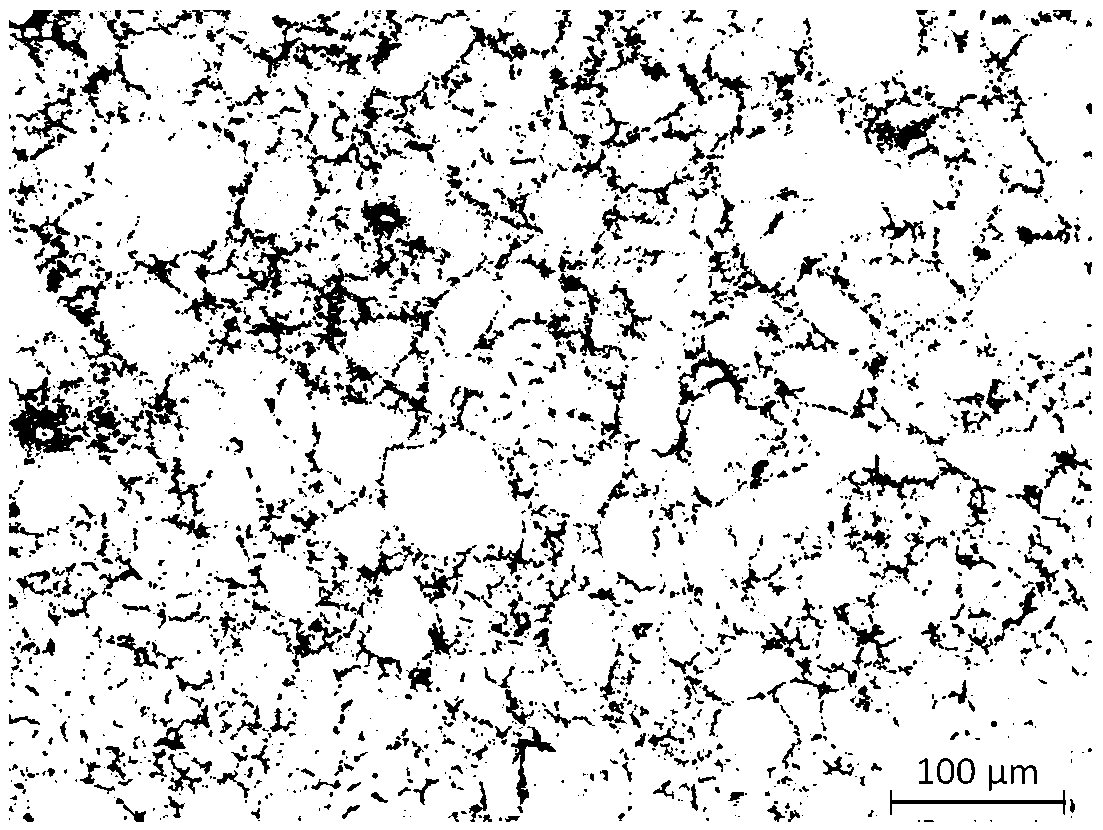

Embodiment 1

[0025] The weight percent of the alloy composition is: Al 3.0%, Sm 0.5% and Bi 0.3%, and the balance is Mg.

[0026] The as-cast room temperature tensile strength and elongation of Example 1 are 198 MPa and 7.0%, respectively, and the tensile strength and elongation at 150°C are 169 MPa and 26.5%, respectively, and the as-cast flow length is 410mm.

Embodiment 2

[0028] The weight percent of the alloy composition is: Al 6.0%, Sm 1.0% and Bi 0.3%, and the balance is Mg.

[0029] The as-cast room temperature tensile strength and elongation of embodiment 2 are respectively 220MPa and 12.5%, the tensile strength at 150 ℃ and elongation are respectively 162MPa and 14.5%, and the as-cast flow length is 460mm; The die-cast room temperature tensile strength and The elongation is 285MPa and 16.5%, respectively, and the flow length of the die-casting state is 1870mm.

Embodiment 3

[0031] The weight percent of the alloy composition is: Al 7.0%, Sm 3.0% and Bi 0.75%, and the balance is Mg.

[0032] The as-cast room temperature tensile strength and elongation of Example 3 are 210MPa and 12.0%, respectively, and the tensile strength and elongation at 150°C are 151MPa and 13.5%, respectively, and the as-cast flow length is 430mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elongation | aaaaa | aaaaa |

| Elongation | aaaaa | aaaaa |

| Elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com