Method for preparing three-dimensional microfluidic chip

A microfluidic chip, three-dimensional technology, applied in the field of microfluidics, can solve problems such as rough surface, difficult to realize, and opaque materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

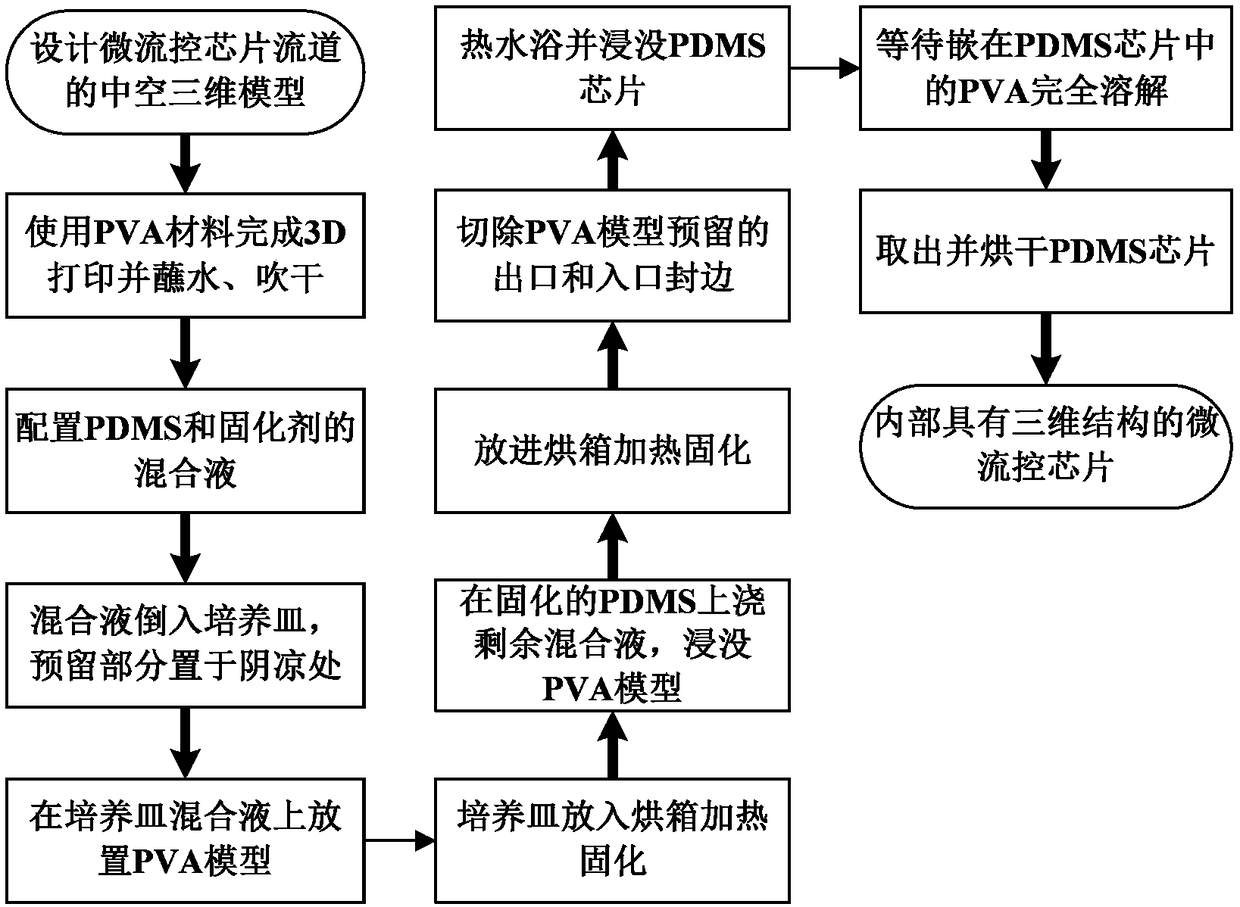

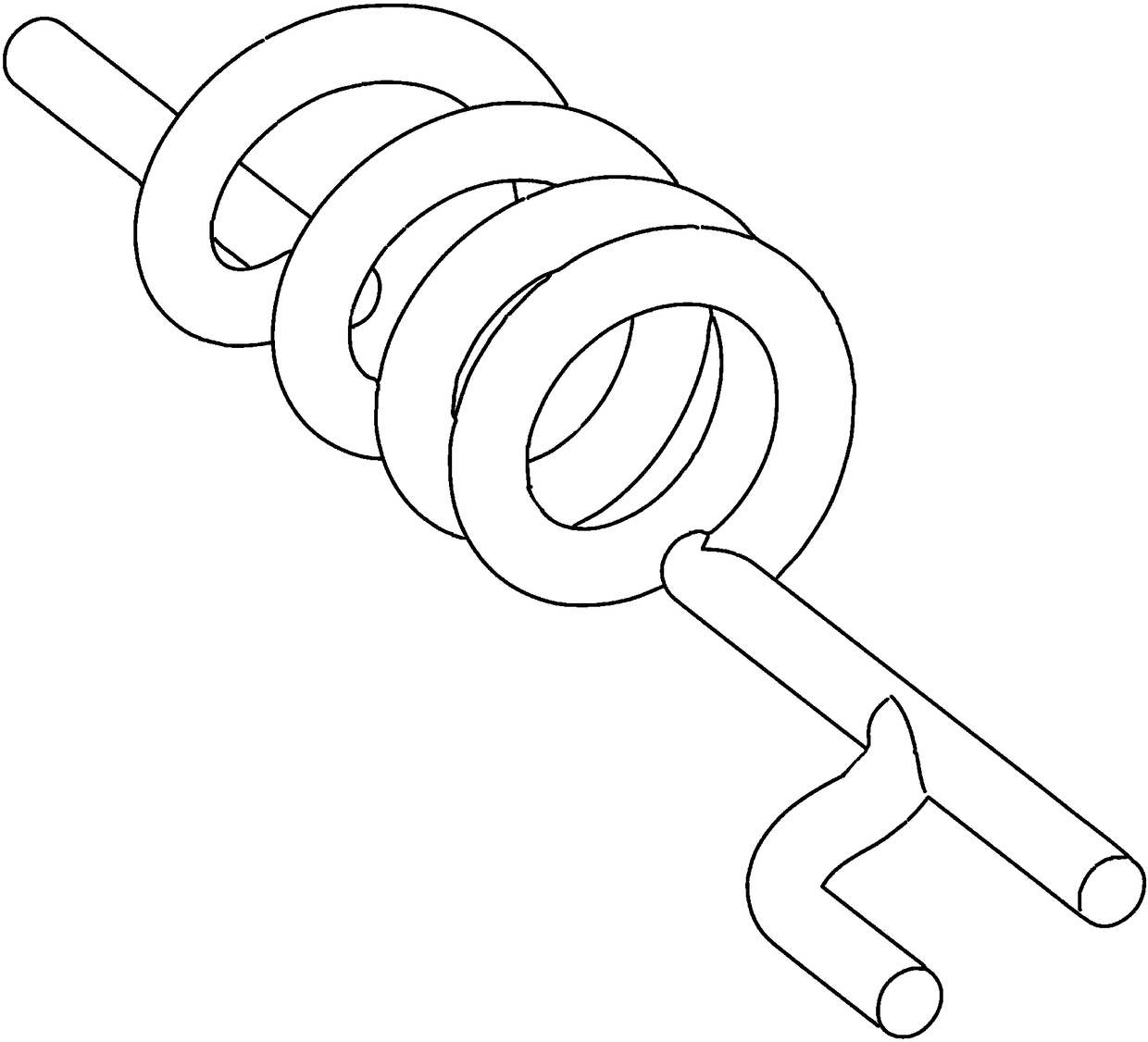

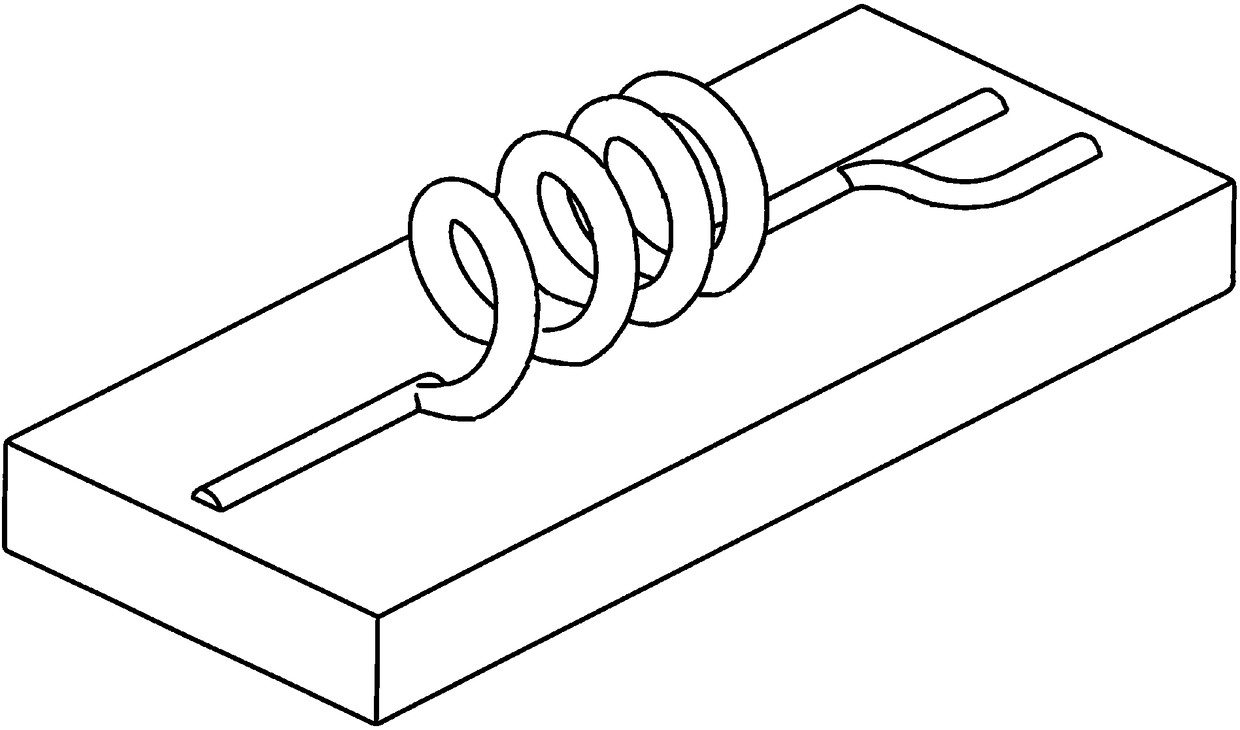

[0041] 1) Use the commercial computer-aided design software Solidworks to draw a three-dimensional model of the internal channel of the microfluidic chip with internal hollow features, and the three-dimensional model has reserved parts for subsequent resection. The model is as follows: figure 2 shown. The flow channel model is helical, which can be used for micro-mixing operations, and has higher mixing efficiency than planar structures;

[0042] 2) Use a 3D printer, load polyvinyl alcohol (PVA) consumables, import the 3D model into the 3D printer, and obtain a 3D printing model of polyvinyl alcohol (PVA) material. Turn on the oven, set to 80°C and preheat for 20 minutes. After the 3D printing is completed, dip the polyvinyl alcohol (PVA) 3D printed model in cold water at 10 degrees Celsius, and quickly put it in a preheated oven for drying. The temperature of the oven is set at 45 degrees Celsius;

[0043] 3) Prepare a mixture of polydimethylsiloxane (PDMS) and curing agen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com