Double-face paint spraying device

A paint spraying equipment, double-sided technology, applied in the direction of spraying device, surface pretreatment, device for coating liquid on the surface, etc., can solve problems such as pollution, and achieve the effect of avoiding environmental pollution, effectively spraying paint, and improving effectiveness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

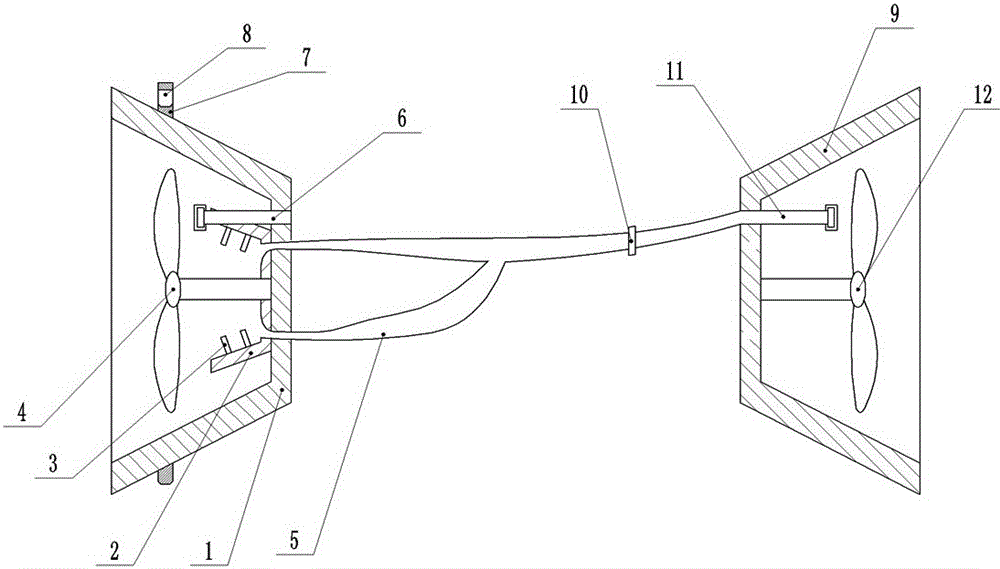

[0029] Basic as attached figure 1 Shown: double-sided painting equipment, including the first painting hood 1, the first painting hood 1 has a trapezoidal structure with a wide opening and a narrow right end. A gear 7 is sleeved, and a rack 8 meshing with the gear 7 is installed on the right side of the first paint spray cover 1, and an end of the rack 8 is welded with a cylinder. In the first paint spray cover 1, a suction fan 4 is connected by a rotating shaft. The suction fan 4 includes three fan blades, and the inclination angle of the fan blades is 15°. There are several blades 3 clamped on the side wall, the recovery cover 2 is located directly below the suction fan 4, and the bottom of the recovery cover 2 is integrally formed with an annular recovery pipe 5, which includes a gas recovery part on the left end and a paint mist dissolution part on the right end , A one-way valve is installed at the left end of the gas recovery part, oil is installed in the paint mist dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com