Preparation method of micro-nano molybdenum carbide powder

A micro-nano, molybdenum carbide technology, applied in the direction of carbides, tungsten/molybdenum carbides, etc., can solve problems such as difficulty in popularization, complex structure and preparation process of metal complexes, expensive ligands, etc., to reduce airtightness Effects of sexual dependence, prevention of mutual association, and shortened reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

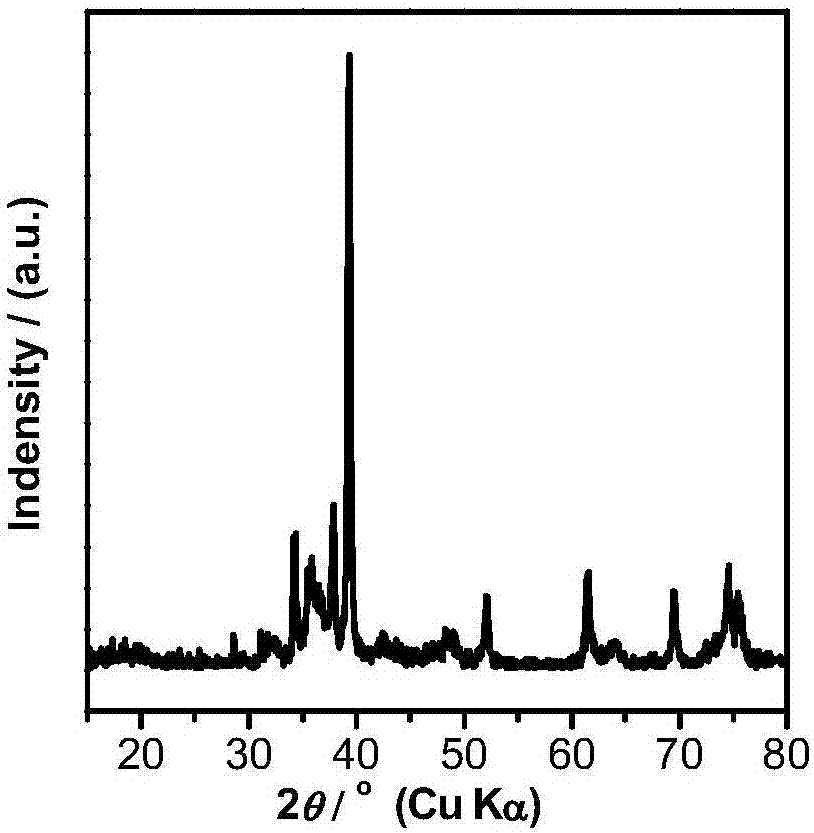

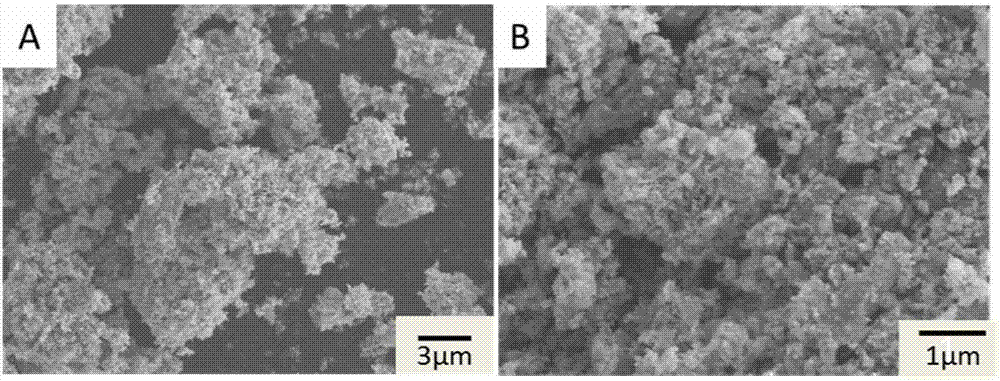

Embodiment 1

[0043] Mix 1.356 grams of lithium chloride and 1.644 grams of potassium chloride and use it as a molten salt (melting point: 353 ° C), then add 1.26 grams of melamine and 0.63 grams of ammonium molybdate, and grind for 20 minutes; the above solid mixture is placed in an oxidation chamber with a lid. Aluminum ceramic crucible (capacity 30mL). The crucible containing the reaction precursor and the molten salt is placed in the middle of the microwave muffle furnace, and microwave heat treatment is performed in an air environment. The microwave treatment conditions are as follows: the temperature is raised from room temperature to 750°C at a rate of 10°C / min, and the temperature is kept at 750°C for 2 hours. After the reaction was completed and the sample was cooled, the obtained solid was washed with distilled water for more than 3 times to dissolve potassium chloride and lithium chloride, and dried at 80°C for 12 hours to obtain molybdenum carbide micro-nano powder.

[0044] In...

Embodiment 2

[0047] After mixing 1.356 g of lithium chloride and 1.644 g of potassium chloride uniformly, it was used as a molten salt medium (melting point: 353° C.), and then 1.26 g of melamine and 0.63 g of ammonium molybdate were added and ground for 20 minutes. The solid mixture obtained above was put into an alumina ceramic crucible (capacity 30 mL) with a lid. Place the crucible in the middle of the resistance muffle furnace, and heat it in the air environment: raise the temperature from room temperature to 750°C at a rate of 10°C / min, and keep it warm for 10h; after cooling, wash the obtained solid with distilled water for several The second time, potassium chloride and lithium chloride were dissolved and dried at 80°C for 12 hours to obtain molybdenum carbide.

[0048] In this embodiment, the mass ratio of melamine to molten salt is 42:100, the molar ratio of lithium chloride to potassium chloride is 59.2%:40.8%, and the mass ratio of melamine to ammonium molybdate is 2:1.

[004...

Embodiment 3

[0051] Mix 1.356 grams of lithium chloride and 1.644 grams of potassium chloride evenly as molten salt (melting point of molten salt: 353°C), add 1.26 grams of melamine and 0.63 grams of ammonium molybdate; after grinding for 20 minutes, put the above solid mixture into an alumina ceramic crucible (capacity 30ml). Place the crucible in the middle of the microwave muffle furnace, and process it in an air environment: raise the temperature from room temperature to 850°C at a rate of 10°C / min, and keep it warm for 4 hours; after cooling, wash the obtained solid with distilled water for several times , Dissolve potassium chloride and lithium chloride, and dry at 80°C for 12 hours to obtain molybdenum carbide.

[0052] In this embodiment, the mass ratio of melamine to molten salt is 42:100, the molar ratio of lithium chloride to potassium chloride is 59.2%:40.8%, and the mass ratio of melamine to ammonium molybdate is 2:1.

[0053] From Figure 6 It can be seen that the crystal p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com