Deformed magnesium alloy and casting method and deformation processing method thereof

A wrought magnesium alloy and deformation processing technology, applied in the field of wrought magnesium alloy and its melting and casting method and deformation processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The weight percent of the alloy composition is: Zn5.5%, Zr0.6% and Dy0.3%, and the rest is Mg.

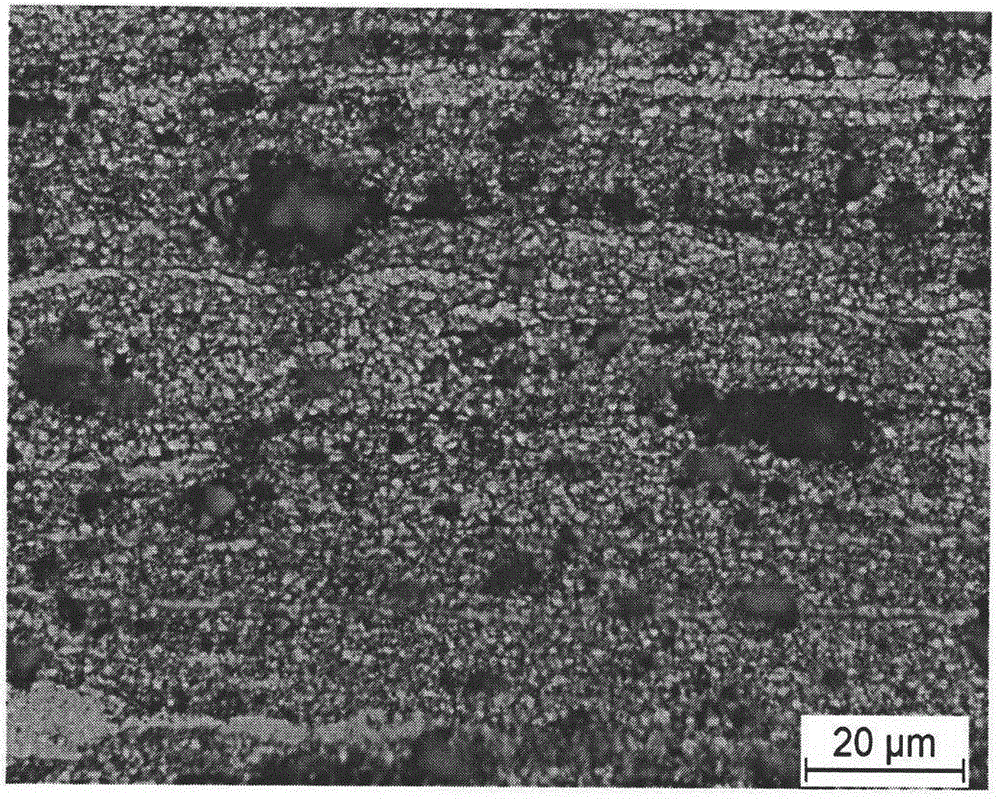

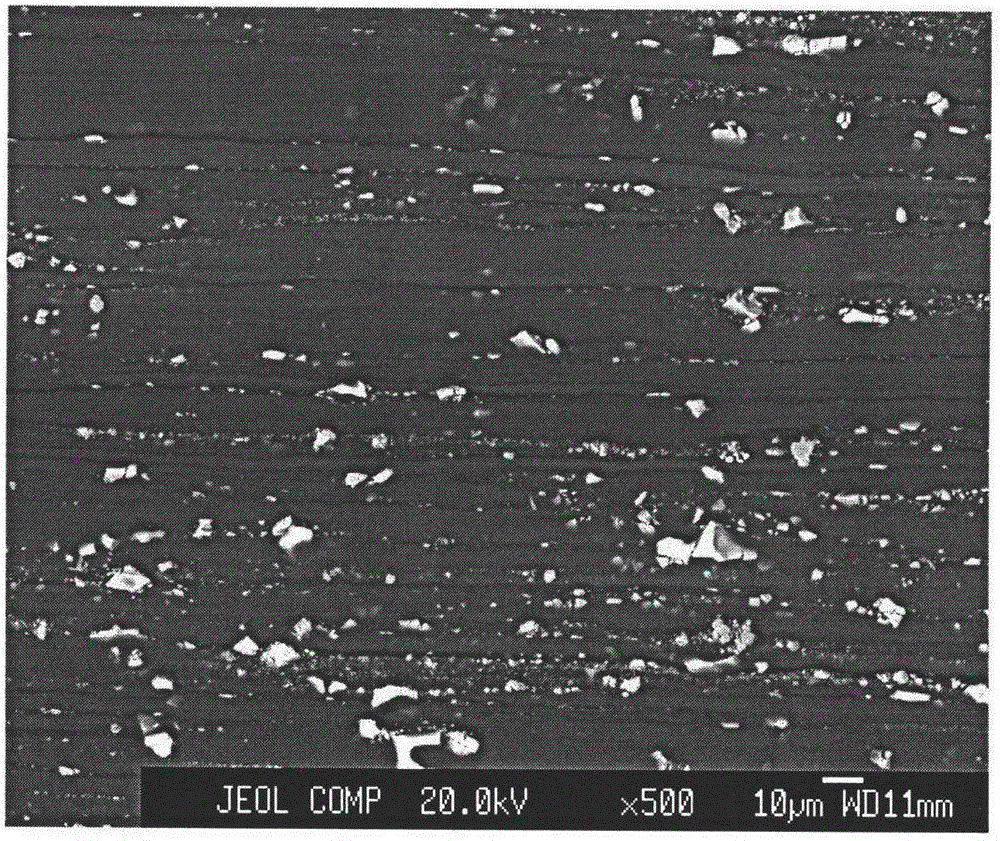

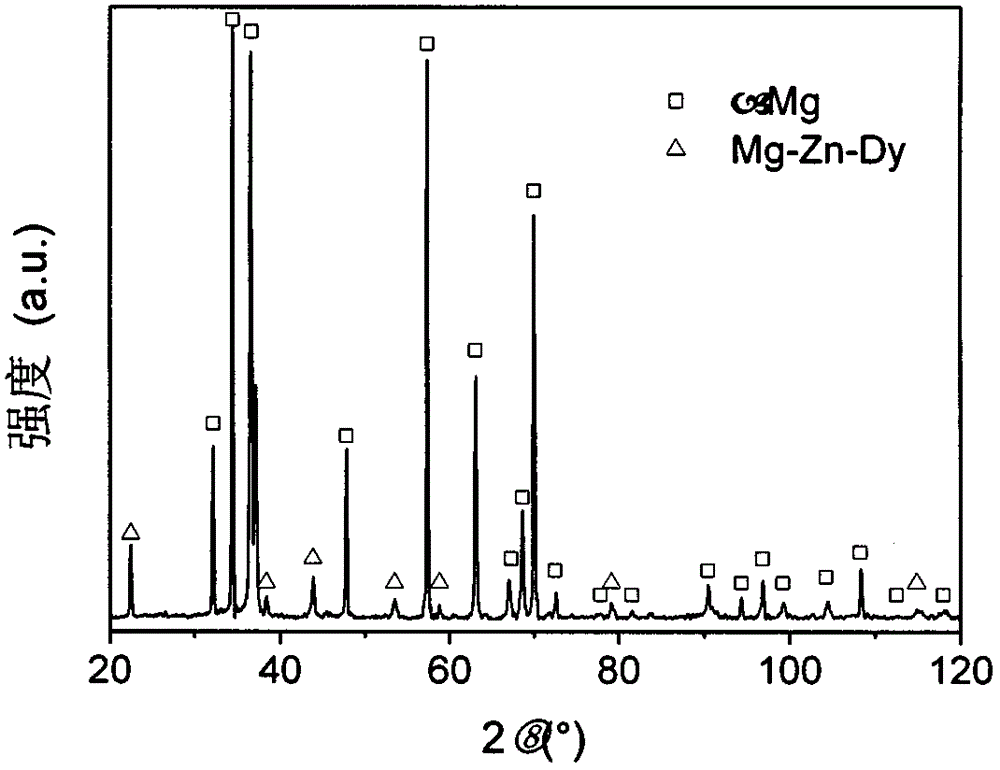

[0023] The alloy is prepared according to the above composition, and the casting method is as follows: in N 2 and 0.2vol% SF 6 Under the protection of mixed gas, after the industrial pure Mg is melted, the temperature is raised to 730°C, and the industrial pure Zn, Mg-Zr, and Mg-Dy intermediate alloys are sequentially added to the melt every 5 minutes; the melt is stirred twice within 1 hour; and then added JDMJ-type refining agent is stirred and heated to 750-760°C, and left to stand for 30 minutes; finally, after the melt temperature is cooled to 715°C, it is poured into a forced-cooled cylindrical mold after removing slag, and is rapidly solidified into a billet. The deformation processing method is as follows: the above casting slab is homogenized at 400°C for 8 hours, adopts a forward extrusion method, the extrusion ratio is 40, the extrusion temperature is 320°C, and ...

Embodiment 2

[0026] The weight percent of the alloy composition is: Zn6.0%, Zr0.9% and Dy2.1%, and the rest is Mg.

[0027] The alloy is prepared according to the above composition, and the casting method is as follows: in N 2 and 0.2vol.%SF 6 Under the protection of mixed gas, after the industrial pure Mg is melted, the temperature is raised to 730°C, and the industrial pure Zn, Mg-Zr, and Mg-Dy intermediate alloys are sequentially added to the melt every 5 minutes; the melt is stirred twice within 1 hour; and then added JDMJ-type refining agent is stirred and heated to 750-760°C, and left to stand for 30 minutes; finally, after the melt temperature is cooled to 715°C, it is poured into a forced-cooled cylindrical mold after removing slag, and is rapidly solidified into a billet. The deformation processing method is as follows: the billet is homogenized at 400°C for 8 hours, using a forward extrusion method, with an extrusion ratio of 40, an extrusion temperature of 330°C, and an extrusi...

Embodiment 3

[0030] The weight percent of the alloy composition is: Zn5.0%, Zr0.3% and Dy4.3%, and the rest is Mg.

[0031] The alloy is prepared according to the above composition, and the casting method is as follows: in N 2 and 0.2vol.%SF 6 Under the protection of mixed gas, after the industrial pure Mg is melted, the temperature is raised to 730°C, and the industrial pure Zn, Mg-Zr, and Mg-Dy intermediate alloys are sequentially added to the melt every 5 minutes; the melt is stirred twice within 1 hour; and then added JDMJ-type refining agent is stirred and heated to 750-760°C, and left to stand for 30 minutes; finally, after the melt temperature is cooled to 715°C, it is poured into a forced-cooled cylindrical mold after removing slag, and is rapidly solidified into a billet. The deformation processing method is as follows: the casting billet is homogenized at 400°C for 8 hours, adopts the forward extrusion method, the extrusion ratio is 40, the extrusion temperature is 340°C, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com