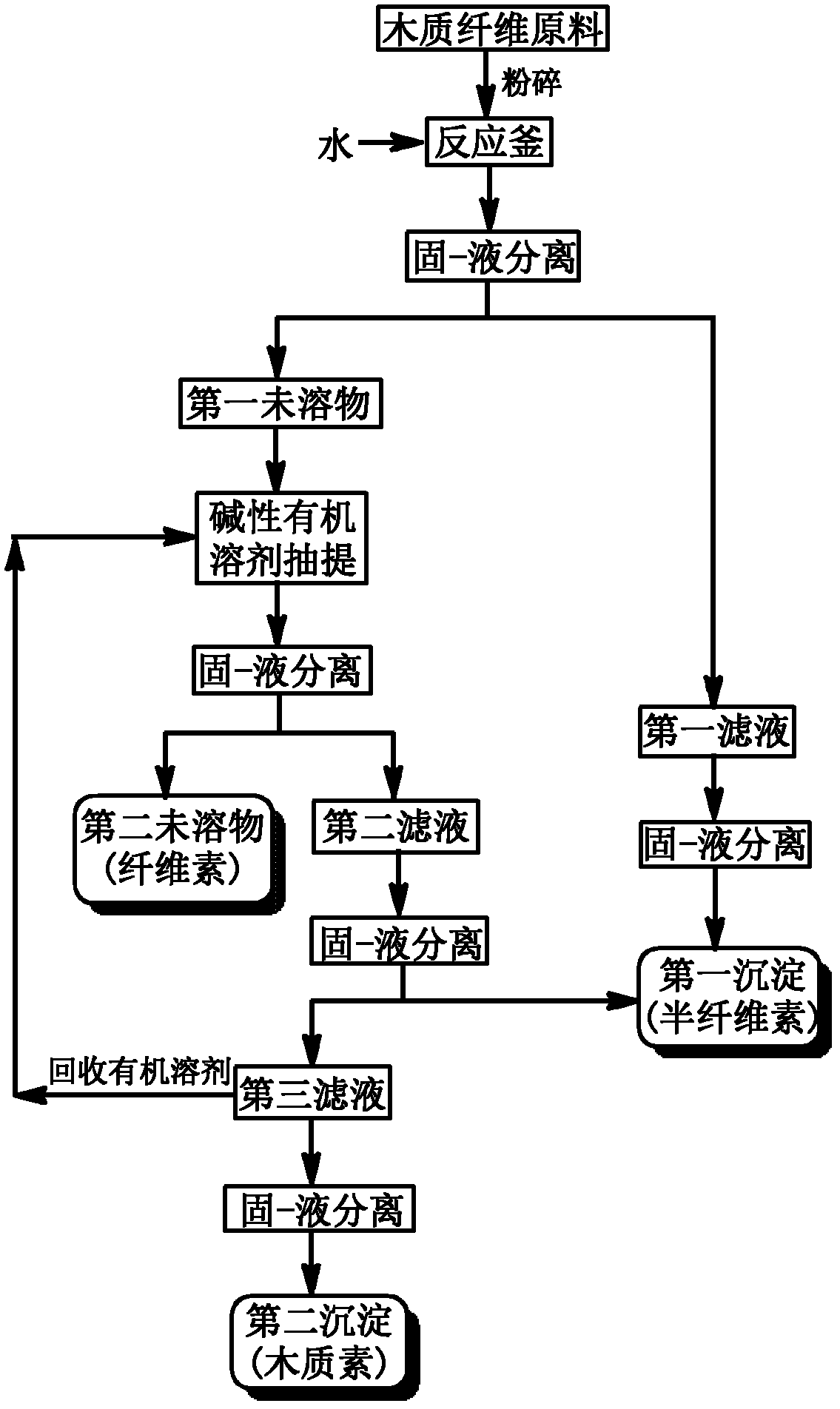

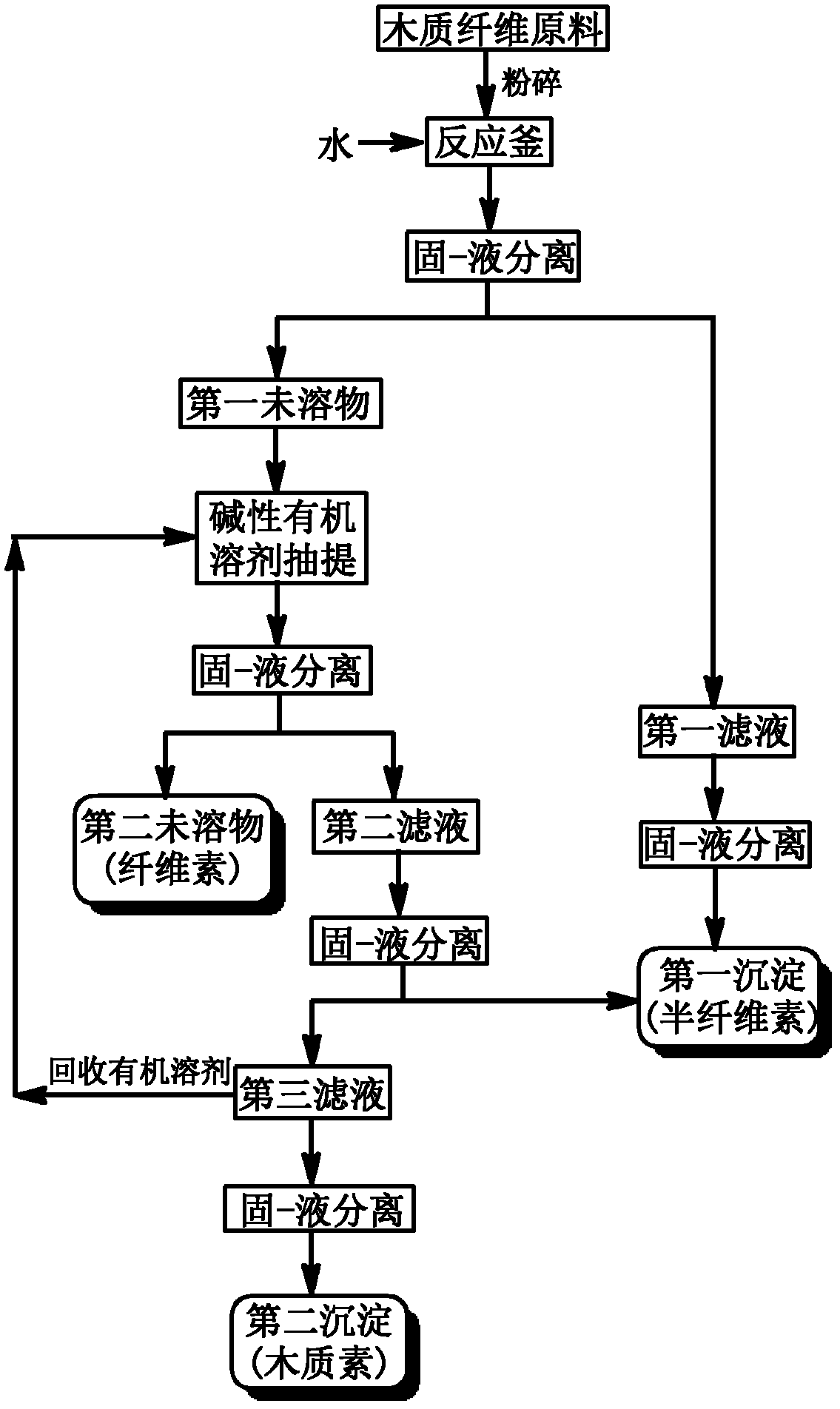

Method of extracting hemicellulose, cellulose and lignin from wood fiber raw materials

A technology for lignocellulosic raw material and hemicellulose, applied in the field of extracting hemicellulose, cellulose and lignin, can solve the problems of high production cost, long reaction time, harsh conditions, etc., and achieve high-efficiency hydrolysis, wide social and economic benefits , Environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) 3g shrub red willow powder crushed to 40-60 meshes and water are fully mixed in a mass ratio of 1:10, then transferred to the reaction kettle, placed in an oven and heated to 100°C, and reacted for 0.5 hours, Filtration obtains the first undissolved matter and the first filtrate;

[0028] (2) Fully mix the first undissolved matter with an organic solvent containing 0.5% NaOH and 60% methanol at a solid-to-liquid ratio of 1:10, react at 78°C for 3 hours, filter to obtain the second undissolved matter and the second Filtrate: the second undissolved substance is the target product cellulose;

[0029] (3) After the first filtrate and the second filtrate obtained by step (1) and step (2) are mixed, the pH of the solution is adjusted to 5.5 with hydrochloric acid, and after filtration, the solution is concentrated under reduced pressure on a rotary evaporator to a water content of 5 %, then add 2 times the volume of ethanol to the concentrated solution, and filter to obt...

Embodiment 2

[0033] (1) 3g shrub red willow powder crushed to 40-60 meshes and water are fully mixed in a ratio of 1:15 in mass ratio, then transferred to the reaction kettle, placed in an oven and heated to 120°C, and reacted for 2 hours, Filtration obtains the first undissolved matter and the first filtrate;

[0034] (2) Fully mix the first undissolved matter with an organic solvent containing 1% NaOH and 60% ethanol at a solid-to-liquid ratio of 1:20, react at 78°C for 3 hours, filter to obtain the second undissolved matter and the second Filtrate: the second undissolved substance is the target product cellulose;

[0035] (3) After the first filtrate and the second filtrate obtained in step (1) and step (2) are mixed, the pH of the solution is adjusted to 6.0 with hydrochloric acid, and after filtration, the solution is concentrated under reduced pressure on a rotary evaporator to a water content of 10 %, then add 3 times the volume of ethanol to the concentrated solution, and filter t...

Embodiment 3

[0039] (1) 3g shrub red willow powder crushed to 40-60 meshes and water are fully mixed in a mass ratio of 1:25, then transferred to the reaction kettle, placed in an oven and heated to 140°C, and reacted for 3 hours, Filtration obtains the first undissolved matter and the first filtrate;

[0040] (2) Fully mix the first undissolved matter with an organic solvent containing 2% NaOH and 60% ethanol with a solid-to-liquid ratio of 1:25, react at 78°C for 3 hours, filter to obtain the second undissolved matter and the second Filtrate: the second undissolved substance is the target product cellulose;

[0041] (3) After the first filtrate and the second filtrate obtained in step (1) and step (2) are mixed, the pH of the solution is adjusted to 6.0 with hydrochloric acid, and after filtration, the solution is concentrated under reduced pressure on a rotary evaporator to a water content of 15 %, then add 3 times the volume of ethanol to the concentrated solution, and filter to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com