Cooling water tank for machine tool

A technology for cooling water tanks and machine tools, applied to metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve problems such as inconvenient operation and simple structure, and achieve convenient cleaning and operation, good isolation effect, and improved precipitation effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

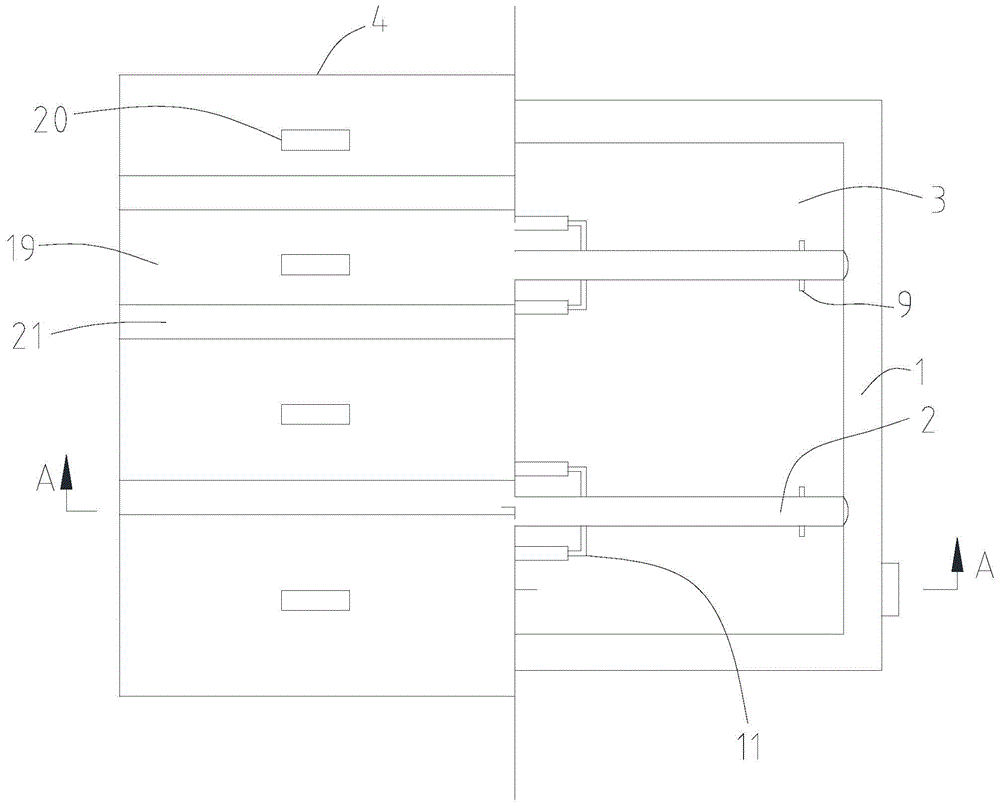

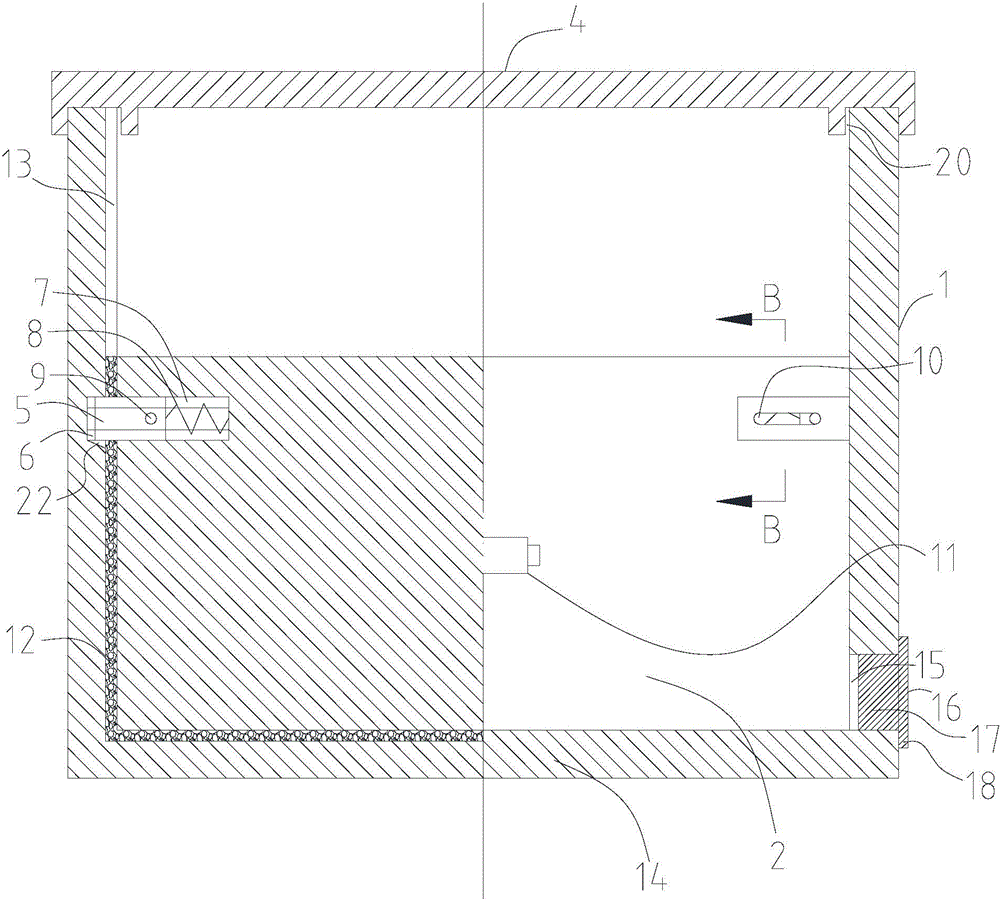

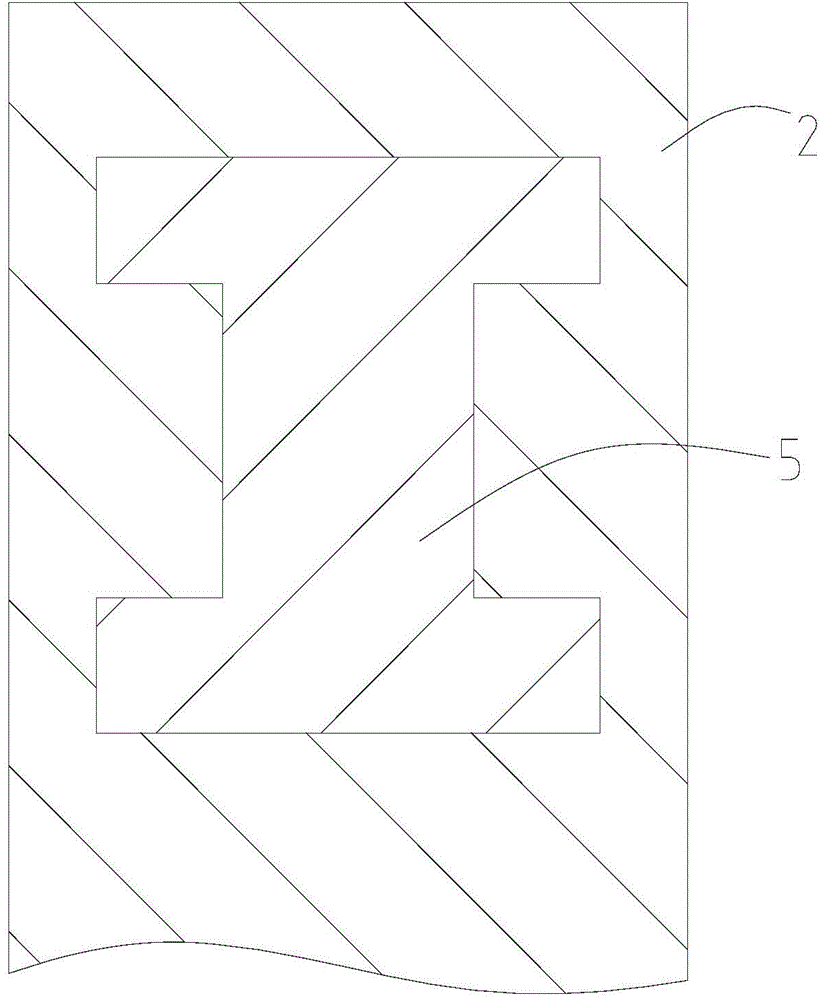

[0017] The cooling water tank for machine tools of the present invention will be further described below in conjunction with the accompanying drawings. Such as figure 1 , figure 2 , image 3 As shown, the cooling water tank used for machine tools includes a hollow box 1, and the box 1 is provided with partitions 2 for dividing the box 1 into several sedimentation tanks 3, so the height of the partition 2 is low The depth of the box body 1 also includes a cover for closing the box body 1. The box body 1 should also include structures such as a cooling water pump for extracting cooling liquid and an identification window for marking the water level in the box body 1. The cooling water pump and the identification window described above are all cooling water pumps and identification windows in the prior art, the partition plate 2 is plugged into the box body 1, and the partition plate 2 is provided with a connecting block for connecting with the box body 1 5. The box body 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com