Photoetching development method

A technology of lithography and photoresist, which is applied in the direction of microlithography exposure equipment, photosensitive material processing, and photolithography process exposure device, etc. It can solve the problems affecting the etching process and photoresist residual interconnection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

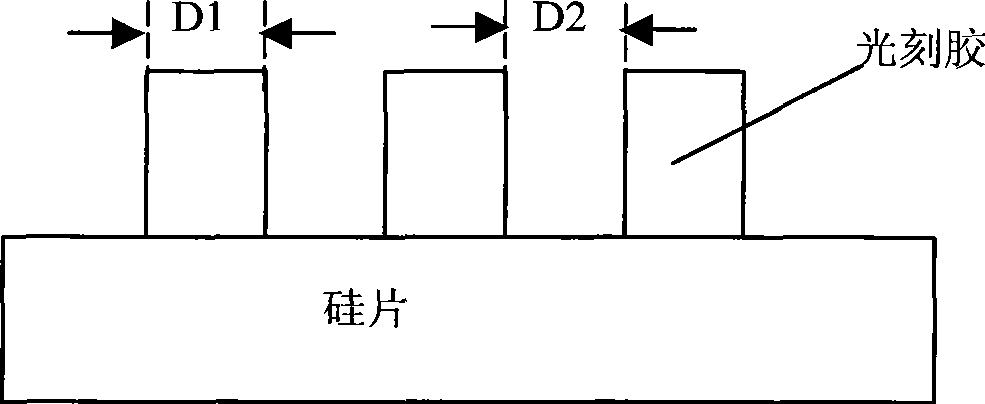

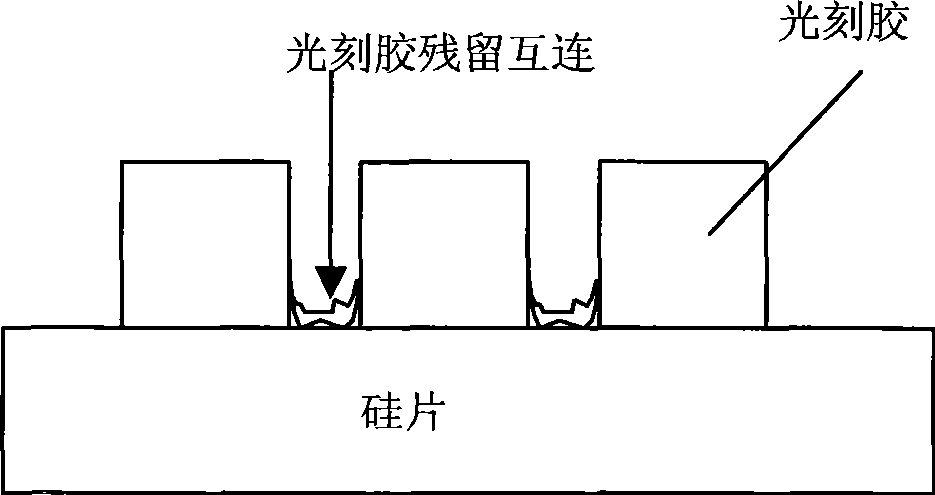

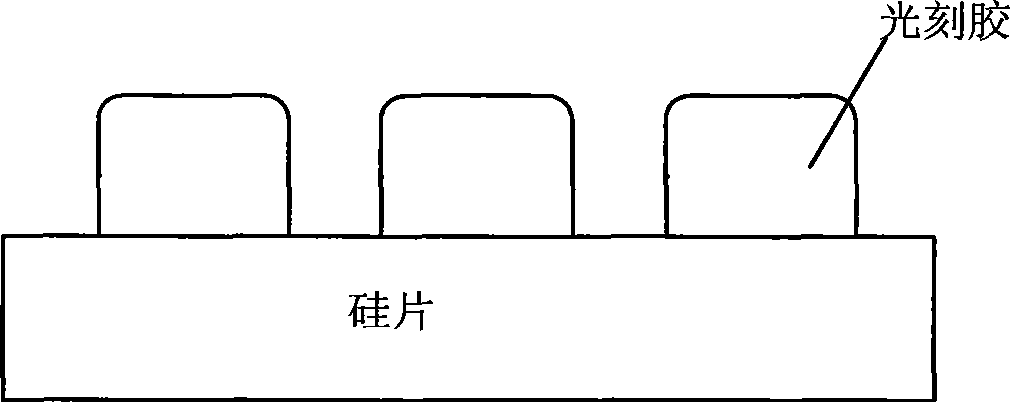

[0010] The usual photolithography development methods include coating, soft baking, exposure, post-bake, development, hard baking, and measurement of photoresist patterns on silicon wafers. In the preparation method of the present invention, the photoresist patterns are The feature size D1 is set to be smaller than the target value, generally about 1% to 30% smaller than the target value, which is equivalent to making the feature size D2 of the photoresist pattern gap larger than the target value, so the ratio of the two is D1 / D2 becomes smaller, so it can avoid the formation of photoresist residue interconnection in the gap of the photoresist pattern after development; while the hard baking needs to increase the hard baking temperature, because the increase in temperature makes the photoresist slightly in the hard baking process After softening, the characteristic size of the photoresist pattern gap after hard baking is finally within the target value range. In this step, due to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com