Synthesis method of ethyl trifluoroacetate

A technology of ethyl trifluoroacetate and a synthesis method, which is applied in the preparation of carboxylate, chemical instruments and methods, preparation of organic compounds, etc., can solve problems such as unsuitable drying of crude products, meet the requirements of simplified equipment and simple operation process , the effect of improving purity and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

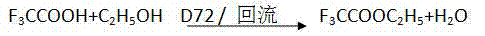

[0021] A synthetic method for ethyl trifluoroacetate, comprising the following steps:

[0022] Step 1. Use trifluoroacetic acid and ethanol as raw materials, use strong acidic cation exchange resin as catalyst, add ethanol dropwise at 40~50°C and normal pressure and keep it for 20 minutes, heat up and reflux to separate the mixture of water and ethanol to complete the reaction ;

[0023] Step 2, collecting the mixture of crude product ethanol and ethyl trifluoroacetate;

[0024] Step 3: After receiving the mixture in step 2, continue to use the catalyst and ethanol at the bottom of the kettle; add a small amount of water to wash the collected crude product with ethanol, and layer it to obtain a qualified product trifluoroacetic acid with a content of more than 99.5% and a moisture content of less than 0.1%. Ethyl ester, the yield is more than 95%;

[0025] Step 4, reflux to separate the dilute ethanol and merge with the dilute alcohol washed in step 3, and rectify to obtain ...

Embodiment 1

[0029] Put 200g of catalyst D72 resin and 360g of trifluoroacetic acid into a 1000ml single-necked bottle, stir to raise the temperature to 40°C, add 300g of absolute ethanol dropwise, and keep the temperature at 50°C to complete the dropwise addition. Stir for 20 minutes, heat up and reflux to separate about 60 g of the mixture of water and ethanol, start distillation, collect the product and the mixture of ethanol and water, and stop heating when the gas phase temperature reaches 65°C and there is no distillate. 510 g of crude product were collected. The distilled crude product, containing 15% alcohol, is washed once by adding 20% of the weight of water, and the liquid is separated. The crude product of about 95% in the lower layer can be washed twice according to this method to obtain ethyl trifluoroacetate with a purity of 99.5%. Slowly heat up the product to 50-60°C for dehydration, and obtain 415g of a product with a moisture content of less than 0.1%.

[0030] The se...

Embodiment 2

[0032] The reaction kettle of Example 1 was drained of the jacket steam of the reaction kettle, the temperature of the circulating water was lowered to 20° C., and the second batch of materials was added: 360 g of trifluoroacetic acid, 200 g of absolute ethanol was added dropwise, and the same operation as before was collected to collect the product. The catalyst and undistilled ethanol are reused.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com