Water-based flash-point-free viscosity reducing demulsifier with ultralow freezing point and preparation method thereof

A freezing point, water-based technology, applied in the direction of chemical dehydration/demulsification, etc., can solve the problems of high dehydration temperature, low safety, low flash point, etc., achieving good safety, low production cost, and simple preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The preparation method of the water-based non-flash point thickening demulsifier of the ultra-low freezing point comprises the following steps:

[0022] 1. Prepare materials: weigh the surfactant, polyalcohol ether, pour point depressant and deionized water according to the stated weight percentage for future use;

[0023] ②. Mixing: Mix the surfactant, polyalcohol ether, pour point depressant and deionized water weighed in step ① in a mixing container;

[0024] ③. Stirring: Start stirring to fully mix the surfactant, polyalcohol ether, pour point depressant and deionized water in the mixing container to obtain the demulsifier.

Embodiment 1

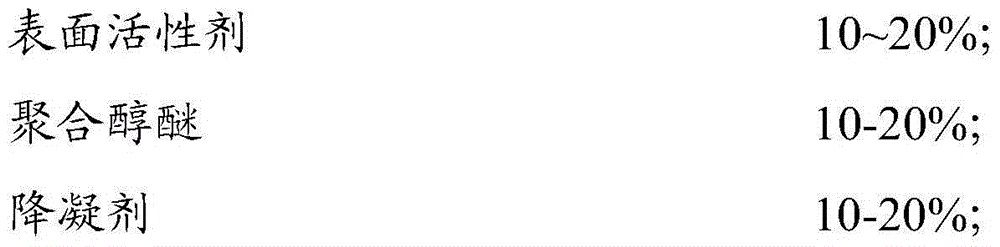

[0026] The water-based non-flash point thickening demulsifier with ultra-low freezing point is composed of the following raw materials in weight percentage:

[0027]

[0028] The preparation method of the water-based non-flash point thickening demulsifier of the ultra-low freezing point comprises the following steps:

[0029] 1. Prepare materials: weigh the alkylphenol and ethylene oxide condensate, laureth-9, ethylene glycol and deionized water according to the percentage of 10:10:20:60, for subsequent use;

[0030] 2. Mixing: Mix the alkylphenol weighed in step 1. with ethylene oxide condensate, laureth-9, ethylene glycol and deionized water in a mixing container;

[0031] ③. Stirring: Start stirring to make it fully mixed in the mixing container, and then obtain the described thickening demulsifier.

Embodiment 2

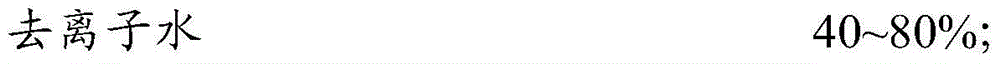

[0033] The water-based non-flash point thickening demulsifier with ultra-low freezing point is composed of the following raw materials in weight percentage:

[0034]

[0035] The preparation method of the water-based non-flash point thickening demulsifier of the ultra-low freezing point comprises the following steps:

[0036] 1. Prepare materials: weigh the alkylphenol and ethylene oxide condensate, ceteareth, ethanol and deionized water according to the ratio of 15:15:15:55 for subsequent use;

[0037] 2. Mixing: the alkylphenol weighed in step 1. is mixed with ethylene oxide condensate, ceteareth, ethanol and deionized water in a mixing container;

[0038] ③. Stirring: Start stirring to make it fully mixed in the mixing container, and then obtain the described thickening demulsifier.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com