Laminating machine convenient to install and maintain

A laminator and workbench technology, applied in lamination, lamination devices, lamination auxiliary operations, etc., can solve problems such as difficulty in installation and maintenance, influence of vacuum degree, lifting hot plate, etc., to achieve reliable quality and easy installation The effect of low maintenance and failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0019] Since the mechanical structure of the oil heating laminator and the electric heating laminator are basically the same, and the safety technology of the thermocouples is completely the same, so the installation technology of the thermocouples of the two laminators of the present invention is introduced.

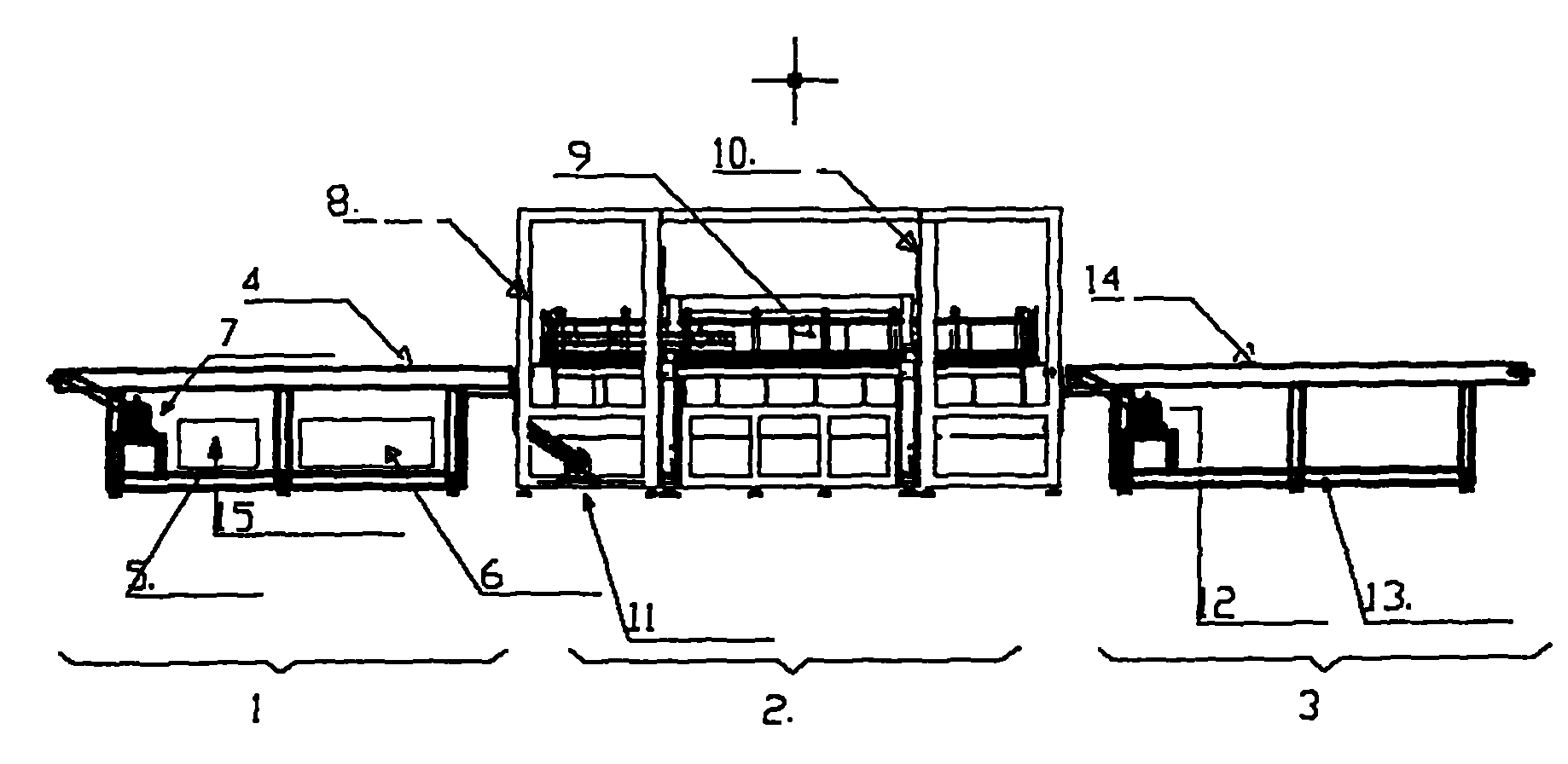

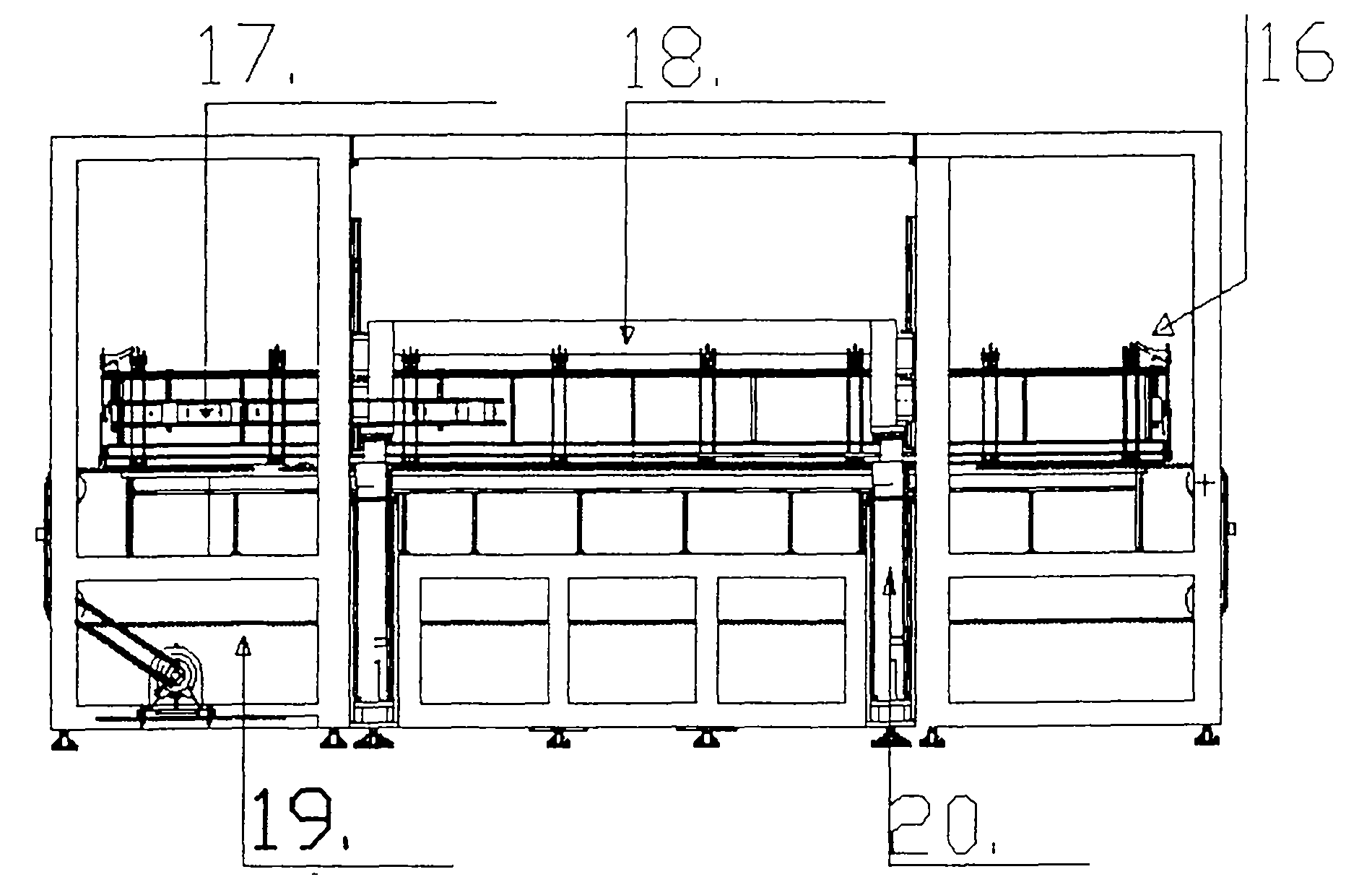

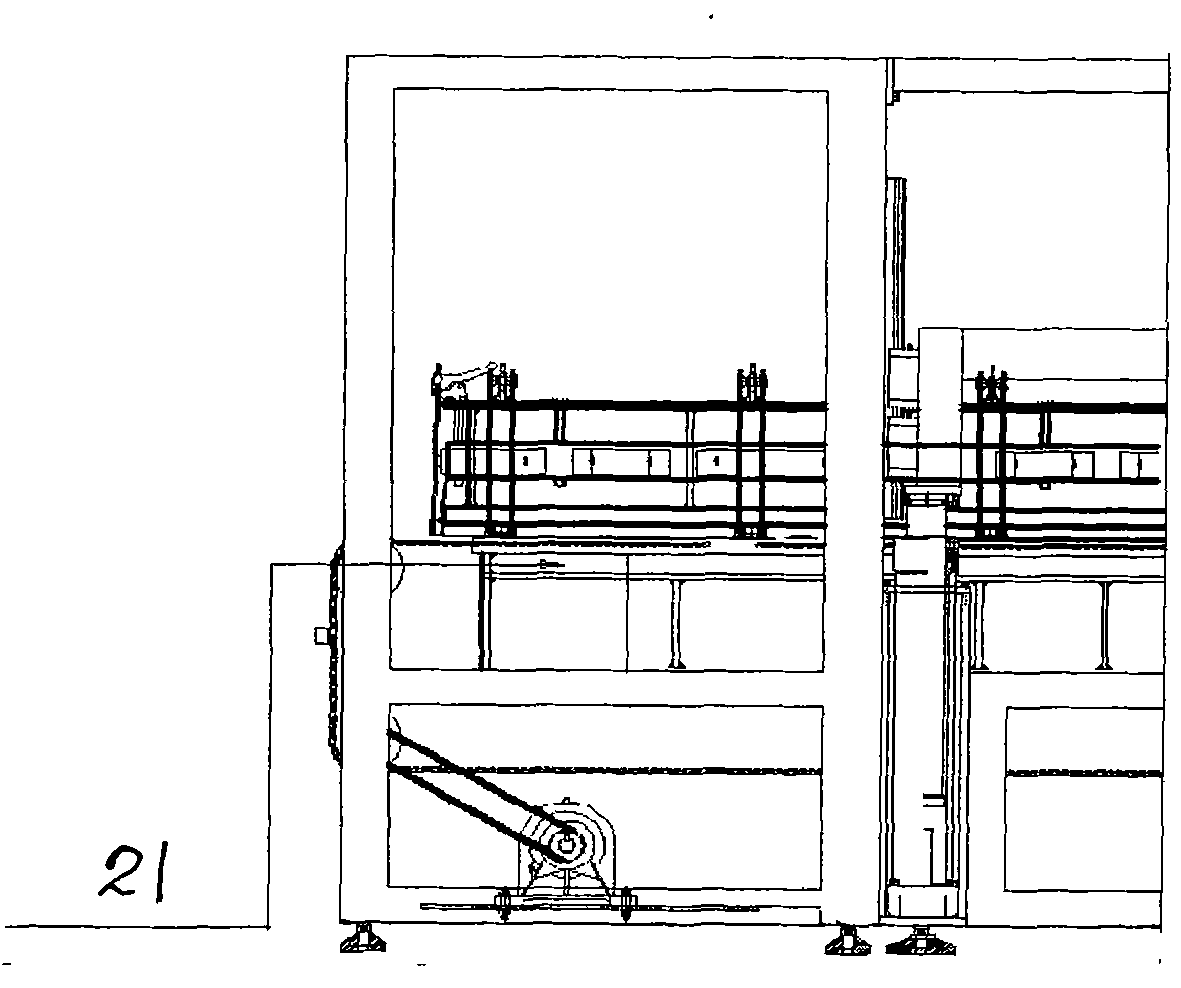

[0020] Such as figure 1 , The new electric heating laminator is mainly composed of three stages, namely feeding table 1, laminating section 2, and discharging table 3.

[0021] The function of the feeding platform is to place the installed solar cell components flat on the feeding platform by making an appointment. Feeding platform: The supporting frame 5 of the feeding platform constitutes the main frame of the feeding platform, the control system 6, the thyristor and the transformer 15, and the feeding machine 7 is usually installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com